All Activity

- Yesterday

-

Den, I took a look at the log this morning. I have a couple observations vs. recommendations this time looking at the idle sections only. 1. The TPS varies from 0 to .5 and I think this is causing other issues. Do you think the throttle plate is hitting the throttle screw stop every time or the butterfly is not closing correctly every time? Could it be electrical noise. Does the throttle cable has slack in it? At the start of the log its .02 at the end its .05 one time. Looking at my setup it only varies .01 at idle and has a very stable TPS reading. 2. At 16.833s the timing jumps 6 degrees because of the Idle adaptive advance timing is firing off. Why I am not sure. 3. At 26.433s the Accel enrichment is firing off with a PW spike of 15.5 and then a Timing advancement, but I could NOT see why in the accel enrichment table. Now the timing advancement could be cause by the spike in fuel and then the dip in RPMs. I think this issue need looked into. This should not fire off at idle. 4. At 93.905s the Accel enrichment is firing off with a PW spike of 14.5 and then a Timing advancement, but I could NOT see why in the accel enrichment table. Now the timing advancement could be cause by the spike in fuel and then the dip in RPMs. Again, I think this issue need looked into. The idle controls are different on the Microsquirt vs. the Megasquirt so I don't understand all the settings, but I hope what I found gives you and area to look at.

-

Cool Z car. And you have had it for so long....a lot of memories. I hope you are able to eventually get her back on the road.

-

agreed, touching the header is a bad deal. If the header were at least wrapped and you put a loose fitting aluminum sheath over the hose that might save the hose. That drain hose in the pic looks VERY small. What happens if oil backs up is it will force oil into the turbo and you will get smoke as the pressurized oil is pushed past the seals, and if you have a catalytic converter, it could plug the converter and start a fire. It can also damage the turbo, as it is trying to spin with the friction of the oil hampering it. You can do a google search on all of this, but it can't be stated how important that drain hose is. I am getting by with a 5/8 drain hose and fittings. like I mentioned 3/4 is better. Ideal is no restriction at all .......the oil hits the drain and is gone.

-

yes, IF.....IF the diameter of the hose is large. 5/8 is acceptable, 3/4 is even better. The idea is to ensure that the oil can drain fast enough to not "back up".

- Last week

-

Update: I figured out why my RPMs were so low and the IAC wasn't adjusting its steps. My TPS in the Closed-Loop Idle PID Activation Settings, was set at 0.8. The actual TPS was 1.1 that day which meant that the CLI would never kick in when I was sitting in the car at idle. I re-calibrated it and decided to play it safe and set at 1.5. Today the car's CLI worked as intended. I am still dealing with wonky IAC which can be at steps 90 and barely allowing any air in. Also, I noticed that even if I select the MAT table to be used for reference, the ECU was still looking up the CLT settings. I posted this question on the msextra site, maybe it is a code glitch or this is how they designed it or I am missing another table. I might just use the CLT reference table and call it a day. I am posting the updated tune and the drive log. 2025-07-03_12.14.29-drive.mlg 2025-07-03-v104.msq

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

no exhaust, straight off the down pipe, now back on full exhaust. crappy video, but you can hear a bit of it. click this below: V3.MOV -

sffan25 joined the community

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

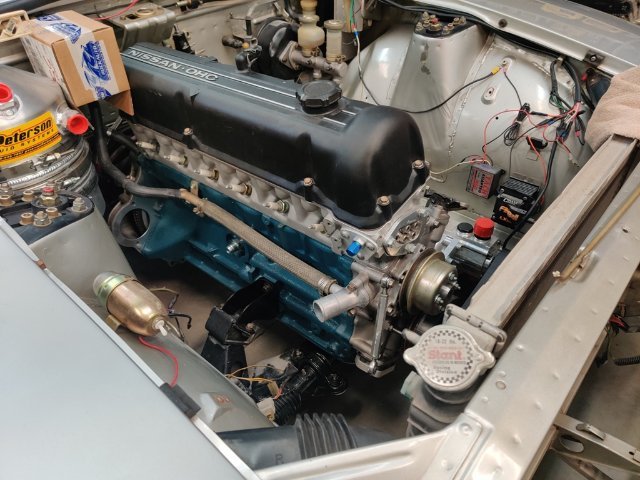

07-02-2025. Well my Z car is finally done......again. it was finished a year ago. But then I decided to turbocharge the engine and that involved redoing the braking. it's done. lightly turbocharged. It now has the one thing I felt it was missing. took 8 months and enormous amounts of patience and going back and forth jetting, etc. Powerwise? Who knows....at the rear wheel.....probably 200-210 max. that would be about 250 or so at the flywheel. it's just a cruiser and a real 10 footer. DONE. whew! -

