-

Posts

2986 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by z-ya

-

Bondo and block sand with a long sanding board with 80 grit. My roof was badly dented, now it looks great. Took a lot of sanding and filling, but I'm happy with the result. The other thing to keep in mind is if you headliner is in good shape, normal dent removal using heat or hammer/dolly tools is not an option.

-

Not relevent to a stock S130, but here are some cool parts for the Bob Sharp twin turbo 280ZX IMSA car: It is amazing how light this wheel/tire combo is: 19"x17" Bet you want one of these in your S130..

-

What about 280ZX body parts. I have the molds for this car: Front fender molds, rear flare molds, front bumper and air dam molds. I also have 5 of the ZXR whale tail style rear spoilers. 2 are original made from a rubber material, and I have three that are fiberglass that two were used on this car. The last is a new fiberglass one setup for racing. Here are some more:

-

Anyone know more about this radiator? It's aluminum, and heavy duty. Four core, but cores are much thicker than stock. Has machined (not stamped) filler neck.

-

I would seriously consider one of these. http://www.msdignition.com/Products/Ignitions/6530_-_MSD_Digital_Programmable_6AL-2.aspx Jegs has them for $350. I plan one using one on a vintage racer soon. Lock down your distributor and program your timing curve exactly the way you want it. If you are going to the track this week, just put a few gallons of race gas in for a little insurance. That should cure any detonation problems.

-

I LOVE this! Paul, thanks for answering the menial....

-

Yup, know that (I run MSII/EDIS on my road racer). Thought he was interested in an off the shelf plug and play system. The other nice thing about the MSDs is that they can go in the engine compartment. The price is not bad considering that an L6 Mallory Unilight distributor with adjustable advance is more money. It's got a warrant too, which MS doesn't. You can get them for $350 new on Ebay BTW.

-

I think we talked at ZCON. I was one of the organizers. I had my orange 240Z there with the RB25DE. The one I posted previous does change the timing curve, but it is fixed and needs a regular MSD box to fire a coil. http://www.msdignition.com/Products/Ignitions/6530_-_MSD_Digital_Programmable_6AL-2.aspx This on will let program the timing curve and it has a CD ignition built in. Pete

-

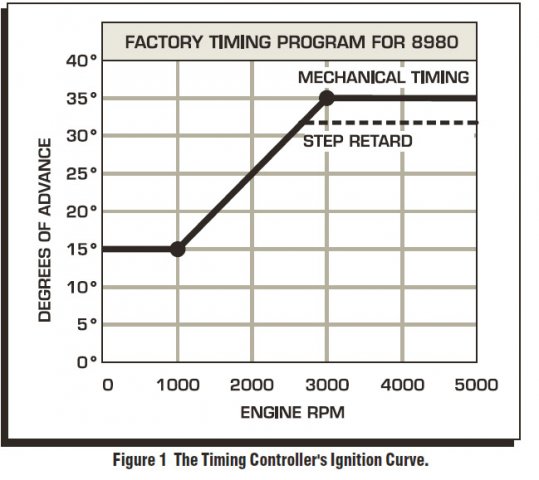

Anyone use one of these with and MSD6AL? http://www.msdignition.com/product.aspx?id=6997&terms=8980 It is a fixed curve, so you need to lock the advance in your distributor. You can also set a step retard. Or this one that is adjustable: http://www.msdignition.com/product.aspx?id=6929&terms=8680 It's probably not all that useful since your really not changing the curve.

-

Redrilling wheels with a new lug pattern?

z-ya replied to logan1's topic in Brakes, Wheels, Suspension and Chassis

Just sell those and get a new set with the right bolt pattern and back space. Centerline wheels are not too expensive considering you can order them with the bolt circle, backspace, and width. http://centerlinewheels.com/sub_wheel.php?mw_id=35 On most all except the most extreme Zs, a 5 bolt conversion is a waste of money. Nothing wrong with 4 bolt hubs. -

Thanks guys. Ron, it was great to hang out with you at the convention. See you next year. Drove the car to and from Nashville (2500+ miles), without any issues (except a leaky brake hose). Engine ran flawlessly. 32MPG! Here are a couple photos from Autoblog of my car sitting out front of Nissan at the show: http://www.autoblog.com/photos/23rd-annual-z-car-convention/

-

I run a single 12" fan on both my turbo Z and NA track car. Both cars use a standard 192F thermostat. The ECUs control the fans, and are set to come on at 198F with a hystersis of 5F. So when the temp drops to 195F, the fan will shut off. Both will idle all day in 93F temperatures without exceeding 198F. The turbo car is using a stock 280Z radiator, and the track car is using a 4 core 240Z radiator. Running a 160F thermostat is really not a good idea. First of all, these engines were designed to run in the ~190F range. Second, if you cooling system does not have the capacity to maintain a 160F or less operating temperature, then the thermostat will never close. Having the thermostat close actually makes your cooling system perform better because on average the coolant stays in the radiator longer. I've run L6s with 160F thermostats, and they never actually ran at 160F. They were always running hotter. Ran the track car in the autocross and lapping events in Nashville at the convention last week. Zero overheating problems in 95F+ heat.

