-

Posts

2521 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by TimZ

-

Read through this thread a couple of times for some great pointers on exactly the part of engine assembly you appear to be venturing into. The title is misleading - they start off talking about the Kameari tensioner and then spend the rest of the thread talking about how to properly assemble the engine. Great advice from some really knowledgeable builders.

-

Race Car Brake Assistance, no vacuum available

TimZ replied to 260DET's topic in Brakes, Wheels, Suspension and Chassis

I've have good luck using the electric vacuum pump from a diesel VW/Audi - they are readily available on ebay - search "VW electric vacuum pump". Harder to find is an adjustable Hobbs (or similar) normally closed vaccum switch (i.e., opens when vacuum exceeds a reset threshold)... -

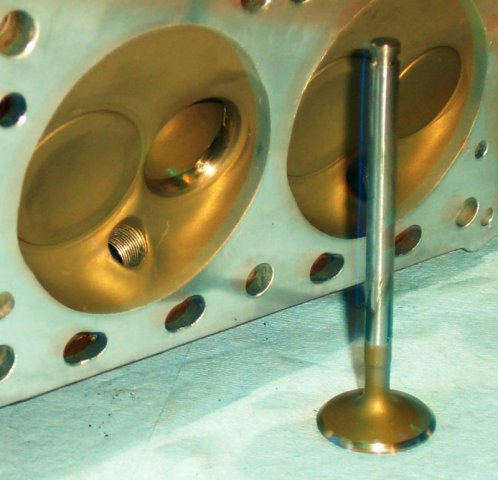

Yes I have ended up pulling the head periodically and have _never_ seen an issue with the coatings. I think 0.5-1mm thick coatings would be a whole different issue (and not a good idea for this application), and none of the mainstream coating suppliers do that to my knowledge. Not sure on the higher temperatures comment -when I was running the Elgin cam and prior to switching to E85 I was seeing EGTs in excess of 1850 degF - still no issues with the coatings, but I did end up dropping an exhaust valve seat. Even this did not cause flaking on the coatings, but they had to be re-done after the resulting head work. I did follow up with Ferrea "super alloy" valves rated for higher temps and more extensive coatings, as shown in the pics.

-

I've been using ceramic coatings for years now with no such issues. Even if there had been, I'm kinda curious how people think that some "flaked off" bits of ceramic coatings would destroy anything. I used Dart coatings on the combustion chambers, pistons, valves and intake and exhaust ports...

-

Yes, you're on the right track. Once you have this orientation between block and head the chain has to have a specific number of links between the marked tooth (marked with a dot) on the crank sprocket and the similarly marked tooth on the cam sprocket. This is what the two bright links on the chain are there for. Side note: This method only gets you "close enough" to run reasonably well. It doesn't guarantee exact cam timing. To do that, refer to this thread. It's a bit more involved process and requires a dial indicator and a degree wheel, but if you've got the engine out already this a great time to learn the proper way to install and time a cam.

-

Yes if it will reach

-

Have you retorqued the head since the rebuild? I always retorque the head on a new head gasket after a few heat cycles. It is certainly possible for the gasket to "settle" a bit and lose some clamping force. I would do this now if you've got access to proper tools - it's certainly not going to hurt anything. Do the retorque with the engine stone cold (let it sit overnight), use the proper tightening sequence and a proper torque wrench, and back each bolt off 1/8 turn or so before torquing. Just back each bolt off right before its turn to be tightened - don't back them all off at once. Sorry if you already knew all this, but a surprising number of people don't...

-

How much free play should there be in wheel bearings?

TimZ replied to damesta's topic in S30 Series - 240z, 260z, 280z

I would suggest following the FSM instructions for cleaning, repacking and reseating the front bearings. God only knows how long it's been since that's been done, if ever. It _was_ supposed to be a regular service item, as I recall. -

Dyno'd my stock L28ET today - coolant everywhere!

TimZ replied to AlbatrossCafe's topic in Nissan L6 Forum

Yeah, in general the higher the gear multiplication, the higher the loss from friction. Also 4th is direct drive in this trans, so it's preferred over 5th (no gears meshing at all in 4th). So 18% loss is probably about right for a 3rd gear pull.- 32 replies

-

- stock

- horsepower

-

(and 3 more)

Tagged with:

-

Dyno'd my stock L28ET today - coolant everywhere!

