-

Posts

431 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by DuoWing

-

I figured I was probably good to go, but is there any reason why there's so many different posts and guides telling you to have the distributor shaft inline with the distributor mounting holes? Even in the older FSM with the 11:25 positioning, the picture still looks pretty similar.

-

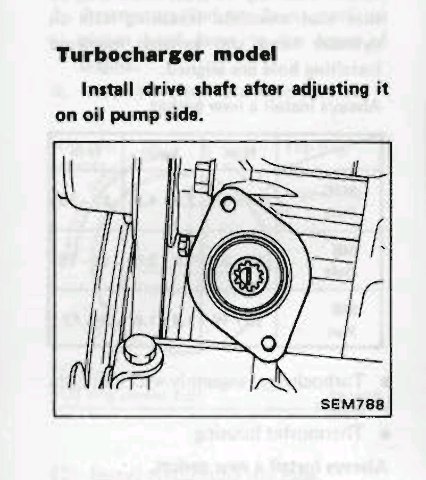

After a long time of not touching this thing I'm trying to get back to it and actually get this car running well. While I prepare to get my MS setup installed I saw a post by Chickenman about phasing the distributor rotor so I decided I should do that as I build my harness. I've never had an issue with being able to set and adjust timing with a light and a distributor, but I figured I should check the alignment of the shaft. This is an 83' Turbo motor. It was pulled apart and freshened up when swapped into my 76' Z. So I'm trying to figure out what the actual positioning of the distributor shaft is when the motor is at TDC. I've seen so many posts, different things being said for the alignment, etc. I have the timing mark lined up with 0* TDC, I've verified the cam lobes for cylinder 1 are both pointed up. FSM: My Shaft: I saw another post by Chickenman which had a picture looking just like mine. I'm thinking I'm fine since my shaft matches the drawing in the FSM, but I figured I'll ask here and see what the consensus is.

-

I'm about push this in a lake..Plz help!?

DuoWing replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Was the temp sensor replaced by you or the previous owner? Also was it the temperature sensor or the temperature sender for the temp gauge itself? This sounds really similar to the temp sensor being bad. Also I'm not sure if the 280z did it, but I know with the ZX up over a certain speed or it might be RPM the car goes into open loop where it reverts to just using the ecu programmed fuel maps and doesn't really use the sensors. Years ago my turbo ZX was running awful, but if I really got on it or on the freeway when you're cruising at over 65 (3-speed auto)/higher RPMs I'd suddenly notice the car ran really good. As soon as I went back under it started running rough. Reading through the FSM I found out about it using closed loop under lower RPM and open loop at higher.- 13 replies

-

- backfiring

- high idle

-

(and 1 more)

Tagged with:

-

This thread sounds exactly like what I need. Especially considering you can even buy one of these civic driers for about $10. The only concern I have is, would this be too small of an amount for a surge tank, or it really shouldn't matter?

-

I'm considering the Phantom 200. I like the placement, but how do you ensure that the pump stays in the fuel in that location, or is it adjustable in such a way that the filter and pump can be vertical even when the bracket is horizontal? Nevermind, I didn't realize this was a later 280Z tank. I've never seen one, and didn't realize the sender is actually on top.

-

So I ordered the T3 Rear Lower Control Arms to put on my 280z forever project. Anyway I got them installed loosely, and I didn't tighten down the bolt and nut because the car is currently not going anywhere, but I see how I have a lot of space between the rod ends and the mounting point at the bottom of the strut. Is there an additional bushing that goes here, or do I just install the washers/shims in this space? If I'm installing the shims, does anyone have the order I should put the shims to end up with stock alignment?

-

Techno Toy Tuning - GTX2 Control arm and T/C Rods

DuoWing replied to ktm's topic in Brakes, Wheels, Suspension and Chassis

I've been searching around trying to determine what to use for my front suspension. I was thinking of going the stock style T3 control arm and t/c rod, but this set does come out a bit cheaper. I would like to track my car a little at some point, but primarily would just be street driving. Would there be any reason to go for the stock style ones over the gtx2 set? -

This is something I'd definitely be interested in. So with this you would just need the brackets, the calipers, and to re-drill/bore out the rotors?

-

I'm looking to do the conversion to the Z31 Turbo CVs and I wanted to see if anyone has a set of the companion flanges and CVs for sale. Let me know. PM or e-mail: duowing@gmail.com Thanks.

-

Techno Toy Tuning R230 swap kit with long nose R200?

