-

Posts

5399 -

Joined

-

Last visited

-

Days Won

58

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by RebekahsZ

-

Rear Rollbar Drop Brackets?

RebekahsZ replied to 900ss's topic in Brakes, Wheels, Suspension and Chassis

Yes, had same problem. Made spacers with wood. -

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

You are next! -

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

Bump for videos. For some reason on my computer the link is opening two video files simultaneously, so click one off on your task bar or you won't be able to hear (echo). The psi that you hear me talking about is not boost, rather it is tire pressure. These slicks at 15 psi were all over the road on second half of track; 20 psi straightened things out. Area for improvement: driver courage to hold pedal down when car is drifting in the lane. -

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

Due to delays caused by every obstacle imagineable (all non-automotive), I finally got to the track at 9:45. They closed early at 10:30. I got 4 (1/8 mile)runs in. I had daily driven on my slicks and skinnies this week to get used to driving on pillows. I kept them aired up to 20psi, and found that my wear pattern offitted the outer 3/4-inches of the tread. So, before going to the track, I lowered the tire pressure to 15psi. That was a mistake. On my first 2 runs tonight, the car hooked well, but at the far end of the track, it was swaying back and forth and really scary. I had to back out of it. So, I aired back up to 20psi, and the car was much easier to keep in my lane. The times reflect the improvement. Run 1 8.54 Run 2 8.32 74.5mph Run 3 8.16 87.9mph run 4 7.92 89.1mph I'm in the 7s - and there is a lot of motor left! The driver needs to get a lot better. In-car videos as soon as my buddy has it processed. Maybe next time I'll have more time. -

78 Datsun 280z ------> 5.3 build

RebekahsZ replied to SUNNY Z's topic in Gen III & IV Chevy V8Z Tech Board

That is the tool used to crimp the Rockford-style clamps. I was of the impression that you had a different type of band. Honestly, I'm doing fine with regular screw-type hose clamps. Daily drove on them all week and just got back from the track - no trouble. -

How worried should I be about my half-shafts?

RebekahsZ replied to matt_w's topic in Gen I & II Chevy V8 Tech Board

Be sure to run your suspension thru its full range from full droop to full squat. I have the exact same set up and with the stock swaybar endlinks, at full droop, the swaybar rubbed the CV boots and the driveshaft flange. I found that spacing the swaybar down from the floorpan 3/8" and using aftermarket swaybar kit with a 4-inch bolt changed the geometry enough to keep everything comfortably clear of moving parts. The swaybar still rubs the driveshaft at full droop just a bit. That means I can't ever run-up full drivetrain until I have my droop limiter straps designed and installed. It looked just like yours at standard ride height. -

Drove the hell out of it.

-

1972 240z LS1/T56/R230 build

RebekahsZ replied to Fuzzydicerule's topic in Gen III & IV Chevy V8Z Tech Board

I don't fully understand the problem. Can you move your shifter in and out of gear as if the clutch is in and won't release? If so, it has to be do to limited mechanical pedal travel. Disconnect the push rod and see if you are then unable to shift from neutral INTO gear. That will confirm it. When I swapped masters Saturday, that remote bleeder made bleeding a snap. I do use my finger to "bench bleed" the master to remove air before hooking up the line. Then bleeding took about two pumps by my assistant with me under the car with a bucket. I have all stock clutch system-didn't even inspect it. -

1972 240z LS1/T56/R230 build

RebekahsZ replied to Fuzzydicerule's topic in Gen III & IV Chevy V8Z Tech Board

It is not as loud once you get it out of an enclosed space like a garage. Also my three-ish foot long collectors must make a big difference. I can tell from the length of your post that you are really jazzed. I'm praying for you that your clutch problem is outside the bell housing. There are certain rpm and load conditions where the car is actually pretty quiet. Yay for you! It took me 18 months to get to the point where you are. -

Wheel Show! Post your pics of you wheels

RebekahsZ replied to k3werra's topic in Brakes, Wheels, Suspension and Chassis

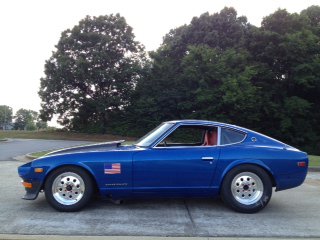

Street wheels and tires: 16X8 Rota RBR with 225/50/16 cheapest brand I can get since I love to "waste 'em." Drag wheels and tires: 15X7 rear with 26X8.5X15 MT ET Drag (tubes and wheel screws), 15X4 front with 155/80/15 BFG skinnies. Autocross (no picture): 15X7 nasty no-name mesh with 225/50/15 BFG R1 all 4 corners. Copious brake dust. Smoke 'em if ya got 'em! -

