ktm

Donating Members-

Posts

1725 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ktm

-

Run three is the best. The problem is that that torque scale on the right changes between run 2 and run 3. On Run 2, the scale goes up to 400; on run 3 the scale goes up to 500. They both fall off the same; as a matter of fact, run 3 is a bit flatter since I am able to hold 1.5 psi more boost at the higher RPMs, thus helping the curve not to fall off as fast.

-

I decided to hit a Dynojet before I leave later tonight on my two week vacation. I always wondered what my car is putting down to the ground now, especially since I've added methanol injection. I am still tuning and the runs show it. You can see where I am misfiring/hesitating in the runs. I kept pulling fuel and it was getting better, with the last run the best. I was still hesitating some, but not nearly as bad. I will say that I was NOT running methanol these runs but rather ethanol. I ran out of methanol yesterday and supplemented it with ethanol. I know I can make more power with methanol, maybe even hit the big 4. So far I am pulling 20%!! of my primary fuel map when injecting ethanol, as well as adding 5 degrees of timing from 2 psi up to 20 psi. The operator did not detect any signs of knock while running. I am also running on a 95 Octane blend (California Craptane 91 plus 100 octane) I am running 20 psi, but you can see that I am bleeding off to 15 psi. The last run I held up to 17 psi. The operator and I think this is caused in part by the rich mix and the hesitating. I have a GM type boost control solenoid that is set to drop duty cycle with RPMs to counter the bleed-off, but it is not apparently effective right now. Lastly, the ONLY thing I did between runs was pull fuel across my map under boost (when injecting methanol). I gained 10 wft-lbs and 10 whp by simply pulling fuel. Onto the runs. I apologize for the large picture, but you can compare all three runs side-by-side this way.

-

Slow Old Car, clearance for one. try welding a NPT bung on there and see if it will fit.

-

I am simply using braided in this case for appearance given my engine bay. I like pushlock as well and run some of the fittings for my vacuum lines. Goodridge has a nylon-esque type of braided product that is much easier to work with than braided SS. You get the same benefits without the chaffing issue.

-

Paul, I am running the 7MGTE (Supra) 440cc injectors (11 mm o-ring). I simply used the stock lower o-ring and the 11 mm o-ring at the rail. I do not know just how deep the injectors sit in the manifold. The top of the lower o-ring is flush with the injector body, that is, they are as deep as they can go. The 7MGTE injector "pintles" are not very long, not much longer than the depth of the stock lower o-ring. Six Shooter, I know the old saying, but you gotta start some place.

-

Mine came with the engine, a 1983 L28ET. I would venture a guess that any L28E or L28ET from 1981 to 1983 would have one (basically any 280zx).

-

That's odd. I am running the same later model thermostat housing and did not have a single issue.

-

What seriously unequal runner length? The manifold runners are about equal in length. What you are looking at is the equivalent of the "downpipe" of a single turbo application. The "seriously unequal" pipes connect to the exhaust housing after the turbine.

-

Paul, it was already too late otherwise I would have done exactly what you described. My car actually stalled out due to the errors and I had to pull off to the side and shut her down. I waited 20 seconds and she fired right back up and did not do it again on the way home. I went out shortly after I posted and did a 30 minute drive with the laptop connected. I blasted through all the gears, held 3000 RPM or thereabouts for as long as I could, etc., etc. and I did not ONCE get an error. Maybe it was just a rare synch error.

-

Paul, good to hear. I just started having this issue....I think. I did not have Wolf hooked up, but it was acting exactly like what you described. A short cut-out, car nose dives, kicks back in and wham! drive-line shock. This is the first time I have experienced this on the 5.03 firmware and it occurs right around 3000 rpm. To date I have never experienced this on this firmware version. I am going to go out a little later with the laptop connected and see if I can duplicate the phenomena. I am running the modified CAS as well.

-

Yasin, the added length is insignificant. I posted pictures of my setup here and on Zcar when I first routed it, and there was a debate on both sites as to its "effectiveness". Look at it this way, if your IC has an inlet and outlet on opposite sides, you need to get the air from the turbo to the IC inlet. My lateral distance across the engine bay is the same as those routing it behind the radiator. Now, you still have to get it forward to the IC. Again, my longitudinal distance is damn near the same as routing it behind the radiator. My transitions are MUCH smoother. I am not running all 90s; my setup is 90 out of the turbo to the oil pan, 70 from here up, 70 again pointing to IC inlet, straight to IC inlet, 45 degree from outlet to TB. Check the turbo forum for my first post about this setup and you will see the debate. Edit: Here is the link

-

Its an internal pump? Is there a screen on the pump? You want to filter the gas before it enters the pump. Your two filters after the pump are overkill, you don't NEED one after the pump, but having one after the pump is good insurance. You do NEED a filter pre-pump and I am assuming that your internal pump has one.

