-

Posts

13742 -

Joined

-

Last visited

-

Days Won

68

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JMortensen

-

L28ET Valve float and spring recommendations, aftermarket cam

JMortensen replied to Zcardude's topic in Nissan L6 Forum

I had a machinist set up a cam for me and he checked a couple different springs and landed on Schneider's as having the best seat pressure for my .490/280 cam. The springs and retainers are easy to come by. -

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I checked it out and it's easy to see why the scrub is reduced. This actually looks like a pretty easy solution. I'm guessing there is a 12.2" Wilwood setup for an S13 that's readily available too. Still want to see what can be done with the dual ball joints, but thanks again, very helpful!- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

That's a really interesting option, thanks. How would one go about figuring out which spindles to try? Assuming some Nissan stuff would have the same bolt pattern so might be able to bolt the existing suspension up to it, thinking would need new front brakes, or at least new caliper brackets. I know Nissan used the Set 2 and Set 6 bearings up through the 300ZX, so that part might be the same if I stayed Nissan.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

That's an interesting idea Dan, but I'd have several problems: 1. The cage is built to support the stock strut tower, and I'd be moving it over quite a ways. 2. Car would be way wider than it needs to be 3. Don't really want staggered tires. Always had issues getting the front end to hook up, and that's going to be exacerbated with narrower front tires 4. Tie rods will interfere with the wheels. Possible that a 16 x 10 or better, a 16 x 12 might work, but one of the reasons I went with the 15x14 is the easy availability of the FA tires 5. Doesn't really fix the scrub radius issue. Obviously would be less with a narrower rim, but might still be 4" if I couldn't do the 5.5" backspace. I like the dual ball joint thing because it could potentially be easy to implement, we'll see what the computers say. If the dual ball joint doesn't work and the car doesn't hook up with my new tires then I think I'll go one of two ways; either SLA or go to a 3" flare and run a 15 x 11 with the 275/35/15 Hoosier or 16 x 12 if I can find an appropriate slick to fit.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I told Cary I would get some more measurements. The rack on mine is 5.5" in front of the LCA pivot. Tried to measure the height of the inner and outer pivots but car is on jackstands now and I didn't want to take it off just for that measurement. Stock steer knuckles and rack moved forward and up and tie rods are using .9125" bumpsteer shim. Bumpsteer is minimized. Hopefully that gives you enough to go on. If not it will have to wait until next week most likely.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Looks like I should be ready for either/both days.

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

The way the wheel moves is the part that kinda blows my mind. It moves back and forth a little bit, and you would think that would be really bad for steering feel or make the handling wonky, but new Mustangs are really good autoxers, so they must have something right. Same with the single ball joint BMWs. Many (all?) of the newer ones have the ball joint offset forward from the bottom of the strut. Again, this is going to mean that the wheel isn't going it pivot around that lower ball joint, so that should cause some weirdness in the feel, but they're very successful autoxers. I have power steering so I can't tell you how heavy it would be without. I know it was pretty hard to turn at low speeds with 10" slicks on it, so it's probably not good with 14s... There is a lot more to transplanting another strut system than it seems like. Angle of the struts and spindles, steer knuckle length, brakes, etc. If I were going to do that I'd rather figure out SLA. Probably same effort and if done correctly, better end result.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Front Suspension Swap? Anybody done one

JMortensen replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

General rules: Front engined cars usually have lower roll center in front and rear RC is slightly higher than front. For performance, low front roll center is best. If it's too high what it does is force the wheels to move outwards in order for the suspension to compress. This can really make it hard for the outside suspension to work under load. Conversely, an underground RC will want to compress the suspension more than it would otherwise with cornering forces. Higher roll centers can be used to allow softer spring rates. If you spring the car stiff enough, you can run low roll centers and not have excessive roll and reduce the jacking forces. As a kind of rule of thumb, 80% of the turn happens in the first 1/10th of the turn. This is why the minutia is important. If the car won't turn in the instant you turn the wheel, then you're not getting around the turn very well, regardless of what it will do once it changes direction and is in a steady state corner. Again, as a general rule, the end of the car with the lower RC will tend to grip better, so RC is a way to change handling balance. This is why you have a lower RC in front. Solid axle cars have a hard time with high rear RCs and they use different solutions to lower the rear RC to improve handling. Not really germane to this convo, but here is a link to a discussion of a Mumford link, which is a modified Watts link that can lower rear RC: http://www.locostusa.com/forums/viewtopic.php?t=77 -

