LooseRocks

Members-

Posts

112 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by LooseRocks

-

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

Can you measure the tooth height on that tone ring? Thanks. -

ANOTHER Datsun Z/LS3/T56 Swap Thread

LooseRocks replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

FR4 is basically PCB glass. Really dense, strong and has a low coefficient of thermal expansion. Not sure how the properties compare to what your panel provider uses. -

Those of you that are running BBK: What BBK are you using? Which wheels did you go with (size and offset)? What size tire are you running? I'm going to switch to T3 300 mm BBK front and 290 mm BBK rear. I'm looking at TE37V 17x8.5, 5x114.3, 0ffset -6. There's like zero info for what the backspacing or wheel profiles to determine if they will work. I like them but I'm not committed to this wheel choice. What others would be a fit? RSW-8SRT 17.x85 5x114.3 offset -6, Rota RKR offset -10, ... Suggestions?

-

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

From their site (typo and all): "Front and rear mounting faces are in the exact same postion as the factory 240Z so no special offsets are required to run these." -

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

I'm going with you on the T3 hubs. I'm hoping you get to the end on this. It'll definitely save me a bit of noddling. -

Did you cross over to the cold side in the tunnel? Or did you come out of the tunnel where the OEM ones come out and then routed them over. I'm in the process of installing new hard lines from the back to the front. The plan is to use the OEM brackets with new lines (enlarge the rubber mounts). I was thinking I would pop out of the tunnel where the OEM lines come out then bend them up and over to the cold side along the fire wall. Terminate them to a pair AN bulkhead connectors at a custom bracket mounted to the firewall below the hood latch just to the driver's side. From there I could make the connection to the engine with soft lines. I'm not oppose to going to the last OEM bracket in the tunnel then crossing to the center or driver's side in the tunnel and coming out to that bracket. Maybe located the bracket lower on the firewall. Just trying to get some ideas about what other people are doing.

-

Front brake upgrade with slip-on rotor

LooseRocks replied to calZ's topic in Brakes, Wheels, Suspension and Chassis

The outboard face is 8 mm from OE which means the center is 4 mm out. Will that require new brake caliper mounting brackets that allow for the 4mm offset? I suppose some spacers and longer caliper mounting bolts might work if having the caliper 4 mm away does not cause some weird stress issue for the caliper mounting brackets. Might be wheel fitment issues for those that have wheels with minimal caliper clearance. With no basis for a single grain of truth (not ME or have run any CAD stress sim) I can't imagine 4 mm being an issue for too much added stress on the caliper mounting brackets. The wheel fitment might be the only stopper for people that already have their wheel fitment dialed with their current setup. Would love to have over hub rotors though. If you can figure out a formula that works with T3 current 300 MM BBK that would be awesome. I don't really understand why the don't just make a deeper hat option so it can go over the hub. -

Front brake upgrade with slip-on rotor

LooseRocks replied to calZ's topic in Brakes, Wheels, Suspension and Chassis

What exactly do you mean by "inboard face"? The face in contact with the hub? -

How did you route your fuel lines? Did you cross over in the tunnel to the driver’s side? When you came out of the tunnel how/where did you terminate the lines before hooking to the engine (bracket on firewall, regulator on firewall, somewhere else)?

-

Grannas Racing: https://www.grannasracing.com/pages/black-friday-sale It's mostly Supra stuff but T56 + 2J bells housing applies for those wanting to spend a boatload of moneys.

-

Techno Toy Tuning 240Z Micro Big Brake Kit

LooseRocks replied to Miles's topic in Brakes, Wheels, Suspension and Chassis

I would have gone that way but only available in 4x114.3. It's going to be either Silvermine or T3. -

Techno Toy Tuning 240Z Micro Big Brake Kit

LooseRocks replied to Miles's topic in Brakes, Wheels, Suspension and Chassis

I don't think T3 has a rear brake solution that will work for 15" wheels. Silvermine has fronts and rears that work for 15" wheels. I'm sure it's the same as Z-car in that only certain 15" or 16" wheels are a fit. I'm not sure if you can get fitment template from either Z-car or Silvermine. T3 fronts only are $995. No rears for 15. Silvermine fronts are $685. Silvermine rears are $685. Silvermine rears+parking are ~$1100. Z-car are $3000 for the set + $300 for parking (only 4x114.3) (cost are from today's date 11/25/19) -

Something like: https://www.apexengineered.com/store/p31/Rear_Suspension_Conversion.html For a lot less work they also have: https://www.apexengineered.com/store/p29/Rear_Tubular_Strut_Brace.html I have no affiliation with them nor have I used these products. The quality of their products looks decent though.