1972 240z LS1/T56/R230 build

RebekahsZ replied to Fuzzydicerule's topic in Gen III & IV Chevy V8Z Tech Board

Anybody can correct me if I'm wrong. Stock on LS2 was 3/4. Most guys on forum use 7/8. I used 1" after 3/4" required all of my travel and left me no adjustment space. 3/4 was nice and soft, 1" is very stiff. So, the concensus of 7/8 is probably right. But, that is using stock Z-car pedals. Don't you have an alternate pedal setup? I imagine that changes everything..... Way to go on start-up! I put a pressure gauge on my master cylinder in order to help me know if I am in the pressure part of the pedal stroke. My gauge shows no pressure when I'm in the "slack" part of the pedal, then pressure rises imediately to 500psi, then very quickly drops again to almost zero at the bottom of the pedal stroke. I'm adjusted for about 1/2" of slack at the bottom of the pedal stroke. Pressure gauge came from Jegs; I think the AN 90 degree tee fitting did too. I'll be using a similar gauge setup when adjusting my brake rod inside the brake booster. (I got lots of slack at the top of the brake pedal). -

Proporsioning valve and brake system question

RebekahsZ replied to 280z4me2's topic in Brakes, Wheels, Suspension and Chassis

If you can't spell it, you probably shouldn't put a wrench on it. Totally kidding. Go crazy and throw caution to the wind. Just do your first test drive in a big parking lot. You got a lot of guts - go for it! -

This is a pretty tough job and you will see lots of screw ups on the pages of this forum. I bought my kit from a guy who was getting out ot IT racing, parting out his race car, and it was still a lot of work to put together, researching struts, cleaning to bore of the strut tubes, refinishing rusty parts. The guys who do this conversion professionally earn every penny that they make on it. Single best mod I've done to my car.

-

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

Bought gopro rollbar mount already. Gonna buy a gopro camera between now and then. Everybody loves a good burnout, but I'm gonna do minimum burnouts unless more is needed. A drag video with no smoke can be pretty boring. Daily driving on bias ply slicks is awesome. The car feels like a boat, you sort of suggest a direction instead of driving very exactly as you would with low-profile sport radials. Gotta let some air out. I'm at 20psi and I'm not using the outside inch of the tires. Practice launches seem quicker starting as I would when street driving. High revs and clutch dump still just shred the tires. -

78 Datsun 280z ------> 5.3 build

RebekahsZ replied to SUNNY Z's topic in Gen III & IV Chevy V8Z Tech Board

Oh....that would suck. Once you have the axles out and clean the old grease off of the place where the seals are, they pop in and out much easier (if they aren't welded in!). The first time you remove them is the hardest, then it is easy after that. I've seen the write up on that banding tool. Please let me know how it goes and also a source for the bands. I REALLY like how easy the Rockford bands are, they just don't have a good means to provide bands only - and I screw things like that up all the time. I mean, what happens if you crimp something wrong and it self-destructs?? You go to the shelf and get another one, but what if you can't get one? I ran my old u-joint axles with regular hose clamps on the new boots for years without incident. I'm gonna keep using them on this new kit too, except on the outer because of clearance with the swaybar. The CLSD with the drag slicks is freakin insane! No squal, no chirp, just rocket-like thrust (I'm not dropping clutch). If you can't get those axles out, just use that open diff for now with the new axles. That will keep you from grenading your new axles. At the drag strip, I usually got both wheels working even without LSD. I really only needed LSD for autocross because of unloading of the inside tire in turns. If you go straight, LSD is a little over-rated. Don't buy that advice you are getting. Stock Z31 CLSD diffs and carriers have been all over ebay lately. The VLSDs there now are way over priced. In the past month I've seen 2 stock carriers without a case and about 5 complete CLSDs. I now nave 2 CLSDs (sorry one is in car and other is for spare), 2 VLSD, one open R200 and a CLSD R180. I accumulated all that in about 3 months of keeping my eyes open. -

