AydinZ71

Members-

Posts

1073 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by AydinZ71

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Thanks @clarkspeed ! I was already leaning towards EFI, but your assessment is is consistent with mine! Yep, it’s the manifold I need to settle on before the head can start porting since it needs to be matched and possibly indexed. You know Mike Yoes? He is doing the porting for me. I called VARA yesterday and the EFI/carb won’t effect the class. I’m already bumped to GTU for the 3.0. thanks again for all your support! -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Hello friends, Although I am working as fast as I can to get the EP car done, I have a few irons-in-the-fire for future long-lead projects that I’d like to chat about. One of them is a 3.0 L-series motor I am building at the moment. Since an EP motor (which I have a head for) is very narrowly specific, I wanted a motor that I could use for vintage racing (wider rules tolerance). My priorities for this motor is reliability/durability first, followed by power. I have the block at my local machine shop waiting on CP rods and pistons. They have already straightened the LD28 crank and checked the cylinder walls of the core. Il be shooting for a modest 87mm bore. I have a decent N42 core head with my porting magician, and I’m trying to settle on a manifold to match to. I do have a call into VARA to get a better understanding of how I could be classed with SU’s, vs. triples, vs. EFI. Besides that, I wanted to get some feedback from the community before I settle on a manifold which is the prerequisite to having the head finished. would love to hear your pro/con for these three options, and which option you would go with given my goals and priorities. 1) DCOE racing carbs by OER (47mm) 2) Jenvey ITB manifold. I believe this is 50mm throttle, 40mm port-side and is intended to be port-matched. 3) conventional EFI manifold. I have a protuners model which was intended for a turbo build on the street car. Mon a personal level, I have zero experience with DCOE’s but have confidence in running/tuning EFI before a full dyno tune. looking forward to your thoughts! -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@clarkspeed thanks friend -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

oh good! Then I can cut this silly, thick, heavy plate out. You can see the bar is slightly below the seat pass-through, and my shoulders are slightly above. Sounds like that works! Here comes the cut-off wheel…. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Hi all! Need your help on the shoulder strap mounts for the 5-point harness. The cage as it came from the PO has this 1/8” plate with bolt holes for the shoulder straps. Seeing how close and level the roll cage is to shoulder elevation, is like to just cut this out and use the cage itself as a loop-mount vs a bolted mount. Any thoughts? i designed the car to have a passenger “joy ride” seat, and I will do the same for that side. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@clarkspeed that's a good idea! I’m not confident I can reach the bolts from underneath but it’s worth looking at. A small door to access the fuel fill would be ideal! Il have to look at that. 7lbs is 7lbs. This is the struggle with building a car… every time you see the finish line, an idea for improvement pops up and says “not yet…” 😂 -

darn, I left my copy with my machinist. I must have read the section on heads dozens of times. Il ask him for a recommendation based on his experience. Thanks Jon.

-

Can always count on your years-old comments being helpful Jon. I will need to do the clay test on my L24 head with the .500 lift. What is an acceptable margin at TDC and max valve opening, between the valve and the piston? 1/16"? I recognize there is always a risk when factoring valve float, rpm, etc. Was curious if there was a "rule of thump" for L-series motors.

-

Front tires rubbing on fender

AydinZ71 replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

60 is a big aspect ratio for a 235 tire on a Z. Was this for aesthetic reasons? That large of a tire will rub in my experience without removing the OEM fender lip after your flares are mounted. I suppose you have already heard the downsides of putting on wheel spacers vs. having the right offset on your wheels. Even after you eliminate static rubbing, you are likely to have rubbing when your suspension travels. Coilovers will allow you to make micro adjustments on your ride height. You will need to limit suspension travel if you want the wheel in a super-tight fit. I suppose you could try a heavier spring or make a custom bump-stop, but either will effect your ride quality. You will have some performance sacrifices in making it look precisely the way you want it (like the wheel spacers) but that may not be a concern for you. In the rear, you can center the tire in the wheel-well by adjusting the bushings on either side of the bolt/spindle on adjustable lower control arms. As Jon said, I don't know anyway to adjust the wheel position forward/aft without changing your caster. -

I have not used the tool you are looking at OP. I use a cut-off wheel for 90% of my sheet metal cutting. It is a versatile tool for me. I can cut muilitple angles, which makes cutting-out a template very fast. Can switch sheet thicknesses, handles big and small lines. I use the Wheel to de-Burr the metal as soon as it’s cut. For complex curves, I use a flat or die grinder and remove material up to a a marker. i use the shears Jon is referring to for thin metal like 20 or 18 gauge, but only if I am OK with the warping that comes from the end of the sheers. I didn’t like that for complex shapes from in-sitiu panel replacement, because the warping would mess with the fit. That works for small pieces where I can hammer the edges flat on a table. I did not like the HF ones I picked up so I upgraded to a more expensive brand capable of thicker metal after researching a bunch on Amazon.