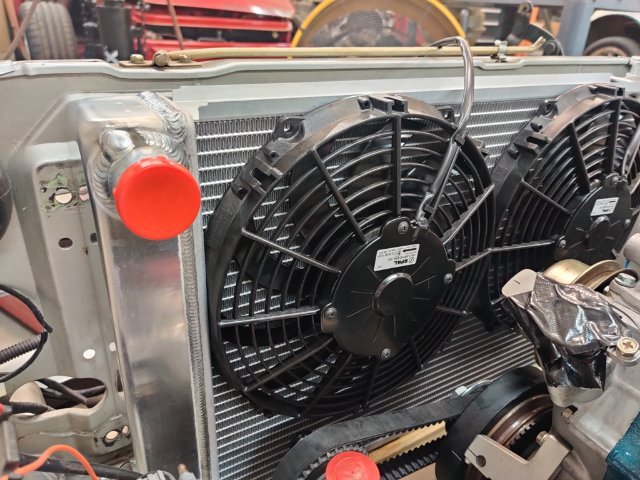

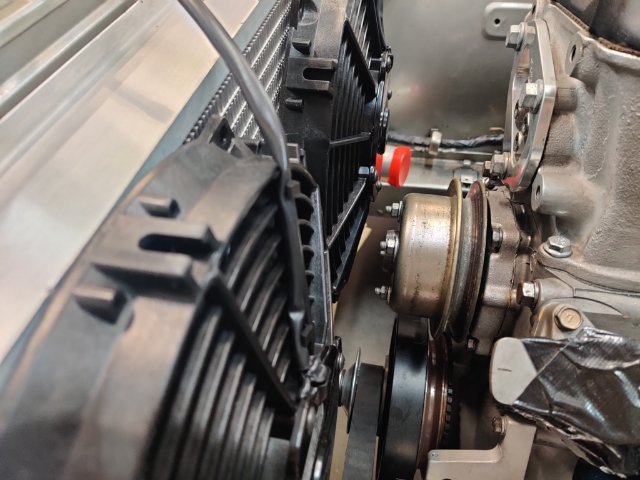

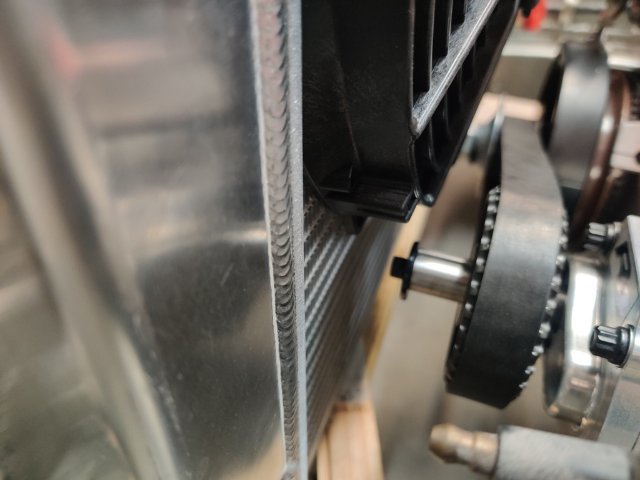

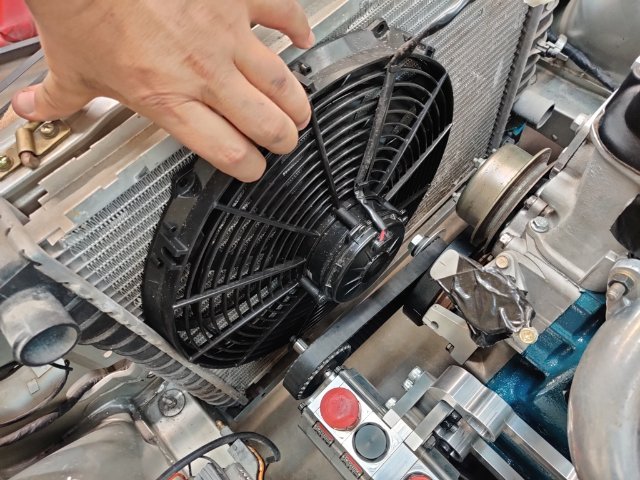

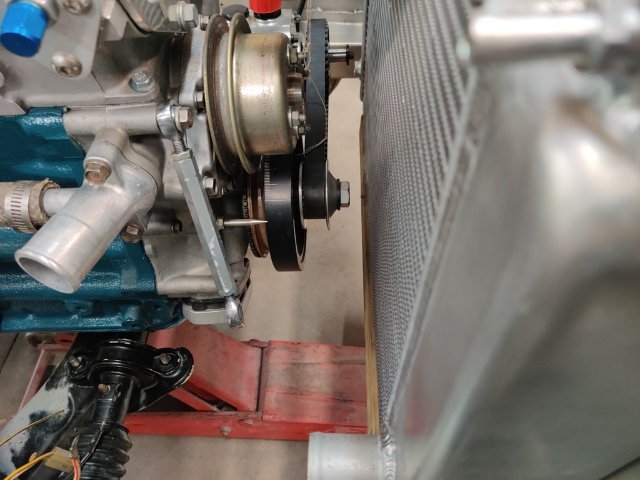

After lots of measuring and thinking, I ordered another Griffin radiator and two 10" Spal fans. This radiator is a bit wider and the same height as the other Griffin I bought years ago. However, the core has two 1" wide tubes instead of the two 1.25" wide tubes. Thus, the core is a bit thinner and that helps provide a bit more room for the fans. Being a bit wider, the two 10" fans fit better as well. Here are some pics: I will mount the fans at the top as shown. This will put the fans above the oil pump shaft and crankshaft dampener bolt. I will probably shorten the oil pump shaft, as the extra length is not needed for this application. The bottom edge of the radiator aligns with the bottom edge of this blue painter's tape. The side tanks fit just inside the stock radiator mount bolt locations: I am very pleased with this combination from a fit standpoint. Each fan is rated at 802 CFM. I repeatedly came across information where the CFM was higher when they were used in pairs in combination with shrouding. So, I plan to add some shrouding as well as some directing panels on the front to improve total CFM. I won't be able to measure it, but I think bumping the total up to 2000, an amount that should be good for a 6 cylinder engine, should be possible. Next, I will figure out how to mount the radiator, and wire up the fans.

-

Thanks for Repairing my PassWord Problem. Is there anything that I need to do prevent this problem from occurring again? Toolman

-

TreadSlayer joined the community

-

Love it Ben, great to see the car back on the road and being used as it should be!

-

Its an ebay header so Im guessing the builder didn't spend much time confirming clearances, so no help from them... I know the drain should be as straight as possible out of the turbo, but would a 90 off the bottom fitting be acceptable?

