rejracer

Donating Members-

Posts

422 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by rejracer

-

Option 1: heat the head, aluminum expands faster than steel. Try and rotate it out by using a sharp punch. The force of the impact will also help loosen the bolt. If it helps grind small dimples into the ez out to have a point to Option 2: If you can weld another bolt to it, do it. The steel weld will not stick to the aluminum. Be reasonable with the welding, preferably welding up so the melted bits fall down, not into the hole. Option 3: Very carefully grind the ez out with a small dremel size grinding stone. Buy lots of stones, expect to spend silly amounts of time, and damaged threads when you're done to get it out this way For what it's worth, this is the most effective style of bolt extractor I have ever used: http://buy1.snapon.com/catalog/item.asp?P65=&tool=all&item_ID=10523&group_ID=1262&store=&dir=catalog

-

You can test the switches with an ohm meter. Connect your leads, put the meter in beep mode, then sit in the drivers seat and go through the gears. The meter will tell you when it's switch is closed.

-

I would go with the lower gears with a t56. The gearing on the T56 was originally with with lower diff ratio's. What did the doner car have in it? What do you intend to do with the car? In choosing gears, it's best to set your highway cruise speeds with the differential ratio, (assuming a fixed high gear ratio), and choose the transmissions 1-3 ratio's from there. Since you are past the planning point as far as transmission gearing, what are the transmissions ratio's? if 6th is .68 go for the 3.70s, if it's .5 then go for 3.90's (or lower). I build a speed / RPM calculator for just this purpose. You might want to check it out: Speed - RPM Calculator

-

I just highlighted the columns green that you can change (when you download it locally) and that will update the columns in yellow / orange. If you want a new transmission in the template, just send me the gearing, and of course the model of trans. If it's a common trans with different gear sets, indicate what vehicles it's from. I'll be glad to throw it in the master for you.. ...and my final choice on transmission was the FS5W71C with 370's out back for the time being. I may try and change out the 370's to 3.54's depending on how I like the feel after the turbo conversion. -robert

-

Hey there Hybrid, I made this spreadsheet in excel a few years ago to help me relate what different trans/diff combos would do to shift points and highway cruising speed. I just uploaded it to google docs. You all should be able to read it. The spreadsheet basically contains all the transmissions I was considering for my 240 as well as every possible gearset out back. Every line in it is a calculation, so if you change one parameter, it affects how the results. To change the parameters, change the "variables" section of the doc. It will calclulate the MPH and MPH in gear columns. Hope you find it useful. https://spreadsheets.google.com/ccc?key=0Ato3KCDX86aedFBpTkI0X0o5R2pQaHlrQzgzbGVrQXc&hl=en&authkey=CPTj89IN -Robert

-

Hey Bill, Remember when you helped me set the ride height on my car, specifically the points we measured from? I would measure from those points to determine if the car is sitting level. If the car is still on jack stands, the front or rear may be higher than it normally would be, thus throwing the measurement from the diff/trans to the ground off. Good progress. From what it needs, sounds like the trans needs to come up 2.5 degrees and the diff down .5 degrees to give you 1.5* equal. I found a good thread on the angle bit: Driveline angle I have a laser pointer, if you want we could make a jig to mount it to the back of the trans or front of the diff for a visual comparison if you think it's helpful. -Robert

