AydinZ71

Members-

Posts

1073 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by AydinZ71

-

John made a good point about our meandering conversation on someone's wheel/tire post so I started a new one. @JMortensen, @Dat73z Attached is the specific tire we run in EP (I say "we", as if I actually have the car on the road). Il post some pics of the wheel/tire combo on the car. Agree with Jon that the racing tires certainly feel a lot lighter than DOT street tires, although I have not weighed a 245 tire as a comparison. As I said in my previous post, the combo came-in at 33lbs w/ a wheel weight of 13.6lbs. I am still amazed how Koenig can achieve that knowing the top-of-the-line TE37V is just under 11lbs in the same size. The Koenig's were $109 ea on Summit and lighter than the conventional (and much more expensive) panasports.

-

So I am only familiar with the class rules in SCCA EP and ITS. In E-production is sort-of the closest thing to C-production which is no longer a class raced at nationals. Not sure if its still around regionally. ITS is less-modified than EP. higher weight limit, etc. EP, we are limited to 15X7". ITS seems to limit the wheel and tire widths: 7" w/275. 8" w/225. It all comes down to the specific spec. line in the particular racing league and class. The point I was making much earlier in the thread is given the power, braking, chassis/suspension limitations of a particular class, ultra wide wheels/tires is not always "better". At some point, you pass an inflection point where the rotating inertia and weight of the wheel & tire starts fighting you and the additional traction from larger contact patch is giving you diminishing returns. If your braking and torque can't utilize the extra grip, that still leaves cornering grip but you are still adding inertia and weight. Now if you had a Z with unlimited brake modifications, unlimited wheel/tire and torque far above what you can get from an NA L-series motors, you can certainly gain a lot from going wider than 7"! As a point of humility, I don't have the first-hand experience of racing for years like others here. This opinion is from many conversations with those that do, but my perspective is narrow. Assume whatever Jon, John, or Cary say supersedes my opinion haha.

-

Certainly not an expert by by a large margin, but I don't think 245's will work on 15X7 w/ street tires. Hoosier makes these slicks for racing, but even more so they list "Prod, GT" in the description of 245/580R15. Meaning, the tire was specifically designed for production racing where clearly the width of the wheel is limited by class rules. The contact patch is much larger than the wheel width itself, hence "cantilevered slicks". Using only deductive reasoning, I don't think DOT tires can have a larger contact patch than the wheel width? Recalling Cary and Jon's previous posts, I think they know a lot more about this subject than I do. @tube80z, @JMortensen E-production is limited to 15X7" wheels but that's not a terrible thing given the ~260hp EP L24 and the 245 tires. With Volk TE37 wheels and the hoosiers, the combo is remarkably light! I just weighed the wheel/tire combo with my 13.6lb Koenig wheels and its only 33lbs! Again, no expert but that seems pretty darn light for a 245 contact patch. on a 15" wheel.

-

Ah, yeah I certainly am unfamiliar with GT-2. My perspective is clearly limited. From the conversations I had with Greg and a few others, 245’s Cantilevered slicks on a 15X7” wheel kept the weight of the whole assembly very low while providing quite a bit of contact patch. Of course these are L24-28 NA EP, CP vintage, and VARA cars so greater torque would change the calculus. Fair enough to say you have more and broader experience.

-

Maybe there are a few folks (my self included) who would be willing to moderate if we were provided permissions but maybe Cary or someone will read. I enjoy the forum and don't feel it is a huge impediment (periodic spam) but I'd be happy to help delete the bots.

-

Hi all! ok, setting class rules aside for the moment, what would be your first choice for brake caliper/rotor setup for a 15” wheel, and why? front And rear. curious whAt the current consensus is. From what I can see, all these vendors are offering big brake kits but no idea if there are any differences: Zcar garage big brake kit T3 big brake kit silvermine MSA

-

Hi all! ok, setting class rules aside for the moment, what would be your first choice for brake caliper/rotor setup for a 15” wheel, and why? front And rear. curious whAt the current consensus is. From what I can see, all these vendors are offering big brake kits but no idea if there are any differences: Zcar garage big brake kit T3 big brake kit silvermine MSA

-

Hi all! ok, setting class rules aside for the moment, what would be your first choice for brake caliper/rotor setup for a 15” wheel, and why? front And rear. curious whAt the current consensus is. From what I can see, all these vendors are offering big brake kits but no idea if there are any differences: Zcar garage big brake kit T3 big brake kit silvermine MSA

-

Because they want to make it looked “slammed”. Or whatever the kids call it these days. im kidding, I think it’s cool that everyone’s got a style in mind. I agree it’s not a performance oriented decision though. Z’s set up for racing rarely go wider than 15X7 because of a combination of racing rules, reduced weight (both in the wheel/tire combo and the much lighter ~1900lb or less, car), and generally topping out at 250-350 for NA L-series motors. I feel the early s30’s are closer to a Miata than other popular and larger modern GT cars, in terms of size, weight, and handling.