DuoWing replied to DuoWing's topic in Drivetrain

Yeah, at first I was looking at it from a savings stand point. Then I put more attention to it and realized I wouldn't be saving that much overall. I was looking at this vs. say the billet stub axles and the wolf creek cv kit. So they'd come close in price, but almost be better to just go this route as so many more advantages in the end. -

I've been searching around and trying to find some information. I tried e-mailing T3, but perhapsperhaps I wasn't saying what I wanted to properly. Would it be possible to take portions of the kit and do essentially the CV, later wheel bearing, hub, and brake conversion while maintaining the original long nose R200? From what I understand is that as long as you swap a LSD intended for an open diff 240sx you end up with the same spline count as the S30. So I would assume you could also grab those axles. I guess you'd still be looking at a pricey conversion, but you'd be able to maintain the stock driveshaft, moustache bar, etc and switch to coilovers while moving away from the stub axles. Is there anything about this that I'm missing or that might not make this work?

-

As asked is your pump mounted in the stock location? These pumps almost need to be mounted low enough to be gravity fed by the tank otherwise they will sooner or later start complaining. Do you have a filter between tank and pump? This can cause the pump to complain. One big thing that I've found through JeffP's posts and my own experiences is that using the stock wiring and stock relay is not advisable. Any aftermarket pump needs to be pretty much upgraded to bigger wiring. Using the stock wiring I was experiencing a very hot relay and a 1v drop from relay to pump once warm. Part of what I did was get one of those 70amp relays they use for the electric cooling fans and upgrade to 10 gauge wiring.

-

I'm still looking for one of these if anyone happens to have one for sale

-

Akira, sent you a PM

-

WTB: 76-78 280z R200 Companion Flange/Pinion Flange/Yoke

DuoWing replied to Akira's topic in Parts Wanted

I came across this thread and I figured instead of start another, I'll throw in that I'm looking for one of these as well. I'm looking for second/middle pinion flange in the above pic to mate the diff to the driveshaft in my 76' -

I'm looking for the throttle body off a L28ET. If anyone happens to have one up for sale let me know. I'm located near Cleveland, OH. E-mail: duowing@gmail.com or PM me. Thanks!

-

Quick question I figured I would ask. I bought a 37/64 drill bit and drilled out my cold start injector hole so I could tap it for the intake air temp sensor for my MegaSquirt setup. Well I got all that done, but I see there's not really a whole lot of actual thread area for the sensor to grab. Anyway I can thread my sensor, and it doesn't seem to get tight until it's pretty much all the way in. I took a little 3/8 npt plug and although I didn't go all the way with it, it seemed like if I wanted to I could just keep on threading it all the way through til it fell out. It never felt like it got tight like you normally get with NPT threads. I don't know if I have a bad tap, or I did something wrong or what. Can I still get a decent seal? I haven't tested it yet, but I got the thread sealer that I used for my fuel rail, made sure the sensor and threads in the intake were clean, then threaded the sensor in and out a couple times to really work the sealant into the threads then hand tightened it and gave it maybe a 1/4-1/2 turn. So we shall see. I'm not sure if this is something anyone else has run into? I think I realize what I did wrong. I ran the tap til it pretty much bottomed. I didn't realize you're supposed to actually stop a lot sooner to provide the taper. Hopefully the sealant will allow an actual seal?

-

I came across this thread through some searches and there's some good motivation for my Megasquirt build in here! Anyway I had a quick question about your injectors and manifold, I see you bored the injector holes out for the EV1 injectors. I've been planning on using the 440cc Bosch Green injectors which from what I can tell look almost identical, just a different color. Anyway, are you still using the nylon spacer that sits between the O-ring and the end of the injector? A quick test fit seemed to show that the injectors would fit if I removed that spacer similar to what I had to do with the SVO injectors.

-

The only way I'd say go the stock harness route is if you can get it all for really cheap and just need the motor to run. Otherwise I recommend against it. It can be made to run decently, but I've struggled so much with rewiring and fixing things just to get it to run decently.

-

Hey guys I recently swapped in my 14mm pallnet rail and my brown top SVO injectors. I resized the injectors in NIstune and the car seems to run and idle decently, but it does seem to be rich so I'll have to play around with the settings, but I was wondering if anyone happens to know the latency at 14v for these injectors? I've been searching all over and I haven't been able to find that particular information. I know a few people run/have run these so maybe anyone has some info?

