makaofox

Members-

Posts

256 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by makaofox

-

Nice build! the color and wheels look great and the cf flares set it off. Let us know how you like cx racing mounts. I have mine im also doing an 2jz na to t but havent gotten my motor back from machining. I brought bulk of what i need and im probably gonna have a hard time with the nick nacks. What turbo you going with? if your not staying stock twins that is. Im hoping my motor comes back around sept so I have a winter project.

-

I don't have measurements but the cx racing doesn't set the motor as low or far back because it is using the stock mount locations. The lowest and furthest you could have brought was from beta motorsport. But cx racing isn't far off it wouldn't take much to push back and lower if you needed too.

-

Whose Selling ZG Mount Kits ?!

makaofox replied to datASSun's topic in S30 Series - 240z, 260z, 280z

I brought what hypertek suggested months ago and have been happy ever since. Initially years ago I did rivets but that was a huge hassle if I had to remove my flares. However with nut inserts it makes life easier. -

That extra adjustment will be an issue with vibration and such. Make sure to use Loctite. Maybe you can route the oil return a certain way? Then wrap it with some heat shielding.

-

Differential issue + wolf creek racing cv axles

makaofox replied to makaofox's topic in S30 Series - 240z, 260z, 280z

Well removed everything and took the adapters off. The grease was holding onto them for dear life. Required a lot of work to take them off. Also ended up getting a diff from a local. Its an R200 3.54 welded which blows because I like the 3.7. So if you buy wolf creek axles and pack the grease try to clean up as much as you can on the lip! -

Differential issue + wolf creek racing cv axles

makaofox replied to makaofox's topic in S30 Series - 240z, 260z, 280z

Well the stub axle slides in and out freely its not correctly seated in the diff. That's part of the circlip issue. But the adapter that connects the axle to the stub axle is held by 6 bolts. I removed the 6 bolts and it would release. A slide hammer wouldn't work because the stub already comes out half way so it wont be effective, plus lack of room. -

Previously I had a R180 welded diff in my 76 Datsun. Since soon I will be doing a 2jz swap, I wanted to get the rear end dialed in prior to doing the swap. Purchased wolf creek cv axles, r200 Diff (welded), modified driveshaft, rt diff mount with poly bushing, techno toy tuning r200 mustache bar and some stage 8 fasteners. Basically its been hell since I started the swap, but mainly my differential has been giving me one heck of a ride. So I had a z31 R200 non-lsd welded. Now I go to put in my stub axles the passenger side goes in fine (I checked I put the correct length with the corresponding side). However, the driver side (short side) is giving me the issues. From the start I tried to put it in and it was very loose, just keeps popping out without effort. So I checked the other side and it had a circlip which clipped in and keeps the axle in. The driver side however has 3 grooves and I wasn't able to get the circlip in. Then one day I beat it a few times and it went in and was in there solid without the clip. So I though ok maybe it was really in there? Nope! Installed it and now the stubbie comes out and it drove but I knew something was odd. So jacked it up tonight and saw the axle was going in and out. So issue number 1 what the heck is going on with my stub axle. Why isn't it going in and clipping it? Now I ordered 4 new clips but how do I install them, when I try and put it in the groove and tap the axle in it moves out of place. Now before I tried putting it on the stub itself and getting it in there but that didn't work out too well at all. Im almost certain this diff and stub go together. So any help would be great! Issue number 2, uninstalling my wolf creek axles to get the stub axle off to examine it and I cant! the adapter to axle WONT LET GO! I have unbolted the 6 bolts and the adapter is just not letting the axle go. So any ideas? I tried a hammer and screw driver but not a ton of room and im not trying to destroy the metal. Now I have greased it and im thinking the grease is using itself like a suction and not letting go of the adapter. This is a real pain and I DONT want to drop the entire subframe again just to see whats wrong with my stub when I can remove it once the adapter lets go of the axle. Any help would be appreciated!!

-

I like how this guy made his mounts. His thread is on here and is recent. Take a look at his album it is AMAZING. You will not be disappointed. 2jzge-t with lots of amazing fab work. These mounts are very simple but go on directly to the chassis, as opposed to oe mount location.

-

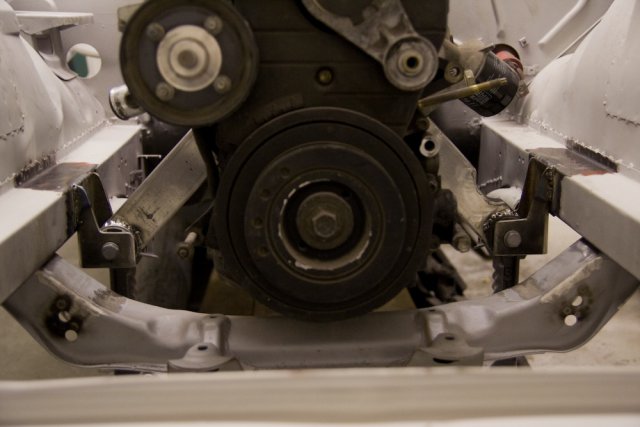

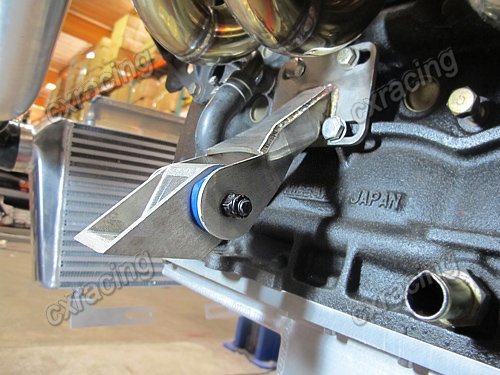

Here are some pics of the mounts I have collected. You can see the part I like is the mount connecting to the oe location. the part I don't like is the part connecting to the block, which I may modify.

