-

Posts

397 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by z240

-

-

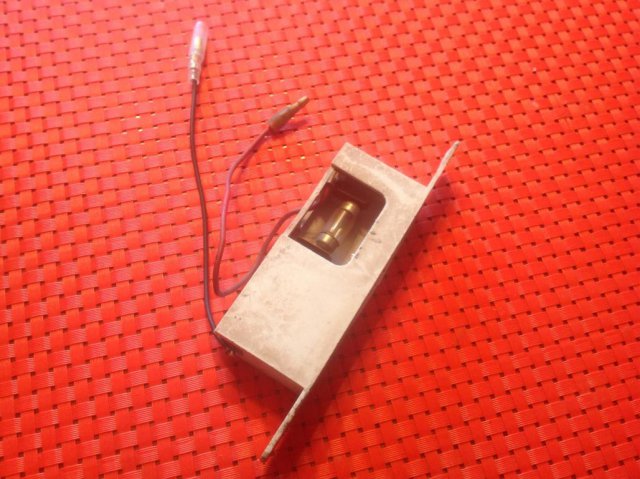

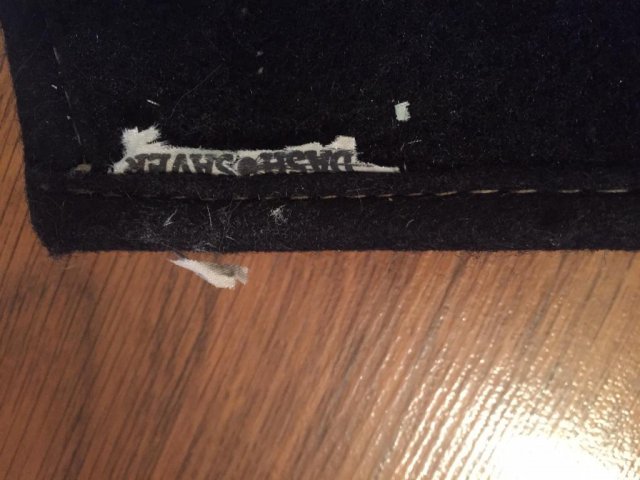

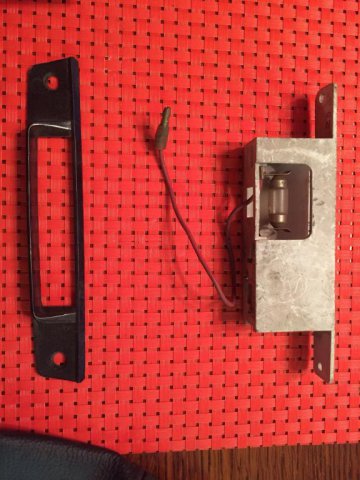

Pictures! Map light is missing a ground lead. I'll attach a brand new black wire with correct OEM bullet terminal. Shift boot has a crap cable tie at the top and no leather shoe lace. Otherwise it's new, not used. It is real leather. I can do $100 USD including shipping (postal) for everything.

-

I have a new dash toupee that I thought I'd never find a home for! Excellent Just gathering parts now. Will have pics a few minutes.

-

Got most of those goodies except the plate light. Dang hard things to find in good shape, aren't they? Question. Dash mat, do you mean that toupee/thin rug cover thing that just sits on top of the dash? Is that what you mean? Let me get some pics together. Drop me a line to z240@shaw.ca.

-

What year? The 77-78 cover is quite a bit larger than the earlier ones.

-

There is torque spec to check that rotation tightness. It's not very tight, you can turn it easily by hand, but it feels nice and stiff and smooth. You cannot make it spin free with a flick of your wrist for example. I think of it as the feel of a really old high end stereo volume knob. It feels like the knob weights about 10 lbs. Does the rotation have tight and loose spots? Shouldn't. First obvious question is did you remember to put the distance piece (that spacer pipe) in between the two bearings? Were the bearing seats perfectly clean so the bearing seat dead square? What torque did you tighten the big nut to?

-

All is good as is. Nothing to remove from the control arm.

-

I'll bet the tiny hole has a tiny bit of buildup/plugging that's causing the off axis squit. I'd want to clean those holes.

-

I'm not exactly close, but I have one for you if no one closer responds. Let me know at z240@shaw.ca

-

Haven't seen many "cross the block" lately here or on the other forums in the last few months. Does this equate to increased rarity and increased value? or not popular anymore? Hard to say. Post it for $2000, then lower the price by $100 every two days until someone bites. Give us the sale price and set the new standard.

-

Regardless of how you measure it, if the gap really is 1/4-3/8 then one or both covers are beyond help. I'd like to know how make that much of a warp without cracking something. No amount of lapping or grinding or whatever is going to give you a servicable cover.