Front Suspension Swap? Anybody done one

JMortensen replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

I've started my own thread on the dual ball joint setup, going to see how feasible it is because I have serious issues with scrub with 15x14 wheels. -

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Inner control arm pivot height: 5.5" Ball Joint height: 6" Control arm length: 11.5" Clearance to xmember: 2 3/4"- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

If that's all it takes it sounds pretty easy to do, but I feel like there have got to be some complications we're not factoring in. Looking at that Pontiac video looks like the end links will have to be reworked and made as long as possible. Cary has some software that figures it out too. He's asked me for a few dimensions, but he's gone until next week, so I haven't gotten around to measuring yet. Thread should pick up next week.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Cages - Experiences wanted

JMortensen replied to EF Ian's topic in Brakes, Wheels, Suspension and Chassis

That's similar to how the Autopower bars attach. They used to be SCCA legal. Not sure if they are anymore. I do think it's a LOT better for seat clearance, but it's very hard to connect door bars to. I haven't seen one of their bolt in cages in a really long time, but I seem to recall they had one door bar that clamped to the roll bar then bent down in front of the door and went forward to the A pillar. I don't think the door bar bent into the door area and I think it was only a single door bar. -

Cages - Experiences wanted

JMortensen replied to EF Ian's topic in Brakes, Wheels, Suspension and Chassis

Looking at your cad drawing I have a couple suggestions. First is the strut tower to dash bar. Hitting the middle of the dash bar is not ideal because there is no load path. The BSR car had the tube from the middle of the dash to the main hoop. Also not the best, but a lot better than just ending in the middle of the dash bar. Built the way you drew it, it will probably be an improvement over no strut reinforcements, or reinforcements to the (weak) firewall, but a better idea is to do an X from the strut tower to the dash hoop, and then hit the dash hoop on the other side with the upper door bars. I don't know how much interior you're going to have but it's tight in that area. Also will probably have to have a plate on the inside of the firewall and then bolt in the part in the engine compartment so that you can take the engine out. I actually have the bars as you have them and I had to tweak the windshield wiper linkage to clear where they went through the cowl. Another issue is the shoulder bar is bent back for seat clearance (necessary if you're over about 5'7" or so. The problem is that your diagonal looks as thought it is bent back to the bent shoulder bar. That's illegal per SCCA, NASA, etc. You could put the diagonal in the main hoop and then put a short tube in to connect the diagonal to the shoulder bar, or you could do a straight bar across the pass side and then bend around the back of the driver's seat. I was also able to take bars from the bottom of the A pillar to the strut tower. It managed to squeak in without interfering with the clutch pedal. Not hard to do and the stronger the strut tower reinforcements are, the better. -

280Z stubs are 27 spline vs 240 at 25 spline. 280Z stub axles are far from unbreakable. Even the 37 spline ones can be broken, especially with drag strip launches. Rather have mtnickels's weld on adapters than adapters bolted to the stock stub which bolts to the CV, so move that one up a spot from "the rest" and it falls behind MM's billet Z31 adapters, which have a thicker, more nicely radiused flange than the stock companion flange.

-

The longnose R200 loads the strap mounting holes vertically, the way they are deisgned to take a load. The shortnose does not. It adds what acts like a lever to the mounting holes, then pushes up on that. This is why there have been a few cases of high hp guys tearing up the unibody right there with shortnose diffs. If it has happened with a longnose and RT mount, I haven't seen it.

-

Eliminating the stub axle is a good idea. The TTT upright looks like a dumbbell weight to me. I'm not a big fan of shortnose R200 swaps either because of the way they usually attach to the strap bracket in the chassis. Some good, some bad there IMO.

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

No, it doesn't, but the angle of the TC rod doesn't change any of the geometry of the control arm though, having the arm in line with the ball joint just loads the TC rod straight instead of at an angle. You can look at a BMW or Porsche lower control arm and they are shaped kind of like a boomerang. More room for the tire, but the geometry is controlled by the pivot points, not the shape of the arm.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Typical race car "10 lbs of shit in a 5 lb bag" stuff. Looked again, due to tie rod to rim, steering rack to alternator, and other space constraints I'm going to have to stick to this wheel offset to make everything work, or do a whole bunch of other work to make it all fit.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I can swap rear wheels to the front and the drop center on the wheels is different and won't need the spacers. I'd have to check but I believe those wheels are 5" back space, so that would lessen the scrub to closer to 5". Might have issues in the rear with hitting fenders, and possibly front wheels hitting splitter.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

