-

Posts

994 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by rayaapp2

-

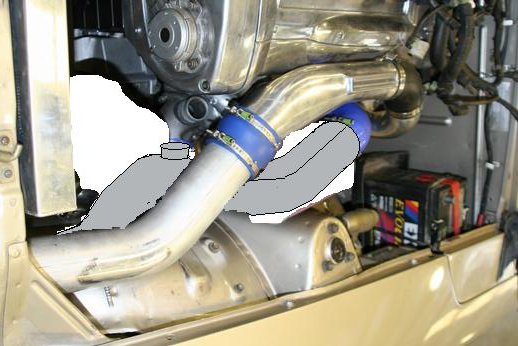

You could have a local shop put something together that resembles the top twin turbo pipe along the bottom that collects the 2.5" into a single 3"-3.5" pipe and run it under the current IC hot pipe to the front into a nice filter. like this Personally I went with 3.25" intake piping for my RB25det. A good shop can weld that thin wall aluminum and come up with the proper bends without having to bend them as they can usually only be ordered in pretty standard angles. Saves room in the engine bay. Allows you to run the bigger piping. Then route it to the front and get yourself a AFE filter for a diesel truck. If they can flow and hold up to a turbo flowing at 30-50psi then it can survive your twin turbo 2.6L.

-

Those all appear to run the MAP or D-jetro style systems. No MAF sensors. If you are doing the same thing why dont you collect the 2 together near the front turbo and do a single filter element near the front or out to the front? Check out the single turbo piping kits like: and see the collector? It may not be usable but it could give you ideas. I found a local place to do custom aluminum piping and had all mine made up for fairly cheap. I assembled it after they fabbed it up. That is if youve gone the MAP sensor way and dis-guarded the MAF sensors.

-

Some people run dual pickups and pumps in parallel for certain applications. Depending on how they are routed it could be that one has a return or can be used as a return. + 1 on the RC Engineering Injectors. Ive been happy with RC injectors on 2 of my cars and one for many years now. Personally I also would recommend the Bosch 044 fuel pump over the Walbro 255 unit any day. Costs a little more, but seems to actually work as designed and last longer that way. Again just my personal opinion. And as rossman said "3) Yes and you need to flare the tube". I made that mistake with my tank when I first put the AN stuff together having never messed with Aircraft/Navy fittings before in my life. Make sure you flare it... or it leaks and/or comes apart. Wish I had, had that advice.

-

If you neck down right off the TB to like 3" and immediately take a 45* turn then I think you can. I have seen a few do it this way. Personally I prefer the larger diameter for throttle feel and large displacement of air column behind in front of the throttle plate for response. Everyone has their opinions though. I rubbed/beat out part of my inner fender well and used a large 45* coupler to make the bend.

-

it measures 107.89mm too... Ill have to straight edge it and blast first before it goes to the recyclers. It was free after inspection so no big deal. I may have a can of that 'pink' stuff around to check it now that I think of it. EDIT I just came up with a better idea if this head is toast. IF this head is ape raped then its the perfect place to experiment with porting and such.

-

Story: So I just picked up a spare E31 for my L24 build. It was on a complete motor in a complete car that looked like it sat on the coast to long without a bath. So I had the owner pull the valve cover and both manifolds so I could pull the head when I got there. As Im loosening up the last head bolt I notice a valve on #2 is hanging half cocked in the spring. I look over at the owner and say well its got 1 bent valve, but I was able to get all the head bolts loosened without breaking them off in the block. I shove a 1" piece of wood down the font, pull the timing chain off, and take out the head bolts the rest of the way. I was able to get the head loose from the block with very little effort. Once the head is off I can see valve heads in several chambers along with some bugs/spider creatures. After propping the head up for inspection I can see that all 12 valves are bent to some degree and that 3 valves have lost their heads. #2 chamber has some biffing near the spark plug threads. Question: So I dont believe there is anyway to bend all the valves like this unless the cam was 90 degrees out in either direction. I didnt even bother to set the engine up at TDC when I pulled it apart to check the cam, because the cam chain and tensioners looked pretty toast to me(even though I stuck a piece of wood down to prevent the tensioner from falling out). I really dont see how this could have run. Is there anyway that the cam could have been off 90 degrees and the starter could have bent all the valves enough that 3 of them lost the heads? In fact two of those broken valves punched holes in their corresponding pistons. What I am worried about is that the valves were in there and could have seriously damaged the head. Im not a head guy so here is question 2. How do cracks form in these heads? Could large metal chunks make cracks or is it mostly a heat issue? Im aware that the head will need new seats and guides, but I was planning on N42 valves with newer style seats and guides(to get away from additives in fuel and oil for the originals). When I get the sand blaster and wash tank going Ill know more about its current condition, but for now I thought Id give you guys a poke at it. Ill get pics up in a bit.