-

Brad-ManQ45 started following '83ZXT to MS3Pro using all efi and fuel pump relays?

-

I have searched and have not seen where anyone has stated that they have utilized all of the fuel pump relays and efi relay for their MS install on a factory turbo car. Wondering if this is overkill or not needed.

-

Close is one thing, but resting directly on the header isn't good. What's the line routing look like from factory? Does the header manufacturer have any pictures of it installed on an engine that you could use to figure out where they intended the drain to go?

-

https://a.co/d/9XKdee7 Just got this one. Haven't driven with it yet to see the stability, but you can put it up high and out of the way, and bend it into all kinds of positions. You have to stick a metal ring onto the back of your phone for the magnet to hold it.

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

07-01-2025. I had a crack in the fuel line, so I took the time to change it up and use a bit of 1/8" pipe and fittings to make it so it is supported versus kind of floppy before. I deleted the cheap fuel psi gauge I got from Amazon which was spotty at best. Click on "V1MOV" below for a short video V1.MOV -

Turbo guys, this is my first time working around a turbo and I have a question on the oil drain. The manifold, turbo, drain fitting are all really tight and the drain line ends up laying on the header, is that going to be a problem? It's all so compact and close that it all looks problematic to me, but I'm pretty ignorant on what might be an issue or not... Any suggestions are welcome! A couple pics of the current layout

-

Went out for some Auto-x this weekend, and had a proper blast. Highly recommended for anyone here who still hasn't gone to try it. Enjoy a slow lap, some V8 noises and straight cut gearbox whine. I have a handful of things to think about and address moving forward, but overall I'm very happy with where this sits. Next up is OnGrid at the Ridge in late July for more testing, and maybe, just maaaaybe a little redemption.

