-

Posts

994 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by rayaapp2

-

Hello folks, Last week after many years of putting this off I finally installed my bad dog z frame rails on my 260z. I thought Id give you all a brief overview of the install for anyone looking to do this on their own. This was an early 260Z with a non-catalyst floor pan. I opted for the full length rails. I bought these back when Bad Dog first started making these full length. I think sometime between 2004 and 2006, I dont really recall. The front rails are sweet. As long as you have solid straight rails to start with they are pretty painless. I had to do a little beating on the passenger side rail to get the rail to slide over snugly. All the undercoating and paint was removed with many hours of propane torching, chiseling, grinding with a sanding disc, and finally wire wheeling for a good surface. A word of caution though, strip the in cabin floor of tar and paint as well when welding. I stripped the tar off for the most part several years back to patch various rust holes, but forgot to strip the paint off again inside. The inner side of the frame rail towards the transmission tunnel will require special attention while you are welding. The transmission tunnel vinyl and organic matt is very close to where you are welding and can/will catch on fire! I kept a fire extinguisher and a spay bottle with water on hand. I ended up spraying the matte and vinyl down with the water bottle to keep it wet and catching on fire. It started to smolder several times. The only other spot that was difficult was near the inside of the front frame rails against the T/C rod bushings. Take them out before welding. They can catch on fire or melt. EDIT: Dont forget to remove the rubber floor plugs... I did, just forgot to mention it. When your fabricating for over 48 hours straight with no sleep, the drink of choice is Monster for us. You can see our "Import" can stickers were just peeled off and placed on the speedo and tach gauges. We started putting them everywhere on the car... lol The carpet and seats were removed for this job as well. Once the front rails were in place and placed as far forward as possible near the T/C rods I was able to fit and trim the rear rails for fitment. I will get back to the front frame rails in a moment. The rear rails did not completely fit the floor pan in the valley towards the rear box frame. There was a gap near the top and next to the box frame. The pad that lays on the box frame also had to be modified. It was welded up from bad dog so that it was 90* exactly from the frame rails. The rear box frame had a slight angle in it. so I cut the pad off and cut the rear rail to angle the L pad to fit the box frame on the back. There was still a gap at the top with about 3/8" of clearance that I could do nothing about. If I had more metal around I could have filled it, but it was like 3am by the time we had this figured out and decided that it would be okay to have 2" of gap there and that I could go back later and weld in some filler plates if need be. You might be able to use the rail pieces that you cut off to fill the gap if you really want to get anal about it and dont have any extra metal around. Once the fitment was dealt with we welded it all up. We constantly had issues with thinner rust areas in the floor while welding. This resulted in holes in the floor that had to filled in later. Back to the front rails. You will find that if you weld the front rails on full forward and up against the T/C rod plate(where I sometimes jack it up because its extra thick there) that the rails are just straight and that the outside of the original frame rails curve in. I cut a slit on each side several inches back and C-clamped the rails into place and welded them to the original rails. This worked out beautifully. Over all Im very happy with the results. But Im use to all the difuculties of working on old rusty metal. Do not expect your car to have perfect floor pans no matter how good they look. They were probably pressed out which resulted in thinner spots in some areas and oxidation over time may have taken its toll where you cannot see it from either side. Tack weld them in place with your car leveled out out in the area and supported from strong areas like the front cross member and rear/front diff mount to try and prevent any tweaking of the frame. Once you are tack welded up stitch it together, but dont focus on one area to long. General welding rules apply.

