-

Posts

726 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NZeder

-

Yes I sold Frank those to number of years ago. Globerrunner513 good luck with the ITB project and let us know how go with getting adaptors made etc.

-

Yes TWM do a setup but what is in the youtube you have linked to are EFIHardware items from Melbourne Australia (well 35 minutes out side of Melbourne) that car is Dimitri's he is member on here.

-

Unfortunately these were a one off - one these 3 were made and I never made extra for sale etc. They were simple I gave the engineer/cnc machinist the RB26 intake manifold, a DCOE ITB and some nice alloy and I got the adaptors back Re injector locations as rayaapp2 has stated in the top of the trumpet is an option aka F1 style. The further away from the head the better for performance, I am lead to believe, but not good for emmissions and the like which is why OEM install injectors right next to head. I already had the DCOE ITB so that is why I am using them an not the stock RB26 items + this is a hybrid site so my NA RB is a hybrid

-

Well if you use a triple DCOE/PHH manifold with an adaptor plate it will work I know as I have gone the other way - removed RB26 ITB - bolted up my adaptor plate and mounted DCOE based throttle bodies on my RB hybrid NA setup that I will be running. The bore spacing is very close and just some port matching on the adaptor plate is required. Using the RB26 ITB you will have the weld on some injector bungs on the triple manifold and like. Anyway here are some pics of my setup for my RB Click thumb to see larger pic

-

Same as the Coolant temp sensor = M12x1.5

-

I too am working on something along these lines but still using the stock 280z (aka my 260z downunder) heater/blower setup with some mods. Today I picked up a control panel from our 90's Maxima J30, the actuators and cut the basics out of the loom before leaving the pick-a-part wrecker locally. My aim is you use Maxima control panel which has a cable for the temp/tap and electronic actuators for all other leavers/vent/def configs. Thus allowing me to relocate the heater controls to were the radio would normally go. I can then use the old space for some extra gauges and switches/warning lights for my track/road car - want to keep the stock heater for when I am using it on the roads etc. I believe the Maxima we get here has the same heater control/actuators as the early 90's 240sx (S13) you guys got. Once I work things out I will post more details.

-

Custom Tie-rods That Fit Standard Suspension

NZeder replied to Whittie's topic in Brakes, Wheels, Suspension and Chassis

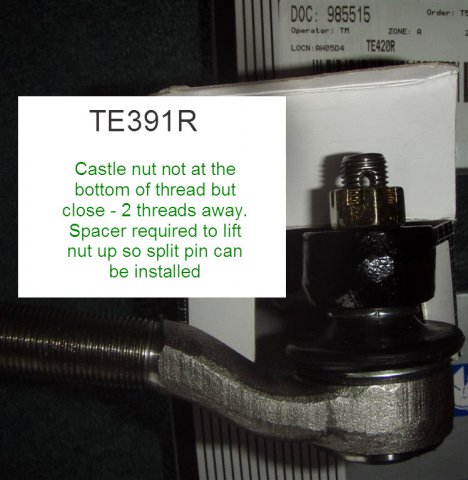

Update time. I will let the pics tell most of the story. But there are 2 type of tie rods for the XT-XW-XY range of falcon. Those known as early Ford and then the later type. Tapers are different but all other dimensions are the same. So for you guys state side the partnumber for Moog items are as follows (used on Mustangs and many other Ford's of the late 60's early 70's) AU/NZ supplier numbers <==> Moog numbers TE391R <==> ES360RL TE420R <==> ES387R If you feel so inclined I guess you could also ream out the stock steering arm so the Ford Pinto sizing can be used = 7 degree taper with .554 top and .626 bottom then you can use ES445RL -

