-

Posts

2943 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

The greasier her hands got, the more fun she had! And I think she was bummed the flesh wound was 'puny'

I hope she doesn't think every engine tear down begins with farm equipment

Glad you guy's could make it out.

-

I'm thinking now I may have installed the distributor drive spindle slightly out.

Wolf doesn't care where the 'sync pulse' is relative to cylinder one. It can all be handled via the software. Just sequence the coils accordingly and the result is the same. The only real downside is when you disassemble things, you must get it back on the same spline or your timing will be off. On the other hand, if you start off with quill shaft clocked 'correctly', it makes it easier when it comes time for reassembly.

-

1

1

-

-

-

Can you charge them rent?

-

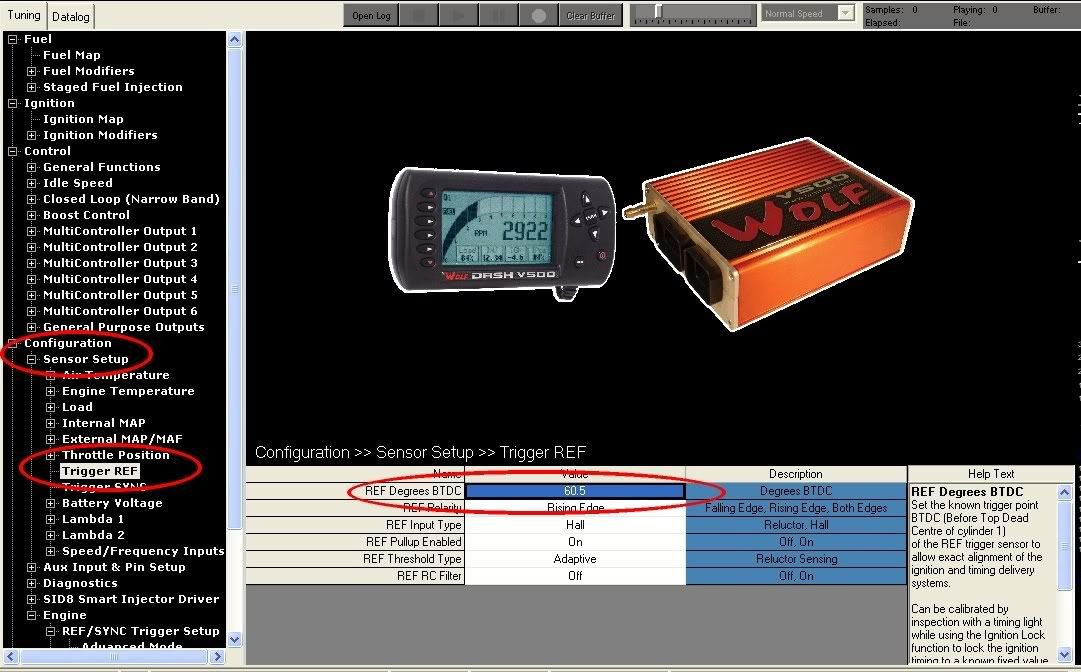

The V500 has been set up to use a CAS from an RB25 using all four wires plugged into it when the RB was installed.

Most likely using a plug in adapter. Way different config for that.

I thought they were virtually the same sensor as the L28ETVery similar, yes. I see you (or somebody) added a sync hole on the 280zx CAS. Is that how it was installed on the RB? If not, the config is wrong.

I'm assuming it's only using the low res input but I'm trying to find where you can setup the high res input in the Wolf software..

Don't. It won't gain you anything. The low-res will work well for you, as long as it's set up correctly. Email me your map, and I'll have a look.

PM with email addy on the way.

-

Thanks for the help and you were right! I locked the ignition to 10' and rotated the distributor till it could start and run (barely). Took a pic of where the distributor ended up before it could idle.

Looks like you'll need to adjust Ref Degrees BTDC...

Drop that number down until your timing light shows 10 degrees. I wouldn't go any lower than about 55 or 60 on a stock compression/street driven motor. If you cant get all the way 'there', you'll need to re-sequence your ignition, as Hugh mentioned.

