AydinZ71

Members-

Posts

1073 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by AydinZ71

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@jhm yes sir, fabbed myself. There is a face mounted bearing that goes on those drop mounts. They have two ribs on the back side you cant see, for stiffness. I would say the centerline of the bar drops about 3". I mocked it based on how low I needed it to clear the oil pump, from my street Z. I think there are some older posts of mine that should have it in a lot more detail. I will have it mounted soon and will give you some more pics. @calZ Thanks. Yep, I believe I solved my problem. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Got the STI carrier into the 4.11 open diff. Time to remount the diff. Curious question now is, was there a difference between the series one mustache bar and the 71-73’? Will get it mounted and see how far the diff alignment is. front suspension also complete. Need to install sway bar and front wheel bearings. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

yep, this is an R180 bar. The bolt holes don't align between an R180 and R200, so the mustache bars are dedicated to each of their own respectively. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

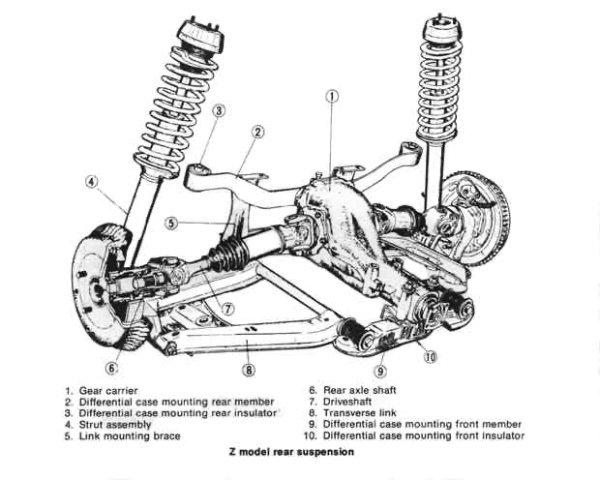

Hi all! Thank you for your help @jonbill @clarkspeed @jhm So I am a little confused on the mustache bar. This is an R180 in a series one 240Z. Looking at the stock photo (attached), it shows the mustache bar in the same orientation as I have it now. Do you guys have the mustache bar mounted behind the LCA vertical supports for an R200, or also for an R180? hmmm... any idea why the OEM photo has it turned the other way? I bought a laser level, but it really was not designed for what I am trying to check. The back of it was curved, and seemed limited to something used for hanging something on a wall LOL. I need something that would sit flush against the diff axle output and check where the cross-hatch ends up on the hub/stub axle. Have not found a tool that can do this yet. I Pulled the diff, and thank you John for the nudge. The Subaru STI R180 and the Datsun truck R180 w/ the 4.11 gearset are at the diff shop. They are going to swap the STI carrier into the 4.11 for me. I have CV axles adapted to the STI carrier splines so should work OK. I read a few posts about folks having trouble with the RT mount and a series one. One post mentioned turning the mount 180 degrees, which puts the fuel line notch on the wrong side, but I suppose I can accommodate. I am attaching some photo's of how I have it mounted today. Maybe someone sees something wrong here. In conclusion, I guess I need to definitively conclude which orientation of the mustache bar is correct for a series one with an R180. I can do whatever I need to for the RT mount to make it work. John mentioned the mustache bar really should be setting the for-aft orientation of the diff which makes perfect sense to me. Thanks again for all your help folks! -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Thank you John! @jhm, Clark! @clarkspeed here are some shots of my mustache bar installed. Had an R200 w/ accompanying mustache bar when I bought it. I sourced a 240z mustache bar locally to accommodate the R180. I recall it was a bit difficult to get the RT mount into place. Took some rubber mallet hammering, and the bolt/nut interface took some static force to get into position. Was there a significant issue with the series one diff location (as I appear to have it in now)? I would imagine fixing the alignment issue will require me to slot or re-drill the single bolt drop-mount in the RT brace. Totally doable if necessary, but like everyone else in history, I hate dropping a diff haha. I still need to go get a laser level with a mag mount. Based on what you are saying John, I now have it back in the original series one position which requires a shorter driveshaft than the PO had installed with their R200 and associated parts. Found a local shop that will make me an aluminum driveshaft ($600) which I can seamlessly shorten to correct this issue, while lightening simultaneously. So it sounds like now I just need to decide if I should shorten the driveshaft or move the diff back a 1/4” or so. If you have a laser level you enjoy using for these applications, let me know and il source it on Amazon! Very clearly, drivetrain and suspension angles are not my strong suit, haha. Thank you! -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Hi all. Looks like the community may not know what could be causing the length issue on the driveshaft. I would like to try this another way. Are the axle shafts intended to be on the same XY plane of the wheel hub, and just angled down to accommodate suspension travel? If so, I can put a laser level on the output of the diff to make sure it is not too forward/aft. Then I will have confidence that my long driveshaft issue is not also causing an axle shaft misalignment. Then I will just shorten the driveshaft and call it a day! also seen some chatter on hybrid about rear diff alignment issues with a series one (which this is) but I could not seem to find a solution documented or my specific issue. what are your thoughts? -