-

BankockZ is running the same MC as me without the booster. He says it works well and doesnt mind not having power brakes. He has a N.A. L28 with minimal mods though so he isnt pushing the power that I am. He did not connect the system up like I am doing though. He is running a 240Z with the distribution block still so he has one of the front fittings blocked off on his MC. He is already aware of how to connect it 'properly' and says it works fine the way it is. The faster you go though the more you realize that the brakes need to be tip top... or your dead.

-

I replaced the front mount. The mustache bar had worn bushings esp on the drivers side. I have a set of energy bushings for it on the way, but in the mean time I have it mounted with R200 top and bottom bushings to keep it secure. It doesnt clunk like before so I assume its tight for now. I knew I was going to have to take it back apart. I had to drive it yesterday so I made sure I had it temporarily band aided. All I can think of is that the pinion shaft must have enough play to oscillate at a certain speed. It wont be together like this for long. All I can say is I dont know how track drivers get around corners with a setup like this. As much as the local track drivers rage about welded difs being better for track use, but unusable on the street goes I dont believe it. My other Z has the clutch LSD in it and its far superior from what I can tell. The more traction I can get down from all four tires the better. I did not expect to run the welded one for very long, but dang. I can feel a loss of traction even in high speed cornering. So I guess in the next couple of weeks when I get a chance to put the bushings in I will be setting up the gears as well.

-

sigh, Well then there must be another issue at work here. Oh well I didnt pay that much for it. Thanks John

-

So I blew my old 180 out not long ago. I found this R180 with 4.11 gears in it and a welded carrier. It was dirt cheap so I dont mind if there is something wrong with it. When I get the car up to speed it howls from the the new rear end when I am on the pedal. When I let off the pedal the howl goes away. By howl I mean loud howl btw. So my guess is that I have a Nissan Pickup 4X4 front differential that has been welded and the reverse cut gears are making the noise. The seller wasnt sure what it came out of, but it felt like there was very little play in it before I installed it. It had a little play, but much less than others I have seen. So now Im curious if reverse cut gears would howl like this and there isnt something else more serious going on? And if it does have reverse cut gears then where does that put me with this thing? Its gotta come back out again when I get the new carrier anyway, but if the gears are reverse cut then I have to wonder about loading and on the back of the gear teeth and such. Ive seen Datsun guys install those reverse cut gears in prety much stock datsuns without much of an issue. I never heard of them making a howling noise before, but it would make sense to me that they would. Should I be on the hunt again for correctly cut gears in 4.11 if I want to put 200ft/lbs of torque out the rear? Thanks for input guys and gals Ray

