-

Posts

111 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by sonomaz

-

Miles, Just read the lnk you provided. This is really well done. After 40 years the left rear has come loose so its time for a change. I was wondering what I was in for so the link was very helpful. I particularly liked how he mentions the 27mm socket. I could see it would have been a pain to figure that out. Paul

-

robello stroker engine vs home built stroker

sonomaz replied to intangible3's topic in Nissan L6 Forum

I'm surprised at you guys! Where is the support, the belief, and the joy of engine building. Where is the encouragement to help a fellow enthusiast to go build his own. Most of us have done it and with an NA L Series, piece of cake!! Intangeble3, Yes, I believe you can build a 250 horse Honda killer for less than 6K. My suggestion? Start with a fresh, stock L28 short block that is balanced. Search in hear for the best head tricks, port, polish and manifold match. Add trip Webbers or Mikunis ( if you can find them). Pick out your favorite cam and go one step hotter. And the coup de gras? Nitrous!! Start a thread and add all your steps. Everybody will chime in with their two cents worth. Have fun!! Go fast!! -

This may be of limited help but when I bought my 72 in 84 it came with a dealer installed AC because factory AC was not available. It had a York piston compressor mounted on the right side of the engine up high on a welded bracket. The evaporator was in a box in front of the heater blower housing that only drew air if the top heater lever was all the way to the right which drew air from the cabin and not the outside. There was a "pod" that mounted to the the left of the center console adjacent to the fuse panel cover that had the temp knob. I think it was made by ARA who is now out of business. If you want a good system, Motorsport Auto has one that is very similar but uses a Sanden rotary compressor that is much better. http://www.thezstore.com/page/TZS/PROD/SAC02/16-7565 Good luck. Paul

-

Idle fluctuates 500 to 2500 and back with Holley

sonomaz replied to gtg704a's topic in Nissan L6 Forum

While you have it apart pull the carb off the manifold and change that gasket also. When you put it all back together do not hook up any vacuum connections to the manifold or the carb and make sure all ports are caped with rubber plugs (get a full set from Napa or O'reilly). Get it running with the timing mentioned by beermanpete. If you have the vacuum fixed it should run really well regardless of the carb settings. Now tune the carb, set the idle, set the idle mixture. From there reconnect the vacuum stuff, vacuum advance for the distributor, PCV, vacuum for the brake booster. If you have any dramatic changes undo the last thing and diagnose why, fix the leak then move forward. When you fix everything, pick up a holley specific book by hanes or someone and tune that carb. When you finish I bet that engine will rock!! Good luck! Paul -

30 minutes down and I have good news and bad news. The good news is it looks like everything is wearing really well. Here is a pic of the number 1 rocker and lobe. The bad news is number 4 intake has a problem. Take a look at this. So after heaving an emotional break down I came to this plan. I think there is something that has been smeared on the lobe. Notice the difference in color. I'm going to continue to run it and check it about every 100 miles to see what it does. I also have an e-mail into Crane to ask what to do (hoping for a miracle here). At this point I have no time or money to go to a new cam shaft. And if I did I think it is time to pull the head and start at the valve installed height, spring force, etc, etc. all the way to a new cam. I took it out for a spin and man I love it! First drive in more than three years!!

-

So GJC, what did you do?

-

I started this thread in Aug of 2008 and worked on it for several months until things stalled. Which seems typical with most my projects. With in the past several months I was able to get back to it and have slowly been re-assembling the cam and components. I have completed the rocker arm wipe pattern adjustment and timed the cam to manufacturers specs. I also coated all the cam lobes with Moly lube. Today I plan on putting together the rest of the engine and starting it up for the break in period. So this is my plan. I have taken photos of rocker arm and cam lobe of cylinder No. 1 intake and I have posted them here. I will run in the cam for thirty minutes and take another set of pictures and again post them here. Then after 500 miles another set, and another at 1000 miles. So if any signs of wear show up you will be able to see it along with me. Obviously the goal is to have no wear at all. So this is how the engine is at present. I drained the oil, dropped the pan and cleaned it. I did find a few metal shavings and I found allot of blue silicone gasket maker in my oil pick up screen. Changed the filter and added a Filter Mag. I have reinstalled the pan and poured in Comp Cams break in oil. So next is install the radiator, valve cover and a few other items and it is Vrumba time!! The cam has been reground by Crane. I have installed new aftermarket rockers (all I could find or afford). As mentioned earlier the wipe pattern has been set with all new lash pads. Lash pad wipe pattern was checked. Valve clearance has been set cold (obviously). So next time you hear from me it will be good or bad. Wish me luck. Paul

-

Do I HAVE to hoist my engine to replace oil pan gasket?