-

Mine too. I drilled out the stock temp sensor and tapped it with an NTP thread so I could use an Autometer sensor.

-

Yes, I measured one recently. Use the same settings from the 450cc/min DSM injector to start.

-

There should be a separate wire for the check engine light. It should connect to a low wattage bulb, then to ground. I'm using the choke light in my 71'. Works great. For the Nissan Consult connections do what others have suggested, get a plug fromt he junkyard and splice it into your harness.

-

What are you using for a gauge? I find the cheap mechanical ones are not all that accurate. I've seen 5psi difference from one gauge to another. Does the pressure increase as you open up the throttle?

-

Can the admins add a fixed width font to the site? "Courier New" is still variable width. Fixed width fonts are nice for drawing schematics. Thanks, Pete

-

OK, I finally have the tach information. So to use the 280Z tach with an R34 ECU, you need a 1kOhm pullup to 12V on the ECU tach output. So the output from the ECU is "open collector" for you electronics geeks (like me). 12v o | / \ 1K Ohm 0.5W / | | o------ TACH ECU I would wire the resistor into the dash harness rather than the tach harness if you can (so that you can swap tachs easier if you need to). Or just wire the resistor on the back of the tach. Pete

-

I feel like I'm watching Red Greene http://www.youtube.com/watch?v=U0d_KEiIHiU

-

225 50/15 too much for a stock 280z?

z-ya replied to darom's topic in Brakes, Wheels, Suspension and Chassis

I'm running Eibach springs with 225-50R15 on 15x8" zero offset wheels. No rubbing. -

What? Don't sweat the tune on a 20psi turbo motor? That is the problem here. He has no idea what the ignition map looks like inside that Haltech. Until I see the ignition map I wouldn't push any boost on that engine. Pete

-

Not to pick nits Tony, but I did say "280Z", not Fairlady. As far as I know the 280Z wasn't available in Japan. So I am correct in saying no 280Z came with flat top pistons. Correct me if I'm wrong (and I know you will). Pete

-

I would pull the plug on one of injectors and measure the resistance at the injector without anything else in the circuit. You need a good quality DMM to measure low resistances accurately BTW. So you are better off measuring them individually. Most all Bosch injectors I have measured are around 2.4 Ohms. What resistors are you using? I don't think the problem you are seeing is related to the injector settings. It is probably related to some other setting in Megatune. What WBO2 are you using? Have you calibrated the output voltage from the WB02 with Megatune? Pete

-

Did you check the DC resistance with a good meter? What did you measure? If they are high Z, it would explain a lot.

-

Yes, the best way to find the correct PWM measurements is with a scope and current probe. But you can also use a voltage probe and get pretty close. Or use a low resistance power resistor (like .5 Ohms or so) and then float the scope and connect the voltage probe across the power resistor. The problems I see with your measurement are: - Finding the correct PWM settings is an electrical measurement related to the coil in the injector, not the fluid flow rate through it. The purposes is to find the safe electrical settings so that the injectors open completely without excess heat in the injector driver circuit and the injector itself. - When you use your method, how do you know when you have increased the PWM time far enough beyond where you think the engine "sounds" good. What about the PWM current limit, how can you hear when the injector has enough current? - The coil in the injector is non-linear, that is why flow rate increases in a non linear rate as opening time or duty cycle increases. - You don't need to change the injector opening time for most all injectors. 1ms should be fine. Only adjust the PWM time and current limit. The injectors you are using are Ford (Bosch) low impedance? If so, the DC resistance should be around 2.4 Ohms. I would use the Bosch settings from my spreadsheet: http://forums.hybridz.org/index.php?/topic/55910-injector-opening-times-spread-sheet/ Turn O2 correction off until you have your VE table really close. You can't use the O2 correction to tune the engine. The VE table has to be pretty close to ideal before you can turn that on. Spend an hour or two on a dyno to get the heavy load tuning done. Then drive it around for a while using the O2 logging to get the drivability good. Then when you think you have it running really good, turn O2 correction on. Let face it, closed loop mode is only good for improving economy at cruising speeds and idle. When you have your foot into it, O2 correction is turned off anyway. Use your WBO2 for tuning, and only after it's running great should you think about turning O2 correction on. Hope this helps. Pete