-

Posts

152 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by niner11

-

Stony, I might have missed it but what spring are you running with your tial knock off. I have no idea what the stock spring is but I ordered a reall tial replacement spring that is either 11 or 12 lbs. Can't remember. My BOV sounds like it is leaking under moderate boost but I'm not sure.

-

This map has worked well for me. Using a t3/to4 hybrid 57trim .63ar on a stock longblock with 240sx tb. So far nothing more than about 12psi

-

Choosing a blow off valve, what should I be looking for?

niner11 replied to Evan Purple240zt's topic in Turbo / Supercharger

I have an ssautochrome tial knock off and it works fine but I have no way of knowing what spring is inside it. Looking at my vacuum at idle I ordered the correct one. Once I open it up I'll post pics of the whole tear down but for now it works fine. Boost is about 13 currently -

I have bought a lot of things from them and its always quick and painless. Good tech support too. Think of it this way, you will spend many hours chasing down little problems with your install so having a known good ms unit will make life easier in the beginning.

-

I agree with getting some dyno time to see what works best for you. Thats on my list while I'm still running the junkyard motor. My initial MSQ came from CygnusX-1 and ran pretty good but like everybody else I redid all of the maps with input from different things that I've read. It seems that the VE tables take care of themselves when you find the AFR that you like and run the car enough for megalogs VE analyzer to correct it. I could probably lean out the lower KPA bins a bit.....might be the MSD that keeps plugs from fouling.

-

My primary concern was not to burn a piston or blow the head gasket so these numbers are pretty rich. Many people will tell you that WOT in a normally aspirated engine will be close to 12.5 or 12.0 to 1 so at 100 KPA it's a good place to start. No problems with fouling plugs...I always thought that 12.5 was pretty rich for an idle but the car likes it. What part would you change?

-

I just posted this in the screenshot msq thread but since I don't read it much maybe others don't either. Any comments are welcome....... screenshots are in the other thread. Here you go: current 2.88 msII code as of 1 28 08.zip

-

Currently running 12psi max with no known detonation. Plugs look okay and the exhaust is very quiet....so hopefully I would hear pinging. No guarantee but worth a shot. My best throttle response comes from a mix of x tau and traditonal accell bins used in this file. Working on an all x tau msq but its just not as good as this one yet. For anyone looking at possibly using 2.88 code...it was a big improvement for me with regards to mapdot and throttle response. I could probably run it as low as 35 for map and 10 for tps but I can't feel the difference over more conservative numbers of 50 and 15 respectively. I saw that using the tools in the VE table you can scale your reg fuel up and down with very little trouble so trying that with your specific injectors would be an excellent starting point. Using 9.0/9.0 REQ FUEL the idle sits around 12.5 AFR. Car runs very well few more shots current 2.88 msII code as of 1 28 08.zip

-

my current setup: 280zxt stock longblock/t3/t04 hybrid turbo pallnet fuel rail running 32lb high impedance injectors at 50psi 240sx tps/82 stock dizzy wired per moby/diyautotune for MSII petez downpipe to a 2.5 inch exhaust MSD with magnecores (needed to eliminate MS resets) FMIC with knock off 50mm tial bov....11psi spring MBC and internal wastegate Innovate LC1 wideband Running MSII with a relay board wired per moby's/DIY autotune write up. MSD intall was directly from MS website. Fidle has been running fan relay with zero problems

-

CygnusX-1, it's like a disease.....I'm constantly tuning! How lean are your AFR's when you are cruising around? I have a nice conservative map when the boost comes on (around 12psi or so) but with MAP around 30 or 40 I have it leaned out to 15.5 from around 2500 to 3500 rpm. Not sure of the mileage right now but is that anything close to what your AFR's are showing while on the highway?

-

All things being equal I don't think that you could do better than a set of Magnecore wires. I searched a while back and had no idea that taylor wires were so bad.