Another thing, found a write up on installing the Wolf on the zed, and was told not to use the pin 30 but pin 28. When I do that,there is no signal. Using pin 30 which works for some reason?

You should be using Pin 28. I'm *guessing* the previous configuration was using both the hi-res and low-res channels of the CAS. If so, that needs to be corrected. You're using only the low-res channel, correct?

-

Chrysler did it in the 60's to give the correct U-Joint geometry. Seems like a similar Idea...

And the OE location for the L-series in an S30 is also off center

-

There are oodles of good starter books at common bookstores.

-

Do these things, in this EXACT order...

1) Verify timing.

2) Verify timing.

3) Verify timing.

4) Let us know what you find.

-

1

1

-

-

1 fast z, Just thought you should know the coward hiding behind the username "thatzguy" is Justin Hodges (280ZForce).

-

They do say they'll fit any 7" round traditional forward lighting application.

Justin Hodges, time for you to stop being an ass. You've been banned from this forum permanently. Take a hike.

-

Check fuel filter, may be plugged.

Filter was my first thought

-

Isn't that the turbo from Ron's 510?

No. Mine is bigger!

-

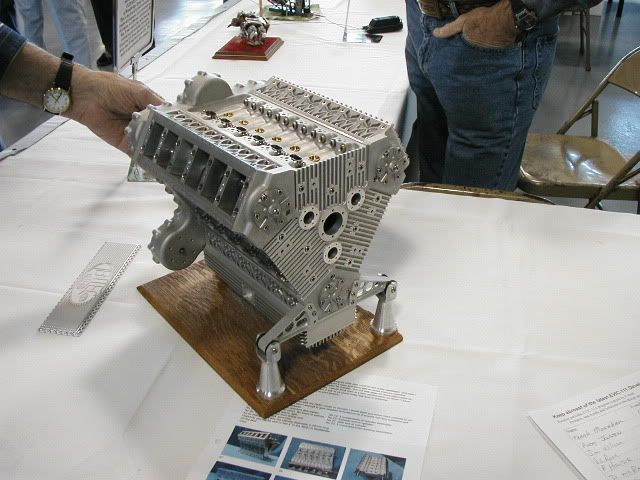

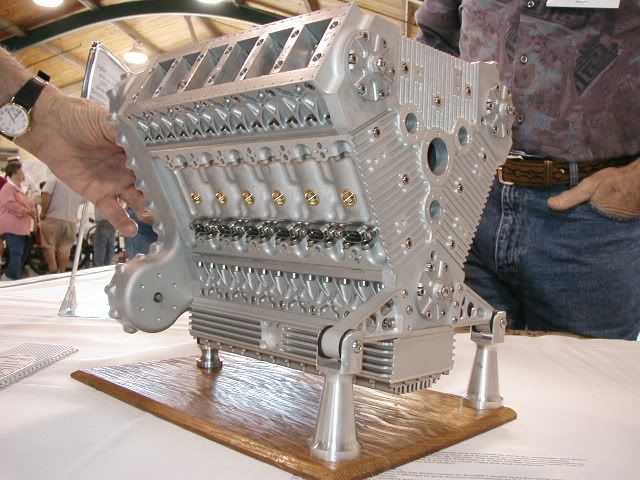

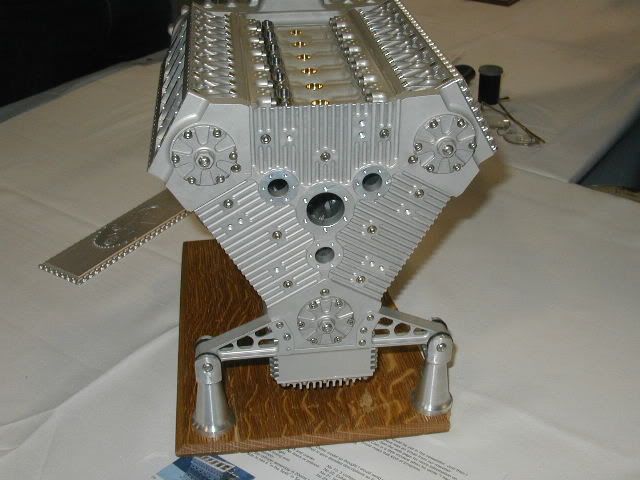

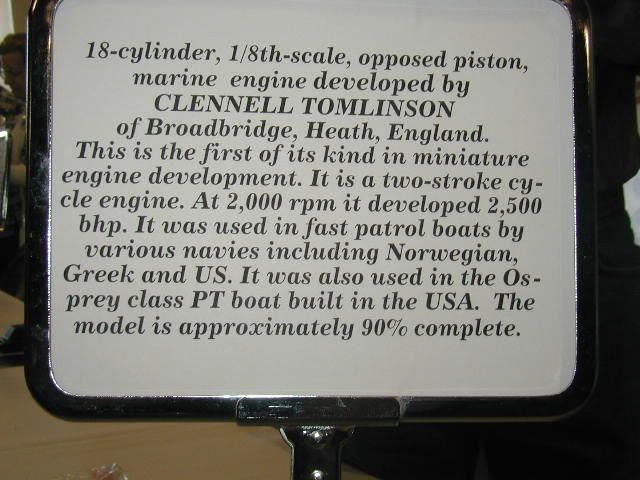

If you want an interesting scale model, get one of a Deltic Engine.

Scale Deltic, you say? Took these at the 2001 PRIME show in Eugene. 18 cylinders, and 3 cranks...

Forgive me for the thread jack... it's Tony's fault

-

Unless I'm forgetting something about the studs, it should be fairly intuitive... longer studs go where they pass through the cam towers, shorter studs where they don't.

-

There may be a term for this, but I can't remember it. The Peter principle?