-

I am using the exact same intercooler as well. I was limited by dimensions too and wanted something that would fit exactly between the two large openings in the radiator core support. I've been very happy with its performance to date.

-

Digger, when I received my upgraded ECU I simply swapped it with the old one and the car started right up. Saying that, I have gotten noise and synch issues once or twice, but a quick power-off reset cleared them. I have not had one in a few months. Does this happen ALL the time, or was it just the once? Have you tried to slowly rev the engine past 2000 rpm and see if it occurs? Are you sure that you did not move any wires or expose your signal wires? What are you using for your trigger reference? Have you shielded this line from the trigger to Wolf?

-

Paul, a tip about screenshots. Hit your Prnt Scrn key with Wolf up. Open up MS Paint, Edit -> Paste and it will paste the screen shot. This can be used for any desktop screen shot you want. I don't use Wolf to datalog but rather my Innovate LMA-3 aux box. I log RPM, EGT, MAP, Meth Pressure, and IAT. My MAP and EGT signals are VERY smooth compared to what Wolf logs. Unfortunately, all of my logs were on my work hard drive that crashed and may be unrecoverable. I'll post a screen shot of an older log I have on my personal desktop later tonight.

-

I am running the 75 version software along with the latest (O2 enabled) firmware.

-

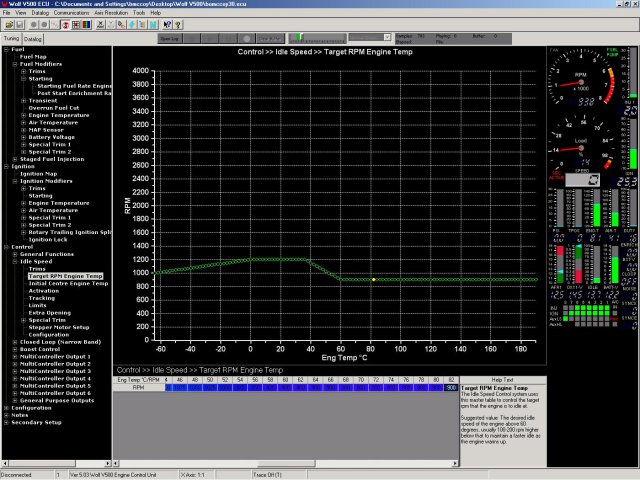

Paul, Following are my settings. I actually got the ICET to respond to my changes dynamically, but it takes a few seconds for it to respond. I would make a change and it may take 10 seconds for it to implement the change. I am still adjusting my settings, but so far so good. You are correct about setting ICET values as I read that exact same thing. I adjusted everything on the ICET table first before turning on Activation to stop the hunting. When my electric fan kicked on, the RPMs would drop, you could hear the solenoid increase, RPMs would climb over my target RPM and then drift back to the target RPM. Activation and Tracking are for your warm idle conditions only. I enabled tracking and have the following settings: Activation LIBR: 600 LAAR: 610 HABR: 1500 HIAR: 1510 ABTP: 2.1 IATP: 2.5 Tracking TDRB: 100 TNRB: 200 TNS: 20 TFS: 12 TRS: 0 TSS: 1

-

Correct. I am not referring to the TPS but rather the butterfly valve. I was out experimenting some more tonight and I got it to idle fairly steady at 900 rpm. I experienced a little bit of hunting, but I think I may have tuned it out.

-

Paul, Second question: I have a 240sx throttle body with an idle set screw. Should I let the idle solenoid control my idle speed and back out the screw, or should I keep the screw set and just use the solenoid as a cold start feature?

-

Paul, Thank you! I figured it was either Engine Temp Centre settings or Tracking. No matter what changes I made to the settings, the PWM solenoid kept on trucking and the engine would not change its idle RPM.

-

Sorry to hear about the incident Phil. I had the exact same thing happen to me in January - an older lady in a Lexus was blasting through a parking lot and did not yield, clipping my right front corner and taking out the headlight bucket and my new Kaminari air dam. I swear, our cars must have been separated at birth...... Good luck with the repairs!