-

Posts

2943 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

What manual trans are you going to go with for the VH?

Well, I can't speak for OTM, but he could configure his Wolf3D system to run the VH automatic... Paddle shifters just became 'easy'.

-

Key to any harmonic is to pass through it as fast as possible to minimise the chance for resonance.

I prefer to pass through all RPM's as quickly as possible

-

Automatic transmissions are good for 120K miles behind the 12 cylinder. If it hasn't already been repalced, plan on replacing it.

My son-in-law's tranny went belly-up under 100K (V8). Maybe a fluke?!?!

-

-

My son-in-law has a 740i. Its been temperamental since day one. I'm fond of BMW's... but not that specific model. It doesn't strike me as very representative of the rest of the BMW line, from a 'drivers' perspective. I much prefer the feel of the 5 series.

If you haven't driven a 740 yet, I recommend that be your next step.

Happy Hunting,

-

Now all I need is a second bathroom scale...

-

My pleasure.

Thanks for letting us know it worked!

-

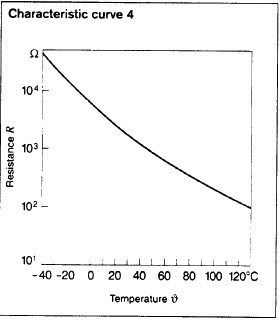

Bosch Part# 0 280 130 085.

Indeed there is an O-ring on the shaft.

Shaft dia., .468". I suspect a .484" hole (31/64ths) would be 'just right'.

Mounting hole, .260"

Temp range, -40 to +130 C.

.

.

Also, the calibration curve...

-

Unbelievable.

-

what do you think i should do change the cam or what i really think the cam the problem

Do you have a boost leak?

What's your timing like?

What are your AFR's like?

Is the motor in generally good health/tune?

Explain ♥♥♥♥ boost?

What is the sequence of events prior to the symptom?

Other relevant history?

Other mods?

Etc, etc, etc.

If you give us a thorough account, we stand a chance of giving you a thorough response. Cause and effect.

-

-

How does the Audi sensor make a seal if there is no pipe thread? Do you need to machine a hole, then drill and tap a hole next to it for the mounting screw?

I'm told there is an O-ring at the mating surface. I've been eyeballing that sensor for a week or so, and since I have no self-control, I ordered one. Should be here in a couple day's. I'll post pictures when it arrives for confirmation.

-

There is a plastic open element GM iat sensor. I came upon it in the intake pipe of an early 90's Buick. Seems like this would be the most accurate solution, regardless of placement. (and without having to find the curve on the Audi one.)

That's the sensor I frequently run across. I wouldn't be afraid to try it. Though not boost friendly due to mount style.

The Audi IAT curve wouldn't be that hard to come by methinks.

-

Some observations and opinion...

Early GM MEFI used a central plenum location.

GM abandoned that location years ago. Most GM IAT's seem to be either in the airbox or the intake tube upstream of the TB.

All locations are a compromise.

I'll agree that the closer to the valve, the more potentially accurate the reading, but its not realistic with current technology.

If your tuning is such that you can keep you're AFR's consistent with varying temperatures, you've won, regardless of location.

Transitional pressure changes shouldn't be an issue if the filter settings are correct.

The insulation idea, used in conjunction with a Bosch style sensor, might backfire... if its heat soaked long enough to bring the insulation 'up to temp', it will take that much longer for it to return.

I was looking at the Audi 1.8T IAT sensor and it seams very well isolated. Might have to snuggle up with it...

-

Congrats!

Shhhh, dont tell anyone... I've done the dance myself.