If a person does a job well, they get promoted . This cycle continues until they rise to the level of their INCOMPETENCY !!!

They can no longer do a good job...and that's where they stay. Performing a job they are not qualified for.

.

The Peter Principle is the principle that "In a Hierarchy Every Employee Tends to Rise to His Level of Incompetence." While formulated by Dr. Laurence J. Peter and Raymond Hull in their 1968 book The Peter Principle, a humorous treatise which also introduced the "salutary science of Hierarchiology", "inadvertently founded" by Peter, the principle has real validity. It holds that in a hierarchy, members are promoted so long as they work competently. Sooner or later they are promoted to a position at which they are no longer competent (their "level of incompetence"), and there they remain. Peter's Corollary states that "in time, every post tends to be occupied by an employee who is incompetent to carry out his duties" and adds that "work is accomplished by those employees who have not yet reached their level of incompetence". -

that zx manifold is niceeee....

Can I ask what it looks like on the inside and why the rationale of using a zx tapered manifold over a larger non-tapered unit? (or is that super-secret?

)

)It was 13 years ago when I cleaned up that manifold. I used it because it's what I had

-

Welcome to the staff!

-

It just made me think that I' d better start getting some critical L6 engine parts NOW if I intend to keep driving the cars I have with the L6's every day. If I can't get good wear items, I'll have to drive those cars only on weekends.

Time to order some spare sets of bearings, rings and timing chain while I'm thinking about it...

Or you could Hybridize your car with something a little more modern

-

Well... the earliest Z's are 40 years old now.

