-

Posts

1194 -

Joined

-

Last visited

-

Days Won

30

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by 74_5.0L_Z

-

Lug nuts for Rota wheels-quality ones

74_5.0L_Z replied to madkaw's topic in Brakes, Wheels, Suspension and Chassis

I switched to all ARP M12 x 1.5 wheel studs and use the Gorilla open end lug nuts. The lug nuts are 7075 aluminum and are incredibly light. The black anodized finish is very nice too. -

Determining Static Compression and Valve Springs

74_5.0L_Z replied to jgkurz's topic in Ford V8Z Tech Board

If it was my engine, then I would really have to find out what the bottom end consisted of. At the very least, I would pull one cylinder head and the oil pan. With the head off, I could get numbers off the piston. The numbers on the piston would give the manufacturers information on dome/dish volume. The same information is published for the cylinder head combustion chamber. Then with the head off, I'd measure the "in the hole" depth of the piston to the deck, and also get an exact value for the stroke. These days there are a lot of stroker 302s running around. What are the specs on the old cam? I am wanting something a bit bigger for mine. Currently, I have a Crower 15511 hydraulic roller. -

VERY NICE!!!! I've considered doing something similar for a long time (I even have a set of those shock/springs under my workbench). Do you have target camber curves and roll center heights in mind?

-

I feel your pain. I too am working on my masters degree. Twelve years after getting my BSME at the University of Florida, I find myself working on my MSME at UCF. I am taking one class per semester while working full time. At this rate, I should finish sometime in 2011. I really miss having a life, and my car has been aweful lonely in the garage for the last year or so.

-

Adjusting Caster via Radius Rods

74_5.0L_Z replied to Whittie's topic in Brakes, Wheels, Suspension and Chassis

If you have aluminum/delrin bushings on the stock lower control arms, then you should be very careful about how much you add caster via the Tension/Compression rod. The aluminum delrin bushing are made to rotate about a fixed axis (the bolt at the crossmember). When you move the outboard end of the LCA forward to get more caster, you need a joint at the inboard side that can pivot in three dimension (a spherical bearing). The aluminum/delrin bearing will bind if the control arm is too far from perpendicular to the centerline of the car. So, if you want to get caster from the T/C rod, you need spherical bearings at the inner pivot of the LCA. Dan -

Celica supra P-type to 280z fitment

74_5.0L_Z replied to Two80z4me's topic in Brakes, Wheels, Suspension and Chassis

Years ago, I ran a set of those wheels on my old 260Z. The center hole has to be opened up quite a bit, and the lug nuts are not compatable with the datsun wheel studs. I changed all of my lugs to the Toyota studs (the toyota studs have a 1.5 pitch while the Datsun studs have 1.25 pitch). All in all, it was a royal pain to fit those wheels on my old car. I only went through the hassle because the wheels were free, and because I was a poor college student. -

Caliper/Coilover interference

74_5.0L_Z replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Jon, get some 8" springs. With the spring rates that you are using, you should be using the shortest springs that you can get away with. I say this not just for clearance reasons, but for spring buckling reasons. Read this link and you will understand why: http://www.efunda.com/designstandards/springs/spring_buckling.cfm Assume that you are trying to stay below the green line. And regarding my oil pan: The pan on my car was made specially to be 1" shallower than stock. The stock pan is 7.5" deep and has 5 quart capacity, and my pan is 6.5" deep and has 7 quart capacity (side kick-outs). -

Caliper/Coilover interference

74_5.0L_Z replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

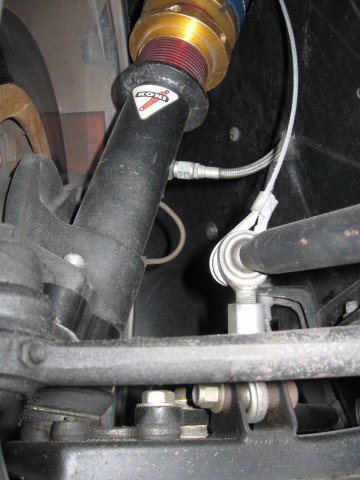

Do you think that you will ever be adjusted that low? I doubt it unless you are using really tall springs. In the spring rates you are going with an 8" spring is the tallest spring that you would want. You can see where my 500# 8" front springs are adjusted to for my ride height in this picture: At that ride height, my oil pan is less than 3" off the ground. -

