All Activity

- Today

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Lots of small fixes the past week: Replaced the glovebox light and made sure it was all working well. Replaced the hatch inner and outer seals. My installation was better, but the Resurrected Classics seal also fit far better, especially the inner. The precision kit felt like it need to be stretched just slightly, but the RC held in place on it's own before adding weatherstrip adhesive and clamping down. The RC seal was pre-cut to provide clearanc for the hinge seals. When I first opened it it seems a bit ugly or poorly done, but after checking fitment it seems to be very well trimmed for correct clearance. Also added new oem style hinge shims when I reinstalled the hatch. The striker on the bottom was adjusted as well. Will need much more work to get the fitment right since the passenger side has a much bigger panel gap despite shoving it over as much as I could, but at least now I can comfortably open and close the hatch without dragging down the seals. Added the rubber stoppers for the door handles to prevent vibration and finally reattached the escutcheon / finisher plastic in the door cups. Looks much tidier and less noisy. Next step here will be to really clean up the door panels from the tiny splatters that I never cleaned from the lizardskin. O2 sensor cable routing was far improved by going through the body harness grommet in the firewall. It's in a safer position away from the driveshaft now. No longer running down the console. Wideband controller grounding was also fixed after I blew a fuse then repeatedly had it blow. Driveshaft was rebalanced. Seems a weight had knocked loose at some point. Was vibrating really horribly on my drive back from SLC with my brother. Replaced the diff pinion seal with a spare I had while the driveshaft was out. New OSG limited slip may not arrive in time for me to rebuild so I wanted to not have that leak in the meantime. Finally added the barb to the turbo intake as a vacuum source for the catch can. Hopefully this resolves any future oil leaking and premature seal and gasket failures. Adjusted the brake pedal travel. The brakes were already a huge upgrade and now it feels even better. Couldn't get it to the FSM's required height, but the suggested pedal height seems excessively tall, so I'll call it good now that the pedal and clutch are even heights and the stoppers are adjusted to make them less noisy. New hardware for the brakes is on the way from T3 and I'm getting some local help to wire up the new electric fans. Futofab HD stub axles arrived yesterday. Very well packaged. The axles should be arriving today, along with the new spare tire from Z Car Garage that will fit in the original spare tire compartment while still working with my new big brakes. More pics and updates to come soon... -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Fourth of July 2025 Pearl Harbor Fireworks and Car Show- This Joint Military Forces Fourth of July Celebration was held at Pearl Harbor Naval Base. It consisted of Two County Western Bands , Big Fireworks display and Car Show. There were over Two Thousand People in attendance from 4PM -9Pm. My 240z won 1st Place Trophy in Classic Rod Catalogue, The Event ended with 15 minute Long Fireworks Display over Pearl Harbor. Next- Finishing Details on the 8.8 Conversion -

Thanks for the welcome back, this car has certainly had a rollercoaster of a fate over the last 10 or so years of ownership. Excited to build it into the best version of itself (for me). Thank for the info, seems like Viking is a non-hype brand that offers shocks that do shock things, which I can appreciate. AE is slow on CS communications but that's understandable given the size of their operation. That said, for a ~$9K suspension kit, a bit more transparency and technical detail on their website would go a long way. If I can find a shock with more travel for the same dimensions or when I blow these out I'll swap. JRi's builder series and some of their GM line looks like it would bolt right in, only 0.3" longer extended length which seems negligible in terms of fitment (PN: 100-511-300). I agree, it seems incredibly unwise if that were the case but it wouldn't be the first time I'd seen it. I've seen similar suspension choices in GTAC (cars riding on bump stops) but that's usually done purposefully to keep the aero platform working optimally and not appropriate for a package like this. Considering the shock travel is a mere 3.6", its safe to assume this is an extremely low motion ratio design. It feels like a missed opportunity to fully leverage the bell crank inboard design (traditionally speaking) but perhaps packaging constraints of the S30 chassis left little room for alternatives. I'm hoping the bottoming out feature will be at the upper A-arm which would allow me to mount a 3D printed polyurethane bump stop on top of it. Going to email AE for an update on the wheel rates and now information motion ratios, thanks for the idea.

- Yesterday

-

Good post. I was frustrated for a long time with companies not sharing spring rates on these parts. FWIW, Viking is legit, lots of fast SCCA guys run those things with good results. IF those spring rates were chosen to prevent bottoming out of the shocks, that's pretty poor design. My guess is that the motion ratio of the bellcrank will be the limiting/bottoming out feature here, and that the conversion to pushrods has resulted in some high force multipliers. My guess would be Viking starting point is mounting in a "muscle car" front end, where the motion ratio is fairly low. I'll be interested to hear what the APEX guys say!