Custom Tie-rods That Fit Standard Suspension

NZeder replied to Whittie's topic in Brakes, Wheels, Suspension and Chassis

Re the tie rod end Whittie has used. For those state side the Ford Falcon XY tie rod Pedder’s Part #PTE391R is the same as......well more research to follow.....I was lead a little down the garden path via and incorrect catalogue and therefore path number.....I will edit this thread/post again. And JMortensen not sure about the guys in Oz but here in NZ we normally use the US/imperial rod ends as they are cheaper and easier to get than the metric items even in this metric part of the world- go figure. -

jakeoster, I too had a radiator a bit like yours ie cross flow with the intel and outlet on the other sides. However mine did not have the fan shroud like yours so I had a local fabricator here in Auckland, New Zealand, laser cut one up for me. At the same time I asked what could be done about the issue of now requiring both inlet and outlet on the same side of a cross flow radiator. Not a problem they just made it into a double pass - ie they split the side tank with the inlet/outlet.

-

I will get some for you this coming week.

-

hmm good point....I am very slow with my project and the engine is still on the stand waiting for me to finish up my rewiring of the engine bay. The only other issue with the Jeep mount from ES is the lugs and centre stud are inline this is not the case with the stock L6 mount which are slightly offset.

-

Can You Race With An Automatic Transmission?

NZeder replied to vijay12's topic in Ford V8Z Tech Board

my first 240z track car was an automatic, at the same time 4 other zed's on the local track were auto's also so that was 30% of the zed that were active at the track (mid 90's). All were factory 3 speed items with high stall torque converters. You could run with most of the manual zed but the lack of ratio section let it down on the fast straights and this is were the manual either got away or would catch up (for a bit at least) It did teach you how to corner and brake correctly as the ratio issue meant to stay in front of other cars you had to get it right. -

Overlooked 5-lug option?

NZeder replied to Dan_Austin's topic in Brakes, Wheels, Suspension and Chassis

The other option is the new rear leg setup that TTT (TechnoToyTuning) sells that allows the install of the Z32 type rear hubs = much stronger alxe setup too. But that does get up there on the cost too but you do have a CV conversion and rear disk conversion at the same time (install the whole Z32 rear back setup including internal handbrake drum) -

2001-2005 sentra se-r rotors on 240z Front Brakes

NZeder replied to Tyler's topic in Brakes, Wheels, Suspension and Chassis

well if you have to machine the centre bore from 68mm to 81mm you can also redrill for the correct mounting pattern at the same time. -

2001-2005 sentra se-r rotors on 240z Front Brakes

NZeder replied to Tyler's topic in Brakes, Wheels, Suspension and Chassis

one quick thing to point out is the 240z/260z/280z/280zx and the 4 stud Z31 300zx rotors are not mounted using a 4x114.3 PCD but a 4x103 PCD to the back of the hubs. -

AC Delco inner tie rods - any experience?

NZeder replied to ktm's topic in Brakes, Wheels, Suspension and Chassis

That works, as like you say, the thread on the rack at either end is the same it is only the shaft out of the "rack end" that is different. -

Stance has made coilovers for us.

NZeder replied to LoneStarS30Z's topic in Brakes, Wheels, Suspension and Chassis

Sorry guys I don't really get all this. Why is there so many people looking for this type of setup - when Dave from AZC has a setup/solution already? Either way there is fabrication involved like most coilover setup's in our 40+ old designed cars. Now having said that - it is just me but if you look at the Stance inverted shock and then look at the shock that comes with AZC kit do they not look the same? Could this be why Stance has the Steel weld on tubes that when looking at them also look very close the units with the AZC setup? Look Dave did all the R&D on his setup and it a good kit that is well priced comes with camber plates (ok weld in - so maybe for those that don't want to weld in a camber plate work on Dave and see if a different solution can be sorted) I see figures of $1100-3000 in the above posts as Stance pricing. The GR+ Pro for $1200. AZC $1600 not much more for something already proven and who knows might be Stance units from the look, and is sold for our suspension already, no need to purchase S13 stuff, remove the bits that aren't required and add the steel tubes to the cost - why not just get the AZC kit? Or am I off base with all of this? -

