-

Posts

13742 -

Joined

-

Last visited

-

Days Won

68

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JMortensen

-

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I've heard of a few people have had issues with the upper bushings in the Konis, and I suspect that there are a lot more who have the issues but don't know it. Cameron aka Heavy85 is the one I can point to off the top of my head. Opinions on shocks are kind of like brakes IMO. You get people who put gigantic brakes on the front of their Z and couple them with rear drum or crappy tiny rear disc and then they report that the car stops so much better, etc. Most people, IMO, don't know what proper brake bias feels like, I say this because I was actually one of these people. I went to a driver's school with my Toy 4x4 setup in front and 280ZX disc and drove through a puddle and slammed on the brakes and the rears didn't lock in water. One of the driving instructors told me that, then I figured out the fronts were way too big, and ended up going back to stock front calipers and I was able to dial in the bias correctly and only then did I know what correct brake bias felt like. I think the same thing is true with shocks, and that there are people racing with worn out strut bushings who just don't know, and the vast majority don't know and couldn't tell you if their shocks were valved anywhere close to correctly. Doesn't mean they're not fast, but being fast doesn't mean that they're right either. Add in the fact that a good shock setup costs so much money, and a cheap ass Chinese coilover is cheap, and I think if you polled Z owners you'd probably find that Chinese coilovers are the best option, Konis are too expensive and they suck because you still have to buy the coilover parts, and the kind of stuff I'm looking at is just stupid because it's either hyper expensive or not adjustable. Aydin, I think the rebound is more important generally, and single adjustables do actually adjust both a little bit. This page might help: https://wilhelmraceworks.com/koni-shock-dynos -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

After taking a step back, I started thinking about the revalved 3000GT struts. Called Bilstein, they are no longer doing revalves in house. They also don't make 46mm struts anymore, FYI. They said they farm out rebuilds and revalves to Performance Shock Inc, who apparently is at the Sonoma race track. Called them 800-965-5664, they said $320 each for a revalved 3kgt shock, and if I sent them my graph, they could try to hit those numbers. I asked about revalving the P30s too, and Bilstein did say that I'd be much better off with the 36mm, Performance Shock said the cost to revalve the P30 would be about the same as buying the 36s and revalving them. One issue is that I really need to get my hands on one to see how I will have to modify the strut housing. Would like to do that before I commit to 4 of them. I'll reach out to MCA and see how their stuff compares and make a decision. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

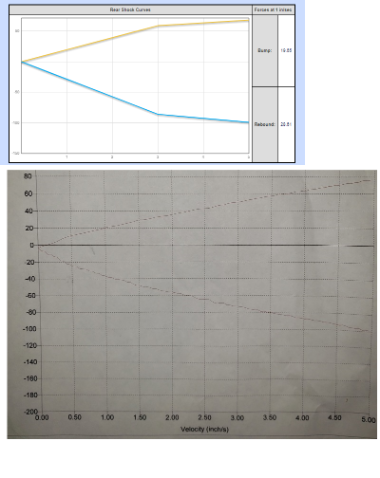

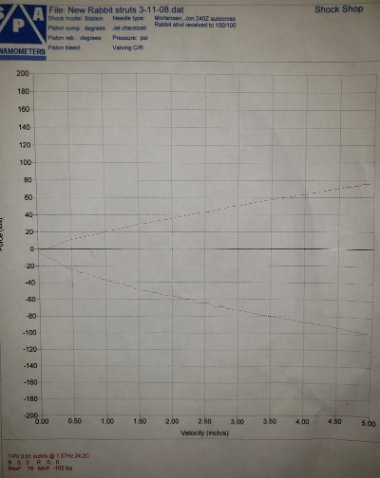

What did that cost you, Richard? Their single adjustable setup is about $2300 US which is pretty reasonable. BTW I was talking about this some more elsewhere and someone suggested DG's Far North Racing website to give shock valving suggestions. I've quoted that site here many times, didn't realize it had the shock valving suggestion page though. Bought the guy's book yesterday too, just out of appreciation. My rear shocks are surprisingly close to their suggested valving. Graphs are in different scales, but man, it's right there despite the lack of digressive pistons. Fronts are pretty far off though. -

Brake proportioning valve

JMortensen replied to AydinZ71's topic in Brakes, Wheels, Suspension and Chassis

I had that prop valve on my Miata. Worked fine. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