TimZ replied to AlbatrossCafe's topic in Nissan L6 Forum

The OP's rear wheel number is about 18% below the stock flywheel number. The OP didn't specify what trans he had nor what gear he used for the pull, or at least I didn't see where he did. For an "actually stock" manual it''s a _little_ low, like maybe 5hp. For an automatic it's about right.- 32 replies

-

- stock

- horsepower

-

(and 3 more)

Tagged with:

-

Dyno'd my stock L28ET today - coolant everywhere!

TimZ replied to AlbatrossCafe's topic in Nissan L6 Forum

FWIW I've been running an LM-1 for years now with zero issues. Also, if it's truly a stock setup, they only rated it for 180hp at the flywheel to begin with. You're maybe a little low, depending on what trans you have, but that's right in the ballpark of what you should expect.- 32 replies

-

- stock

- horsepower

-

(and 3 more)

Tagged with:

-

FYI - Steve regularly posts in the "Church of L Series" group

-

With 40+ year-old wiring you really can't separate the two. LEDs give off more light with less current, less current means less voltage drop to the LED, so brighter still. Agree with previous posts that adding load resistors is defeating the purpose, and the worst possible way to implement this.

- 55 replies

-

I used this company when I had my 300ZXTT CVs re-done, and was happy with them... http://www.axlesunlimitedinc.com/index.htm

-

S30 RB25DET T4 Twin Scroll Turbo Manifold Design

TimZ replied to Jeff9727's topic in Fabrication / Welding

A recurring problem with exhaust manifolds for this head is that as they heat up they grow longitudinally. Since they're held captive on the head, this eventually results in warpage and/or cracked primaries. As HuD 91gt pointed out, this is why the Euro manifolds have them (expected extended high speeds on the Autobahn). For the manifold in this thread, a slip/expansion joint on each of the two runners running longitudinally after the 3-1 collectors and before the wastegate/turbo would help alleviate that. I post about this pretty much every time one of these designs comes up and nobody ever listens 😜 -

S30 RB25DET T4 Twin Scroll Turbo Manifold Design

TimZ replied to Jeff9727's topic in Fabrication / Welding

*Cough* Expansion joints *Cough* -

Wait - what? Am I reading correctly that you have a crank pulley with no keyway? Where are you getting your ignition timing from?

- 15 replies

-

same output pressure with less air at the inlet = more work/less efficiency. I'm only making the argument that the issue isn't different for turbo engines.

- 25 replies

-

Ever noticed the difference on a turbo engine's response on a 70 degree day vs a 90 degree day? It's the same effect. Low density air at the compressor inlet causes heat and lag. This is the same argument that people use to justify spending money an a "cold air" intake that draws hot air from under the hood - it's a poor argument there too.

- 25 replies

-

The turbo has the same issue, though. The lower the inlet pressure is for the turbo, the harder it has to work to supply a given amount of air, and the less efficient it will be, so more heat will be created.

- 25 replies

-

LOL! I was wondering what happened to you!

-

Soylent Green is TONY!!!!1!!1!!!!

-

Th OP specifically asked about using a BHJ damper with expect use above 7000 rpm and what to use to secure it. I have very specific experience with this and offered my recommendation, based on several conversations with BHJ after having a damper fail at the keyway. He's got a BHJ damper ordered, so he's already in the realm of "over-doing it", and what to do if you're revving past 7000 is not going to be covered in the FSM. Nobody but you said anything about "slathering on" a bunch of red loctite into a bunch of oily threads. I ASSumed that the OP would be smart enough to chase the threads and clean it first, and it was already mentioned that you don't need to use a lot. I guess I'm mostly offended my the insinuation that I'm an internet bullshitter with no experience. Seriously? Completely uncalled for.

-

I missed this the first time round, but the part you Highlighted here is the preferred solution that BHJ suggested, which I do intend to do next time I have the crank out. I guess they don't have any experience either and probably just rely in internet rumors on how to install their own dampers though. I left that out before just because it is a bit more extreme than most will be willing to do - that and I honestly don't know that it's possible until I get a good look at the location of the oiling passages. In absence of this solution I'll stand by what I said in my original response. If you don't want to use loctite I don't really care - the original stuff works great if you're never going to rev past 6400.

-

I'm confused - did you think that CM and I weren't talking about real-world experience? WTF Also I was relaying much of what BHJ TOLD ME TO DO when I had one of their dampers fail. You should know by now that I don't just make this shit up.