-

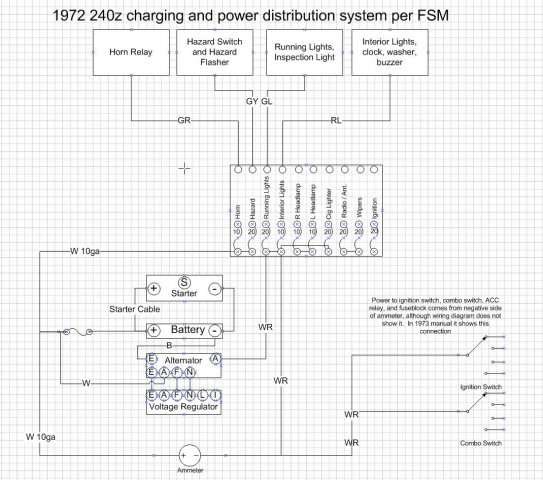

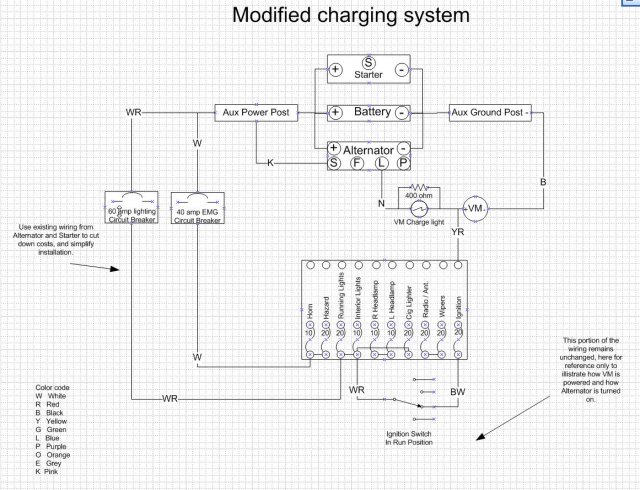

Hey there hybrid. Attached are a couple of wiring diagrams I made up. The first is the OEM setup from a 72 USA Z. The second is what I am doing to it. So far I have got as far as getting the alternator installed and functioning. I am using a 200 amp Alternator from Alternatorparts.com which does away with a lot of unnecessary wiring. I still have the ammeter installed, but it's essentially out of the loop as the original wire going to the alternator is not connected to anything at this point. The purpose of reconfiguring the charging system is to enable a higher output alternator to be safely used, replace fusible links with circuit breakers, and replace the ammeter with a voltmeter. Instructions: 1. install aux power and ground posts. I will install them below the battery tray on a fabricated bracket. 2. Make new battery cable assemblies, each cable assembly is to connect the Battery, Starter, alternator and Aux Posts. Positive and negative cable assemblies should be made out of 2ga cable to all devices. I made my own 3. Install 40 amp circuit breaker to aux power post(APP) and APP to fuse block using white wire.to power Horn and Hazzards 4. Install 60 amp lighting circuit breaker to APP and Circuit breaker to WR wire originally connected to Alternator to power Running and interior lights. 5. Bridge ammeter connections together, remove as much of the wire as possible. Ensure ignition switch and combo switch retain power. 6. Install volt meter. Wire the existing fuel gauge YR wire, jump it to the + side of the VM and the + side of the VM charge indicator lamp. From – side of the VM, run a new brown wire (18 gauge) to the L terminal on the alternator. From the – side of the charge indicator lamp, run a black wire to the Fuel gauge/VM sending unit ground. 7. Install Alternator, wire up new Alternator connectors. Enjoy

-

I would ditch the MN47 for the P79 or P90 head. The chambers on the 47 and 79/90's are very similar, plus you don't incur the added cost of putting in the larger valves. With the lower compression ratio of the P79, it will provide additional reliability. If you do go with the MN47 make sure you get the smallest piston to head clearance as possible this is where detonation resistance will come from.

-

I think he is referring to the splash guard plate. HCS01, that thin plate between the engine and trans is not structural. It's more of a splash guard. There are only 4 bolts that hold a L series engine/trans together. If you wanted to bolt the lower portion of the plate to the trans you can do so. An 8mm bolt would work just fine. Another option is if the engine you have is a later block, and is machined for the braces CGSHEEN shows pics of you can use those instead. If you have an earlier 5spd you will need to drill and tap the holes in the trans bell housing. I currently have a 75-76 N42 block, and it's not machined for the engine to trans brace. My old 79 5spd was not drilled for the braces either. If I were in your situation, I would not worry about it, the lower brace is not needed. The transmission tail housing, If there is only 1 ear on it (used for mounting exhaust hangers) then it's an 81-83 5spd. based on the picture, it looks like you have an early block (no holes drilled/tapped on the bottom of the lower mounting ears). If that's the case you cannot use the braces shown in the picture above.