-

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

Do you think that this setup would work in a 4 lug hub? -

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

T3 is 4x114.3 or 5x114.3. Oops wrong info. That's the hub blot spacing -

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

I think that you've already done the hard part. i don't see an issue with mounting the sensor. I was planning on doing a sandwich type mount on the OEM backing plate. I'm probably going to start with a 10 mm wheel spacer. I have a friend that can turn it down for me as needed. -

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

I don't have access/skills for printing something like that. I was thinking of using a 5 mm wheel spacer. How thick did you make your spacer? -

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

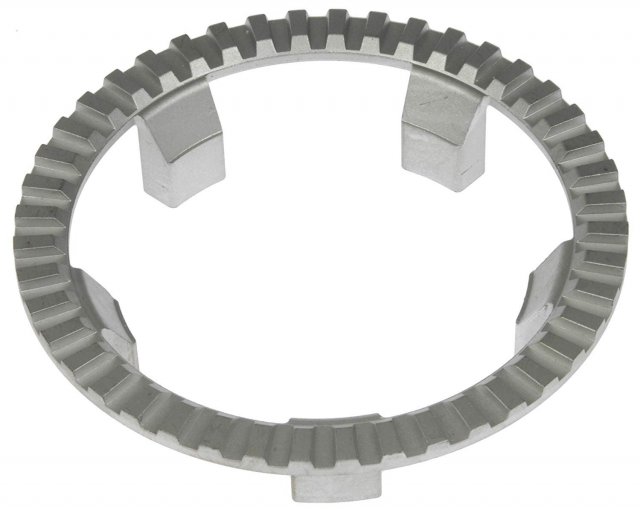

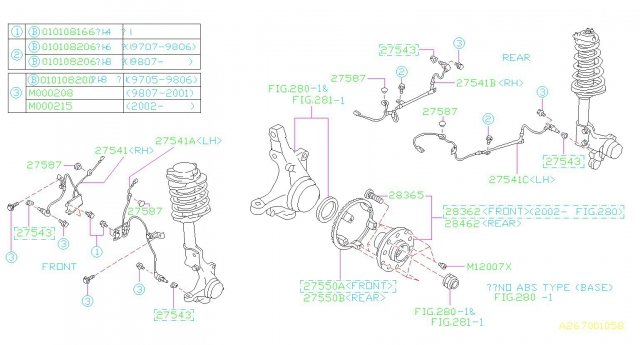

Is that the outback tone ring? -

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

You could remove the hub. It's a PITA but it might make the work easier. Also give you a chance to do a re-lube on the bearings. -

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

I might try to source an aluminum wheel spacer for the large aluminum ring. The smaller spacer could be made from bar stock. -

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

'98 to '08 Subaru Forester. I was thinking you could use a longer bolt for the bolts that hold the brake rotor onto the front hub. This longer bolt could hold a ??? mm thick aluminum ring which would have the screw holes for the tone ring. The thickness of the aluminum ring could make up for spacing between the tone ring and where the sensor poked through the brake dust cover. The entire kit could be: Source your own Forester ring PN#??? Source your own sensor PN#??? Two large aluminum spacer ring with four or five holes matching the bolt patter to hold the rotor to the hub. Four or five longer bolts to mount the large aluminum ring and clamp the disc brake to the hub. Five screws to go trough the aluminum ring to mount the tone ring. Sourced from Subaru. Two small aluminum spacer with a hole for sensor and a threaded hole for sensor screw. The sensor goes through the brake cover into the large hole in aluminum spacer. The screw to mount the sensor goes through the sensor mounting hole, through the brake cover and into a threaded hole in the small aluminum spacer. It would minimize the custom parts to two aluminum rings and two small aluminum spacer. That was what I was planning. But if I could just buy such a kit my life would be easier. -

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

I was thinking something like this mounted to the back of the hub so the mounting for the sensor could be simple. It could be held in place on the brake cover backing plate with a hole for the sensor and one for a screw. -

If I re-tap it and it works I know it's just going to be loose/weak. And it being one of two bolt that is responsible for holding the front of the rear LCA to the car I just didn't feel good about that. After going back and forth in my head about a million times I decided to cut that nut out. I went in from the top (thanks granny). The captive nut measured out to about 20 mm (.78"). I could have put in a thin wall M10 (M14 hole) insert but thin wall are not recommended for high strength application. That and I would have been left with about 3/32 of steel after running a tap. Not ideal. After taking in some measurements from below and figuring out where the window for the nut should be I marked my opening and said my prayers. Pretty much hit the opening dead on. The captive nut is made of an extremely hard material. It took couple hours of quality time with a demel to get it gone. I probably could have just enlarged the hole in the captive nut and just welded the new nut to the top. There was enough room. Maybe should of thought of that before I started hacking away. Probably better this way anyways. If you're going to go nine yards might as well take that last step.

-

Front Wheel Speed Sensor kit

LooseRocks replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

Would be interested in one for 4 lug front hub with tone rings/sensor. Would use a 5 lug if I had to. I was looking at mounting a tone ring from a Subaru Forester onto a hub. The ring is 90 degrees so the pickup could potentially be mounted to the dust cover. It would probably play nicer with a 5 lug.