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Got the front wildwood brakes installed today! A couple small quirks along the way on my install: First side I installed the rotor on the adapter ring to the hub wrong and the caliper didn't line up. It has two separate mating surfaces, one for a 240z and one for the later 280z hubs. Since I've replaced my 280z hubs with the T3 hubs, I failed to realize they're essentially a universal hub for early and late models which is why they had an extra shim ring of about 10mm to account for where the 280z mounting surface is. I took the ring off, so technically I had to install them where the 240z ones are, unless I wanted to run my rotor ring AND the hub spacer shim that they came with. Avoiding too many unnecessary pieces so I redid that side to mount on the 240z mating surface of the adapter and we were fine. Problem 2 - because I ordered the 280z brake kit, the included hardware also assumes you're still using stock 280z hubs. It's on and worked on my short drive, but I noticed in the picture where they're installed that the bolts don't go all the way out to the mating surface for the wheels. Quite a few threads left unengaged. It's probably safe for the time being, since I thought about the forces on those specific bolts and it's not really in or out since they're perpendicular to the rotational force applied by the brakes. I also didn't feel like I had particularly few threads engaged as I was bolting the rotor to the hub. Probably safe for casual driving, but it's a high priority fix right now to get the correct length bolts from T3 or locally. Better safe than sorry! Other than that I'm really happy. Bled the system with my new Motul brake fluid, which should cope much better with the heat off the turbo vs the cheap generic O'Reilly fluid I had before. -

Heavy Duty frame rails and connectors

armorer replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Appreciate your detailed installation thread on this kit Will be starting mine shortly, nice to see it done -

Update: replaced the mustache bar bushings, re-torqued the strut lock nuts. I don't hear any more banging noises now. Still not sure what fixed it though. When I was checking my rear Bilsteins with springs compressed, I didn't feel any extra movements to give me that noise. I also swapped my master, slave clutch cylinders and clutch hydraulic hose. The old ones had some 'brake fluid sludge' inside from the internal leakage. I adjusted the clutch pedal at 8 inches (i have a carpet/sound insulation), the master cylinder rod of the replacement unit was the same length, no need for an extra nut. I could put the pedal at the max height (over 9.5 in) and the rod was still good. The free pedal travel is within specs, 15 mm. I was observing the operation of the slave with my $20 endoscope, 15 mm of the clutch pedal before the slave starts its movement. The clutch fork throw is half an inch (12.5 mm). I could push the slave's rod back towards the front, the rod gets back to its self-adjusting position. I did some searching - it sounds like 15 mm is a better number. My reverse and 5th get engaged without grinding noise and without any difficulty. The clutch operation is smooth. I used Rockauto's Luk's: LMC245 and LSC199 parts. Appreciate your guys' help. After fiddling with my closed-loop idle, I am still chasing my tail. I posted a thread on the msextra.com forum at: https://www.msextra.com/forums/viewtopic.php?t=82151 The RPMs get dropped very low, the ECU is not commanding enough steps for my IAC (or it is telling to give, for ex., 60 steps with not much difference). The car is driveable, but with rpms sometimes hitting low 300-400s, which is not good (CLI is not even running when it happens). Here is my updated tune and drive logs if anyone wants to take a peek. Thanks, Den 2025-06-29-v102.msq 2025-06-29-cold-start.mlg