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Bookmarked. Thank you! -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Hi all! So I need some help with the driveshaft. When I received the car, it has an R200 installed and this driveshaft (the one I am using). I swapped out the R200 for a Subaru STI R180. I also swapped the bottom-mount for the RT top mount. Unfortunately, the driveshaft no longer fits. It has bottomed-out in the trans side and appears to still be a few millimeters too long for the diff side. I measure 29.75”, or 755mm from the end of the yoke to the diff mounting flange. Is there a shorter driveshaft that was made? I had the impression all the S30 driveshafts were the same length. Could there be an issue with installing the RT mount on a series one (which this is)? I can have a shop shorten the driveshaft, but I’m concerned there is a bigger issue such as my diff sitting too far forward -

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Hey @clarkspeed.Bummer on the re-work and fit-up issues. I know how you feel! I’m experiencing similar difficulties, but I’m relying mostly on the OEM geometry. The sway bar is the only 100% custom aspect of my suspension. I placed my regulator mount too close to my filter and have to do a loopty-loop of hose to make the connection. Annoying, but not worth the extra time just to make it “look” right. Hope you get everything worked out! speaking of bump steer spacers: Greg said he had two 1” AL pieces welded together to get a 2” spacer. I guess Sam Neeve struggled to get his bump steer correct. I’m starting off with a 1” (since that’s the biggest off-the-shelf unit) and going from there. I found plenty of tutorials on setting roll center, but I have not found a decent one specifically for McPhersons yet. Let us know how you end up dialing that in on your car. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

All hydraulic lines complete. Accusump installed. Fuel system 80%. Beginning oil cooler plumbing and front suspension installation. 3.1L is nearly complete and contemplating installing it with SU’s until my budget can accommodate injectors, ECU, etc. IMG_1422.MOV -

The protuners one is good for what you are paying. I agree with Zetsaz on the L-series being a non-cross flow head as the primary issue. Saying something is poorly engineered is bold statement. Detailed engineering and testing costs money. It is very difficult to get a custom manifold made out of 304SS, hand welded, sold for ~$1k, and still make some profit. There really isn’t any engineering that went into it at all. they picked a primary diameter, and arranged bends and straight lengths to have them all come together one one location. If you want a manifold that takes into account actual fluid dynamics etc, you are looking for something double the price or more. There isn’t enough volume to make money off them. We have some talented TIG welders out there, and none of them offer something better because they know they couldn't make a decent return with the labor necessary. I suspect Hussein orders many at a time out of China. Take a look at there NA headers for instance. You can get a pacesetter or MSA for cheap, but they are garbage compared to the $1-$3k stainless headers from Zstory, Kameari, Fujitsubo, etc. you get what you paid for I suggest contacting a header fabrication shop and ask them to quote you a custom unit. You will likely end up again choosing between the two options you mentioned.