-

Maybe Im not reading any of this right and it was already properly answered but, You need a plenum port. I do not know how the RB26 was setup from the factory with their different manifold, but Im sure it was simply plugged into one of the rear runners behind the TB(engine side of TB). I have a brake booster from a GTR with the check valve installed still. So with your current setup you would do the same thing. Get 'manifold' vacuum from the plenum behind the TB. Run a check valve between the booster and the vacuum source. Almost any Nissan check valve will do. Id dare say even the stock 240Z valve will work as I have ran them with L28et's and my RB25det. Just verify it only goes one way(flow towards manifold) and you will only get vacuum to the booster and not boost. As for a vacuum canister Id say you dont need it. Ive never used a 240Z booster with one of these engines, but the stock 260Z and 280Z boosters will hold enough vacuum in them for your braking. The only way your going to run into a vacuum issue is if your double footin it and hard. Where you would want to install a vacuum reservoir is in an application which doesnt produce enough vacuum in the first place. Engines that have radical cams(or no throttle body), or something that needs a constant source of vacuum like HVAC systems in which most cases get a dedicated vacuum motor. You can if you like, but seems like extra weight to me from what youve stated.

-

Found this and thought it could be useful to this thread. BMW M & S motors in order

-

Everything is internal on this MC. Thats why I can delete the older stuff. I have larger brakes already on the car, but I will be going bigger as soon as I can. This MC is the same used in the 300ZX Z32, Q45, and a few others. This is a common MC used by the 240SX groups. Its actually widely available here in the US. I ended up with this unit after a friend parted his GTR front clip. I discovered I could use it by accident. I believe and I could be wrong but this MC was used on Non-ABS equipped cars. There is actually extensive information about it from the 240sx groups installing them into their cars. So there are actually diagrams for converting your old ABS system to this style MC. A few guys from down under have from what I can tell done exactly what I am doing as well. So I am not the first. Now that is the MC. The Booster unit isnt the same as the Q45 for sure. I have one for comparison. Im not sure if any of the other Booster units will fit in place the way this R32 GTR unit does. This unit literally bolts into place into a 240Z without any hangups. Ray

-

So Ive opted to use this: in my 260Z. It deletes all the extra 36+ year old devices attached to the brake system like the proportioning valve and NP valve. The MC bore is quite a bit bigger than the stock 260Z as well. I also have the matching booster. It came out of a BNR32 GTR. It bolts right into a 240Z, but not a 260z unfortunately. So I was working up to the point where I would install this, but Ive been forced into it now. My stock booster died today. Im not buying a new one. If you look closely you will see that the MC has 3 lines coming out of it rather than 2. It has two lines for the front L and R and one for the rear. So I need to replace the driver side(left) line completely to the strut. The right front and rear lines need to be replaced up to the NP valve. Here is where I run into an issue. When I pull the NP valve from the bulk head from behind the motor I will need to connect the old brake hard lines to the new brake hard lines. One would think that someone makes a coupler for this, but I cannot seem to find it. I can find T fittings and other odds and ends but no couplers. If Im not mistaken Im looking for a M10X1.0 double flare coupler. I would think Summit racing or someone would have something, but I havent been able to find anything that will work with these double flare fittings. Anyone have any ideas? Please dont tell me that I should just use a different MC or something like that. Id just as soon replace the complete brake line system first with something new that I know wont hassle me any further.

-

240Z vs 260 & 280 Z pedal assemblies

rayaapp2 replied to rayaapp2's topic in S30 Series - 240z, 260z, 280z

You totally jinxed me... My brake power booster died this afternoon. I suddenly had hard brakes and was almost killing the engine at idle because of the vacuum leak it created. Murphy strikes again. You know that booster has lived there for like 36 years without much issue. Ive replaced the MC, but as far as I can tell the booster has never been replaced... Despite the FSM stating that certain internal parts should be replaced every 2 years, certain other parts every 4 years all inside that thing it lasted at least the past 11 years Ive owned it and the previous 20 before that by the the Meth-head PO. The Original owner(aka meth-heads dad), maintenance the car well and had all the papers since new on it. I guess I now have to make up 3 new brake hard lines and buy/find hardline inverted flare couplers somewhere. Not to mention now I have to drill the bulkhead for sure. LOL I guess Im ready to put some large vented rotors up front. Someone got like $4800 in cash they wanna donate to me so I can get my CCW wheels and some nice 315mm tires so I can clear said vented rotors? Oh wait I gotta fix the brakes first... but seriously Ill take donations -

Yeah, I try to make sure there is no one anywhere near the car when I execute such things. I was really expecting one of those half shafts to have broken loose, and that would have been the scary part for me. It turns out my gear fluid was slightly low. I got just over a quart out of the rear end. I believe it should have been around a quart and a half. The fluid smelled and looked good though other than the broken bits. I guess I should have done a fluid check on the car. I kept up on all the other fluids. Somehow I over looked that diffy.