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

Bump. Last post edited to show last night's progress. Editing previous post doesn't flag updates. -

Steering Shaft Play in column

RebekahsZ replied to Lazeum's topic in Brakes, Wheels, Suspension and Chassis

I have the same problem. I have a little play in the u-joints in the shaft that connects the steering column to the steering rack. I don't know if this could be your problem or not. If it is...the steering shafts are not available. There is some research on this on the forum. Seems the only way to fix it is to have a custom shaft made with aftermarket u-joints. I think that the splines on the shaft are somewhat hard to find in a replacement u-joint. I have not completed this repair, so I know this only from doing forum research. Try searching steering shaft or something of that nature. -

78 Datsun 280z ------> 5.3 build

RebekahsZ replied to SUNNY Z's topic in Gen III & IV Chevy V8Z Tech Board

I've got a thread on this (axle removal) somewhere in drivetrain with picture and everything. Use a cold chisel as a wedge or ramp. It works great and even works when the diff is in the car. Slide the chisel between the axle and the diff housing. Do you still need those part numbers for boots? If using the Rockford band clamps, be sure to do a dry fit with all clamps first. The inner CV uses a different large clamp than the outer CV. I'm still having trouble with this because Rockford won't sell just the clamps in quantities less than 100ea (costs $100) and there are 3 different sizes. I can't seem to get any of the inner CV bands. It seems to me that they have the part numbers backwards for the inner and outer boots. Part numbers: 626-22 Boot Kit-Inboard, 175-21 Boot Kit-Outboard. I think the inner/outer is backwards. The kits come with boots, clamps and blue grease. The kits are marked "Motor Master" so maybe they supply to Rockford? Several of my boot kits have been missing the large clamps and I still can't seem to get the inboard/outboard thing straight. I bought Rockfords clamp pliers for $32, but I bet you could do just as well with some wire cutters that bite on the end, as opposed to diagonal wire cutters that bite on the side. They may call them lineman's pliers or something like that. They look like a little pinchers or a claw and out to be available at a good hardware store. The Rockford pliers haven't done a very good job, so I'm buying the pliers before I do any more. For temporary to get my car on the road, I used good old screw type hose clamps from the local parts store. The big ones are either 3 or 4 inch clamps. I really like Rockfords clamps, if I can find another source of supply, I'll get more, but not top priority. I need the part number stamped on the inner large clamps to move forward, but I can't pry it out of Rockford. -

78 Datsun 280z ------> 5.3 build

RebekahsZ replied to SUNNY Z's topic in Gen III & IV Chevy V8Z Tech Board

Yes your new axles will still work, so go for it. Keep an eye on eBay. Several CLSD diffs or carriers have been sold for between $300 and $600. Shipping is usualy 80 bucks nation wide. If you decide you want to go vlsd, I have one that I can sell. You would want to put it in your case because my case is really rusty-like big flakes. I have the vlsd axles too (they are different). The inner cv housing has a different length splined portion. I would just be patient and a CLSD will turn up. Just keep your eyes peeled and surf eBay daily. You didn't get ripped on your open diff, that is pretty much the going rate. Is the diff in your car open or welded? Is there no ratio stamped on the ring gear?' -