-

My understanding is that all R200 long-nose ring and pinion’s are interchangeable in any R200 long-nose assembly. However, I would watch a few YouTube vids before you take on the challenge. It’s not really “easy” if you aren’t experienced. You need a dial gauge to set backlash, or some enamel paint to check tooth surface contact. It’s also a bit of a pain in the ass to get the center assembly out. Lots of banging with a rubber mallet to get things in/out etc. might want to just hand it to a local diff shop and pay them for 2-3 hrs labor

-

1971 240z bent rear trunk near the tool bin

AydinZ71 replied to Rivvs1's topic in S30 Series - 240z, 260z, 280z

So looking at it closer, there may be a link between the pass-through on the sway bar and the buckling. He bored a hole right through the unibody support. If the car was then rear ended, it would definitely buckle at its weakest point which is precisely where you see the damage. If the material removed is severe enough, the unibody could simply be warping from the stress of the road alone. What I am saying is plausible, but really there is no way to know for sure so take my thoughts with a grain of salt. -

1971 240z bent rear trunk near the tool bin

AydinZ71 replied to Rivvs1's topic in S30 Series - 240z, 260z, 280z

Mann… uncoated carbon steel and everything. I applaud his creativity, but he must not have been too concerned about corrosion 😂 what is your goal for the car? If it was a great deal and you want to turn it into a cruiser, I’d say you can keep going and as long as the suspension geometry isn’t too out of wack, you may be OK I wouldn’t use this as a base for a track car though. The buckling will just introduce another point of bending/articulation in the unibody that you don’t need. You could add a bunch of reinforcement, but it may warp it further if the unibody is already compromised. Tough call. Did you get a really good deal? I see a lot of rolling chassis on offer up for $5-8k. I bet they would negotiate since there are so many of them. -

1971 240z bent rear trunk near the tool bin

AydinZ71 replied to Rivvs1's topic in S30 Series - 240z, 260z, 280z

to give you some context, the race car I restored had also been rear-ended. Luckily, the buckling I experienced was right where the vertical supports surrounding the taillights intersects with horizontal panel housing the spare tire (mine is gone, fuel cell). I have about 1/4" of "dive" on the horizontal panel. No net effect to the outside bodywork after metal work, straightening, and filler. My concern for you is that your bucking appears to be forward of the shock towers. If you draw a rectangle around all four shock towers, everything inside is critical to the dynamics of the car, and everything outside is just "dead weight" with no direct effect other than aero and chassis stiffening. once the towers get pushed around (closer, further, left/right), the vehicles dynamics will be effected. It CAN be fixed, but if you balked at major rust repair, I am afraid fixing a buckled chassis is a much greater risk for success. Good luck! -

1971 240z bent rear trunk near the tool bin

AydinZ71 replied to Rivvs1's topic in S30 Series - 240z, 260z, 280z

looks like it is buckled. Get underneath the car and see if you see any other buckling from underneath. There two unibody tube supports that go along either side of that ramped surface. They should show some signs of damage as well. You just noticed this now, and not when you acquired the car? Can't tell you what caused that, but my guess would be an accident. An S30 can be rear-ended and repaired, look OK from outside, but still have buckling in the main unibody structure. Misaligned panels can be contoured with body filer. -

Yes, it’s fine. If this is for a street application, it’s 100% OK. Felpro also make their head gasket interchangeable across all L6 engines. there are only a handful of manufacturers of head gaskets for an L-series so assume that it’s ripped-off from another manufacturer and re-branded. I am partial to OEM Nissan followed by felpro. if you want to be extra safe, check all your oil and water galley’s are indeed pass-through on the head.

