-

Posts

1078 -

Joined

-

Last visited

-

Days Won

34

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by A to Z

-

I'm keeping it simple and easy to get done. not going to a mirror finish, just a factory level finish. I build drivers, Sir. I was going to use that dry guide coat until I realized you can't paint over it.....so it is ANOTHER step to get it off then put the mud when you took it off, then smooth it out then another guide coat then block. I just used black primer, mud the deepest bottoms, and use about 4-5 coats of the THICK primer filler made by duplicolor.....specially made for deep scratches. red oxide color. Not advocating any of this it's just experimentation and finding a way that works for me. It will go quick this way. Mud only where needed. when you cover the whole panel, 90% is sanded right off. Using glaze, it sands so easy, I can block it with 220 grit within about a hour and have it ready for filler primer....will it be razor straight? No....but it will look pretty nice.

-

thanks a lot. I added a bit more hardener and then no problem. I will post pics later, but I put a thin coat of black primer right on the steel and then blocked it this morning. Did the same with the sail panels. It worked great. I then wiped it down with rubbing alcohol and put pieces of blue tape in all the low spots that filler primer won't fill in. I will use glaze with a hardener now. I am well versed with it and it is so easy to work. I just want a decent job, I don't need a show car body. when all is said and done, if the clear doesn't "pop" enough, I will wipe on a coat of glossy Poppy's patina. Poppy's Patina - The Original Patina Clear Coat.

-

12-30-2025. The filler i had put on the roof of my 260Z never hardened up.....it just stayed "gooey", so this morning I went to it with a wire wheel attachment in my drill and got it all off. I then went ahead and sprayed some flat black primer on the roof and the sides a bit as well to go ahead and start blocking it out.

-

There was chatter at one point about the welds on CX racing stuff being a concern (particularly the exhaust turbo header).....so you will want to check the welds carefully prior to putting everything together. Front and rear strut tower braces, a roll bar, Apex front side structure supports, and maybe stiffen up the rails .......bad dog used to make thick steel rails that fit right over the originals and then have them welded on. 500 horsepower is an incredible amount of power in a Z car. 300 horsepower in a 280Z is a windowmaker. Good luck!

-

12-27-2025. Started the day by going over the dried filler with a DA and 40 grit and smoothed it up and shaped it. Next will be to start block sanding the main panels. Then I went ahead and installed the new powdercoated headlight buckets, the MSA Air Dam and the MSA fiberglass front bumper. Then went to the back and started the install of the Hot Rod Chop Suey rear roll pan. Still a bit more to do on that. As I mentioned before it is custom, had them fill the exhaust cutout. Lastly my intercooler came in and took a few pics. it's 18X12 and already polished. Pics follow. Cheers!