My front suspension is droop limited using cables, but only to the point that the front springs are at their free length when the cables are taut. To make mine, I attached a 1/4" clevis yoke to the top of the strut tower inboard and forward of the upper spring seat, and connected this clevis to a sway bar end link using a 1/8" cable and thimbles. I've attached some low quality pictures that show the set-up with the car at ride height (slop in the cable). These cables are not as close as they look to the brake lines. In two years of autocrossing with these cables installed, I have seen no evidence of contact. My rear suspension is droop limited by the strut assemblies (I sectioned them a little more than I should have). I have about two inches of droop travel in the rear from nominal ride height.

-

Front lower control arms and new subframe

74_5.0L_Z replied to zclubhouse's topic in Brakes, Wheels, Suspension and Chassis

I think you have too many degrees of freedom in your lower control arm / TC rod. The rod end at the junction between the control arm and TC rod needs to be a solid end and not a spherical bearing. Otherwise, the effective length of your TC rod will change as the control arm rotates about its long axis. Oops, BJhines beat me to it... -

Here is an older picture (old engine and no paint) of the car in which you can just see the mid-plate: The mid-plate sandwiches between the block and bellhousing. The mid-plate is 0.090" steel and mounts to two brackets welded to the frame ~1" forward of the firewall.

-

I use a front plate and mid-plate to mount the engine in my car. It works great, frees up a ton of room under the engine, and makes the engine a structural part of the car. The set-up does transmit some mechanical noise, but it is not a bad as I would have thought.

-

Brake help.. Pics included.

74_5.0L_Z replied to abes's topic in Brakes, Wheels, Suspension and Chassis

Are these race pads? Race pads don't work very well until you have a bunch of heat in them. On the street, you will probably never get them up to operating temperature. I use the hawk HP plus pads on my car which does mostly autocross. My pads have to work while cold or moderately hot, and I have been happy with the Hawk pads. They do generate some dust and wear the rotors noticably though. Your rear inside pads are obviously not wearing correctly. Is the outer edge of the pad contacting the structure of the caliper? Is the caliper slider perpendicular to the rotor surface? -

Where are people mounting ECUs in S30s (not 280Zs)

74_5.0L_Z replied to z-ya's topic in S30 Series - 240z, 260z, 280z

My Ford EEC-IV ECU is install in the glove box of my 260Z. I cut a rectangular hole in the back of the glove box that fits the 60 pin connector. -

Having the rear pivot of the T/C rod slightly above the inner pivot of the lower control arm is a good thing. It provides a small amount of increased anti-dive (assuming the outer ball joint is lower than the inner pivot), and a little bit of dynamic caster gain during braking. Just be sure that the inner pivot on the lower control arm is a spherical bearing, or you will get some binding. The inner pivot of my lower control arm has been raised my 3/4", and the rear pivot point of the T/C rod has been raised by the same amount. I have been toying with the idea of raising the rear pivot point a little bit.

-

How much tubing to make a roll bar?

74_5.0L_Z replied to heavy85's topic in Brakes, Wheels, Suspension and Chassis

Looks good. When I installed mine I lined it up so that the roll bar was parallel to the line of the quarter window. To do that, I had to remove the "little nubbin" that you referred to below the quarter window. To remove it, I just used a hole saw. Because it is a tight fit, you will have to strategically plan your welds. If you are not careful, you will end up with welds that you can't reach. I planned mine so that the main hoop, diagonal, downtubes, strut support, and the tubes that go from the sides of the main hoop to the strut brace could be completely removed from the car for final welding. The following picture shows all of the rear structure installed in the car but not welded to the car. Basically everything in this picture was completely welded together before final installation into the car. I could tip it forward and wrap it out through the passenger side door. Once everything making up the rear structure was completely welded, it was put in place and welded to the car as shown in the second picture. Actually, to complicate things further, I also had the door bars to contend with. So the rear structure was put in place but not welded to the car, then the door bars were placed and partially welded to the main hoop. Then the entire structure was shifted forward to gain access to the remainder of the door bar welds, then finally everything was put in place and welded to the floor and strut towers. This stuff takes careful planning. -