-

Instead of guessing I will offer diagnosis. This will require you get your hands on some real tools if you dont have them already. Connect a digital multi meter or DMM securely to your + and - posts on your Fuel pump. Your looking for voltage drop here. Secure everything and take it for a test drive while you monitor your Voltage across the pump. IF nothing suspicious posps up then its time to try the next aproach. Fuel Pressure gauge. Harbor freight sells them darn cheap, and I believe most local Autoparts stores have a rental available. GEt one. Connect it and run the gauge up to the windsheild under the wiper arm. Test drive again and watch your fuel pressure. Report back what these things are doing. Personally I have not heard good things about the Walbro 255 pumps. I chose the Bosch 044 unit. -disregaurd lack of ignition. Lack of spark results in raw fuel = rich condition at O2. -Dont worry about what the stock FPR regulator can or cannot handle at the moment. Outflowing the stock FPR cap will result in a rich condition not lean, and the early pre OBDII global systems are not fast enough to cause a lean swing that would result in the data you have presented. -Knock sensors do not CUT fuel usually. They affect Ignition Map Timing and possibly a few other minor things., but not usually Fuel Cut. -A boost leak would likely result in a rich condition as well. Metered air allowed to escape under boost = less air and same amount of fuel. "What is your fuel system consist of? (tank, filters, lines?)" Name off used parts too like if you used a 1975 fuel tank or whatever! My money is on pressure falling out, but at least you will be able to dis-include the wiring for the fuel pump for further diagnosis. Sorry computer is on dope this week, and I did not mean to come off as an ass or mis-spell everything. My computer just takes a million years to catch up with my typing.

-

Im in need of a stock RB25 Turbocharger. It needs to be in good shape(My old one is perfectly fine as a core so please dont offer me another). I would be willing to spend $125-$200 for a good Turbo. I would also be open to trading parts. PM or email me for best response.

-

Man, your typing is pretty bad. Why can you text me in perfect English and talk fairly well, but then come up with discriptions like this man? I feel for you though. I know you just had that head off. I was looking forward to seeing the twins fire off. Looks like you will be hitting up Ron again and seeing if he has a top end? Or will you buy a valve set?

-

Some of them dont fit my L series vary well at all. They do not sit correctly on the lash pads or at least anywhere near correctly. There are many small differences though.

-

Im still looking for any insight you guys may have on valve stem seals. I will report back my findings with the SuperTech Viton seals IF no one has a known better product that I should try? I will be installing these this weekend if nothing changes.

-

I need a set of all four shocks for my early 260Z. 240Z shocks will work. Im interested in Tokico Illuminas mostly, but I would settle on a set of HP's or anything else you might have. Im not interested in GR2's. My last set lasted a whopping 8 months. Please PM me. Ray

-

Your still far to vague. So your ECU is burned out, but you have fuel and that ecu is still controlling injectors and delivering fuel. You have spark so can we assume your engine is turning over with the starter? How can you have spark, fuel, and air, but not turn over... Without a better picture via your description Im completely inclinded to say, go MS.

-

Thanks Derek, The trigger assembly just arrived and it looks great! Ray

-

Yeah you should be pointed Westward when typing your description up for us detailing exaclty what happened when you did what. Did you kill your batterey, did your starter die, did you blow a fusable link, did your key break off in the ignition column of your 1981 Datsun 210 wagon? What does turning over for 20 seconds and then dying have to do with your ECU exactly? Because as the guy above addressed we dont know what your talking about. We have no idea if your engine doesnt crank when you turn the key to start or if your engine cranks and will not fire up. So be specific and we will be happy to try and help. And I must say I wish I had saw your avitar picture like back in Febuary before I lit myself on fire in my living room(true story IC for 13 days and a few scars later).

-

I figured for under $40 to my door Id give the Supertechs a try. I just got them in, yes I ordered them for a RB25det. So I open the package up and find 2 stickers and a banner card. The companies name is IPGparts.com. Okay stickers, whatever. But then I see the card. Click for Sound Effect: http://youtu.be/zsdXmYGFBcU

-

S12, S-36, S82, S89R, and S49X. I find myself digging through wrecking yards for good rockers. I never find complete sets in good shape. So I take whats good and leave the rest. So now I have several sets worth of rockers, but no matches. Ive listed the casting codes from the ones I have. Why did Nissan make so many different ones. Im guessing that for the most part these codes are for weighting and pad height. I see a few where the rocker is actually a few mm longer like the valves or pivot point were moved in the head. Anyone have any better ideas of what these casting codes were for? Hopefully that will lead me on the hunt for the an optimal set or at least figuring out which ones to use where. Thanks