-

Id just go custom. Try and find someone that is willing to make mounts for you. I have a friend that made his mounts and was willing to make mine, but I found out AFTER I brought the cx racing mounts. Im still going to have him make my mounts even if I have the cx racing ones lol.

-

I purchased them 2ish months ago. I like some of it and hate some of it. So im gonna keep the part that mounts to our oem mounts and ditch the part that actually goes onto the 2jz black and make my own. I brought them as a template I guess I didn't really expect much from cxracing. But for $200 or $300 im not that mad since im using half the kit. The issue is the part that connects from the block to the actual mount, it has too much movement for my comfort and doesn't seem strong enough for anything more than 300 hp.

-

2JZGTE Swap Wiring Harnesses - Plug and Play

makaofox replied to wiring specialties's topic in Toyota L6 Forum

Sweet! Finally lol. I have a 2jz na to t using an aem standalone and going with the 6sp 350z and I love that you have all those options! This winter I plan to start, and I will definitely have to order from you guys. -

Better make it work! Looking out for you, its gonna get tiring real quick lol. How didn't it work? you weren't getting the right degree? Or it was to costly to use the bender? Nothing wrong with tig welding it, after your first few you'll figure out more efficient ways.

-

Would it be easier to get one long tube and mandrel bend it? Saves you from welding 10x and reduces it to just 2? I could see you getting exhausted doing 10 welds each cross member lol. Powder coating is a good option.

-

Sweet! Cant wait for this man, I plan to start working on it this winter.

-

Interesting, did not know maverick motorsports made an adapter.

-

Where are you getting this "good clutch selection"? Curious. Collins offers a few stages 425, 700 or 800 and 1000+ but wish it was closer to 500 hp. Been waiting to get pick up the adapter, I know some supra guys piece together from the 4runner, mr2, and sr motor. I made the choice a long time ago to go 350z but haven't reached that point of getting it. The v160 is 2x the 350 swap, the r154 gets close to 2k easily and shifts like a truck and the w58 is garbage. Solstice trans or t56 was iffy for me but figure id stick to the z33 trans. My friend has this set up and shifts like butter, hasn't driven yet though..

-

Finally! Cant wait, made the mistake of putting off purchasing the crossmember and bit me in the ass since it was no longer produced. Cant wait for you to start I will buy one. I was going to make my own but just not in the mood to spend time on that when I can buy the engine mount and spend that time making the trans mount and other brackets. Just general questions: Price range between $200-$400?? Tig welded or mig? Thickness of the steel? Quality? Looking forward to this, by the time you have a few ready to ship ill purchase them.

-

Thanks California mirrors but not sure of the brand. I know you can still purchase them though for around $100-130?

-

Some pics I told may 25th

-

After talking to my friend building his 2jz 240z he also said the same thing -8 feed and -6 return. Worked well on his z32 2jz and will work well on his 2j 240z so im going to go that route. Still going to order the same thing. Im actually glad this came up because I didn't know any of that. I know for sure on a turbo the oil feed needs to be small and the oil return needs to be huge (-3 or -4an feed and -10 return).

- 26 replies

-

- 2Jz GTE FUel system

- inector

-

(and 3 more)

Tagged with:

-

I was gonna run -6 feed -8 return (initially wanted -8 feed and -10 return) aluminum hard lines with a bosch 044 external. Stock is external, its not that loud. I wouldn't mind getting an aluminum tank with an intank fuel pump but the 76 tank is more than enough, so im running with it.

- 26 replies

-

- 2Jz GTE FUel system

- inector

-

(and 3 more)

Tagged with:

-

^im thinking about going z32 gear box just waiting on funds. Awesome thread man any more info on the s13 rear sub? I have a welded r180 and was strongly advised not to stay r180 even if its welded and even if I put billet axles. I know plenty of s13 diffs out there so that would be easy to source.

-

That make sense. My friend built his mounts to go to the stock location. It didn't look weak but it didn't look right. I wouldn't know how that would pan out until its done. I figured directly to the frame would cause some issues, that oil filter is a pain lol. The crossmember ive been seeing looks easiest.

-

Quick question to those making mounts or have a jz already installed. When making mounts like most have been making replicating Beta, why make the cross member? Why not simply make the mounts directly to the frame? Or if you are crafty to the stock mounts? Because when I dropped my motor to make measurements the s30 stock cross member was in a good spot for the 2jz to sit on. It wasn't right in the middle of the motor but if the mounts failed the motor wouldn't drop to the floor the cross mount would hold it up? So why make another cross mount? Is it for safety or is it just easier to build something like that than putting it directly from motor to frame. Im just curious.