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

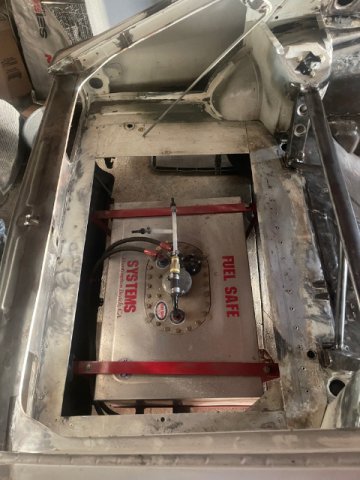

Continuing to remove the finish inside the car to prep for primer. Stitch welding several of the OEM sheet metal lap joints, and tying the roll cage to various spots on the unibody. This part is tedious… Also ground-down the PO’ roll cage welds and re-welded with a thicker filet, confirming fusion and using pre-heat to make the puddle sit flatter. also cleaned-up the fuel cell cover. Sucker is 7lbs! Checked the rule book and it does state “metal”, but not a thickness. Thinking about trying a box frame and thinner (.025” maybe?) AL for the skin. IMG_8275.MOV -

Rear spoilers, opinions and comments welcome

AydinZ71 replied to fusion's topic in Body Kits & Paint

I will have to make a block-off plate for the engine-side of the firewall so I have it handy in case the stewards flag the experiment as a no-go. It’s not completely futile since it replaces much of the stiffening the OEM heater chimney/manifold used to provide. The firewall (in multiple spots) and windshield sill are conveniently tied to the roll bar. i will definitely be doing the string-test Jon mentioned just to see which direction the air is moving. -

Rear spoilers, opinions and comments welcome

AydinZ71 replied to fusion's topic in Body Kits & Paint

Cool! Yeah, unfortunately I am unable to add anything to the body besides flares, and a front air dam. No new vents or openings into the body. No scoops etc. what you had on your MR2 makes sense! Makes double sense with front-engine cars so you can get rid of the hot radiator exhaust air vs. warming all your under hood components. Especially if your intake/carbs are pulling from the engine bay my initial reason for opening up the space between the engine bay and the cowl was to expel heat under the hood. In that context, it didn’t matter if the air went in or out of the cowl vent, as long as it’s moving. I would imagine similar would be true for alleviating the pressure differential between the top and bottom of the hood. -

Rear spoilers, opinions and comments welcome

AydinZ71 replied to fusion's topic in Body Kits & Paint

@JMortensen ahh! Yeah you are right, I misspoke. The air going overhead is creating the negative pressure on TOP, hence the ballooning hood. I thought this could relieve the high pressure under the hood, but like you said il have to stick some yarn on there and see how it performs. Might not work or be counter productive. We’ll see! the rad support area I made is just the steel mounting surfaces and structure, but I can duct the air in various ways with AL sheet. The goal was to stop air from diverting away from the rad. The pass-through’s that did not serve a purpose were removed, so now it’s ready to have AL on top, sides, and bottom during assembly. The ramped opening (I guess they are called diffusers?) for the rad and other coolers is something I saw in the 80’s Paul Newman turbo ZX car as well. Il have to look more carefully at what I’m allowed to do in the front. The bumper was used in EP as a tool to block more rad opening surface, so il have to look more carefully as how much (if any) of the OEM opening can be restricted by simply blocking more of it off. Absolutely agree the opening can be much smaller than OEM for a road racing car, and diverting air around to the sides of the car should reduce the drag coefficient. hey I’m all ears for any other ideas you have! -

how do you feel your engine swap changes the character of your Z?

AydinZ71 replied to thedarkie's topic in Non Tech Board

OH, and I just looked-up Tesla's fastest model available, the S Plaid version... 1,000hp! ...aaaaand 4800lbs. batteries, batteries, batteries. -

how do you feel your engine swap changes the character of your Z?