-

If i were to hellcat swap a 280zx what rear end would i use?

AydinZ71 replied to 79datsun280zx's topic in S130 Series - 280ZX

It sounds cool, and it certainly would be a great platform for a 1/4-mile drag. I just think as a road vehicle 700hp(the torque is the dangerous part) in a sub-3000lbs car means one of two things. Either you won’t use all that torque on the road (you will choose not to use WOT), or you will slip and slide and have the potential to total the car. Cage is a must for chassis stiffening let alone safety, but even with all the safety stuff you can still total your prized possession. After 20 years, I guess what I’m saying is bigger isn’t always better unless you are competing in a closed/controlled course. -

Those holes are really quite easy to weld shut if you have already committed to re-painting the cowl cover. Otherwise, the easiest and most convenient thing to do is measure the hole opening and buy a rubber flush plug, like all the other spots on the unibody. Weld or no-weld, it will be difficult to get a true delete (like it was never there) without refinishing the whole cover. Color-matching, filler work, etc. The piece is small enough to have sent-out for media blasting.

-

In my experience, adding coolant to the turbo bearing cartridge is most valuable in preventing the oil from cooking (and fouling the bearing) between boosting. If you have appropriate oil pressure at your turbo, you should have sufficient flow to keep the bearing cool during operation. The coolant is a heat-sink to prevent the bearing and oil temperature from peaking above when the oil begins depositing coke dramatically (300deg+?). Most valuable for short runs where the car drops back to idle with a glowing-hot turbine housing, simultaneously oil pressure dropping (idle). I have seen folks with typical oil-bearings without a turbo-timer having no problem thanks to the water jacket. In general, I just let the car idle for 5 minutes before shutting down. In this way, the thermal-syphon works pretty darn well. Even is worst-case, temperature of the water rises above 250 it will start to vaporize which makes room for water column to take its place. If done correctly, it should be self-correcting (some call it fail-safe). At least for street applications, I have not seen a need to ensure active flow through the bearing housing. Always exceptions. These are just general observations.

-

If i were to hellcat swap a 280zx what rear end would i use?

AydinZ71 replied to 79datsun280zx's topic in S130 Series - 280ZX

Ford GT 8.8 would be my vote. @Invincibleextremes Goodness, everyone wants the insane power builds. Are ya'll drag racing or is this for bragging rights? Makes total sense to drag, but its reallllly dangerous having that much torque in street Z. Just my opinion having driven a wide range. -

ok, I highly, highly, highly recommend having the interior and engine bay vapor blasted. looks like the body is OK so you can mask that all off with thick mil plastic. You give them $500-$800 bucks, do the masking, deliver the car and it will come back to you completely ready for epoxy primer and paint. What you are doing (piece by piece, by hand) is absolutely comendable and its precisely what I did on the race car im working on. But. i regret it. You will be chasing little rust pockets and hard to reach areas for months... years even (2 years in my case). Vapor blasting is neat. They use media combined with water so they are able to use a finer grit. They use water to keep the surface an even temperature preventing warping, but the water is warm enough that it flashes pretty quickly. It comes out essentially as steam, hence vapor. once you get the car back, you will see precisely where your cancer spots are and you can get to work. Seam seal, Epoxy primer, and you are on your way! You are doing great work

-

There might be a few folks on here that may know, but in general most of us active folks are gearheads focused more on performance (street or track). You are looking for something very specific from an aesthetic perspective. I will say, the look you are going for seems to be very popular and several people are trying to replicate that look. From a technical perspective, just keep-in-mind the closer your tires are to your flares (horizontal plane), the less suspension travel you will have before they rub. Unless you form custom flares with a similar profile to your wheel/tire, your suspension will suffer from trying to optimize the "look". You will get the "tucked" look while having room inside the wheel well for travel. That would be a lot of work and it may or may not look any good. Just some food for thought. I would try to strike a balance between getting the tucked look without going over-board. Those "slammed" cars you see in JDM magazines etc... well, they are cruisers. Similar to the old school lowrider culture. Not ideal for a daily, comfort, or maneuverability.