-

-

My custom modified crown turbo system on my L series six. here are pics of what I fought through and learned lessons very valuable. The Crown turbo kits, are very basic, and were designed to use stock parts to get a turbo onto the engine, and this was back in the days of carburetors and point ignitions. the factory exhaust manifold is used and a "J" pipe, made by Crown bolted on to the bottom of it and curved up for the turbo to mount on. From that point the exhaust went to the right and down, and to the left was an adaptor, the carb, and then you had to finagle on your own a throttle cable, fuel line and air cleaner. It was designed without a wastegate....the idea being your foot is the wastegate....you have to be smart enough to know when to let off. The J pipe, I had to cut off the factory flange and weld on a flange for a T3 turbo housing. I had a welder do this and he had to do so that the pipes from the J pipe came into the flange with any gaps closed off. Here is where my problems began. on the factory Rayjay turbo, the turbo flange came straight down......on modern turbos the flange is offset. So, today, you either have to make a new J pipe that is a tighter bend to make the room necessary, or what i did, which was to cut a hole in the inner fender and part of the strut tower and run the turbo halfway into the wheelwell and angle the intake out and back into the engine compartment. This required me taking the wheel off and bending sheet metal around the turbo to close it off....in effect making a channel down the side for the turbo. I recommend NOT doing that. I would recommend using a 280ZX exhasut manifold and having a T# flange welded on, or getting the CX Racing turbo header and then using the crown pieces to get the charge from the turbo into the intake manifold. Also, I initially ran this on a Mikuni 45 HRS motorcycle flat slide carb, and then went to EFI. EFI is the only way to go. You will have to weld an O2 bung into the exhaust, and while I am thinking about it, know this, with a draw through turbo setup it is MANDATORY to have the turbo rebuilt with CARBON SEALS installed. "G Pop Shop" has done them for me, cost is under 200 bucks. you can't avoid it. without the carbon seals the turbo will create pressure that will pull engine oil through the regular seals and the engine will smoke like a chainsaw. Don't take anyone's word for it that it already has them.....pay the money have new ones installed and they go through the unit and you get back a turbo that will actually work. RLR makes the intake I used. It is made for a draw through turbo to be installed on a air cooled VW engine. In the Draw Through Turbo world, the only ones who anything about it are the air cooled VW guys and the Corvair guys. 99.9% of the people you talk to DO NOT know anything about them....and I was told I would destroy my engine, it wouldn't work, they are terrible, I was an idiot etc. This is not the case. (never got any apologies)...but they are a bit of a wild animal......in a carb'ed setup, you can only tune it to a happy medium, and that frankly sucks. they only run good when floored, every other time, they are a real pain int he neck. Don't debate it with me, I have lived it. spend 800 bucks and later go EFI anyway and the money you spent for that turbo carb was wasted. The Holley Sniper 2 saved me. BUT you have to unscrew the port plug and put the plug in the threaded hole on the bottom, the base....then install a 1/16 NPT nipple into the boost port. This allows the Sniper to make corrections based on actual air fuel ratios in the intake manifold, instead of a guess by the ECU from where the fuel enters the throttle body before being charged. Turbo Joe's is a page on Facebook, and he is the sole tuning source for making these work. Thanks to him, my car runs crisp and normal. The Water methanol injection is my intercooler , is set to start flowing at 4 psi and has added over 30 horsepower on it's own and allows it to run on pump gas. Spark plugs. NGK is the only way to go period dot. NGK BPR8ES..... 2 heat ranges cooler and go .031 on the gap. Well.....Good luck. There is a draw through turbo page on facebook as well. It is ran by a 240Z guy. Pics follow, Peace and God Bless. ~ Joe Guy 12-21-2025.

-

These seats would color coordinate real nice. Any of you have any experience with this company? Miami Blue Universal Adjustable Black Luxury Racing SR3 Style Alcantar– Bull Boost Performance

-

12-20-2025. Today officially started the mud and blocking part of this build. I had to finish removing some of the stubborn old paint and filler and yep.....more hidden damage, well repairs, and they did a good job, so that is good. Then I attacked the rear hatch jamb. Using a wire wheel attachment, I was able to go around both "levels" of the jamb and get it prepped for paint when I get there. I finished going over the entire body with a DA sander and 80 grit to smooth out the rough metal from having to go heavy duty getting it off. I took some pics f it all cleaned off then cracked open the filler and started laying it on the roof and sail panels. It's a learning curve. So, some real progress was made again today. Spent a lot of time getting the body ready for blocking....except I didn't pull the door handles yet, I guess next time. PICS

-

Paint design selection. opinions wanted

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

-

Paint design selection. opinions wanted

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

-

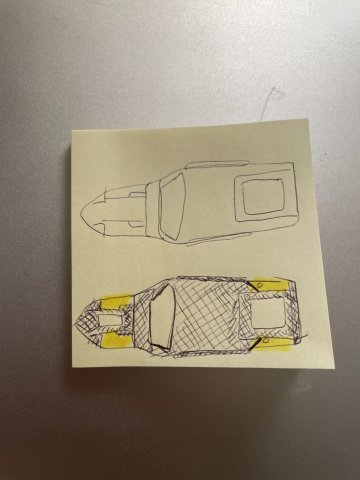

Ok, I posted about this earlier.....but now I have put together the pics that I have been using for inspiration on painting my 260Z the last is a drawing where everything X'd out is black with the highlighted being blue from the top......the sides being blue and the flares either black or blue. I am asking for any and all opinions of idea to think about. there the car is red int he pics, on mine it will be light metallic blue like me engine compartment. Thanks

-

12-16-2025. Picked up some more items from the powdercoaters....headlight buckets, inspection doors, dash plate and gutter trim....all gloss black

-

12-16-2025. Drum Sander. I have been advised to use a drum sander, as it is easier on the sheet metal than a flap disc on an angle grinder. Well, yes it is! However, even at 40 grit, I finished the roof, started on a rocker and a few other spots and wore that drum half way out! Pics follow, you can see the difference comparing both methods side to side. I also took a couple pics to show how it will look ran over with a DA on 80 grit to prep it for filler. DUSTY! closer to starting the blocking.