-

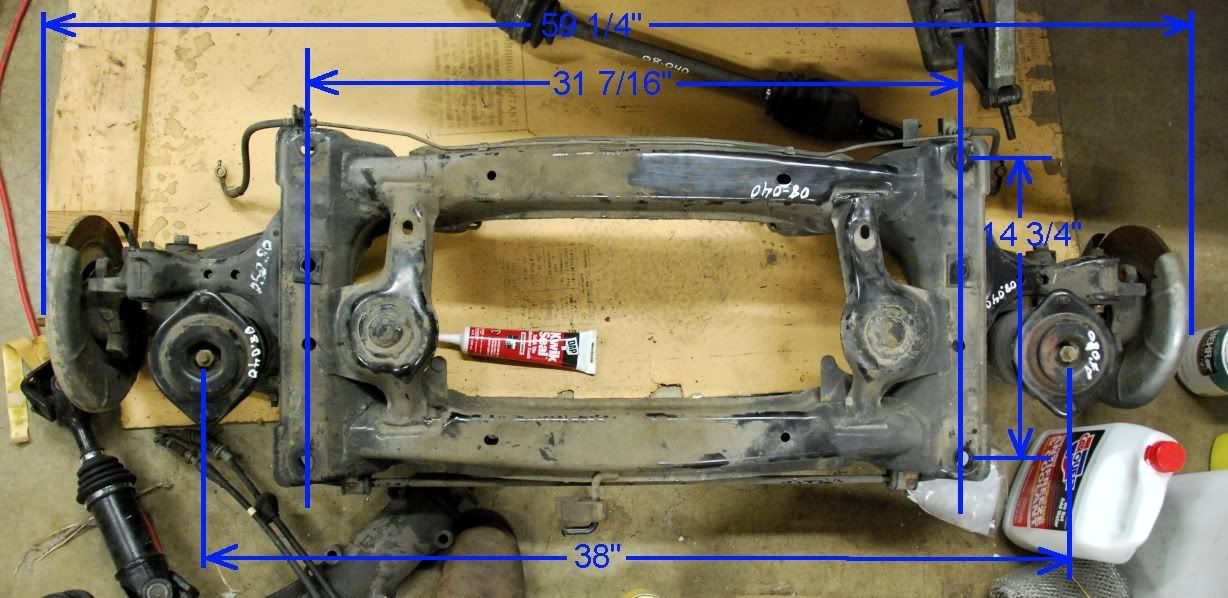

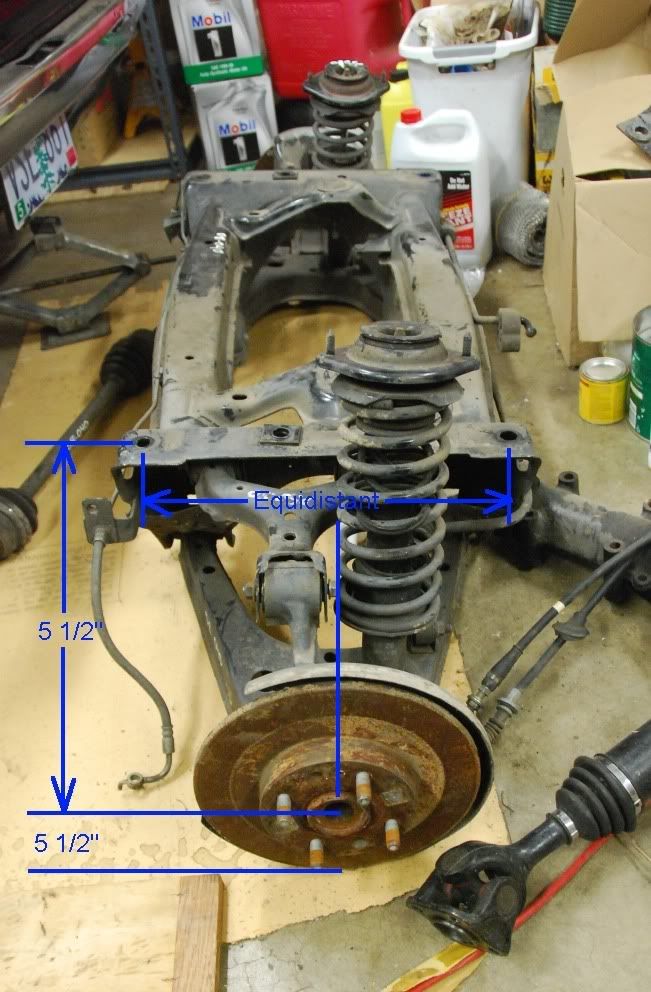

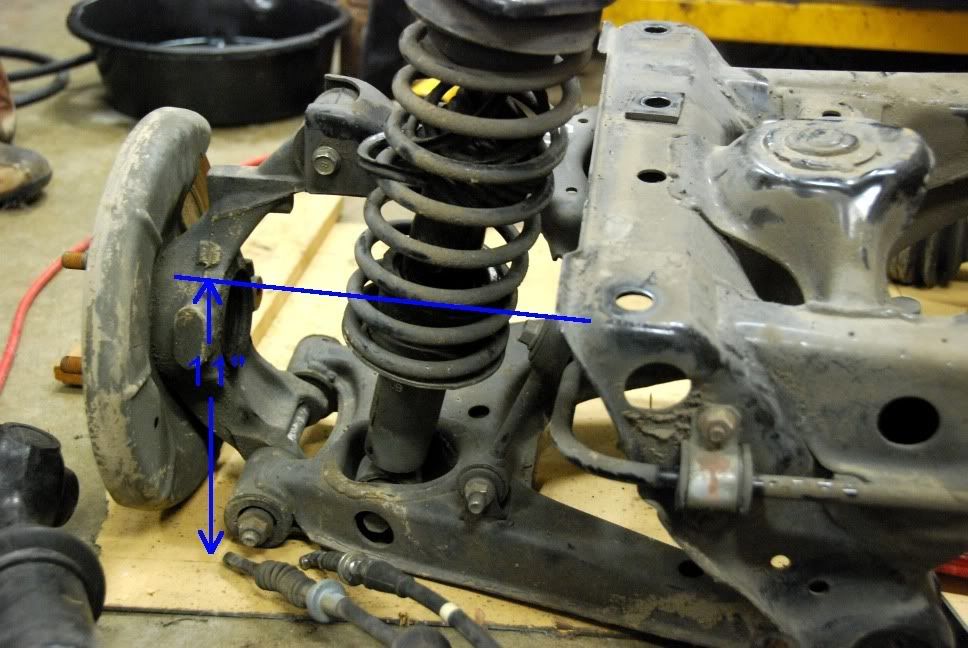

I spent some time with a tape and the mock up car. The conclusion is that it would take either a large amount of work to the chassis, or large amount of work to the subframe, or some combination of both. Briefly, the subframe is too long (front to back) and a little too tall. Also, the spring/shock location would require pretty extensive reinforcement to the unibody.

As with anything, it could be made to fit, but I think there are easier way's to get what I want.

-

Replaced the motor mounts with S30 parts and aluminum spacers. Not a permanent fix but they'll do until I find something that tickles me. In the meantime, the car drives MUCH better. From an NVH perspective, the only time they're noticeable is at idle. A little more of a resonant growl, but nothing I'm not happy to live with.

The more I drive the car, the more I'm liking the front end, and the more I'm disliking the rear. I'll be parking Bart before long... time to start making some decisions.

A few months back, a friend donated the back half of a Dime. Tipped up, it's in the perfect position for head scratching...

Neal (the gent that I bought the SR from) had a 1st Gen. MX5 rear suspension sitting on his garage floor and offered to let me put a tape on it...