-

A buddy of mine bought me one of these. When he brought it over, we spent the next 15 minutes comparing it to my car. Surprisingly accurate for the price.

-

Mark, Increasing timing at lower revs/loads will decrease boost response. What is happening is the exhaust gasses are burning more completely in the chamber. This is a good thing from an economy standpoint. Since the gasses are burning in the chamber (and not in the exhaust manifold), they are losing temp as they exit the chamber. It's this loss in exhaust temp that you are feeling. Have you monitored egt's before and after the timing change?

-

My recollection of the cannon manifold ( I have one with 40 DCOE-18's ) is that the bar that runs between the manifolds is hollow. I was still concerned about this not being enough for the brake booster, so I thought running a vacuum manifold with 6 vacuume lines to each runner would be a good idea. I never implemented it, and went back to SU's. I'll deshelve that project when the turbo conversion is done.

-

I would not use 304 on the fan mounting, or anything requiring strength. 304 is brittle, and weaker than a class 8.8/grade 5 bolt. Stainless will not take the flexing that a class 8.8 bolt will. For this reason, it's unsuitable for applications requiring long term strength. Either MMS is selling you class A-2 / grade 18-8 or has the specs on non-automotive classed bolts wrong. http://www.ssina.com/view_a_file/fasteners.pdf Actually there is a bit more to it than the above. 304 comes in 3 varieties: 304 Tensile strength: 90ksi ( 1 Ksi is 1000 psi) 304-A Tensile strength: 75ksi 304-SH Tensile strength: 125ksi c 8.8 Tensile strength: 120ksi c 10.9 Tensile strength: 150ksi (this is class 10.9 for reference) http://www.boltdepot.com/fastener-information/materials-and-grades/bolt-grade-chart.aspx At best, these are weaker than the OE, as I believe the OE fan bolts are class 10.9. It's fine for most the non critical stuff, but I would not use them on the fan mount. There are stainless specification that are stronger than class 10.9, you just have to find the right ones. So don't give up if you're set on stainless. Just beware, the stronger stainless fasteners are extremely expensive. I use a lot of stainless, and the price on this kit is excellent. I think I might buy one, but only if I can get the heads I want. I like the allen drive stainless heads, especially the pan head style, they polish up very well. Happy wrenching.

-

You have the Maxima N47. With flatops that's a great street n/a motor, if you get the quench and tune right. The non maxima N47's do not have the head temp sensor boss between port 5 and 6 on the plug side. a couple of good threads, (in the sticky's) that's worth a read: http://forums.hybridz.org/index.php/topic/39134-big-and-nasty-headwork/ http://forums.hybridz.org/index.php/topic/62691-l6-heads-pics-and-descriptions/

-

Update on this old thread. The rack for the turbo car was in worse shape than the NA car so I rebuilt the NA rack. it leaked like a sieve, so I ended up buying a rebuilt rack from Rock Auto. It's worked fine ever since.

-

Evapo rust is the best/safest rust REMOVAL product on the market. It completely removes rust, not cover it up or seal over it. So far I have used it to derust the inside of engine blocks (on running cars!). I bought a turbo car a few years ago and it had sat for 2+ years with plain water in the block and no radiator cap or upper coolant hose and not thermostat installed. I flushed the cooling system using the prestone products it would work fine until I revved the engine up past 4k. Then heavy rust scale would plug the radiator, it did this 3 or 4 times. After one treatment of the evapo-rust I never had a cooling system related problem again. I was surprised at all the debris I would get out of the system. With the old evapo rust solution I dropped in a pair of old fencing pliars my father found at our house when I was a kid. They were prob buried for 30 year when he found them. As a knick knack he kept them in the garage. I threw them in the treatment and left them for a week. I was able to get them working again, and the amazing thing is how smooth the action is on them is to this day. I plan on using the stuff on my car when I get into the body work. Evapo rust works by stealing the oxygen atom from Iron oxide, leaving just a iron/carbon coating on the metal. A quick wire brush off an your are then down to bare 100% rust free metal. When the rust removal is complete, the metal has a black coating on it which is easily removed with a wire brush/rag or something of that nature. After the rust is removed then you can prep and paint/coat the metal as appropriate. http://www.evapo-rust.com/