-

12-13-2025. I installed my new water pump, repainted pulley and new hardware, and then re-installed the tensioner bracket and the aluminum plate needed for the additional of an idler pulley to make it all work right. I was able to use a drill bit to hold the pulley in place and measure for the spacers needed and the length of the longer bolt needed. I went to install the alternator, but the kit I got sticks out just a tad too far, and thus the alternator hits the rail.....so I will have to grind down the bracket to bring it in closer to the engine and then it will be fine....also found that my new drive by wire throttle body does not clear in standard configuration, So I was able to get it to work by turning it 90 degrees. Here's to hoping that will work. Then I quickly installed my new 4 core radiator and dual fans to check the fit. because my engine has the radiator spigots on opposite sides, I will be taking my radiator to my fab guy to cut the hose ports and welding on tight 90's with a length of pipe to the other side and then another 90 to make it a nice-looking remedy. I will make some nice aluminum brackets to hold the piping stationary. At any rate, I was able to verify that my radiator height is sufficient to maintain its place as the highest point in the system. After this, I cleaned out the garage, and went through a lot of boxes and prepped the car by covering the engine and front end to begin the sanding and block sanding, to get the rest in paint. I pulled the windshield, but after 51 years, it just didn't want to let the windshield go, and so it came out broken and in pieces. Not a crisis, as I wanted a new windshield anyway....just thank good ness the rear hatch glass came out just fine. I pulled the old hatch off, gutted it and to the dumpster with that rotten thing. I was also able to get a bit closer on the front blinker restoration, getting the housings painted white with rustoleum white. spray paint Only thing left is to lengthen the wires. I tri4d to wire wheel the headlight buckets, but decided they really just need to be sandblasted out. My mobile welder didn't make it today, so welding the clothes hangers in pieces to the front edge of the doors to close up a big gap will have to wait. Here comes sanding and blocking.

-

I was talking about the dashboard frame, that the dash pad attaches also to. It's HEAVY. 12-11-2025. I got a nut and bolt run in today, got some painting going, ended up with a run on one side of the cowl, so once dry I will sand it out and repaint that side. I also started on a restoration of my front turn signals. PICS:

-

I picked up my bellhousing and serpentine bracket for the 4200 engine today from the powdercoaters. The finish is called "polished aluminum". I had them done because frankly both pieces were ROUGH....really rough. R&S Powdercoating in Colorado Springs came through for me again. Sandblasted it out, masked off the gasket surfaces and did their thing.

-

thanks. I just picked up that drum sander they sell. It comes with a 40 grit drum but I also grabbed a 120 grit drum for it also. I got a good deal on this. 4 core with dual fans made to fit the 260Z I am building. It's an eBay buy. Read up on and decided to try the sanding blocks and tape sold by Eastwood that connects you your shop vac and is supposed to eliminate most of the dust from blocking. Here's to hoping THAT works!

-

12-06-2025. I have boxes and boxes of stuff I have bought for the car, and today was the day to start throwing all the stuff on and make some room back! First, I had the mobile welder stop by and weld my radiator support back in, and while here, I had a thick steel plate welded on to the top. It is stronger now than it ever was. Then it was time to start installing parts on the engine, getting the hood on, rear suspension back in and all 4 new wheels. I took the dash down from the rafters so I could start on it on very cold days indoors, and it is a lot heavier than I remember......I am going to swiss cheese the frame and lighten it up a bit......I don't need that weight! Pics:

-

thanks. It's a very expensive hobby I have.

-

-

On the hood for my 260Z project. I will give some clarification. It is meant to be a picture frame. I want an open engine compartment. no hood at all looks unfinished. this is mean to close off the stuff that is mundane and let the engine shine through. black but blue underneath and a fully polished out engine. So, maybe once done you will understand what I am going for. The Behemoth at Z Car Garage has the same deal.....but the blue engine compartment, shaved, will really contrast with the black picture frame.

-

12-04-2025. Today I picked up the hood from the powder coaters. R&S Powder Coating in Colorado Springs

-

Wow....that is GREAT! NOW is the time for you change things you want to before it is painted! Thanks.