-

Found a R180 4.11 on the cheap. Problem is its got a welded carrier. So Im going to have to buy a second R180 stock 240Z unit and cannibalize the carrier to get back on the road. Hopefully the 4.11's work out well as Im just guessing at this point. I have a feeling I may not be happy on the highway anymore, but thats really okay since this is not a daily driver. anyway cheap pics via phone, cause I know all you really wanna see is carnage.

-

From my observations Federal S30 chassis would have no Cat. The hood says Non Catalyst on it and there wont be one underneath. I have seen them like this through 1978 280z Federal models. Id guess that they would go by the under hood emissions label not plate information. I really need to take that sticker off my own 260Z hood as the hood was from a 76 donor and has all the emissions label info for a 76 Ca car... that may actually get me in trouble at some point briefly, I am unsure. Anyway on that label it will specify 49 state compliance or compliance in California. That is the key as far as I understand it. This information is available on all cars on the emissions label here in the US. Im not sure when they started doing this, but I assume it was early off in the mid 60's under one of the early mandates. Now here is the catch, Any vehicle that has participated in the Ca smog program has already been labeled as one or the other. Its part of the input at the time of the initial smog. Once its in there its in there. The information is used to determine emissions criteria for that car at the time of the smog. I know they keep that information for at least 6 years, but I do not know what happens beyond that. 1975 and older may not even be in the system anymore, or at least I do not have access to that information through a smog machine.

-

? Whats the problem? The series 2 wires are almost identical to the series 1 wires, they just have a different connector/s. Follow Chris Rummel's page up in the stickers and sort out the wires you need. The only problems your going to run into is the ignition power circuit for the series one is deleted and one of the other wires is the wrong color, but can be traced to the ECU pinout for verification. I would suggest removal of all the extra wires that use to run windshield wipers, headlights, etc. that happen to share the harness to narrow down what you need. If you need a detailed wiring schematic I can host if you can make heads or tails. It helped me out, but its for a series 1.

-

Highly recommend not messing with the stock 81 CAS. The 82 and 83 CAS can easily be supplemented in its place. To answer your question though you can simply bolt the bracket and CAS back in place. Leave the lock nut loose, attach your timing device, and adjust the adjuster nut until you get the desired timing. You do not have to rotate the engine to TDC for this install.

-

Ignition Switch Starting Circuit , Turbo Timer install.

rayaapp2 replied to rayaapp2's topic in S30 Series - 240z, 260z, 280z

Well thats Brilliant! And I already have the starter on a a relay... Thank YOU! -

Ditto, that is exactly what you will see if the engine mounts that go between the rubber isolators and the engine block have been installed on the incorrect side. In stock form the engine is setup to lean to the right side(as viewed from drivers position), but if those mounts are backwards it will lean the engine over at an exaggerated angle to the left. Make sure the mounts are not identical or something odd like that and that they are re-installed on the correct side. Perhaps someone has pictures of the mounts that can post them here for you? If they have them already marked L ad R that would help the guy out as well!?

-

I am running the same exact setup as above, and before that I had an open 3.9:1 r200 and I must say I liked the 3.9 gears better. Not to totally thread jack but RB26powered74zcar are you using the stock speedo? Im sitting at 2900 at 70mph with the GPS knowing my speedo is dead saying almost 90mph with a corrected speedo drive(the amount its off by is exponential by the speed its not like 5mph off all the time its all dependent on speed)! Im running 205/50R15 tires so maybe that is the discrepancy. Even like that I much prefer the 3.9 overall. Id love to try 4.10 or 4.11 gears.