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

The wildest thing happened this afternoon: my wife pretty much told me I was going drag racing this coming Thursday night after work. 23 years of marraige and she goes and does something wonderful and totally unexpected. Well she didn't have to tell me twice; I got right to work. Changed oil and filter, checked fuel filter screen (hardly any sand now), installed rear swaybar (gotta get some shortened links tomorrow due to CV conversion), installed new 1" clutch master cylinder (gotta bleed it tomorrow), re-torqued header collectors, checked coolant level, inspected driveshaft bolts, installed rear slicks and front skinny tires and aired them up, cleaned street tires (Porterfield pads are dusty), put on new Rockford Driveline CV boot clamps (for swaybar clearance), increased shift light limit from 5500 to 6000 rpm, installed new wheels and tires on my truck (tow vehicle). Re-spacing the rear swaybar was a real PITA with the CV axles. I have the front mounted swaybar due to fuel pump placement making a rear-mount swaybar impossible. If I have the end links short enough (4" bolts with thinned poly link bushings and a 5/8" tube spacer in the middle of the bolt) to clear the CV boots and clamps, then the swaybar hits the driveshaft flange. Stock 240z links are 6" end to end. So, I finally made some blocks to space the swaybar down 3/8". Swaybar only just rubs driveshaft in full droop. One more reason why I need to make droop limiters. Only an issue when car is jacked up with wheels off the ground, so I'm running it as is for now. I will now have to dent the exhaust pipe for clearance when it crosses under the swaybar. Domino effect.... Took car for a brief test drive with slicks. Amazing. The rodeo I have with street tires is not present with slicks. It is wild - the car just goes (it is almost boring or anticlimactic). I think I even hit full throttle, which I've never done with street tires. I swtiched from a 3/4" clutch master to a 1" clutch master. The pedal is now quite stiff, but I have some adjustment room at the top and bottom now, which I didn't have before. The 3/4" clutch master used 100% of available pedal travel. It was nice and soft like a Toyota, though. 7/8" is probably the perfect size, since I've now had too small and too large. Domino effect...I'll get used to the stiff pedal in trade for the increased adjustability (my line lock and 2-step will actuate off of a clutch mounted switch(s). Glad it is my right knee that is bad. Photos if I find time. Now got to progressively fill fuel tank looking for a leak. I had none on the floor, just more smell than usual at last fill-up. Bleeding the clutch master was a snap with the remote bleeder line. I want to be ready for Thursday night at the drag strip. -

78 Datsun 280z ------> 5.3 build

RebekahsZ replied to SUNNY Z's topic in Gen III & IV Chevy V8Z Tech Board

Yes, I know what that thing is...it's the same thing that I found inside the first R200 "LSD" I got. Luckily mine was given to me. Your car isn't inoperable, is it? -

1972 240z LS1/T56/R230 build

RebekahsZ replied to Fuzzydicerule's topic in Gen III & IV Chevy V8Z Tech Board

I did the same thing, except I had to have the radiator lower tube cut off and a larger one put on with a different angle. Of course, I discarded the label off the hose that had the part number on it. If you still have the label in your garage, please send me the number and the manufacturer. I'm interested in keeping track of any parts I may need to deep up with (spares). I've seen cars blow hoses at the race track, so Id like to keep a spare in my race box. Thanks-your car looks great. -

1972 240z LS1/T56/R230 build

RebekahsZ replied to Fuzzydicerule's topic in Gen III & IV Chevy V8Z Tech Board

Amazing! I can't believe how fast you are getting it done. What radiator and what hoses are you using? -

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

Yeah, SUNNY, I won't argue with you about the rigidity thing...I am taking a risk. I discussed this with the streetrod fabricator who did the work for me. He used a section of driveshaft tubing for the c-notch, so hopefully it will be plenty strong. He felt like it would be OK. I even talked to him about putting a full loop into the frame rail, but he didn't think it was necesary. We'll see. Honestly, the worst thing that could happen is that I trash my chassis and go find another (better) one. I had a huge crack in my "frame rail" right behind this section where my crappy prior body man "welded" my floor pans in (great painter, lousy welder). He basically just covered the really bad welding with seam sealer leaving a huge gap underneath. I autocrossed it for 15 years that way and it was fine-the car didn't bust in half or anything. That was fixed as part of this job. As a uni-body, the car's stresses are distributed over so many different panels that I'm hoping to get away with it. I will be inspecting it regularly for cracks. He said he used every cutting tool in his shop to finally get the holes neatly cut in the fenders. He said he started with a hole saw. I don't know how he kept from burning or scratching the paint. He's awesome - that's why I hired him and didn't try it myself. I like the trim ring too, but I'm afraid of getting rain water and soot (acid) trapped and re-rusting out that fender. We'll see... I'm planning to run a traditional 2-into-1 system to a muffler in the stock location (my stock gas tank and fuel pump placement made a full dual system impractical). I will have the short (and wonderfully noisy), side exhaust branch off the head pipes controlled by electric cutouts housed inside the front fenders (the only place where there is sufficient room). Can't run any autocross until car is quieter - I'm sure the SCCA boys would turn me away with it this loud on straight pipes. Got the replacement rear LCA end-links arrived from Modern Motorsports today. Can't wait to get those installed, the rear has been REALLY twitchy with only .75 degrees negative camber. With my father-in-law living with us on hospice for heart failure and kidney failure, it has been tough finding time for the car. I haven't ordered parts for the exhaust system yet. -

Oh, the jokes we could make from this.....