-

Posts

506 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Twoeightnine

-

Are you talking about Donkey Punch Ricer one?

-

Cross Member Bump Steer Mod

Twoeightnine replied to Twoeightnine's topic in Brakes, Wheels, Suspension and Chassis

Yeh, I keep forgetting about mans favorite removal method.....force. Or better yet....the hammer. I used a large drill bit making shallow passes at the tack weld locations to remove all of the useless bracketry in the engine bay. One of the brackets I simply could not find the tack weld spots so I grabed the trusty vise grips and proceeded to wrestle the bastage off. When it popped off, it had pulled the welds through the firewall leaving really nice jagged holes. But I realize that the cross member is much thicker. So far I see there are no takers for the job. Im under the impression its not a big deal? Maybe Im making too much of it? When I was younger I worked for a time as a precision Machinist and have since then been engineering precision aircraft systems. Perhaps I should knock back the presision side of me. Is that it? Im not really too easy to frighten, I just want them right. J...what type of doubler did you use on your slotted system? Thanks guys for the imput, -

Cross Member Bump Steer Mod

Twoeightnine replied to Twoeightnine's topic in Brakes, Wheels, Suspension and Chassis

Yep. Im at the point were it needs to be painted and thrown back in. I was looking at it and felt that I would regret not doing the mod. Sat it on the bench and contemplated how I would accurately place the holes. After messing with some plumb bobs and laser levels, I actally lost conffidence in the possibility of a dead on placement. Especially inboard/outboard. Knowing that many racers have done it in the past. And that some have a machine shop. Why try and reinvent the wheel. And yes, the washer looks like it would be a bitch. Even with the 90 degree drill motor. Shurely some one can perform the task better than I could. Thanks J. -

Ok I would like to have the bump steer mod performed on my cross member. Problem is....I dont want to do it! Any members out there that can do it for me? I want it done right. Pros please.

-

Wife compliments Z, LS2 update

Twoeightnine replied to Pop N Wood's topic in Gen III & IV Chevy V8Z Tech Board

Yes Yes. I get it. I had forgotten that both ends have their own lasers! Yes that would easy. The "dots" would move away/towards each other if not parallel as you moved the paper forward or back. And we dont want to agitate the "dots"! Many thanks -

Wife compliments Z, LS2 update

Twoeightnine replied to Pop N Wood's topic in Gen III & IV Chevy V8Z Tech Board

That was a nice compliment!! The laser alignment tools I made make aligning the driveline an absolute snap. Just hold up a sheet of notebook paper and count the number of lines between the dots. The light comes right through the paper. Just move the paper from the front to the back and when the dots are the same distance apart (up-down, left-right), then all is good. Gave me good clearance between the firewall and bellhousing when I realized how much engine tilt is needed to match the stock diff. Could you expand on your tool a little. Sounds interesting. I have read the threads on several laser tools but, the dots/lines thing has me intriged. If you have covered this elsewhere, my bad. Toss up a link kind sir. I would like to recheck mine with a laser method. -

Mario Hey buddy, check this out! http://forums.hybridz.org/showthread.php?t=109717&highlight=240+bumper+280

-

-

OK Who's Siiiiick RB25DET 240Z Is This on eBay for $32K..Pics?

Twoeightnine replied to slownrusty's topic in Non Tech Board

Nice car. Im a V8 Jocky so pardon the ignorance but, is 260 H/P correct? Thats decent H/P but I was under the impression theat the"Skyline" was a heavy car. Wwould 260 do it? -

I looked at the catalouge and Black Dragon is "offering the bumpers both with and without the rubber bumpers holes. Clean is 400.00 and with the holes is 460.00. What has been the range of E-Bay buys? Chrom looks nice but I had originally planed for black. Have put it off so far as it can be settled in the end even after she gets out of paint. But I'm there.

-

WoW!! I guess no one is going to give thoes things away!! I want a black one so, fiberglass it is!!

-

-

After last winter with near zero precipitation, followed by three months of no rain. We have, since larry was in New Mexico a couple of weeks ago, been drenched! The first deluge was refreshing. Especially since the three inch wide cracks in the ground gobbled up the water. But it hasn't let up since. Standing water where there never has been before! Are you shure he isn't in Texas yet?