-

Thanks Leon!! Really happy to have the car back out. Dug into the car over the weekend, found a couple loose nuts, and some unexpected and unwelcome suprises! The big one was my front rotors are not handling the heat very well. The car is stopping pretty nicely, but it seems that's coming at a cost. I'm not sure if this is new, or if it's an old crack that I hadn't noticed before, but it's here now and it's a problem. If I get a second crack, that means I now have a mostly disconnected piece of rotor flying around, and generally not a great idea. I've had these on the car since 2021, so I guess I can't be THAT mad at them. Anyway, rather than sinking $450 into new rotor rings, I'm taking the opportunity to go full floating rotor. Wilwood has been making a lot more lug-drive setups, and it will let me get away from the bolted hat/rotor combo. This will hopefully help fight some of the pad knockback issues I've been having, and generally improve braking feel. Consumable cost is about the same, the big cost of upgrading is new hats. Got some routine maintenance done as well, fluids changed etc. Filling the transmission is a pain in the neck, but a little hose and some creativity made it a little easier. I probably could make this a permanent feature if I wanted to. Modern problems require modern solutions. Ordered up some fresh-ish tires, going with a Pirelli slick, 325/660 rear, 305/660 front. Might be a slight challenge fitting the front, but I think this is the tire the car will run from here, so it will be nice to set it up for one size and call it a day.

-

Yeah, it needed a little more bend to clear what I have there, I was thinking to heat wrap the closest header tube to give it a little more protection

-

A little more clearance wouldn't hurt, but I think that's fine if it never gets any closer. You'll have to periodically check that the line hasn't sagged or moved due to being under load and things expanding due to heat. What did you bend? The fitting?

-

240Z RESTORATION PARTS IN THE USAI I found this video by Larry Chen about the relative new source of 240Z restoration parts. Their inventory covers body parts,interior plastic panels, grills,etc. If any one have tried their parts, please let us know concerning fit,quality,price and customer service. Their Website pic shows a 240z salvage yard so they might also sell used 240z parts. the company name is Resurrected Classics in Auburn, Georgia.

-

Apparently this is old news, but I just found out about it. You add 2 copper oil drain plug washers under the shifter detent bolt, and it makes the T56 shift much better. Anyone here done this? https://www.svtperformance.com/threads/want-smoother-shifts-try-this.686622/page-13

-

Hey DJHsuperZ Nice Z Your improvements are going to make this Z really move. The best price I can do is $50.. off retail, being a Hybrid Z member and free shipping($1099.99) You will be charged sales tax to states that Calif. collects on. You may order on our site jdmpowerhouse.com Hope to here back from you on a purchase Thank you Chip JDMPowerhouse

-

Hi HybridZ, its been a while. Took a long sabbatical from working on my S30 to finish college and get a job. For the last 6 or so months its been full steam ahead, the project is currently being rust repaired at a local body shop and I've been collecting parts as budget allows. The first piece major piece of hardware to arrived is the Viking Performance Shocks from the Apex Engineered Track Attack Front/Rear Suspension kit. I noticed that Apex’s website lacks details on shock and spring selection, so I’m documenting my findings here for others and to start a discussion on their choices. What's Included: Box as it arrives from Viking Performance Serial Numbers of each of the shocks (PN: C203) Viking Performance Shocks Link Part Numbers of Springs (600# & 700#) Initial Impressions: The car will be caged and used primarily/almost exclusively on track, so a stiffer setup is expected. However the spring rate selection still raises some concerns: The S30 chassis doesn’t benefit significantly from extremely high spring rates, even with a roll cage. The rear suspension uses inboard cantilevered shocks, which traditionally increase effective spring rate via the lever arm. This spring selection guide from Viking Performance indicates that the spring rate for a car with IRS and axle weights of ~1200-1400# is a lot lower than the supplied springs. I'm hypothesizing that the high rates were chosen to prevent the shocks, which are short to fit the Z’s narrow frame and tight packaging within the front wheel wells, from bottoming out. I’ve reached out to Apex Engineered to clarify the wheel rates for this setup and will update this thread when I hear back. Let me know if any of you have run this kit or high wheel rates.