On another forum someone pointed out that the LCA isn't built to handle the loads from a shock. I was going to argue, but then I realized that the stock shock loads go through the tire, spindle, into the strut housing and to the strut tower, and the LCA doesn't see that at all, so I'd be putting significantly more load into the LCA than it was designed for. Hmm... -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

One issue would be putting all that force on the rod end mount for the sway bar. I think that's likely too much to ask. But could still do a shock mount to the LCA inside of where the sway bar bracket is. Again, this would reduce the throw as compared to the stock strut... -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Possibly dumb/brilliant idea. Why not attach a shock to the sway bar and to a fabbed mount on the chassis, like welded to the front or back of the strut tower? Could just weld a shock mount to the strut tower and hook it up. That would insulate it from twisting with the strut. Would just need a shock that had enough travel. Then I could strip out the bilstein guts and run the same strut housings with the same springs and all, and just have the shock next door hooked up to the sway bar arm. Only real concern would be wheel/brakes/ducts hitting the shock when turning. I'm already fabbing up the sway bar arm anyway. One problem would be that if I mounted in front of the LCA it wouldn't move as far. IIRC that makes the shock harder to tune correctly because it isn't using as much travel. Could make the sway bar arms long and give the shock more travel/better resolution. That would make the shock angle change as it went through the bump travel, but if I put it straight up and down at ride height, shouldn't be too bad I wouldn't think. Then the question is how stiff would I need the sway bar arms to be? I know shocks put more force into the chassis than springs. Maybe I'd be better off working with the solid ones. If I did this I really could use some of those cheapo used race shocks. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

But if you halved the spring rate, wouldn't that mean you're way over-rebounded? -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Oh, I get it now. You don't want to change the SHOCK settings. You want to change the springs/bars. Makes sense. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I thought the idea was that you just want to slow down the weight transfer to reduce sudden pressure changes at the tire. To put it differently, you can hit the magic number on the WTW with different springs, but the softer springs will be more predictable at the limit because weight transfer happens more slowly. Entirely possible I have that wrong. As to the workarounds, I'm not seeing how a rocker would work in the front with hood clearance, but I do recall you suggesting something like gutting the strut and using it just to take the side loads, then welding brackets to the strut housing and the top hat (or maybe the upper part of the strut shaft) and running a coilover shock right next to the strut. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Started down the shocks rabbit hole again after this exchange. Went and looked at the old info I had bookmarked years ago, and the 3kgt Bilsteins are still about $600 for a set, come with 36mm digressive pistons. Looks like DA strut shafts from Bilsteinrun $750 each, so could add 4 of those and already be at $3600, that's without valving or remote canisters and adjusters or figuring out how to mount in the strut housings, etc. Thinking about buying 1 shock and disassembling and screwing around with it. I do remember why I let it go last time though: I figured if it was going to be that much of a PITA I'd be better off going to SLA, then you can find DA quality shocks for a hell of a lot cheaper. Stopped there because changing to SLA requires new everything from stub axles and brakes to uprights and caliper mounts. Almost just as well to build another car. Could get a set of DA Konis and just replace them every couple years when the top bushing wears out. As much as I've resisted Konis that probably makes the most sense from a practical perspective. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

That is it in a nutshell. At the time I bought mine, I thought that the Bilsteins were superior to the Konis which wear out the upper strut bushing and that there is a "correct" valving, but I think having the adjustability trumps having better bushings and a monotube shock. I do think that there is "correct" damping for a spring rate with a dry track, but if it rains that's out the window, and if you change springs, the shocks are no longer correct. For that reason I'm not going to buy anything else that isn't adjustable, and I'm really going to try to stick to double adjustable. The guy who did my shocks had a long career and could say that he set up shocks for so many race winners, etc, but I think that properly setting up shocks is very subjective and also feel that people can drive past the shocks too. I raced with an EXTREMELY fast 510 when I started autoxing in the 90s. Gian Bowles was the driver. Very very fast car. He had Rancho 9000 shocks from a Camaro IIRC in the back. Rancho. R A N C H O, FFS. And he was dominating everyone, taking FTD by a mile. -

I could light up the inside rear on the Miata on the street at times, and did it often at autoxes. Never tracked that car. The tighter the turn the bigger the problem, but the Miata engine was stock, so not a torque monster by any stretch. Car was great, except for the incredible lack of go. Had my doors blown off by a Kia minivan on freeway onramp. Pathetic...