-

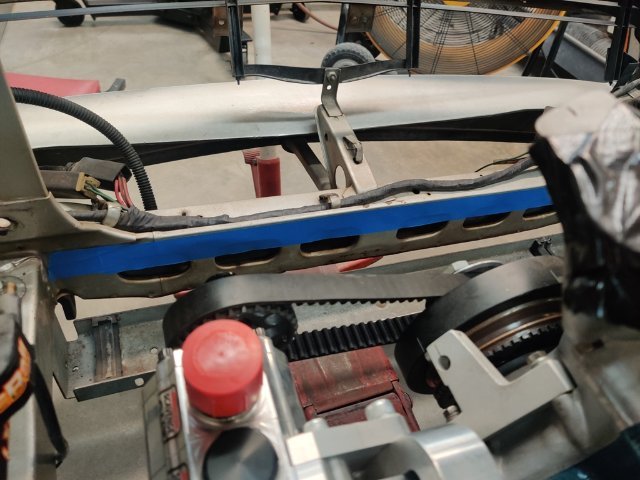

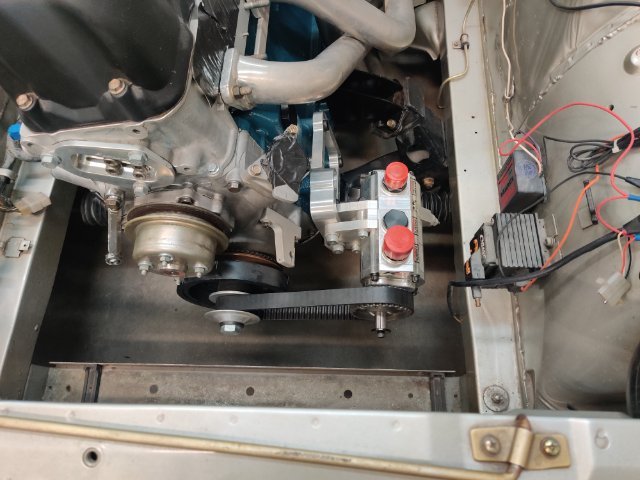

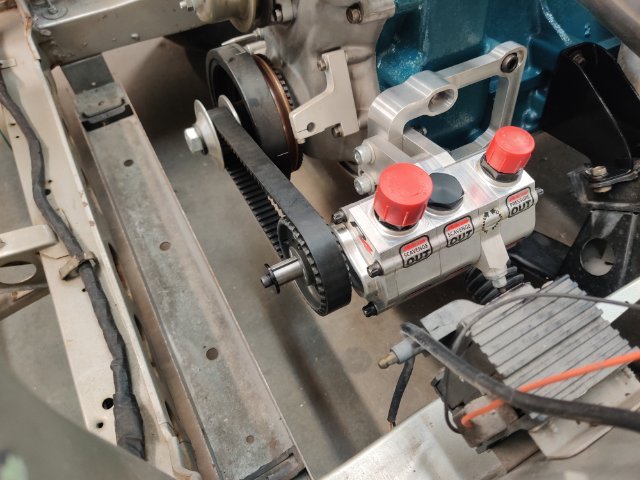

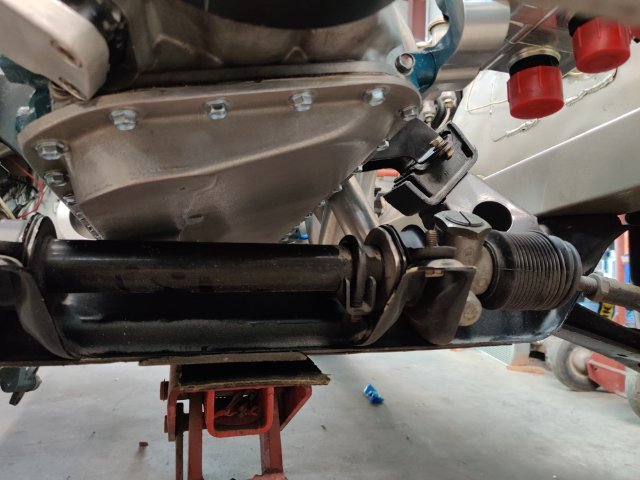

I put the engine in the car last weekend. This weekend I am doing a lot of staring at it and thinking. I need to figure out how and where to route all of the oiling lines. And I need to figure out what to do for a radiator and cooling fan as the Griffin I bought is 3" thick and is awfully close to the crank dampener bolt. Those are the immediate concerns. I still have to wire up and install a set of Speedhut gauges, drain and flush the gas tank and lines, and a bunch of other stuff before I can attempt to start the new engine. Going to put the tank about here: Have to cut sheet metal here to get the tank low enough to fit under the hood: Pump and custom mount: There is a good amount of space under the pan. I will route the two pan scavenge lines under here to the bottom two fitting on the pump. I can clock the bottom of the tank about 90 degrees to get the bottom fitting pointed towards the left side, and then I might be able to run a line from there, across the top of the transmission bell housing to the left side of the engine compartment, and run it along the frame rail to the front of the pump. Radiator situation - Griffin set in place in first pic is very close to the crank and oil pump shaft. The Stealth Conversions radiator is much thinner, but even some the 14" Spal would be a tight fit. And when I was last at the track with this radiator, the temp gauge indicated slightly elevated temperatures from normal. So, I'd prefer not to put that radiator back in this car for that reason. It was fine though for all use except track sessions in the August heat in Atlanta. I had no shrouding and a stock clutch fan (plastic) when it was last installed.

