fusion

Donating Members-

Posts

274 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by fusion

-

-

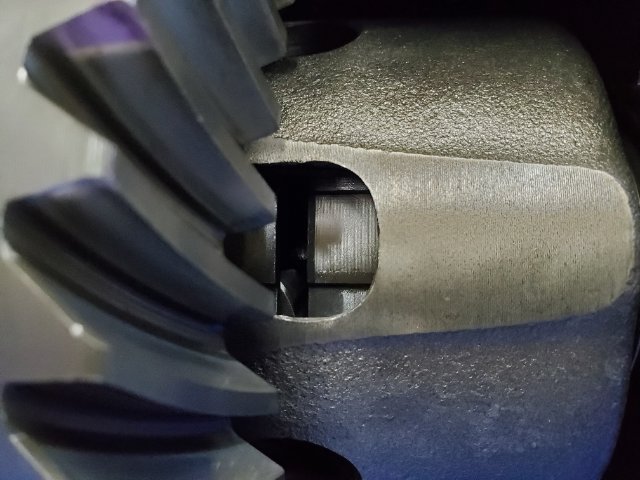

@Ben280 @JMortensen I tried to measure the gear ratio and kept coming up with something like 3.75. it's hard to be exact though

-

These parts are off my 1976 280z. I replaced with the super 8.8 kit. What are they worth? In good shape as far as I know. Rubber isolator is torn up on passenger side strut. Thanks

-

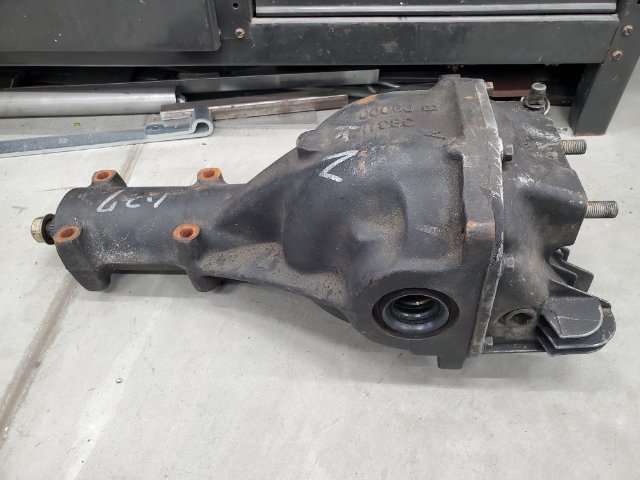

I got this diff as an extra when I bought my 280z. I was told it was an R200 LSD. I am going to sell it but want to be sure I know what it is. Can anyone help identify this? Also, what is it worth?

-

I drilled out all the spot welds on my spare tire well on my 76 280z and removed it to make room for a different gas tank. It is in mint condition, no rust at all. What is something like this worth?

-

Looks sweet, thanks for posting. And thanks to walker for that link as well.

-

Thinking about putting a type 1 air dam on my 280z. Let me know if you have 240z turn signals. Private message is best for me. Thanks

-

Hood struts to replace tension rods

fusion replied to fusion's topic in S30 Series - 240z, 260z, 280z

Thanks man. So the struts you are using are 43lbs, would you recommend like 50lbs would be optimal? -

Has anyone ever installed a double din dash unit in an s30? Looks like a 9 or 10" unit would fit really nice and you get bluetooth, audio, backup camera, gps, etc. I am trashing the HVAC and was thinking this could fit in that spot perfectly.

-

Hood struts to replace tension rods

fusion replied to fusion's topic in S30 Series - 240z, 260z, 280z

Just found another thread here: https://forums.hybridz.org/topic/122185-m-powered-z/page/3/#comments Really good info and pictures. Hopefully grannyknot stops in this thread to comment if everything is still working well and anything he would have done differently @grannyknot -

On my 76 280z I am putting in a turbo 5.3 and the FMIC will force me to remove the tension rods. I was just planning to use a prop rod, but I stumbled across a couple of old threads that discussed using gas struts. This would be really nice if it worked and wasn't super expensive. https://forums.hybridz.org/topic/57247-hood-lift-shocks/ https://forums.hybridz.org/topic/91439-hood-strut-conversion-for-s30/ Most of the links and pictures are dead. Has anyone else done this?