These two are a little akward. There wasn't room to get 'straight on' pictures, but I think you'll get the idea...

A couple misc. pictures...

I've been interested in this suspension for a few reasons...

- Common/affordable

- Successful track history with DD friendly-ness

- Adjustable

- Tough enough for V8 applications

- Track width proportionate to the BMW front suspension

- Same wheel bolt pattern as the BMW front suspension

- Adequate disc brakes with upgrades readily available

- Factory available LSD's (both Viscous and Torsen) with complimentary diff ratios.

- Self-contained subframe construction

BUT... at a glance, it's not looking like it will fit without some fairly invasive modifications to the Dime. I'll sleep on it and take another look this weekend.

- Common/affordable

-

So you're the responsible party for Marc?! We need to have a talk out behind the shed

-

And I understand how saving weight on rotational mass is better for the car but all the fracture points seem to make it not worth it.

Your answer lies in post #4....

If you need the mass to dissipate the heat that you generate in the brakes, then cross drilling is a bad idea. If you don't then it is a good idea.Those "fracture points" become 'no factor' if the rotor is not thermally taxed, as is the case of the VW rotors I posted pictures of.

Dodge Engine in a 240Z - Can it be done?

in 6 Cylinder Z Forums

Posted

Is that the Mitsubishi 3.0?