AydinZ71 replied to thedarkie's topic in Non Tech Board

@Michael I will touch on my main complaint... weight vs. energy. The Tesla model 3 in its lightest form is 3850lbs. Strip that car down to bare-bones, and you still aren't breaking 3000lbs. The 272 mile range drops dramatically if you drive it in its highest performance mode. Pretty soon you will realize the car is not well-suited for road racing since driving at break-neck pace simply robs from your range, and you cant just "refuel" it. The show "Silicon Valley" even had an episode joking about this exact dilemma. we were just discussing last week how @tube80z got his Z down to 1700-1800lbs range. As you experienced, you can throw-in a high-torque V8, trans, heck even a ford 8.8 rear end, and it can still be done for less than 2100lbs. That includes a 50-80lb roll-cage, and everything else you need to meet road racing requirements. As a street car it still works, but the tradeoffs I am describing in a road racing scenario still bleed-over into a street application. I would read-up on the Tesla fine-print for their Insane and Ludicris driving modes: https://www.tesla.com/ownersmanual/2012_2020_models/en_kr/GUID-E692415D-F83C-4F07-B30A-9E50499CFC30.html In conclusion, you end up in a situation where you MUST add weight to achieve/sustain large amounts of torque when electric. As some have mentioned on this forum before, an LS motor paired with a 6-speed is only a little heavier than an L-series w/ a Nissan 5spd (mostly thanks to an AL block). You will not see that same type of relationship when comparing electric powertrains, since we still have not cracked a weight-efficient means of storing electric power. -

Rear spoilers, opinions and comments welcome

AydinZ71 replied to fusion's topic in Body Kits & Paint

wait... do we still get to post about the semi-relevant conversations? Not related to air dams/spoilers, but the tangent of airflow at the front of the car. If so... disclaimer: these are my thoughts and opinions. I don't have wind-tunnel or extensive track experience and I am experimenting. SCCA EP: We are not allowed any new openings in the bodywork (no vents), including between the wheel-well and the engine bay. We can modify airflow once it has made its way past the bodywork, so no problem blocking off air from going over and under the rad. support. A few pics posted and eager to hear your opinions and have a discussion. 1) I put a relief in the firewall to allow access between the OEM cowl vents and the engine bay. The cowl was completely rusted and needed replacement anyways, so seemed like a clever idea. Some say the air will actually flow from the cowl down into the engine bay, but the vents are several inches in front of the high-pressure point on the windshield so who knows. The idea was to relive the low-pressure on the underside of the hood with the means available so we'll see. 2) rad area. I have not put the aluminum cladding in yet, but as several have mentioned I will be blocking air from diverting away from the rad support going over the top and bottom. What you can see is how I block the horizontal flow of air from going anywhere other than for a purpose. There is an engine air intake, two air intakes for the fresh-air ducts (I was told you need as-much fresh air as you can for a race car), and the rad of course. Two holes on the left are for grommets to allow the oil cooler lines to pass-through. Plenty of room and space for riv-nuts for fastening of AL cladding. Eventually I will be installing the 280Z FRP bumper to further block and re-direct air away from this massive front-end opening. -

Thanks man yeah… been looking on eBay, but that’s a good tip and I will continue to do so. Hard to find the wheel that checks all the marks, especially the 4X114mm. Also, as with most things in the automotive world, the used market is flooded with “slammed” street wheels 8”+, and a 0 offset is necessary with my suspension geometry. Truthfully, would I pay $2500+ for a lightweight racing wheel on a street car? Hellllll no, but clearly there are many that have the disposable income! 😂 Just kind of sounds like putting high performance running shoes on hipster with a bacon belly, but who am I to judge.

-

hey, thanks @Nelsonian Yeah it seems every vendor is having a hard time getting them to customers in a reasonable amount of time. I have heard that from multiple sources now, and as you would imagine its worse after COVID. So I am in a bit of a jam. Factory is not making the 15X7" i need to meet SCCA EP spec, only 15X7.5 (kind of odd). They did make a 10th anniversary addition in 15X7" last year but I am struggling to find anyone who still has a pair, and the factory stopped making those too. I might just have to give-up on Volk 😕 They were the strongest, lightest (11 lbs) wheels that could at one point be bought in that size.

-

Rear spoilers, opinions and comments welcome

AydinZ71 replied to fusion's topic in Body Kits & Paint

@JMortensen When you say cover-up the opening in the front, do you mean: 1) Air dam w/ very low clearance to ground. 2) reduce as much opening to rad intake as practical or both? Greg uses the 280Z RFP bumper precisely because it is huge and helps direct air around to the sides of the car vs. slamming right into the rad intake void. I will have to look more closely at how much block-off I can get away with in the front before I run into trouble with the rules. -

how do you feel your engine swap changes the character of your Z?