-

Your ini file has to match what the controller (MS) is using. I have never messed with MSI but it should be the same principle as MSII. You configure megatune to match the code (firmware) that your processor is using.

-

-

Mario, I have a similar problem as far as hot restarts go but probably not as bad as your symptoms. I wrapped the stock turbo manifold with header wrap but I need a turbo blanket of some sort too. Also, just got some phenolic spacers for the fuel rail mounts as well as some insulation for the fuel itself. Firesleeve for the fuel line is probably in order too. I was reading on the MS website about people with similar lean restart problems and it looks like vapor lock of some sort. The only other thing I can attribute it to is a heat soaked IAT sensor....which after some testing was not my problem. Just wondering, when your AFR numbers are changing on a hot restart do your PW's change at all. For example mine are in the area of 2.5 or .6 give or take and even though they are not changing at idle my AFR's will sometimes be all over the place until cooler fuel finally reaches the rail and cools the injectors. As I mentioned in another post, I just enabled my EGO correction at 600 and even on heat soaked restarts it smooths things out very well. I'll take some pic's when I get everything insulated

-

I played around with another IAT sensor this week. When the car would start to run lean on a warm restart I disconnected the temp sensor and plugged in one that was sampling free air....made absolutely no difference. I also tried different MAT corrections with the same result. For now I will try to insulate the fuel lines and rail from exhuast and turbo heat and see if it has any effect. BTW, I have very few oscillations in AFR when I use EGO control to smooth out these warm start issues.

-

There has been some talk on the megasquirt forum of an issue with heat soaked temp sensors causing lean restarts. One option is to mount the sensor on a charge pipe just after the intercooler but before the TB to keep intake manifold heat from soaking the sensor. I will try several different things this week including playing around with the MAT correction tables in Megatune. It may just be the fuel rail heat soaking. This problem isn't specific to v2.88 but on my car the idle suffers more than previous firmware (2.687). Probably will try firesleeve on the fuel lines over the intake and some phenolic spacers on my aluminum fuel rail mounts to limit the heat soak. Dum-bass, if you aren't sure if its lean or rich with the missfire at idle you can just use VE in the tuning pull down and richen or lean the idle "box" that the car is runing in. I checked and if I richen the mixture while I'm having these wild AFR oscillations the car smooths out and runs great. Since the PW's don't seem to change much and the fuel pressure is the same at about 50psi it seems like the problem is due to hot fuel (vapor lock). Just to rule out that this lean condition is being caused by an inaccurate temp value being sent to MS I thought I'd connect a different temp sensor that is reading free air next time I have the hot restart problem. I'll post an update when I figure this out

-

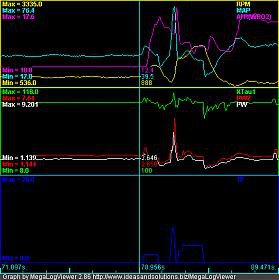

Here is a datalog of a hot restart with the afr numbers changing. It does take a few minutes for the afr's to start leaning out. Looking at the datalog I cant figure out why. Interestingly enough, I turned my electric fan off at one point and it seemed to have a stabilizing effect on the oscillations that I have been seeing. When I turned the fan back on (via the fidle port) it had no negative effect at all. Since the pulse widths don't seem to be responsible for the changing AFR's at idle I'm wondering if it might be the injectors. Fuel system is free of debris and has a constant fuel pressure. Right around record 715 or so in the datalog the problem begins and it ends around 2049. MSQ with288.zip Shortcut to datalog200712131519.xls.zip

-

Just thought that I would add some info about hooking up the tach. I'm running an MSD6a with MSII pretty much like mobys write up with a few changes. Wound up getting a good signal for the stock tach by pulling it directly from the MSD box to the factory tach. Using the tach output on opposite side of box from power cable. Car is a late 74