-

I can't really see how you could do the rod journals. Please enlighten me

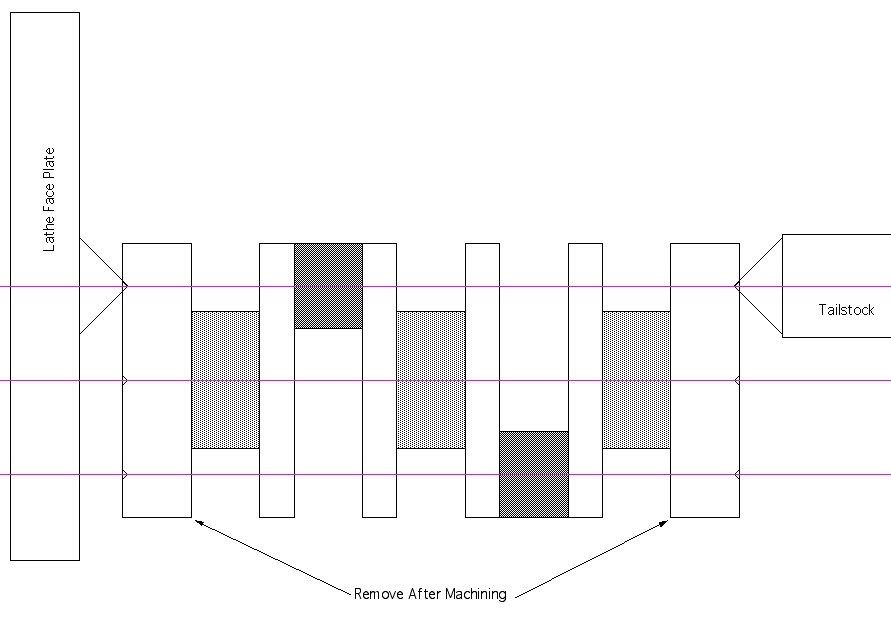

Machining is is like a lot of things... there are usually a number of accepted way's to do any one thing. That said, the below picture illustrates probably the most common way to machine the mains and throws...

In this example, three 'centers' are spot drilled on each end of the blank. Install a Faceplate and Center in place of the lathe chuck along with a Center in the Tailstock. Capture the blank in the Centers (with the Tailstock) and use a Faceplate Dog to drive it (usually Faceplates and drive Dogs come with the lathe). Now you have a means of rotating the blank on each of the three centers. Obviously it will 'wobble' when machining the throw's, but speeds should be low anyhow if using steel. Finally, part off the end cheeks when the mains and throws are completed.

Again, there are numerous methods to achieve the same thing... use your imagination

Hope this helps.

-

PM Roostmonkey, I believe he's building another batch.

-

I can't imagine trying to make a crank or a block with a mill with dial gauges.

I think building a small crankshaft on a mill wouldn't be much harder than a lathe. An upright rotary table with a matching 'tailstock'... and away you go. The biggest drawback might be finish quality, but I think a home-built crank polisher would wrap things up nicely.

Just my dos pesos.

-

We fully expect that to be completed and running by Christmas you know.

Christmas 2015?

