-

Posts

2521 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by TimZ

-

Any overpressure switch made for R134 should do. The main problem (at least for me) was that I had trouble finding a switch with the same size fitting so I had to make an adapter. I also went with a generic receiver/dryer that didn't have a port for the switch, so I just soldered in a tee in the copper line and soldered in the proper size female brass fitting on the tee. It's certainly not an insurmountable problem, it was mostly annoying as I found out about the switch _after_ I had the whole system together and charged. Also I've been running R134 for several years now and it works just fine, and I'm not dependent on going to a shop that will charge me a fortune to work with the r12. There IS prep work that needs to be done as far as flushing the old system out, and what oil to use for the conversion, but this is really well documented on the web.

-

I thought I remembered this happening at the rear of the block - at any rate check both to make sure you don't block oil flow to one of the mains.

-

For an open diff this is true, so in this case 1.5x - 2x the torque at the pinion. For a limited slip I would assume it could send everything to one side for design purposes...

-

Aside from concerns over actually finding a proper seal, and machining the part for proper fitment, etc., my main concern would be that the pinion generally sees less torque than the halfshafts do, by a factor of whatever your differential's gear ratio is (x3 - x4). So, it may not be designed for the torque loading that it will likely see in service as a companion flange. Is there any way to find out a general idea of it's maximum design torque? Not flywheel torque, but the actual torque at the Flange?

-

Are you looking for the under dash pieces? Try searching ebay for "5/8" silicone 90" Also works for other sizes/angles

-

Maybe I'm reading this wrong, but this doesn't sound right. 280Z stubs have 27 splines, 240z stubs have 25. A 240z companion flange would require a 25 spline (240z) stub axle, but a 27 spline companion flange requires a 280z stub. http://forums.hybridz.org/topic/49194-differential-cv-lsd-hp-torque-r160-r180-r200-r230-diff-mount/ Edit - I just figured it out and I wasn't reading it correctly -I forgot we were talking about the 280zx, which had the smaller 25-spine stubs, and used a smaller id bearing that made it incompatible with the earlier stubs. Never mind...

-

Agreed - and a quick search on ebay turned this up pretty quickly (i didn't even include Datsun or 280Z in the search terms, just "receiver dryer")... ... http://www.ebay.com/itm/BRAND-NEW-A-C-AC-ACCUMULATOR-RECEIVER-DRIER-FOR-NISSAN-280Z-280ZX-/291399249547?hash=item43d8bfae8b:g:Z3MAAOSwB09YJMWd&vxp=mtr http://www.ebay.com/itm/Universal-Air-Conditioner-RD2501C-A-C-Receiver-Drier-fit-Dodge-Colt-80-82-/311474800781?hash=item488558488d:g:4IUAAOSw~bFWMn1d&vxp=mtr

-

This is how I run it every day. Well, when it's up and running at least ;P

-

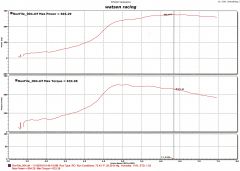

Really on the street the car is very driveable - it feels like a healthy, more "normal" Z when off boost. Of course there _is_ about a 300hp difference between 3500 and 4500 rpm It's also worth noting that the dynojet loads the powertrain a bit differently than what I see on the street, so I usually see a bit more boost at low rpm than what is reflected here. Looking at the data from yesterday, I was seeing about 3.5psi at 3000rpm and 15psi at 4000 in 4th gear. On the street I typically see more like 5 and 19 in third gear, respectively. It's not that aggressive on duration - .540" lift and 270 duration, with a 109degree lobe center.

-

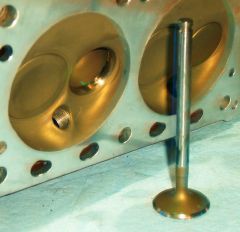

L-Series with a diesel crank, Cunningham Rods and Diamond Forged pistons, 7.5cr, 3.0L Block fitted with BMW under piston oil squirters N42 head - still has an open chamber, but the piston dish provides a quench area Dart ceramic coatings on pistons, combustion chambers and exhaust ports Isky cam (Ron picked one out for me ) SFP exhaust manifold (the one everybody hates), modded with slip joints to end the warping/cracking issues TWM 45mm ITBs on a Mikuni manifold, modified for two injectors per cylinder 32lb/hr primary. 160lb/hr secondary Custom plenum with HKS blow-off valve Long, long list of mods to this car - hard to remember them all! Here's a couple of pics... And here's a video: [sharedmedia=videos:videos:295]

-

From the album: TimZ

-

Just got back from a frustrating dyno session - just seems like it's been one dumb thing after another for the past couple of weeks - pretty much right after I scheduled the dyno session...First I had the dreaded coolant leak under the dash. Had to order replacement hoses and wait - just got it all back together last night and it still leaked, looks like probably the valve was leaking too. So I just pulled the heater hoses and capped the block outlets for now. Got to the dyno this morning and my laptop wouldn't connect to the engine controller - spent ~20 minutes trying to debug, finally reinstalled the serial port drivers and restarted and it worked. During the second and third pulls, the serial port started flaking out again, and apparently caused the controller to stutter. Had to shut everything down and reboot, and then that problem went away. Fouth pull was then very strong and we attempted some fine tuning, but during the fifth pull it appeared that the boost controller thought I was overboosting and cut boost. Oh, and a small fireball around the intake gasket. . So at this point it appeared that possibly the intake/exhaust manifold gasket was suspect - it ran fine but I didn't want to push any farther today. So, a lot of f-ing around and two good pulls... So here it is... 694hp/ 633lb-ft torque at the wheels on a Dynojet 248C... The main new things on the car were: GT4294R with a Mamba billet extended tip compressor wheel a new proper Weldon 2025A pump Three holley hydramat pickups plumbed in parallel MOAR BOOST!!! 35PSI on E85 My son took some videos, I'll try to get a link up on youtube shortly... Despite all the hassles, I'm pretty happy with the results!

-

From the album: TimZ

Best dyno pull from 11/18/2106 -

Sorry if I'm being dense - does this mean that the original post was incorrect, or did something else happen?

-

I guess I haven't been paying that close of attention, but did they reinstate the rolling exemption? I thought it stopped several years ago at 1975...

-

Fundamentals of Vehicle Dynamics: https://books.google.com/books?id=L6xd0nx5KbwC

-

I used a piece of brake line tubing for this same purpose with my EBP. I believe they do something similar in production.