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Thanks Cary. I need to unbox my Jenvey TB's again and take a look at what they came with. Maybe they already took this into consideration! I just got them back from Yoes a few weeks ago, along with the N42 he completed for me (matched to manifold). Either way, it sounds like a great idea. Usenet! that really goes back! I started on the Z31 forum when i bought my first car (an 85' black NA) in 20' There was even a chat room on IRC if I recall correctly. man...things have changed. It feel like overall the trend has moved away from technical prowess and performance to more of an aesthetic vibe. I may be projecting. @clarkspeed yep, Haltech supports it now. I just assumed the added weight of a throttle actuator and another potential electro-mechanical failure point would make it a "bad" idea for a race car but really I have zero experience and no idea. I already completed the pedal and firewall adaptation for the Lokar cable, so now i just need to complete the hookup to the end effector. I'm excited to see someone try it! -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

thats a neat ideal! Il do some research. I ditched the linkages for a lokar cable so il need to fabricate one anyways. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Me too! We are on the same page. I bought the ITB's over a year ago. At the time, I didn't recall if they had another L-series option other than 50mm. Agreed, its going to be a tight throttle margin. Should pair nice with the Stahl header with the 41mm primaries. The collector I have necks-down to 2-5/8" before expanding to 3" over a 3" transition. According to Burns Stainless, that will help broaden the torque band a bit lower than just a straight 3", without adding a noticeable drop in high end. Speaking of which, I welded the collector to the header once I confirmed I can install it in one-piece. Shipped it off to Swain two weeks ago. They are claiming a 10-week lead time so getting to work on the rest of the systems. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@clarkspeed thanks for all the feedback Clark. I have the Jenvey ITB’s, so 50mm taper down to port-matched head. Just got my head back from MR. Yoes. Sounds like the MAP will be less effective to tune with than just a TPS. My cam is 256 @ 0.05”, 0.565 can lift, so I doubt I will have consistent vac anywhere near idle. Main goal is to tune WOT to torque, then just target a AF everywhere else. I also hear some negative things about the knock sensors. My main anxiety is, I have never reliable been able to catch it in my ear at WOT in the past. I blew a few turbo motors as a result. I guess it couldn’t hurt if all I did to start was output a small light until I have confidence it works right. thanks for the feedback on the SDS. -

Ah! Sorry, had not been following your build close enough 🤦🏽♂️. Ya G25 seems too small. I’d Go a size up, and it looks like max efficiency only drops by a handful of percentage points. Lead time is currently 10weeks, so il snap some pics when it comes back. Just FYI, the coating looks good initially but turns ugly pretty quickly with repeated heat cycling (just like the real stuff applied on nasa heat shields). I’m going to call them tomorrow and ask if it can be too-coated with high temp paint just to provide a consistent surface color. The Swain ends up with varying shades of yellow and light brown after moderate use.

-

Cool! I was looking at the G-25. It appears to have a remarkable 80% efficiency on the map I plotted on their website. I sent my protuners turbo manifold and down-pipe off to Swain along with my NA header for coating. This is for the street car, after the race car is finally running.

-

I have a Ztrix fiberglass hood and hatch. The lightest I have found, and I did ask around. If that’s important to you, don’t get distracted. Ask about the weight. Both pieces have been finished with sealer, paint, the works. You will need to make some minor adjustments, but overall I’m pleased.

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Absolutely agree Clark! Came to the same conclusions. Honestly, I don’t want to run closed loop traction control even if the sensors were free. It’s a vintage race car after-all, and the “fun” is precisely in the purely mechanical feel and simplicity. Series 1 race car is the equivalent of a cable driven acrobatic hi-plane 😂, and it’s still a thing! I was pondering pulling my SDS from the turbo street car but then it won’t be running… my version unfortunately still requires the dizzy And they wanted $500 to upgrade the board. Hmmmm… as a type this it may be worth doing when I turn my attention to the street car. I will take a look at Maxx before I pull the trigger on Haltech. many particular sensor feedback you see a need for other than TPS, MAP, coolant temp, air temp, AF, and knock?