-

Hmm I guess I read wrong, for some reason I was under the impression that if you were seeing pressure in the tank it was correct. My old 280zx always had that pressure release whenever I'd go pull the cap off at the gas station. I also could be misunderstanding, but it sounded like with what Tony wrote above that there should be the pressure on the tank to help with the pump and cavitation, but maybe with just an open vent line where it should have been hooked to the canister I'm possibly issues? Maybe I need to see if I still have the charcoal canister and throw that in and try that? The canister has never been hooked up since I did my swap. My pump only seems to become loud after a longer drive. If it's a nice cool day I may never have the pump become louder than being a little audible in an enclosed garage. I actually need to check and see if I'm still dropping fuel pressure once the pump becomes loud. After mounting the regulator directly to the rail I'm experiencing what a few others have mentioned. The fuel pressure reading on my gauge seems to sit very steady vs. the rapid vibration/fluctuation I used to have. I don't know if this will make any difference to the fuel flow and recirculation in the system or not.

-

This is an interesting topic and maybe this is the reason so many of us have the loud pump issues? I live in Cleveland and we get our share of hot days every once in a while, but not often are we above 85-90. I've tried so many things to get the pump to stop being loud. Swapped my walbro for a bosch 044, mounted it horizontal, then mounted it lower in relation to tank outlet. Then I found the relay getting hot, swapped that with one of those big 70amp fan relays and ran a dedicated 10 gauge wire from maxifuses in engine bay to relay then directly back to pump. 10 gauge ground from pump to the grounding spot for the taillights. Saw a huge decrease in voltage drop while hot and the relay only gets warm now. Pump still will get loud on hot days. I always found where my pressure would drop at idle on a hot day after doing freeway/on-ramp pulls vs. just cruising around town. Anytime I pull the gas cap on my 76' even right after running I will have a big pressure release which sounds right. I was talking to a friend who mentioned a similar thing, possibly run a fuel cooler on the return line. I may try this next.

-

I found this thread when I was running into the same problem. I've never had much luck with the sealants. Perhaps it's just me. On my original pallnet rail I just used JB Weld as recommended, but later on regretted it because now I can't change the fittings. When installing the barb fittings onto my old professional products fpr with female npt threads I tried sealants that were rated for gasoline and could not get them to seal. Finally I just used the tape, tightened it, and voila it sealed first try. I assembled my new 14mm o-ring rail with permatex thread sealant with ptfe and it seemed to be good. When I finally was going to take the car for a drive I let the car idle for a bit and very carefully inspected and found leaks. I found this thread and took everything apart, got that permatex thread sealant that shows it's recommended for fuel fittings. I cleaned everything nicely with brake parts cleaner, put the one fitting with the sealant in hand tight and tightened it about 1/2 turn. It seems to seal just fine. The other side with the regulator attached didn't seem to seal at all and leaked worse than the first time. Although this time I wasn't running the fitting that was supplied with the rail I was running the anodized black earl's 1/4npt to -6 an fitting so it would match the other fittings on my regulator. This fitting seemed much lighter and cheaper, so maybe the fitting was partially at fault? Took it back apart, cleaned it up nice, ran my harbor freight 1/4 npt tap through the rail threads, and ran the original pallnet fitting through the die and they both went through nice and smooth. Cleaned it up, put some more sealant and bolted the rail in, hand tightened the fitting, then did about 3/4-1 turn. Ended up having to put nearly another turn on it to get the regulator to sit where I wanted, then I pressurized the rail and so far see no leaks, so hopefully I'm good to go. This seems like a really good thread that everyone should see. Also one thing that came to mind, would the fitting that is carrying the weight of the fuel pressure regulator potentially need more tightening than the other side which is just your standard hose barb?

-

Reading through this thread makes me think of an issue I encountered the other day. I was wiring up my autometer tach to my 280Z and I ran the white wires for the backlighting to the factory pin for the green/white and a separate ground. I put everything in and it doesn't work. I look at the FSM and the harness I had and the green/white wire was in a different location in real life vs. the diagram. So either someone had messed with it or it's some kind of discrepancy. As for the ranger pump shutoff switch it's funny that was mentioned because just the other day I got in my friend's Mazda Rang...B2300 and I managed to knock that switch while getting into the passenger side.

-

84-87 Turbo ECUs will not require will resistor packs. The 88-89 ECUs will require inline resistors. The 86-89 ECUs all use the smaller Titania resistance based O2 sensor, but for the most part any of the ECUs will run fine without the O2 sensor connected.