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

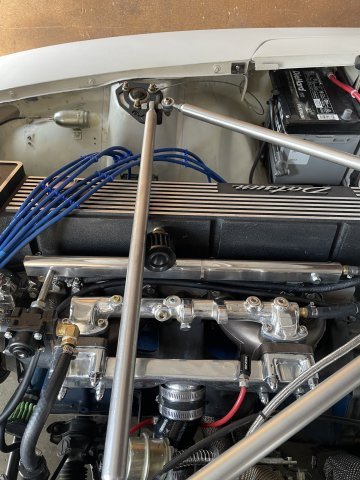

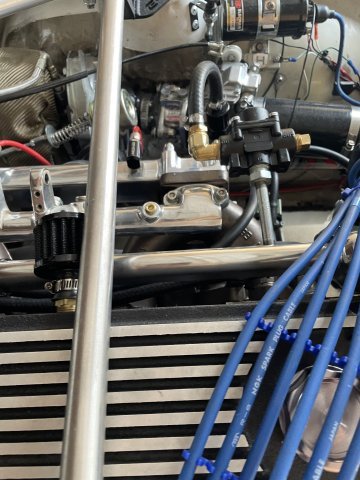

07-06-2025 polish day. Did some waxing. wipe down with a wet towel to get the dust off, and then a coat of pure caranauba wax from Mcquires (the Gold Class Caranauba Plus paste wax). My pallnet fuel rail has always been raw aluminum, but with some mothers mag wheel polish, a rag and elbow grease it turned out pretty good! I took a couple pics where you can see without and with polishing -

- Last week

-

Part 2-More 240Z Restoration- Body Work is mostly done utilizing Oxygen Acetylene Gas Welding. This method of welding was mainly used to repair automotive body repair. I learned this method when I was 15 years old and used it until the 1970s when Mig Wire Welding came in. The Mig Welding is a much productive method as it applied the heat faster and welding with less heat distortion to surrounding metal. However, I still use this method in certain applications to this day. Notice- Use a Small Torch Flame and Thin 1/16" Brass Rod. More Bodywork to come-

- 1 reply

-

- 1

-

-

Welcome to HybridZ, and thanks for your question. Please feel free to introduce yourself and your car on our "New Members Forum": https://forums.hybridz.org/forum/68-new-members-forum/ Are you looking for something like this? Note the exemption in the text "*Not for digital dash on 280ZX." -- don't know if that applies to your car. (I'm guessing not, since your current sensor is single wire.) https://zcardepot.com/products/coolant-temperature-sensor-one-piece-240z-260z-280z-280zx?variant=19278308016241¤cy=USD&utm_source=google&utm_medium=cpc&utm_campaign=google%2Bshopping&gad_source=1&gad_campaignid=17820837536&gclid=Cj0KCQjwvajDBhCNARIsAEE29WoDT0QZie4ihN9KbIOfGu197wEIp5SP7gYahzfJ4Ta0qhc9CthVys4aArmBEALw_wcB#

-

Cool thanks for fast response ... I was thinking about going with the extreme super 8.8 set up... but then i found a great deal on techno toys 4340 billet stub axils new at $600, and a perfect shape oem 300zxt cv axils $119 that i put new cv boots grease in them ,and painted them like new condition .. I think this Mfactory helical set up would strengthen up the open 280zxt 1982 354 r200 dif ,and cv axils thats been in my 1976 280z with 500hp sbc roller motor since 2012 ...

-

jetmail88 joined the community

-

Hi everyone. On my pride & joy, the 1983 280zx, the temp gauge does not come on or show in the dash. Once in awhile it comes on intermittently for a few seconds just enough for me to see the current temperature. Luckily it does shows normal level, about halfway. I've been living with this issue for several years but now the radiator electric fan does not come on during hot summer drives. I think the prob is with the temp sensor? Here's the pic of the one-wire type sensor that's bolt on at the bottom of thermostat housing. Can someone confirm that the elec fan problem is related ? or how can I check this? Also I'm having a real hard time finding a new one-wire sensor out there, could someone point me the right direction. Thanks in Advance !! https://mega.nz/file/hdJX0R4Q#Dp9e3XQXk3R-QTk62DGl_lRym2BkCtfVvfBay-Nqlsw