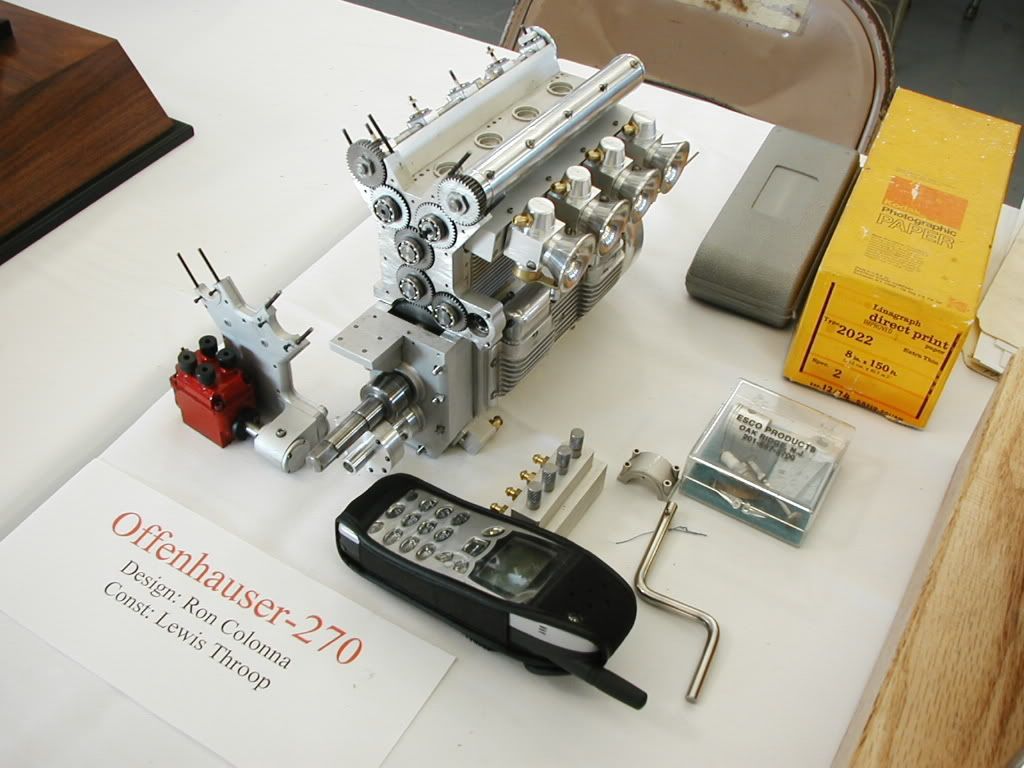

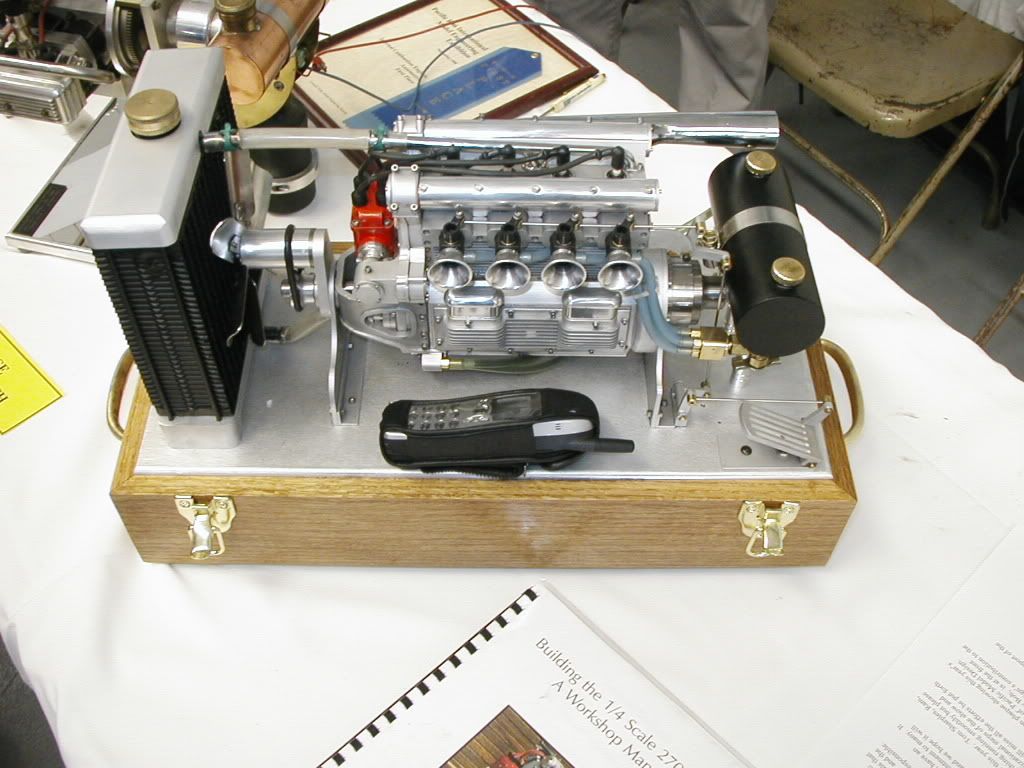

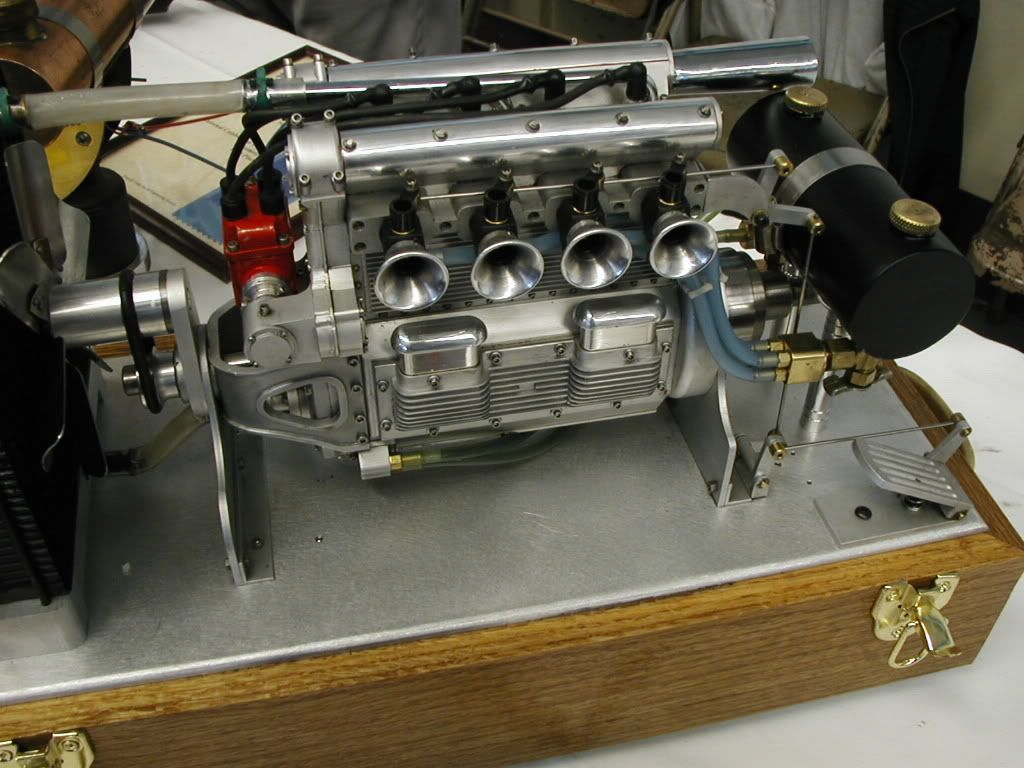

One of my favorites is the scale Offy...

.

.

.

.

.

.

I have the complete prints for it. I keep telling myself 'someday...'

-

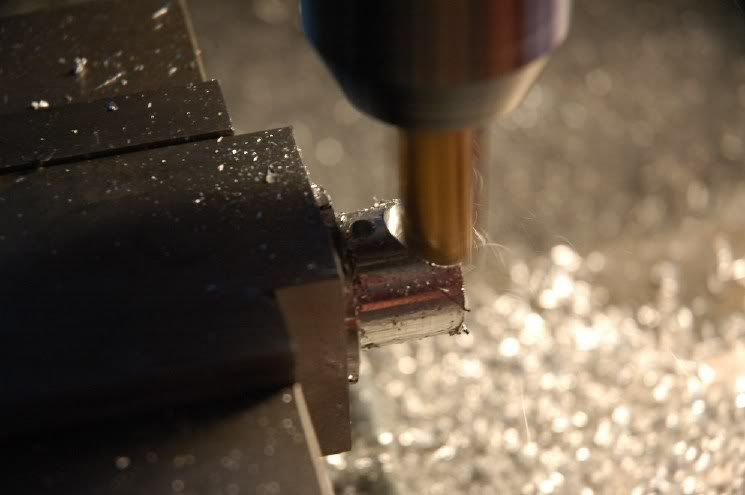

I introduced my grandson to machining over the last couple day's, as he seemed to have a sparkle of interest. The first project was a simple pair of spacers for SuperDan. They were perfect for learning how the machine 'moves', basic safety, cutting tools, and the thought process. He built a pair that were identical to within one half-thousandth on his first go!

Well then... time to graduate onto something a little more fun. We decided on a 1" piston. His work is an impressive first effort at any age, let alone 13...

Some in-process work...

Facing...

Grooving the ring lands...

Milling the skirt...

He insisted on valve reliefs

...

...

The Mad Machinist at work....

Finished...

.

.

I'm not sure which one of us had more fun!

He's already talking about building a conrod.... Its not hard to imagine where this is going

-

There are a couple alternatives listed here...

http://www.zccjdm.com/catalog.php?ref=azcarbum&recview=11&dt=43033&disp=name

-

If you have it tuned for stoich and then closed loop pulls it leaner it will cause some issues.

That's contrary to the OE's. They are normally tuned to 'fail rich'. I too share the opinion that closed loop should be pulling fuel, on a leash of course.

I'm curious what issues you have run into with this method?

-

I don't know what you're building, but google Lokar. I frequently use their products and have no complaints.

-

Hi, I am planning to do a sr20det swap in my 260z. If I go standalone ecu will I need all the cam angle sensor, ignitor chip, or maf? I am just trying to figure out what I need, so I don't spend more $$ than I have to.

It depends on which EMS you choose.

The Nissan CAS is a pretty good system, when used correctly... but not all EMS systems are compatible.

By "ignitor chip" I assume you mean ignition ignitor. Some EMS's will have them built in, but most of the high-end systems will not, to allow the use of the OE ignitor, 'x' brand, or CD ignition.

The MAF can 'disappear' on virtually all of the aftermarket EMS's.

Searching for videos of my third love and found this....

in Non Tech Board

Posted

Spence,

You hit one of my soft spots. Of all the cars I consider affordable by us 'average' folk, my two favorites are S30's and E30's. Here's a few shots of my own personal E30...

.

.

.

.

.

.

.

.

.

.

I used to have a number of similar videos... pre-hard drive crash. Fun cars to watch and even more fun to drive.