sonomaz replied to LoneStarS30Z's topic in Nissan L6 Forum

JSM, thank your Dad for me! The thread idea worked great. Also you have to turn the crank so No. 1 is at 90 before or after TDC then the pan practicly falls out. Lone Star, get a tub of Permatex RTV Black Max gasket maker. Crawl back under and spackle the stuff between the pan and block. Also go around every bolt hole with the stuff. Don't forget to clean everything with Acetone first. Let it cure over night. That should give you a permanent seal with out re-dropping the pan. -

Do I HAVE to hoist my engine to replace oil pan gasket?

sonomaz replied to LoneStarS30Z's topic in Nissan L6 Forum

Wow! Great timing on this for me. Guess what I'm doing this weekend. -

DCZ is right. Go back to basics: Fuel, Spark, Compression. Compression does not go away and come back so check on fuel and spark. The next time it stalls pull the wire off any plug wire and crank to see if you have spark. If yes you probably have a fuel problem. If no you have a spark problem. I must admit it sounds just like a clogged fuel filter. Pull it completely off and blow though it. You should be able to almost breath through it. Any resistance at all you should change it. If it is not plugged climb under the rear of the car and make sure there isn't one back there. For spark I think 73s still had points (before you replaced it with pertronix)so I don't think you have a power resistor. PRs were used with early electronic ignitions like that used in the 280Z and I think they were acctualy amplifiers (but this is beside the point) and they were often effected by heat like after running for awhile and then slowing down to let the engine compartment hot soak. Back to the point: It could be the Pertronix module in the distributor is failing when hot. Simply put points back in to see if your problem goes away. If it does get a new pertronix unit. good luck Paul

-

Consider not venting the lines but just unbolt the compressor and tie it up out of the way. Perhaps one day you can have it vented properly.

-

So the personal budget opened enough to regrind my cam and buy rocker arms. I picked up a set of rockers from Motorsport Auto for ~$250. The issue is they are not manufactured by Nissan. When I spoke to Crane Cams they were very specific about using Nissan rockers to minimize scarf (is this a real word?) issues. So two questions: 1) how important do you thnk it is to have Nissan manufactured rocker arms; 2) where can I get them for a reasonable price? I got my cam back. I'll get some pictures posted soon.

-

All, It been a long time but I am confident I put a 280ZX flywheel on the back of my L24 so I could use my 240mm Centerforce clutch. As I remember it is very important to use the correct collar and the collar goes with the pressure plate not with the transmission. Check out the pics in this link in the third entry. It should clear up the collar issue. http://www.zcar.com/forums/read/1/720966/721049 I recomend you check your clutch movement right after you bolt up the trany mount and before you install anything else (OK you should install the release cylinder). Paul

-

Help: engine does not keep idle unless key turned

sonomaz replied to Hailstorm's topic in Nissan L6 Forum

On a stock series one Z the balast resistor is mounted under the coil on the inside drivers fender in front of the shock tower (USA versions). It looks SIMILAR, not exactly, like the one in the picture. The easiest way to check is with a test light. You can get one from Kragen or Napa for under $10 and it will help in the rest of your wiring problems. It looks like an ice pick with a cord out the back and a light bulb inside. Turn your key to the on position. Clip the test light to ground like the bolt that holds down the coil or the resistor. Touch both sides of the resistor terminals one at a time. The light should come on for both sides but one side should be dimmer than the other. If both sides don't light you are doing something wrong. If one side does not light, the resistor is bad and needs replacing. If both sides light, your problem is somewhere else and you should go with the ignition switch idea. Try this link for what a test light is http://www.partsamerica.com/productdetail.aspx?MfrCode=DOR&MfrPartNumber=86598&CategoryCode=3391 Good luck. Paul -

Ha ha ha.... so many things to say to that, nothing related to Z's!!!

-

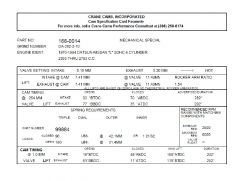

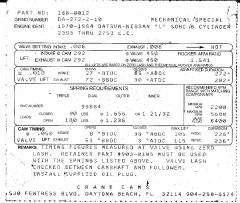

Poindexter, If you look a little closer you will notice their is no number for valve float on Cam 2. Max RPM for cam 1 is 5600 and cam 2 is 6000. I think max and min RPM on the cam card is where the grinder thinks the sweet spot will be. So cam 2 is 400 RPM higher than cam 1. Any one else want to suggest which one I sohould get? Paul