-

Steering wheel shakes

Twoeightnine replied to gretchen/jason's topic in Brakes, Wheels, Suspension and Chassis

-

Steering wheel shakes

Twoeightnine replied to gretchen/jason's topic in Brakes, Wheels, Suspension and Chassis

Yep.. all true. Especially considering how long its been going on. Do you have a set of fronts from a happy Z driver that you could borrow for a six pack? Test drive em. Need to eliminate some stuff here. I chased a vibration one time on tires that were at about 6000K mi. Did the alignment thing, balanced and rebalanced. Balanced at a different shop! Shop number two blamed the tires! They were right in the end. Out of round. Damn cheap Firestones. I would have never suspected. Any how if you can get a set to borrow, and have no probs, you can go after the hubs, rotors. if they have been over heated or otherwise abused you might have em. -

"Welding" stell to aluminum for structural aplications is not practicle due to the differing melting temperatures of the base metals and the incompatability of most fillers. Even when success can be acheived, the dissimilar metal corrosion activity at the "weld" joint will cause failure even when "cracks" are not apparent. If one is hell bent on "hot bonding" dissimilar metals verses "fastening" methods, one can "solder" the two together. The low temp required to melt the solder and gain sufficient "adhesion" with out altering the base metals leaves the joint less structurlly sound than would be found with like metal weld construction or fastening techniques of dissimilar materials. But if you must "torch up", check out these "solder" supplies. http://www.muggyweld.com/super1.html

-

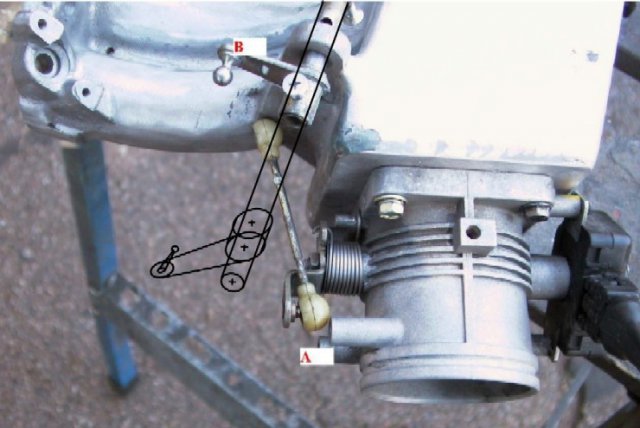

Need Some Ideas On Throttle Linkage BMW 67mm TB..PICS!

Twoeightnine replied to slownrusty's topic in Fabrication / Welding

Yes sir. I just wish I was having as much fun as you are! -

Need Some Ideas On Throttle Linkage BMW 67mm TB..PICS!

Twoeightnine replied to slownrusty's topic in Fabrication / Welding

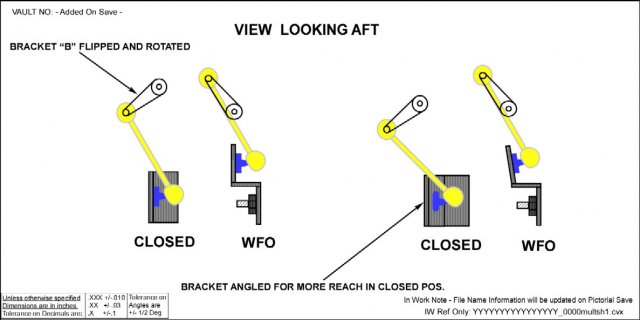

I broke out some crayons. Does this help? Is this possible? As shown, at full throttle (WFO), there is 90 degrees of rotation from closed. Of course the closed pos of a TB is what 5 to 8 degrees open? So true WFO wont be quite as far as the illustration shows. Which will give you a touch more clearance. -

Need Some Ideas On Throttle Linkage BMW 67mm TB..PICS!

Twoeightnine replied to slownrusty's topic in Fabrication / Welding

-

Kinda a stomp on the thread but... I have a design Idea for a new Z shirt. I dont have graphics programs just engineering programs. The design came out computer generated like. Not shure if I like it. I would prefer an artist rendering. If you would like I could e-mail you the design and give me your thoughts. Shoot me an e-mail PM style if you of he is interested. Thanks for the toys man!! Toys are cool!!

-

Terry. You are an awesome american! Your son is very talented. Does he do any graphics work for hire? Or is he just a hobbyist? I looked at your album. Hadn't taken the time untill now. That black Corzette is one bad son of a beeeach! All nice rides. Thanks for all.

-

Hey Terry. I feel bad that you have to work so hard on the deal. 10 is not a prob. Want another s30 and the skyline as well. And anything I dont have. Take yer time. You are greatly appreciated. Many thanks.

-

Houston we have a successful test! Yes more specs please.