-

I installed 2.88 firmware the other day and the new x-tau enrichments are pretty impressive just using the defaults for accel and decel. Also, a HUGE improvement with how MAP is now measured by MS. I have a mapdot threshold of about 30 and the sampling rate is something like 25ms.....the recommended default. Works really well My setup is a stock turbo (82) longblock with a t3/t04 running MSII for spark and fuel. Pallnet fuel rail with 33lb injectors at 50psi, 240 TB and TPS, FMIC, MSD, etc. The car runs great and is currently set at a max of about 12lbs of boost. Here is the problem, the first time that I loaded the new code 2.88 there were some important X-Tau settings that didnt get carried over into Megatune. I wound up recreating my MSQ by hand and later imported my AFR, VE and Spark numbers from saved Vex files. Seemed to work and the defaults showed up....the car ran perfectly. There are a lot of new settings in this code but I can't for the life of me figure out what is going on right now. Car starts and runs great but a few moments after start it sometimes goes way lean....from about 12.5 to 15 or so. I looked at the PW's and they are not changing as the car goes through these oscillations and fuel pressure stays the same. For the most part the lean condition will go away in a few mins or 10 mins at the most. This seems to narrow it down and I was thinking it was a fuel issue but by shutting off the electric fan I can sometimes make these lean oscillations go away immediately. Strange This got me thinking and I took another box that I have for a backup and put my old 2.687 code on it and currently have no more oscillations. Tomorrow I will swap both boxes in and out and try to duplicate what is happening. Will also get a few datalogs. Wondering if anyone else had had a similar problem. Some ideas: warm fuel in the rail (not very likely at these temps) Contaminments in the fuel, rail or injectors that behave differently at diff pulwiths some type of interference with the fan on, but why does this only happen sometimes? Is this prob specific to v2.88, wondering if anybody else has had a similar problem. Thanks, any ideas would be appreciated.

-

My 1 month old Walbro gave up the ghost....recommended pumps?

niner11 replied to ktm's topic in Fuel Delivery

on the bosch pumps you can install a factory check valve like they do in some of the porsche applications. Not sure how much it is but try getting a CIS car to start without a working check valve and it will make you a believer in them. Hope that my walbro keeps working, sometimes it makes more noise than others though -

Jimbo, I had a similar problem that caused my FET injector drivers to fail. It was only one but it dumped enough fuel to hydro the cylinders in short order. I was able to trace down the problem using very low value fuses for the injector circuit. Something like 2.5 or so. BTW, it was easy to spot a short of the injectors using the stim board because the injector lights stop blinking.

-

http://cheapturbo.stores.yahoo.net/gat360trw63a.html I can't remember how much the water cooling setup was...probably under 100 bucks added to the price. Chuck

-

Sorry if I missed it...are you running a relay board? If so I would start by swapping the main relay just to try something diff. Maybe swap with the FIDLE relay. I suppose you could isolate some wiring by powering MS directly from the battery. It should still be fused so no danger there. I understand that the battery was normal when this all started but what does it read now when using a voltmeter?

-

75 280Z with stock A/C, what's it gonna need?

niner11 replied to Daeron's topic in S30 Series - 240z, 260z, 280z

You can get your A/C up and running but I would start with a vac pump off of ebay. I did a lot of A/C work on my 911 and saved a fortune with my own equipment. ackits.com used to have some decent starter kits for DIY as well as rebuilt compressors. I would start with a new receiver drier at a bare minimum but it would probably make sense to buy a rebuilt compressor as well. As for the expansion valve...they are not cheap and the oem condensors are NLA I believe. If you put a vac on the system you will be able to tell if it has any leaks ....who knows you might get lucky. Search around, if you go the r-134 route you will need to make sure the oil in your system is compatible and the amount used to service with be probably closer to 24oz or so. Just some things to think about. Chuck -

Mull....great progress so far! I'll be in Stockholm on wednesday afternoon if you need any free labor! BTW, I know that you changed the firewall a bit but I'm 6'3" and fit very nicely in my 260. Stock seats but leg room is fine. PM me if you are available, Chuck