OK, figured out one problem. Measure to the CENTER of the tread, so that is 6.75" and that gets scrub radius of closer to 6".- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I want to believe I'm doing something seriously wrong here. Please tell me I am. Cary asked for measurements including scrub radius. I looked up how to measure it. Looks like imaginary line through upper strut mount and lower ball joint, and then wherever that meets the tire contact patch. These are 15 x 14 wheels with 13.75" slicks. If I'm doing this right, and I think I am, I'm looking at about 13" of scrub radius. These wheels have 4.5" backspacing and 1/2" wheel spacer. So this means that a typical 15 x 8 with 0 offset and a 23" ish diameter tire is going to have about 7.5" scrub or so. If I have this correct, I will wait to see if Cary can figure out where the mounts would need to be to fix, but I suspect that it's not workable in any event, and the solution will be SLA suspension instead.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Best? www.modern-motorsports.com 930 setup. It doesn't have adapters that bolt to the stock diff output stub and companion flange. It has a proper chromoly stub that plugs into the diff, and chromoly companion that attaches to the stub axle at the wheel. Couple with their 37 spline upgraded stub axles, and that IMO is as strong as you're going to get for the R200. Next best? www.modern-motorsports.com Z31T setup with shorter CV shafts. The Z31T shafts can be tough to find but they're pretty strong and with the shorter shafts they fit well. Same thing on the stubs, m-m sells chromoly stub axles and adapters to connect to the CV instead of an adapter that bolts to the stock companion flange and diff output flange. After that: everything else. DSS, Wolf Creek, Ermish, whatever other vendor you want to pick. These have adapters that bolt to the stock companion flange and diff output flanges and usually use 930 CVs. 930 CVs are strong, no doubt, but attaching to the stock flanges is going to be where the weakness is in terms of ultimate strength. Also 930 CVs are very popular with off road and racing crowd, so there is a wide variety of quality out there. Cheap ones have slack in them and will cause clunking. The other issue is the adapters: they bolt to the stock pieces and the bolts come loose. Seems to be the norm with this setup, bolts continuously coming loose. Heard of this happening to 510 and Z guys, most recently Mark Haag's car as he had issues with vibrations on the dyno, traced it back to the CVs.

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

No, I'm talking about the front. Here is that video again:- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

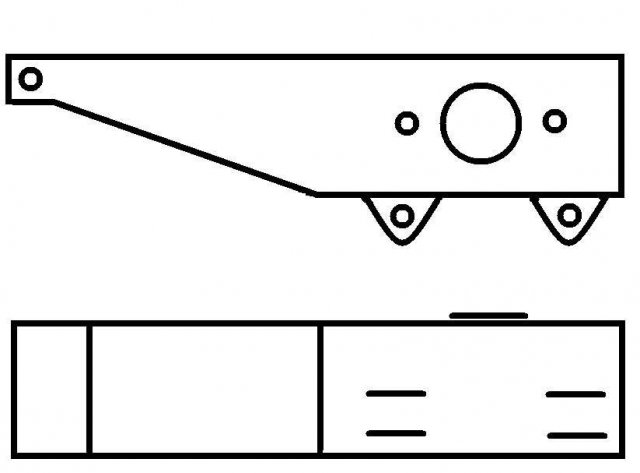

Cary (tube80z) has been mentioning this idea of the dual ball joint front end off and on for the last couple years. I hadn't really given it too much thought until I autoxed my car and was really lifting the inside rear tire, and Dan (74_5.0L_Z) suggested that the problem might be scrub radius and caster related. I guess the idea is that the outside wheelbase increases significantly enough due to scrub that the car leans over in that direction and the inside rear comes off the ground. Recently this thread popped up talking about swapping front suspensions and it quickly devolved into a pissing match for reasons beyond my comprehension, but it did get me thinking more seriously about the dual ball joint idea. Cary seems to think it's doable with the ball joints in the same plane, and had thought of a modified bumpsteer spacer as a possible way to do it. That got me thinking that it might be easier to just make a square tube knuckle and bumpsteer spacer combo, so that's where I'm at right now. Thinking square tube with simple clevises welded to it for the ball joints, and then taper the front end and have it open and then use shims above and below the tie rod to adjust bumpsteer. I have absolutely no idea how to figure out the spacing on the clevises to minimize scrub and that sort of thing but I'm very interested to see if I can make it work, and to see if it would be as easy as I think it should be.

- 38 replies

-

- 1

-

-

- dual ball joint

- scrub radius

- (and 7 more)