-

I have now had a couple of conversations with Mike at Crane Cams and the ZDDP issue is a concern. Mike also raises the concern of using aftermarket versus OEM rockers. He claims the OEM uses "chilled cast" pads that are higher quality and more consistant on the hardness. Any thoughts? I also brought up the subject of coatings. I was thinking about having an anti-friction coating applied to the cam similar to what they put on piston skirts but I have not found any direct information of using this on a cam lobe. Mike said he had heard of this and even knew of a several people who are doing this but did not have specifics. http://www.embeeperformance.com/coatings/antifriction.html Crane has a surface treatment called Micronite and Mike apperantly is the contact for this at Crane. He stated it is not a coating but is a treatment simillar to shot peening except the media used is microscopic and it is not directed from a hand held gun. He said it works very well for gears but they do not have a lot of experience with cams. It turns out my cam can be reground and the the question is what grind to run. Below is the two choiices I am considering. The first is what I had and the second is the next more aggresive grind. I liked the one I had but who doesn't want more power. My engine set up is in my signature. The lift numbers are the same, the only difference is the duration. I like to get this on order early next week so what do you suggest?

-

Right you are, Xnke! Check this out: http://www.valvoline.com/downloads/2008-003a.pdf

-

Hey, all you conspericy theoricists screaming about ZDDP, listen up! I go t a call today from Mike at Crane Cams. First question out of his mouth: "What Oil are you using?" Wait it gets better: " Do you add ZDDP?" That almost clinched it right there. So the answer to his first question is Castrol GTX 10W-30. Second was obviously no. I then went to the Castrol Web sight and searched on "Zinc". The question and answer guy link appeard with questions about ZDDP. The short answer is (and yes you have heard this before) ZDDP was phased out of motor oil domesticly in the 1990's becasue of ordinaces passed by the EPA. His position was the EPA left a hole between new oil requirments and old engines. He closed with Castrol is working on a solution. So I got conspericy theoricists on this forum (a term of endearment I assure you), a mjor cam manufacturer asking if I used it, and a mojor motor oil manufacturer admitting there is a problem. I think that settles it. ZDDP not being in motor oil is causing problems in our engines. "But wait" you say. "You kept asking why only one lobe/rocker went bad, Paul" (I heard you say it). "How does that fit in with this ZDDP thing?" Well take a look at this! When I got home tonight I took a close look at all the rockers and yep, they all look the same. This is the pad on rocker 2E. Notice the black spots in the wear area. When I first saw those I assumed the pad was somewhat pouros (we realy need spell check) and the wear had exposed the voids. But close inspection shows these are actualy pits. Notice there are no holes in the non wear area. So pitting ussualy comes from excessive spot loading on a micro level that pushes the material past ultimate (not just yield) strength and when the force is reduced the "torn" piece pops out leaving and odd shapped pit. With inadaqute lubrication, i.e. no ZDDP, the loading not only becomes compression (straight down on the pad) but shear (sideways across the face) and the two forces combine to be greater than the material strength. Every single rocker has the same spots as this picture. So I believe that all was not well and I lost one. I believe all was bad and No 2I went first. It's late for me but I had to share. I am expecting another call from Mike tomorrow. I will update with more of what he said today and what he adds tomorrow. Short answer-out of warenty, no replacment. Paul

-

Jon, I think you are right about none racing applications so I will park the regrind attitude here. Isky sounds good I'll look into that after I here from Crane (should be this week). Anyone mentioning lubrication, The Zinc Phosphate sounds like a real prblem and you have me convinced to address this issue. However, I don't think it explains one cam lobe versus many or all cam lobes. Remember the other eleven look great! Phred, I realy appreciate your and everyone elses input here and I am willing to read any direction this goes (OK, maybe not any direction). I am terified of installing a new cam just to repeat what happened. JC and Pyro.., You're right and I know it. I don't have to pull the head but it sounds good in my head so I don't have to do the extra work. Like you said, JC, that's gonna suck! Silent, I can see EXACTLY that happening to me!! I took me 8 years to get it back on the road!!! SRGunz, Thanks for the link! I will be buying before I turn the key. All, This is huge help for me and quite unexpected (I don't know why, this is always what I get!!) Thank you so much for what you have contributed already. (sorry for getting mushy) Please, please keep this coming and I will keep you updated. I am expecting to hear from Crane this week so I will post here the jist of that conversation after it happens. Also I will be checking in to ask what next. And I still owe pictures of one of the other rockers. I'll try to do that when I post the Crane discussion.

-

Jon, you're making me anxious about reputations. I was intending to get a replacment from Crane (hoping they work a deal with me) but I definatley do ont want to repeat this. Who would you suggest and why? The basic concept of regrinding a stock cam seams all wrong. As you mentioned, you have to reduce the base circle to increase lift and if you want a faster rise the base circe is even more compromised. Paul