240Z Chassis prep / reinforcements

NZeder replied to Kurai's topic in Brakes, Wheels, Suspension and Chassis

Given I posted a pic - I will just state this - I did so for confirmation that what was written and how my mind was taking in this info to ensure I was on the same page aka learning/taking it in. So back on topic on Chassis prep/reinforcement. I have seen/read about how some add braces to the back of the TC rods to reduce the movement/flex in this area - I am thinking of doing the same so it this a good idea? Or should I spend more time/effort elsewhere aka rear suspension and limit its movement. One more question to those that have seen many 240z/260z/280z shells - we know there are big differences between them with changes that were made over the years. So how much stiffer is the last S30 shell/chassis stock for stock? I know for a pure race car it should not matter as you will be adding a good 10 point cage that should pick up the front strut towers etc will add a bucket load of chassis rigidity - I am asking for those of us that have a dual purpose car that will be street/track so like me I can drive to the track and do club events. I know dual purpose is always a compromise and I think the 10 points that have been posted/listed are excellent for those of us with such goals in mind. But would say a 280z shell be a better starting point for a dual purpose car due to the changes the factory made in the uni-body or does it not matter? (I guess off topic given the thread is about 240z chassis prep but related I think, as if the 280z shell is stronger would it not be a better place to start?) -

240Z Chassis prep / reinforcements

NZeder replied to Kurai's topic in Brakes, Wheels, Suspension and Chassis

I agree that is why I tried to put a pic together - I have a very very large white board at work for just such a purpose. Us IT/IS people love pictures. -

240Z Chassis prep / reinforcements

NZeder replied to Kurai's topic in Brakes, Wheels, Suspension and Chassis

Is like the pic attached? The red lines is this what you mean (ripped pic from the internet - it was the best I could find showing this area) Yes that what I thought - take some of the flex out and hidden in side the fender and not in the engine bay for a street car. -

240Z Chassis prep / reinforcements

NZeder replied to Kurai's topic in Brakes, Wheels, Suspension and Chassis

hmm my car already painted after bare metal strip so missed number 1 and number 2 but it is a 76/77 260z (same shell as your 280z 77/78) which do have a stronger shell 3. Done 4. Done 5. Got that sorted 6. ??? More info? 7. ??? More info again - Would I be correct in saying that would be a support bar across/between the rear of the TC rods? 8. Done 9. Looking to doing this when I replace/install aftermarket seat - some time away 10. Would this be talking about the pics shown in the attached file? I am getting these bars welded in the next week or so - just need to get car back to the fabricator 11. Done via a Beta Motorsport dual master cylinder setup - I am amazed how much this helped in this area 12. The world is full of too many TLA so what is an ARB Mount? 13. Missed that too So I guess that is a fail - only 5 out of 13 not even 50% -

The RB vs L28 would be 30KG more approx and that would be without turbo's so with turbo, air con pumps etc more KG (or LB for those state side that still use imperial ) so as other have stated location location location. Remember Nissan made the Z432 which had an engine that was the weight o the RB anyhow (the S20) so the chassis is up to the weight stock for stock ie RB20DE or RB25DE, RB30 would be heavier as the block is bigger. The point it should not upset the stock handling, however as other have already stated if you want the S30 chassis to handle great, some tweaks are required via adjustable suspension.

-

Using Pathfinder and ZXT axles to install 30 spline Nismo LSD kit (56k!)

NZeder replied to hughdogz's topic in Drivetrain

I think you will find the Z31 axles will be too long. Remember that Z31 has the diff plug in at the end of the axle were as the Z32 setup requires that 6 bolt end to connect to the plug-in that are in the side of the diff. Now all the plug ins I have seen (with flanges ie 3 x 2 or 5 x 1 or 6 x 1) all stick out at least 1.75" so I think you will find the Z31 axles way too long. This is why I got the Pathfinder axles (which I need to have new C-Clip grooves cut into them then I can install and confirm 100% if this is working solution Don't know what happened in this old thread but there used to pics of the trial setup I did http://forums.hybridz.org/index.php?/topic/65177-300zxt-cv-issue/page__hl__cv%20shaft%20length__st__60 Looks like I will have to get the C-Clip grooves in ASAP and get some new pics once I have these assembled once and for all.