AydinZ71 replied to thedarkie's topic in Non Tech Board

@JMortensen Thanks Jon! Gotcha! Yeah I suspected you may have been trying to thread the needle with the CR. I thought about pushing it too, but even my EP head is only 10:1 for now. I don't have convenient race gas nearby and I am a total novice to road racing, so burning cash on extra octane did not seem like a priority. Il bump to 12:1 if I see myself becoming even remotely competitive. Good to hear the feedback on the cam! Il have to brace myself for getting used to the button clutch sounds like. The EP cam was a custom grind. I think I posted a shot a year ago of the timing sheet, but happy to again if anyone has interest. I suppose interest might wait until I can get it dyno'd. Limiting factor will be the SU's naturally. My machine shop made custom bee-hive valve springs for the head too, but I am a little anxious about them TBH. They claim to have a ton of experience on them and were confident they will work, but without any head-specific engineering taking place...we shall see! I will look up Monzter's posts for some insight on the 5.5". -

@tube80z thank you Cary! All very helpful! Amazing you were able to get the weight so low with the 1.5”X 0.125 bars! EP is same spec. I have a set of diamond racing 15X7” wheels too, and weigh-in at 16lbs ea. the TE37V’s will cut 5lbs in each corner, but having trouble sourcing the 7” wide version to be honest. I’m super anxious about working through a “fake” vendor so trying to find a reference from someone I trust. you have definitely given me some homework, and broadened my knowledge. Thanks to you and Jon!

-

how do you feel your engine swap changes the character of your Z?

AydinZ71 replied to thedarkie's topic in Non Tech Board

@JMortensen thanks Jon! yeah I have been nervous about the head on the 3.0. Have a solid lifter P90 for her, and still fiddling with the specs. the EP head I had made is 0.500/320deg, but there isn’t much guess work when you can read rules and naturally max out what you can. Again, same as the button clutch just sitting and waiting for that damn car… any reason you picked 11:1 CR? Were you shooting for pump gas with the E31? I have read some folks going for it, but not sure if anyone had success. in your opinion, how difficult do you find it to drive at lower speeds with a 300+degree cam? I wanted this stroker to be more of a “muiti purpose” motor I could use for shorter tracks and maybe even autoX. Hence looking at something “tamer”. Maybe I should get the EP motor up and running First before I settle on a head design. Greg gave me a great reference for an L6 magician, so I might get started on the porting and chamber work. I can get the cam ground and reassembled locally. it feels like so many of my questions could just be answered by getting the darn thing on the road. -

Thanks @JMortensen again! i should have mentioned, I bought a 5.5” button clutch/flywheel for the L24 a year ago working through Greg. Works with the auto trans flex plate just like you said. Just runs a single friction plate but an L24 doesn’t put out that much torque, even in EP form. I was new to these “button” units so always curious what the pro/cons are to various sizes/configs. Naturally, I have WAY overshot my expectations on a “finish” date, so still prepping the interior for paint while this $1200 clutch just sits on my shelf. the TE37V’s are 5.5kg each, which is just about the lightest wheel I can find in 15X7, but I think the loss of cornering response from a 13” wheel might not make up for the weight savings. Still, I’m so novice on all this that I’m obsorbing the various options like a sponge as I’m sure they will come in handy at some point! you have highlighted for me that I need to learn more about racing tires in my size. Il hit Google and see what’s out there, compare weights etc. thanks again Jon!

-

how do you feel your engine swap changes the character of your Z?

AydinZ71 replied to thedarkie's topic in Non Tech Board

@JMortensen Curious from that experience Jon, do you feel it was your low-end torque that gave you much more confidence on the autoX course? The fundamental character difference I experienced from the L6 and a V8 (not a swap, just another car with an LS) is that immediate, ass-moving torque. I am building a modest 3.0 stroker block right now (CP rods and pistons) that will be for vintage racing, but wanted something more reliable and less expensive operationally. Staying at 10:1 CR, don't think I will break 250 HP without going to a 300+ duration cam, but who knows! A part of the fun is just trying things out. As I get older, I seem to appreciate so many more aspects of an engine package than just max power. I would like to get the "feel" of a 300bhp L series one day, just to get a sense for what the trade-offs were to make that power.