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

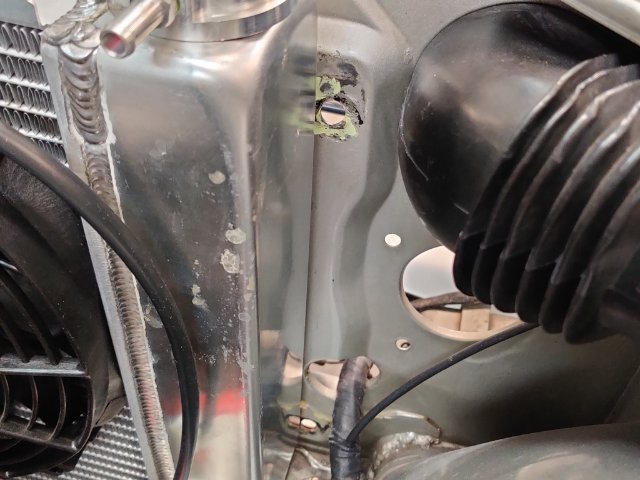

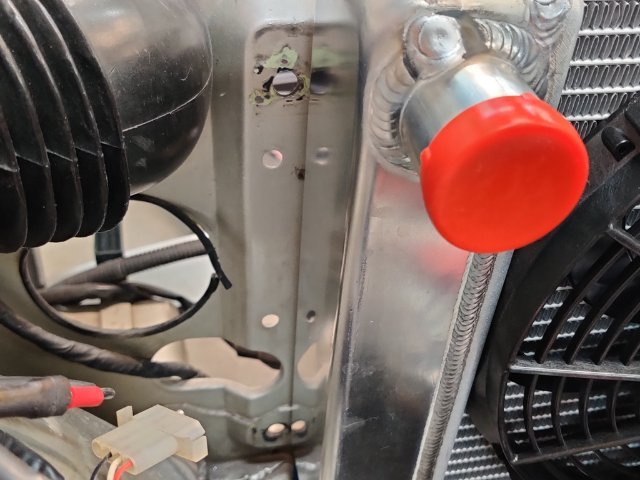

06-28-2025. Putting the new turbo on. With the new turbo to manifold piece, I had to actually remove the intake manifold, put it all together, and then slide the manifold back on. It WORKED! Look at those HUGE ports! I haven't seen them in awhile! That's my Russ Racing prepped and shaved E31 head! I have it almost all assembled, I had to "slip" the top hose clamp up a bit to get a really good seal clamped down. Looks "different" but it is SNUG. I vacuum tested the new wastegate actuator......WAY too high (boost crack at 15 psi !!!) , so I put the older one on, and it boost cracks at only 2.5 psi.,....but I didn't port the turbine housing this time, so keeping that in mind, I think very little boost will be bleed off....enough to protect the engine, but it's going to pump quite a bit of air and fuel! (boost creep expected). The Skillard brake master cylinder heat shield I ordered came in, and is waiting me to custom mod as needed and install. Also went ahead and started clamping down the vacuum hoses to avoid any more hoses blowing off under boost. I have also added on a few pics of my intake ports if interested. Almost done! It is now HOT, have to keep stopping and wiping my face off. I think it was over 86! cheers! pics attached. -

Fast Floridian's 240Z Track Build

A to Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

GREAT! I haven't seen those....I got mine from Z car depot. -

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Thanks, just ordered sway bar plates from bad dog

-

Who's Online 0 Members, 0 Anonymous, 1849 Guests (See full list)

- There are no registered users currently online