-

More V8 swaps??? LOL

-

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Jacking down occurs due to too much rebound and I have way too little and super stiff springs, so no fears about that. By comparison, I had the stock Bilsteins in my 10th Anniversary MIata and it jacked down bad. Was VICIOUS on concrete freeway expansion slots. Would jack down to the bumpstops then the whole frickin car would bounce violently, kinda jackhammering your spine. Luckily the stretch of concrete freeway that runs through Seattle is only about 10 or 15 miles... LOL. I put much stiffer springs in it and it got better, was later told that if I had gone 1/2 again stiffer I could have eliminated it entirely and it would have been better in just about every respect. IIRC that would have been like 5 or 6 times as stiff as the original spring rates. I guess the idea was to valve the shocks for the Spec Miata spring rates, and screw all the idiots that bought Miatas with Bilsteins for street use... The theory the guy was using on my shocks was that it's better to ignore ride quality and focus on keeping the tire on the ground. Most valving schemes are centered around controlling the sprung weight with the rebound and the unsprung with the compression damping. If you have too much rebound and the car goes over a dip, the wheel will get light or possibly leave the ground altogether, see pics of cars pulling a front tire in a turn. This made sense to me at the time because I had a mountain bike with a really terribly valved fork with almost no rebound, and the thing tracked GREAT, but after a couple jumps your hands were beat to hell, so I let him talk me into it. I also found that BMW E30 racers back in the day were running 300/300 with a 3:1 motion ratio, so they were basically doing exactly what I was, and spring rates were pretty similar after compensating for motion ratio too. It still kinda sorta makes sense. The problem is that it's not just ride quality that you need to concern yourself with. Allowing the sprung mass to move too fast creates its own set of issues, like the porpoising that I'm getting. I do think these shocks might work pretty well on a smooth road course. The P30 pistons are linear, and my shock dyno plot shows that. They're not perfectly linear, but they are a lot closer to that than digressive. I have thought about revalving to 300/100, but I think that's wasted effort as you can't get a digressive piston nor are they able to be modded for adjustability. Was looking at 3000GT Bilstein inserts, people have modded them with canisters and made rebound and compression independently adjustable. Shocks are such a bummer for Zs, especially when you look at the options available for more modern cars. You can get Ohlins, Penske, FatCat, all these high end shocks for a Miata. For a Z it's Koni or some one off custom thing. -

When I sold diff parts for Randy's Ring and Pinion we had a shelf full of GM 7.5" Torsens marked down to $150. Nobody bought one in the little more than a year I worked there, partly because the GM 7.5 is too small for the Camaro they put it in and people usually moved away from it and went to an 8.5 or 9" diff, but still. Practically couldn't give them away. Quaifes have this incredible reputation and honestly, the only thing I thought it had going for it was the lifetime warranty. Helicals tend to spin the inside tire way too easy. Huge improvement over an open diff, but I'd rather have a clutch LSD, and the OS Giken is the best of those for our cars, but I'd put the Nissan clutch LSD in front of the Torsen, and probably the KAAZ 1.5 way ahead of the Nissan, although I haven't actually used the KAAZ, the 1.5 way should be an advantage.

-

Quaife is no longer warrantying their units for life. Mark Haag had issues and they basically told him tough luck. I think the shop he was using was able to make it functional again.