-

Bill, I forgot to give you the metal plate before I took off, have not forgot. I would get that plate replaced with a heavier gauge, I don't think it will seal long term. I'll get the metal to you this weekend, then we can make one, once you decide on a thickness. The heavier steel will weld up much nicer, and without the warpage. My understanding of the components in order as the fuel would see them. sock filter to protect the pump pump main fuel filter fuel rail pressure regulator return to tank keep up the good work Robert

-

I see what you are doing now.... You must get matching : throwout bearing collar Fork rod ...and I am not sure about slave cylinder, but I assume so because the newer style has the spring inside. I have a 72 myself, and I prefer the adjustment that's available. Edit: I'm all mixed up... I am trying compensate for the different pressure plate, not the slave cylinder. when I replaced my slave cylinder years ago, Napa sold me a later unit. while it's almost correct the newer style does not nave the eyelet for the 72 fork return spring. I still used this, but I ended up making a bracket to attach the spring to on the slave side. Other than that it works just fine. Edit to the edit: Since you are wanting to replace the fork, rod and slave there will be no problem with the hydraulics. I am running on a stock master and a later slave, and I have plenty of pedal travel. The slave cylinder will work with either fork, just make sure the older slave cylinder has the spring inside like the zx's do. I don't know if it would work, but if yours does not have the spring, you might get by with a few bucks by just buying a complete rebuild kit for the 83. I just wanted to make it clear that the forks are different, but interchangeable, so long as you get the newer rod with it. The older forks have a larger hole for the rod to pass through, and are thinner metal than the later units.

-

go to www.RockAuto.com look up the part for a 72 then click the manufacturer's part number and it will list all the vehicles/years it works with.

-

73 240 round top carb swap HARD TO START

rejracer replied to 5 Star Rising's topic in 6 Cylinder Z Forums

I find the following reference to yield the best results with minimal tools: http://www.gerull.nl/mg/technics/carb/carb_tuning.html -

Ryan, http://www.loctite.sg/sea/content_data/93755_Loctite_660_Quick_Metal_Retaining_Compound.pdf Check the stuff out. I've never personally used it in this application. Downside would be next disassembly is more difficult. -Robert

-

Well we've heard of suicide bombers. They are just upping their services rendered, and now offer suicide shooters. A fairly well thought out solution to the problem.

-

In the Scotch variant of whiskys I would have to say the Glenlivet 18. Others I have had: Johnnie Walker blue, green and black. I did a blind taste test between the blue and green with some friends, and all of us were able to identify the blue over the green. Glenfiddich - it's ok, but I don't care for the peaty taste. I read the above whisky bible and saw one from the Isle of Arran. I was there in 06, but it was a rushed trip. I would have loved to tour a distillery. I do prefer Irish whisky over most scotch, they have after all, been making it a few hundred years longer. My favorite is Jameson's irish gold. Jameson's also has a nice 18yr blend. Above whiskey though, I prefer a good tequila. The spectrum of good to bad in the realm of tequila is much wider than it is in whisky. imo tequila is much smoother, has a far more elegant taste. Just don't get the cheap stuff.

-

The downside to the 14" wheels is the limited tire selection available for them. All the tire manufacturers have moved on to 15" and up sizes.

-

That is a good deal, assuming they are not bent, or corroded on the inside.