-

ANOTHER Datsun Z/LS3/T56 Swap Thread

fusion replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

Why wouldn't you use clear paint protection film instead? -

Thanks for all replies. No offense taken. The reason I asked is because I have seen several videos where they just cut the strut tube without removing anything. Also mentioned on the forum. Examples: Not saying it's the right way, just have seen it done. Also I read that removing the gland nut can be a huge PITA.

-

I am going to be installing BC coilovers on my 76 280z. This question is for the fronts only. I have seen/read a lot of install information. It seems some people fully disassemble the strut, spring, gland nut, etc and then cut the tube. Others just cut right through without disassembling anything. Would be really nice to not have to deal with the spring compression and gland nut hassle. Any thoughts? Thanks

-

Moving front wheels outboard

fusion replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

Got a link to those spacers? I couldn't find them for some reason on T3 site. Edit: Are these what you are talking about? https://technotoytuning.com/nissan/280z/evolved-roll-center-adjusters-datsun-240260280z Does it move the spindle outboard at the sake of increased negative camber? Is it possible to get back in spec with coilover adjustments? -

So I am building a 76 280z. I will be running Marugen ZG flares on all 4 corners. I have BC coilovers. I will be running 15" wheels. I have measured in the back and for a 275/50r15 on a 15x8 wheel a +35mm offset fits really well. 15" wheel options aren't great, but I found a wheel that works that I really like. So now I was looking at the front to see how a 15x8 +35 would fit. Mocked up 225, 235 and 245 tires. Definitely need to move the wheel outboard by about 35-50mm to sit close to flush with the flare. (Still need to get more precise measurements) The rear is already 5x114.3, and the front is still stock 4x114.3. I haven't bought them yet but wheels in question are Rays Gram Lights: I am mulling my options. I really like the wheels and would really like to make them work on the front. Since I need to convert to 5x114 anyway, I could get a pair of quality wheel adapters that go from 4x114 to 5x114. They make them in the thickness range I need and it would be a simple install. It would kill 2 birds with one stone and be the cheapest/easiest option. I've read that as long as spacers/adapters are either hubcentric or lugcentric and are installed correctly, it's not an issue to use, even at big thicknesses. Another potential option would be to install different hubs on the front. I believe the 300zx moves the mounting surface outboard (is it like a 25mm??). Probably wouldn't be enough, but maybe then I could run a thin spacer to make up the difference. Much more work and expense. Any other hubs that would work? Any other ideas/comments? What's the widest wheel/tire combo that generally works on the front of a 280z? Thanks

-

Using 5/8 bolt in place of spindle pin

fusion replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

Any update? Also, do you have a picture of the nylock/wire tie? -

Using 5/8 bolt in place of spindle pin

fusion replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

What did you use for a nut (nylock, lock washer, metal locking, double nut,etc), and what did you torque to? -

Using 5/8 bolt in place of spindle pin

fusion replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

For those that used the bolt, what did you use for a nut (nylock, lock washer, metal locking, double nut,etc), and what did you torque to? -

Thanks Mutant, could you post more pictures? I see you have welting between the flare and body, did you need to do that with the genuine Marugen flare?

-

I'm sure you saw on rhdjapan site that they offer the wide rear flares, but only in standard type. They list the width at 5cm over stock. I would assume this is true for the deluxe version as well, but they don't make it easy to find the information out. https://www.rhdjapan.com/marugen-shoukai-rear-extra-wide-over-fenders-s30-s31.html

-

Marugen makes wide rear flares in standard and deluxe types. http://home.att.ne.jp/sky/FairladyZ/Body/Rwide/Rwide1.htm

-

Flares that fit tight to the body and do not need welting

fusion replied to fusion's topic in Body Kits & Paint

Thanks for your comments. Did you get the standard, deluxe, or special type? How long did it take for you to get them? So you think the flares need some sort of flexible material behind them to prevent cracking of the paint on the flares?