-

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Plan was to start doing HPDEs last year. Again, this year might or might not happen, but yeah otherwise primarily autoxing. I did do an Evolution 2 school a couple years ago and wasn't that impressed and didn't learn anything that I could point to. Look ahead, no further ahead, no further than that was about it. They wouldn't let me spray my R1Rs down between runs and they wore the shoulder off really bad due to overheating. I left kinda pissed off about the whole thing. Their Evo 3 school would probably suit me better. Basically you and a really good driver both drive your car, back to back, switching drivers. That seems like it would be much more helpful. I'm already a pretty decent driver, came in 2nd, 5th, and 14th overall at the 3 autoxes I went to in 2019 and that's on used slicks that were 2 years old already. 14th was the day after a demo derby and the track was slick and having gigantic tires just made it like driving on ice. I think a new set of Avons would put me right up at the front. When I jump online I find myself getting creamed though, so I know there's a trick or two I haven't learned yet. As to sims, I started with a TH300 wheel and pedals and a T3Pa shifter on the PS4 and I had AC, ACC, Dirt 4, and GTS. Found myself sticking with GTS and AC. AC was the more realistic, GTS is more of an arcade game. ACC just wasn't fun, Dirt 4 never really captured my interest. Then I started changing things around, bought Fanatec pedals which are much better, and I switched to PC. I was doing iRacing but found it expensive and the steering didn't feel realistic at all. Also bought RF2 and a crapload of cars and tracks, but it has the same dead wheel problem, so right now Assetto Corsa is my game of choice. I hear that if you use a direct drive wheel iRacing is much better, but I'd rather not spend all that money on a wheel when I can put it towards the real car. AC has H2H, but I've been racing against the AI and just turning laps. Recently I had a break through and picked up a lot of time on a particular car at a particular track, but the annoying thing is that I don't know why I got faster. That's the kind of thing that I think online coaching could teach me. I mean, you have the inputs there, so should be able to use the data just the same way you would out of the race car, in theory. I do need shocks. I had my Bilsteins revalved and the guy who convinced me to do it that way was... unorthodox. Stock valving was something like 250/75, Katman suggested 300/100, this guy valved them 100/100. Then he retired. LOL. Car porpoises a bit. The 30mm Bilsteins have linear pistons, would really like to move up to 36mm, digressive and have some adjustability. But if I'm not going racing, I think FG would at least be a creative outlet, and I already bought a vacuum pump. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I need some DA, both for the car and to analyze my driving. My intention was to get some app for the phone and then get some data from 2020, but I ended up not racing at all last year. Problem is that DA isn't all I need. Right now I have a little cash together, and it's still looking like my racing schedule is going to be sketchy at best this year. So the question now is; new set of Avons (don't want to buy a set and let them sit a year), data acquisition, wing, shocks (car could really use these), online driving coach (people will look at your gaming DA and coach you on driving) or buy fiberglass supplies and learn to do that better and maybe make a wing. If nothing happens this year, could just sit on the cash and see what's going on next year, since DA stuff seems to be getting cheaper over time. Thinking if I have to sit the majority of the year out, online coaching and fiberglass supplies makes sense because it gives me something to do and will improve results when the racing resumes. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Interesting. Cheap enough that if they fall off or get hit by a cone I wouldn't really care. Looks like some of them have remotes to turn them on and off or turn on via motion detection. That would probably be better than crawling all over under the car. Very cool. Thanks for the idea. I have a good phone mount that I've been using for a couple years. Works well, but I do feel a bit hesitant about the phone falling out and getting destroyed. I guess the advantage of the phone would be using a piece of software that would measure g forces and speeds and all that. Can't do that with $13 cameras yet... https://www.ebay.com/itm/Cop-Spy-Nanny-Camera-Wireless-Hidden-Motion-DV-HD-1080P-Mini-Car-Dash-Cam-USA/324272628932 -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

What do you have running all the cameras? Or do you just have them plugged into old phones? Was thinking about wiring in some cigarette lighters so I could run phone chargers and then running a couple phones I don't use anymore and either using the phone cameras themselves or plugging into something else, tablet or laptop that would capture the video. I'm not a techie though, so not really sure how to synch them all up and all that. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Got some pics of fabbed arms. Looks pretty easy, basically just hacked the original arm off and welded up some boxed sections with some tube through to stiffen. Will put on list of things to do this winter.. -

Racing wheels - complete novice

JMortensen replied to AydinZ71's topic in Brakes, Wheels, Suspension and Chassis

No problem! If you're new to it, EP cars use cantilevered slicks, so don't get regular ones. Might hit up Greg Ira, he's a member here (gira) and also on FB. Helpful guy, think he's 3 time national champ now. -

Racing wheels - complete novice

JMortensen replied to AydinZ71's topic in Brakes, Wheels, Suspension and Chassis

You can do better, but 17 lbs isn't that bad. Probably get a 15 x 7 race wheel down to 12 or 13 lbs. Wouldn't be first on my list of things to change on a restoration. -

Heims joints on street cars are pretty well documented at this point, no huge mystery. Those who are sensitive won't like it, those who aren't will. I've told this story many times, but I took my dad for a ride in my Z when he was in his mid 70s, had stock ball joints but otherwise all heims jointed front end, with G Machine aluminum/delrin in the back, coilovers, 200/250 springs and Illuminas, and on getting out his comment was about how comfortable the Recaro seat was. Others complain about poly bushings and the stiff ride from lowering springs. Totally agree on point 2, and with Richard's point about the difficulty of proper suspension design. I would point out that all of your GT class SCCA racers are using SLA front ends and quick change solid axle rears, so at some point you have to decide what a Z is and when one is modded to the point that it no longer qualifies.