-

This 240z restoration in Japan demonstrates bodywork using basic methods and tools. These videos show restoration methods that most Do It Yourself people out there who do not access to more expensive body working equipment could still do the work. The restoration using these methods would take more time but have satisfying results. This Body Man does a lot of Vintage Cars Restoration in Japan. Race Cars are also done. Please give your comments so I can find more videos that will help you restore your Vintage 240Z or other car models. Toolman

-

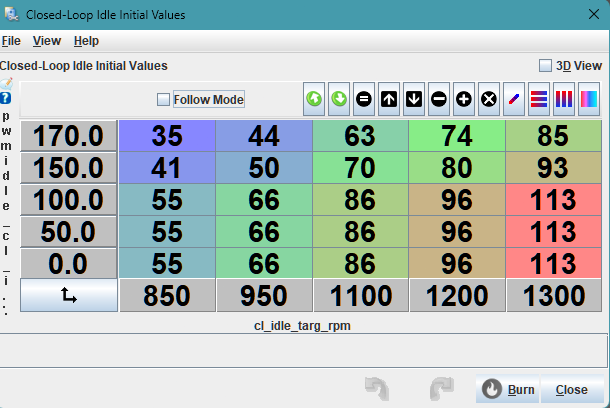

Update: Today I worked on correctly setting up the initial target RPM table. Took two readings per each rpm step, in my case, 850, 950, 1100, 1200 and 1300, when the car was semi-warm and hot. Then added another 10 percent per: https://www.diyautotune.com/support/closed-loop-idle-pwm/ Then from 100 to 170, interpolated vertically. Since I didn't know what steps would be at lower temps, left them the same at the bottom: I switched to using CLT table (not MAT) since I am still clueless where I can find it (unless TS uses the same table for both and it will be just different temp ranges there). I also noticed at hot restart, the AFRs are very lean, 15-16 range due to the injectors getting heat soaked. Searched on the msextra, found some posts about guys using a band-aid fix by adding ASE and taper at higher temperature. I experimented with mine and added some: It does help somewhat in the beginning. I added EGO correction of 8 percent above 800 rpms. This helps as well, and my AFRs get back to normal range. I am posting my updated tune, plus the idle log. I haven't taken the car for a test drive yet. 2025-07-06-v106.msq 2025-07-06_10.40.07.mlg

-

DJHsuperZ I will notify company on Monday of availability Thank you for the inquiry Chip JDMPowerhouse

-

Are these still available ?

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

07-05-2025. Installed my Skillard brake master cylinder heat shield. I had to modify it quite extensively for my use. -

Hi Tom! 1. I ordered another TPS sensor (different vendor) to test. I also noticed that it is not 100 percent stable. I am using the sensor ground for it per microsquirt manual and the 5V feed. My throttle blade is completely closed, the spring is strong in this Protunerz' throttle body. I do have a throttle cable slack. 2. I think what is happening at 16.833, is that for -200 rpm correction per the 'Idle Adaptive Advance Timing' table, it will kick 6 degrees of timing. My running RPMs are 996, when the target is 1200. So the ECU is adding 6 degrees to raise the RPMs. When the RPM of 1200 is matched, for ex., at 27.366sec, the correction advance is almost at 0 degrees, 0.6 actually. 3. At 26 seconds, i was backing out of the garage in reverse, with almost no TPS input. No sure what is happening here either. I also see a -280 RPMdot that follows. 4. At 93sec, there is a TPSdot of 14, maybe this is why my AE is enabled? My target RPM is 1183, the running RPM is 972, I see the Idle Correction Advance is adding another 6 degrees. I am wondering if I should move from 6 to 3 degrees max for CLI control? It might be too much of a change to adjust the RPMs? I will try that and will make another log. Overall, the CLI is the most confusing part for me. When it finally started working (kind of), it surely made my day :-) Appreciate you taking your time checking out my progress! I do have a few questions for you - per your tune: a. you have Shift Settings -> Leave Valve Closed Above:(rps) - 7,000, For this number of seconds - 0. Basically, you don't want the IAC valve to close at all? Any benefit from this setting? b. you are using the table for CLT in the CLI Settings (Use CLT or MAT In Table Lookup). Do you have any heat soaking issues? I read some posts where it was advised to use the MAT table. Any other benefits? Should I use the CLT table as well? I asked the question on the msextra forum why the ECU still checks the CLT table, but no one has responded yet: https://www.msextra.com/forums/viewtopic.php?t=82151&sid=ccd10333b5cfba1911eaded17a655060 Thanks! Den

-

Who's Online 3 Members, 0 Anonymous, 1222 Guests (See full list)