-

Posts

366 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Hoover

-

will do. don't know how'd I ship a gnose if I ever sell it, I just do this stuff for my own cars mainly.

-

first lightweight materials have arrived. the difference is a 1/2 pound per foot of tubing. looks like i'll save 4.5 lbs. in tubing alone.

-

I'm going to make it out of carbon fiber after I fabricate all of the mounts. I like the 5 piece gnose since I can mix and match parts for painted/carbon highlights. The grill I have is an authentic 432 unobtanium part and I don't want it to get damaged. I figured using a Gnose is easier to fix and not so unobtanium for the most part.

-

a customer bought it and the header from me. I'll use it for a dyno session, then install it on her car. I can make multiples of anything with tubing. But if I were to sell one, I would use vband connectors so that it can break down into smaller sections and can be shipped.

-

-

here' some of the materials ordered to build a lighter exhaust system. the mufflers should weigh 2.5lbs. each and tubing approximately 8lbs. my current exhaust isn't heavy, 27lbs., while the normal muffler shop exhaust weigh about 42+lbs. The new exhaust should be a net weight 13lbs. No doubt that it'll be louder, but I plan to build a chamber in the muffler to capture air before it flows out.

-

both t/c bushings are destroyed....not safe. brake lines are still soft, but old..... the more I look, the more I realize that it's an old car and even stored and under car cover, it needs some tlc. not comfortable with the brakes- big brake upgrade here I come.......

-

-

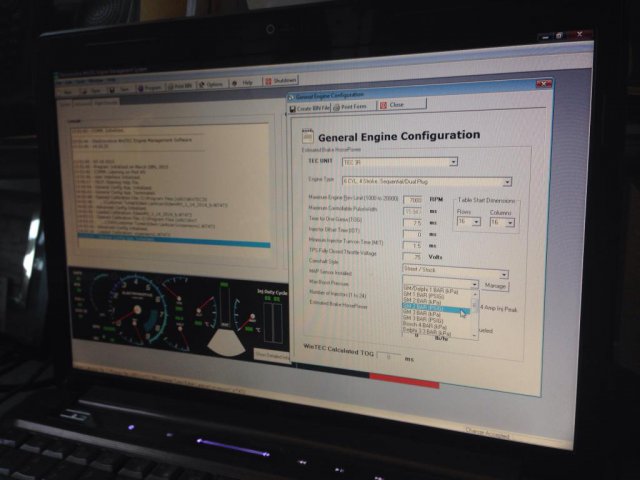

Since I have to wait... Will work on building a calibration for engine startup.... Yes... I lost the original file...

-

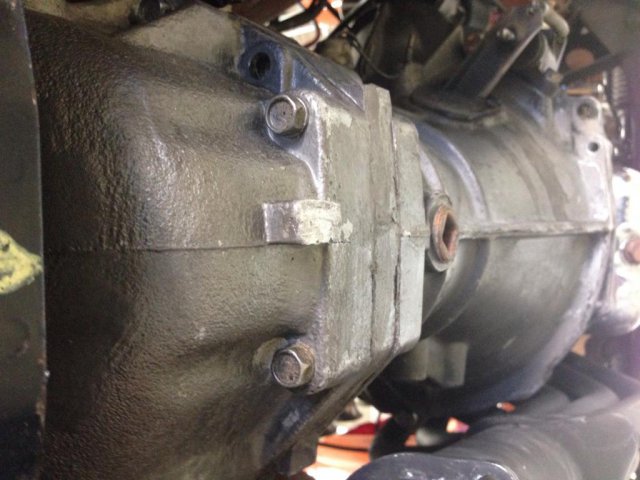

gear box installed..... no fuel tank till friday or monday....... decided to sell my exhaust after we dyno with it and build a light weight exhaust.... I ordered all the materials and will build my own mufflers.....

-

that's what I read as well. I'm not sure how the lower cross member would reinstall. It's over an 1" off. The way we mounted it works for us and wasn't overly difficult for a first-timer.

-

moving up further will misalign the mount bolts, so it has to sit where it sits, there is no adjustability for the vertical position machined into the mount. The adjustment is done by trimming the bushing. The 930 is very expensive, even near the price of a new GTR. It would be fun to swap out to programmable fuel injection, a turbo that isn't so laggy, 5 spd. conversion etc.....or maybe 993, which is still very expensive for a used car- that's Porsche for you, they retain value for certain. Z cars have also surprised me. I've seen nice ones sell for 20K+ and decent donor cars for 3500-5000.

-

no big deal...brake lines... maybe I should upgrade the front brakes at minimum??? I'm certain I could have the trans. and exhaust installed within a couple of hours. Also need a reverse light switch......

-

I bought it from tecnoversion. It arrived quickly via usps. We did trim off the flange, but you can only push the bracket up so far regardless.... Back to the version #1 BTW, your screen name-do you own a 930 turbo? I'd like to build a blackbird and can't make up my mind if I like a 930 or 993. I'll look at turbo options, but I generally like the single turbo of twins.....

-

Out comes the diff. Again for the billionth time in a day.... Going to Swap Out the the mount to the adjustable version.

-

RT Mount- it didn't fit with the polyurethane mount on top. Going back to the first version of their mount and will trim to fit. Maybe it's because it's a 1970?

-

so far looks good. Got the 240z axles to mate with the 720 4x4 diff. It's not a simple transfer or parts, or maybe I wasn't comfortable with letting the button float without some control of endplay. now where's my gas tank!!!

-

the 4.11 I bought is from a 720 4x4. I've read through the procedure and leaving the buttons floating just doesn't seem right. There's no way to control end play. With a combination of parts from the r180 and K R180 and some fabrication, I hope to have this differential working by the end of the day.....again...I hope!!!

-

i may have to put it all back together and deal with the diff. axle problems later.......i need to get it all back together and on the dyno........the diff. can be changed later.......... I've made a short list of round 2 and 3 which includes brakes, control arms, tc rods and cleaning up the entire bottom of the chassis....

-

well......i'm really not happy and more frustrated than ever......... the receiver for the bolt-thru type axle shaft doesn't fit the spur gears on the R180 (from a 260z). I'm going to hope that a 260Z is different and pick up an r180 from a 240z.

-

No joy!!!!! Is a r180 from a 260z the same??!!!

-

This looks like it'll take some time.... probably 1000+ pieces of hardware...... Getting a price quote for new brakes as well..... and waiting for parts....of course......

-

Happy Monday! I went to the warehouse this morning to try and locate some usable door panels to no avail. Found a hatch with wing, IMSA style front end and a cowl. I've brought the cowl back to my shop and considering making one in carbon.

-

what parts do people need? I'm going to make my own carbon parts...... the problem is that parts are only as accurate as the piece you make them from and the quality of the mold. If there's a perfect part to tool off of, it should fit.