-

For the GOOGLE impaired

-

So I need to replace my valve stem seals. Next week Ive got the time. I am looking at OE, which lasted a whopping 80K miles in my original RB25det. Thats okay, but not great in my book. What about Supertech Valve Stem Seals? Are they any good in anyones experience? More importantly am I restricted to using valve stems seals for a RB25 or can I use the RB26 valve stem seals on my RB25 head? Suggestions are welcome, Thanks

-

I dont see any "S30" specifc cross member. Ricky has the Mc Kinney stuff for sure. I do see "S chassis" R31 and R33 cross members for $250. These are, Im pretty sure for the S13 and S14 crowd though as they either bolt in or are easily fitted to the 240sx's. I could be wrong. Rick Wong is either here or on Nicoclub. I cannot remember, but his info is in a post burried in the archives here somewhere. Do a search and you will eventually run across it. He does not have a website that Im aware of. You simply email him and see if he has any left or is going to make another batch soon. I love his mounts, but you still have to fab up the transmission mount, which gives you room to do it anyway you want and in my case allowed me to run a large exhaust pipe through the trans tunnel and not under the lowest point of the car. Ray

-

AEM can charge like $300+ to have their ECU repaired. This is the great thing about the Apexi PFC and Commander though, Apexi USA can have the entire ECU portion completely replaced if need be for a max cap of $150. If your not dealing with the seller at this point I highly recomend you sell me the setup for $100 or send it off to Apexi USA so they can send it back to Japan for the repair. The process takes about 1 month as it does have to be sent back to the home-land.They will call you up when the PFC is returned to Apexi USA and ask for payment with a bill total, and then they will send it back to you. I can tell you this, because I fried the FP circuit and also had some damaged connectors that Apexi fixed for me with my R33 Apexi PFC. Oh, BTW there are like 2 guys down there in the LA basin that consist of Apexi USA tech department, . I had no problems staying in touch with them or getting them to contact me, but there are only 2 guys so be prepared. GL Ray

-

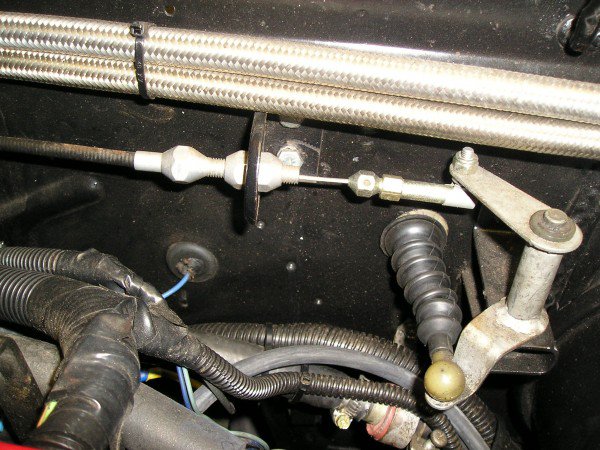

Tony was refering to rotation for a throttle cable not the rod assembly. 90 degrees of rotation is enough to actuate the cable for full throttle so its not like you dont have enough travel to accomadate a cable install. I have done a throttle cable install. Its actually really simple on the firewall side. Check out some of the RB swap installs and you will see what I am talking about. This is different than what Tony is suggesting. Here is a picture of what some of us have done. Throttle linkage post from rb forum Now for the other side Im up in the air. Im building a triple carb L series with the Mikuni manifold. Its a day or 2 away from being installed into the car so Im not there yet. I am currently stumpped in the same way though. I cannot find an eligant and simple way of emploring a cable. Its the same with the rod linkage as well. I have waited on going further with it though until its all installed into the car. I find sometimes that a solution presents itself once I can see what Im dealing with.

-

you mean E30 or P30 blocks? E30 is the L20a/e block and P30 is the L24/L26. Ive not run into a E31 block though.