-

Check the parts micro fiche and see if the part numbers are different. http://www.carpartsmanual.com/datsun/Z-1969-1978/body-260z-280z

-

280z rear lock nut thread pitch

z240 replied to rickyellow zee's topic in S30 Series - 240z, 260z, 280z

20 x 1.5. Pretty sure.. The big set of metric tap and dies from Princess Auto has the ones you need. Whole set might be less than buying a single die from a tool supplier.... Yup, just went out to check. 20 x 1.5. If you end up needed a stub axle, let me know. 240 or 280? -

MSA has decent reproduction new housing/lenses. $269 for a complete pair. Not crazy expensive. I have a decent RH lense I think if that's better for you. Send me a note to z240@shaw.ca and we'll discuss

-

I have a couple of early (no holes in spokes) and late (holes in spoke) style stock wheels that are available. Drop me a note to z240@shaw.ca and we can discuss further.

-

72 240z Identification Help Needed Rear End Clip/Fastener

z240 replied to TBOS2K's topic in S30 Series - 240z, 260z, 280z

There are no commercial suppliers of that clip that I've ever heard mentioned on any Z forum. Your going to need to find a donor car and remove one by cutting the spot weld. I currently have the same problem. -

That might be the most inspiring story of perserverance I've ever read. I would not hit that thing 50 times hoping it "might" move. Might have been easier to drill it all out. Anyway, congrats on beating it. That is definitely a "Stage 5" pin removal. Congrats!

- 9 replies

-

- spindle pin

- how-to

-

(and 2 more)

Tagged with:

-

Generally good information here. Couple of points to help those with stubborn windows get them back in shape. First, it is not necessary to remove the outer winder frame (sash) to get the glass out or in. With the outer squeeze trim off, the glass easily comes out the outside of the frame. You have to have the front vertical guide track off and the short guide track loose. Second, the cause of many difficult windows to roll up or down is caused by excess friction in two key places. One is in the front guide track where the white nylon bar that is attached to the glass frame runs in. The grease tends to harden in there. That white nylon bar is often cracked or broken. Replace as needed. Second is the other end of the glass where the back of it slides in the felt that is inside the window sash section that is in the back of the door. The felt or u-channel lining (can't think of its official name) can get bunched up. Remove or replace. Some grease in there helps the glass edge to slide as well. Maybe equally third are the tracks where the three wheels on the regulator run, (two on the glass, one on the door). These can be caked with stiff old grease and dirt. Clean and re-grease. Now all this friction makes folks wind that crank really hard, and it gets worse and worse. What results is the arms of the regulator get bent, which really makes the whole thing bind up even more. Remove the regulator, the glass, straighten the reg arms (each of the three metal arms with the wheel at the end are supposed to be dead straight and parallel to each other (except where they cross of course). Make them so if not. Remove all old grease from the guide channels, replace with anti-seize or something thickish that will stay in place. Re-assemble and you're off. Getting the glass back in the trick. Most important thing is you will note that one 240 glass, there is one glass roller channel that has only one end where the roller can go in, that end has to go on first, then do the rear one. Hope this helps. Working in the doors is no fun, but be patient, you'll get it.

-

Front spindle thread pitch

z240 replied to rickyellow zee's topic in Brakes, Wheels, Suspension and Chassis

18 x 1.0 -

To settle this, the micro fiche shows that all Z's from 73-08 (ie ALL 260's) to the end of the 280's have the same pedal box. 73's (up to 73-07) have a unique one compared to 70-72 240s, as the master brake booster increased diameter and the spacing between the brake and clutch master expanded to accomodate it. http://www.carpartsmanual.com/datsun/Z-1969-1978/brake/brake-clutch-pedal

-

Since the dashes in the 260 are the later 280 style, I'll bet the pedal box is 280 as well. Look under the dash where the steering column bolts to the dash. If there is two 12mm headed bolts, it's 280. If there are four bolts, its 240. Those bolts actually attach to an extension on the end of the pedal box, the dash is just sandwiched between the column and pedal box with those bolts. Then you can be sure what type of pedal box you need. You actually only need the clutch pedal and its pivot bolt and return spring. The big auto brake pedal can be trimmed to reduce it, or you can change it for the manual pedal. No need to remove and replace the entire pedal box since that requires the dash to come out.

-

As mentioned above, there are at LEAST four distinct harnesses from 70-73 alone. The 73 harness is the most different, especially at the harness junction point under the right side dash. The others are far more similar, but still, there will not be a single replacement harness possible that will do without comprimises or custom adapters that will fit all 240's. I applaud the effort, but you should get at least one each of the various harnesses and decide on a way forward that serves the biggest audience. I think you might concentrate on the engine bay harness first, since most damage I've seen is with that harness due to exposure to heat moisture and location. It's also the place where there are the fewest year to year differences.

-

There has never been a replacement found or discussed for those. They are part of the regulator assembly, and yes, they are usually split, gone or both. I've had the "pleasure" of working on many windows, and have no concern about running without those backing disks, the rollers seem to be fine without them as long as they are well greased, including the channels in which they run. I'd think their main function is to snug up the fit and run in the channel, but as long as you use a fairly thick grease (I use anti seize) they won't rattle and will work just fine.