-

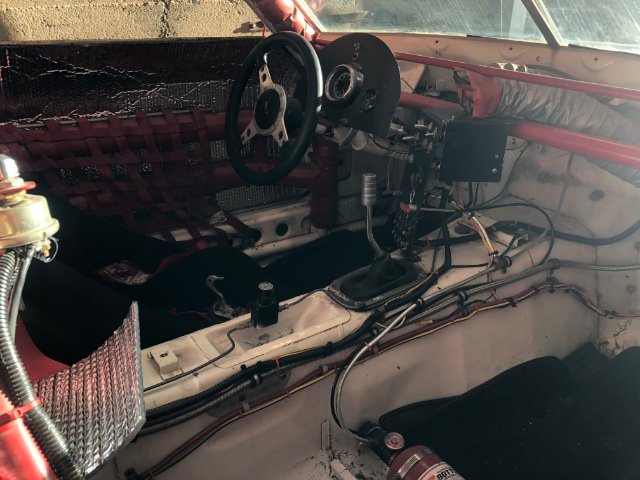

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Interior paint is complete. Now on to the body (Which honestly is a relief). threw a few before/after photo’s taking us back 2 years. -

I looked into this when I was playing around with a swap idea 3 yrs ago. Are you specifically talking about the motor in the production Maserati’s? I believe only the Ferrari motors made 500 and over. I decided against it when I realized how expensive and rare replacement parts would be. It sounds cool, that's about all it had going for it compared to other options.

-

New owner, 74 260z -head gasket woes

AydinZ71 replied to inis's topic in S30 Series - 240z, 260z, 280z

hmm... When you say "sleeves", do you mean the cylinder walls? If so, you definitely do not want to use scotchbrite (maybe the non-scratch kind?) as you don't want to mess-up the prevision hone job that exists. If the cylinder walls had surface rust on them. If you really want to have-a-go at what you have there, you could throw it all back together, pre-lube, and crank it over to check cylinder pressure. My instincts tell me you will not be happy with the state of the motor. It is likely to burn oil (either at the valve seals, piston rings, or both). I would just pull the motor and send it off to a machine-shop for a rebuild. Your seals and gaskets are likely toast as well, which will cause irritating oil leaks. -

Cary, Agree with everything you said! The AL bracket was designed to go-over the unit (hence the bridge-like design, would have looked like it belonged), but given the geometry I had during fit-up it didn't work for me. Too sharp of an angle for the cord to penetrate the firewall perpendicular. It looks silly mounted to the side like that, but I have the room unutilized and their mount is very light. I can reconfigure the air-in/gauge nozzles since it's all disassembled anyways. Photo's were taken before I sent the unit to Accusump for reconditioning. The brass 1/4" nipple and ball valve are pretty darn heavy (over a pound). Agree all of the components could be fabricated separately for a more elegant fitment. Shortening the cord shouldn't be all that hard either. My reluctance is time. Time has been the most watched variable in this build. Since the whole chassis was restored from the ground-up including almost a year of rust repair and chassis stiffening, I'm doing everything I can now to leverage non-fabricated components. The kit was about $110, and when I compared that to the time I would spend it was a no-brainer. Two-years into the project, and I am only now finishing interior paint from bare metal (spraying this weekend). I see a future where I may re-visit many of these considerations once I get the darn thing on the track. -Aydin

-

Post that 3.9 for sale (if you are willing to ship) and I'm sure you could get at least $500 for it.

-

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

looking good Clark! Looks like you are getting close! how much longer you think before you will hit the track? -

Yeah that’s what I had in mind. Running the accusump only (for now) since the oil pan options are quite expensive. Pre-oiling was a big plus. I got mine used for $100 and sent it to accusump for reconditioning ($60). Now that I can mig weld, I thought about just getting another oil pan and modifying it myself. They don’t weigh all that much to begin with, so not quite sure $700 for an all AL one is worth-it. My cable is installed in such a way that it goes through the fire wall, heads towards the drivers chassis air vent, then loops back to my gauge cluster at the center console. I’m still painting the rest of the interior so everything is disassembled. Here is my gauge cluster made from 0.08 5052 AL (because it bends without annealing). I got it down to 1.2lbs without the gauges and hardware. At the bottom of the panel there are two holes. One is for the fire suppression system, the other is for the accusump. Both a pull-cords with handles.

-

Holy cow! Sorry to hear about your loss friend. Hey, I know engine fires are rare but if you really have a sore-spot for this Kinda thing, can I suggest a suppression system? We have to use them on race cars (mandatory). The kit is expensive, but at least you don’t have to worry about the fire bottle expiring every year like we do. Il even give you my old (charged) fire bottle for free if you want to pay for shipping. just an idea! The nozzle comes out fo your fire wall and points directly onto your injectors, but in reality it’s coating everything within 3’ of the nozzle.

-

PS: my battery is downsized and relocated behind the passenger seat. My coolant overflow is below where your inspection light is, and my oil knock-out resevoire from the breathers is directly across from the block breather outlet. This is an NA race car, so I don’t have the turbo charge pipe to worry about.