-

I have yet to actually find a LD28 water pump for sale new anywhere. And I actually owned the Maxima that I needed one for. If you can find real LD28 water pumps please pm me the details after you get what you need. I kick myself for tossing a bunch of them in the recycling. I hate it when I do that. Ray

-

Its all around Folsom ca just naturally occuring in the ground. While I lived up in the Sacramento area I was near Folsom in Rancho. I hadnt realized it came out of the ground and was a naturally occuring thing. Its neat stuff. I think Id rather pickup smoking though... lol At least there is pleasure associated with the risk. Come to think of it, Every house Ive lived in except my parents last house when I was younger has had asbestos in it. Ahh cripes. I may head down to SoCal this summer. If I do Ill be sure to send you an email or call you Tony. If not for some coughing material then at least to drop off a Proto Ratchet, 10mm stubby socket, and say hi. Hopefully I catch you at a time when your in town. Ill get some better pictures later today. Ray A.

-

Its not wedged so much as it is pinned with a spider web of tabs between the manifolds. Ill get a good pic of the underside and between tomorrow when I have a chance. You'll see its more than wedged in there. There is still a chance it might rattle, but I cant get a rattle out of it while I cleaned it up or pounded on it with a hammer. Seems pretty solid. I really would like to pack the bottom with something. I just dont have anything laying around that would work with any success. I will have to make a trip in to town and see what I can find.

-

I have a good sized sheet of aircraft aluminum laying around that a friend dropped off with me. Ive used it to make a belly pan for my 260z RB project. There was enough left over from the front pan that I decided that while I wasnt to busy today that Id make a heat shield for my triple Mikunis. I have a Mikuni manifold with some 40 DCOE Solex Mikuni carbs and a Greddy/Trust/Nismo whoever header. I spent a little time getting the fitment right near the manifold flanges. I cut and bent the ends to make tabs that would guide the heat away from the intake even near the top flanges that is. So I cut and bent little tabs to clear that hard to reach areas. I made up 3 mounts from bits of aluminum and steal I had around from other projects. So its wedged in near the manifold flanges and hung by 3 mounts that mount to the sides of each carb. Then as many have suggested with their own adaptations I bent the edges down and rivited them together for strength. It seems to be pretty ridged and doesnt rattle around so Im happy with it. They only step I didnt/havent taken is some sort of heat insulation for the bottom of the shield. The engine is on the stand and currently so its not a big deal that it isnt finished yet. In fact the long block isnt even the one Im going to use, but it worked well for mockup purposes of both manifolds. I pickup the new bottom end tomorrow and the head currently on the car will be used. Anyway check these out. Id appreciate any input you guys might have. Garage was dark and the sun was out so they arent the best pictures but you can make it out well enough.

-

I had a shop hot tank the head, replace all the valve seats, check the guides, repair 2 small cracks, 3 angle grind the valves, lap the valves, leak test it, and surface 3 sides for around $360 at a reputable shop that 'needed' the work 3 hours from where I live. I could have done it locally, but it would have been much more. Being on the island Im not sure you will have many choices like that. Im not sure what the 260z e88 head would have come with from the factory. Its probably the 'C' cam but could have been an 'A' or anything else they had on the shelf depending on where it was on the production line. Its generally from what I can tell accepted that they came with the 'C' though.

-

Another option is OEM style filter. Aluminum sheet metal, rivets,some of these latches, and some nail it caulking. Build an OE style air box for a flat rectangle filter and fit it either in the engine bay with a tube to the front like OE or simply build it up front like the OE Z chassis did until very recently. Its a bit of work but could look nice on the cheap and it solves fitment issues with cone style fitters.

-

Purchase a Nismo head gasket and run the E88 on the F54 bottom end. I believe the gasket thickness is .7mm which will bump the compression. Use the E88 cam if its in good shape still. It should be a 'C' cam, but you will have to verify the stamp on the back as it could have anything in it 35+ years later. That should bump you up to 8.6:1 compression and give you a little more bang for your buck. You just have to justify the cost of the Nismo MLS head gasket(around $200, but still available). Im in the process of building the same bottom end .020" overbore with a E31 cylinder head which has a slightly smaller combustion chamber and which will result in a slightly higher compression ratio. While doing the valve seats and IF you plan on continued use of the turbo bottom end you might try using the valves from the P90 head if the margins, stems, and other measurements are still good. The stock valves are stainless. The P90 valves would be slightly bigger(a few mm) and will offer slightly better flow, but it will be marginal with a stock setup and little to no chamber work as far as HP increase. Just an idea.