After doing about two minutes of web research, I came up with the following: The GT40 heads have a nominal combustion chamber size of 64cc and the early 302 have a nominal combustion chamber size of 58.2 cc. So the downside would be that you would lose compression ratio. The upside is that you would get bigger valves and better flowing ports. Why not go to an aftermarket aluminum head? They are available with small (58cc) combustion chambers and even better flow rates. Currently, I am using the Edelbrock P/N 60379 aluminum heads on mine. They are great heads for a stock bottom end. They were worth 10 mph in the quarter mile over the stock heads. Recently, I upgraded my bottom end to a stroker, so I plan to remove the Edelbrock heads sometime in the future and go with either an AFR185 or the new Ford Z302 head.

-

I bought some GT-40 heads for my father-in-law's 1968 302 that we put in his 1964 comet convertible. The heads were a straight bolt on. The later model heads utilize a pedestal mount rocker arm, while the older heads use the rail type rocker arms. The newer rocker arm design is much better, but you need to be particlular about which push rods you use. For his application (hydraulic flat tappet cam) we ended up using push rods for a 1982 Mustang. The 1982 Mustang had a hydraulic flat tappet cam and the new style rocker arms. If you are going to use aftermarket rocker arms, then ignore the above, but be sure to get the proper length push rods.

-

How much tubing to make a roll bar?

74_5.0L_Z replied to heavy85's topic in Brakes, Wheels, Suspension and Chassis

I had my roll bar bent by the guys at ChassisShop where I bought the tubing. They bent it using a die with a 7.0" centerline radius. I asked them about their bending equipment before I generated the drawing. The as received bar was an almost exact match to the drawing. They charged me $80.00 to do the bending, but the quality of the work was worth it. -

How much tubing to make a roll bar?

74_5.0L_Z replied to heavy85's topic in Brakes, Wheels, Suspension and Chassis

Cameron, The dimensions on my roll bar gives a VERY tight fit. If the guy bending your bar makes an error tell him to make it on the narrow side. If the bar is any wider than my dimensions, it will not fit. Here is the fit in my car: -

How much tubing to make a roll bar?

74_5.0L_Z replied to heavy85's topic in Brakes, Wheels, Suspension and Chassis

Here are the dimensions that I used to construct my main hoop. I believe that the leg length dimensions are a little long (so you will need to trim to fit). A few members have already built roll bars based on these dimensions. I have gotten feedback that the fit was good. http://album.hybridz.org/showphoto.php?photo=2004&ppuser=7833 -

You don't want a 9" deep sump. If you lower the car, the factory 7.5" deep sump gets pretty close to the ground. I had Kevco racing make me a 6.5" deep front sump pan with dual kickouts, racing gates, and a matching oil pump pickup for about $200.00. I now have 7 quart capacity, better oil control, and an extra inch of ground clearance. The guys at Kevco were great to work with.

-

OK. So, if you were looking for the lightest, smallest, best flowing muffler that would satisfy scca noise restrictions, what would you use?

-

This is related I swear: I currently have dual flowmaster 2 chamber mufflers (2.5" in/out). I've been running them for about ten years. The car sounds good and is not overly loud, however with recent engine modifications I feel that the exhaust system is holding me back. The flowmasters are known to be restrictive and this pair was not very well installed. So, I am starting to upgrade the exhaust starting at the back. I am cutting the two crush bent 90 degree bends and the two Flowmaster mufflers off the car and replacing them with mandrel bent 90s and probably a pair of Borla XR-1 mufflers. The main use of this car is autocross, so I am concerned that the Borla XR-1 mufflers may be too loud. I know johnc has experience with these, so I am interested in his opinion. Here are the engine specs: 327 ford stroker 10.5:1 compression 348 rwhp (I expect more after the exhaust modification) I like the Borlas because they are light, compact, and free flowing, but will the Borlas be too loud?

-

Crashed into a wall lastnight

74_5.0L_Z replied to COmputoman's topic in S30 Series - 240z, 260z, 280z

That is how my car looked when I decided to cut the front off and build a tube chassis. It definitely takes a lot of time, effort and skill. If the car is as nice as it looks, the chassis should be sold cheap to someone who wants to undertake the project. It would be a shame to let it get crushed.