DuffyMahoney

Donating Members-

Posts

491 -

Joined

-

Last visited

-

Days Won

14

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by DuffyMahoney

-

You guys are all way too smart! All way over my head. The engine starts and runs terrible, kind of like a terrible tuned carb that’s super cold. I’m hopeful it’s injectors but both haltech and injectors labs say I could have caused damage. Haltech believes the ecu should be fine but has never tested running the engine a lot with the wrong ohm setting:) Injector labs said they could hear the click in the video. The clicks don’t go in time with anything. They sound almost completely random. Also go away as soon as I’m above 1300 or so rpms. I have gotten a few trigger errors. I will try to why what they were. I need to figure out my data log. So far that doesn’t work.

-

Well it's either the ecu or the injectors that have an issue. I am sending the injectors off to be tested by Injector Clinic. That is where I got them. Fingers crossed, that would be the cheapest fix!

-

I understood that lower ohm was opposite. So 1-3 would require beefier internal wiring. So running a 12ohm injector with 1-3 ohms with thin internal wiring would Ruin them? I'm not an engineer at all. I should have asked more questions. I don’t believe the haltech has anyway to test without the car running. I know some ecus do.

-

I asked an electrical engineer buddy, he doesn't know much about injectors but said low ohms towards them could have fried the windings? Super common in the car speaker world, which I am more familiar with. You can't send say 2ohm to a 4 or 8ohm speaker very long till it ruins it. Very common for people to wire speakers incorrectly and damage the speaker or the amp. I guess I could have damaged the ecu? I asked injectorlabs about it. Waiting to hear back. The video doesn't show the sound that well.

-

Well, I at some point I must of changed the settings in the haltech software from high own to low ohm (should have been set high or 12.8ohm) , then over the next 15 hours of tuning I believe I have ruined my injectors:( The odd clicks are coming from the injectors.

-

I should have a test bracket in my hands soon, maybe tomorrow?

-

I had a throttle body not seated all the way. I switched from studs on the intake to bolts and it fixed it. I am in the middle of tuning and trying some settings. Frustrating, but also sort of fun! There are so so many settings! I am also trying to track down a weird hesitation that seems to come and go, so either spark or fuel. I kind of wish I would have made a hand throttle using my stock choke lever for bumping the rpms for warm up, sure would have been easier. With the same tune, the engine doesn't run the same with the large balance bar. Also have the balance bar after the injectors isn't ideal.

-

All will be checked, but they should be spot on for the $.

-

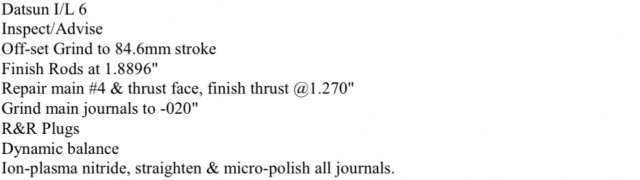

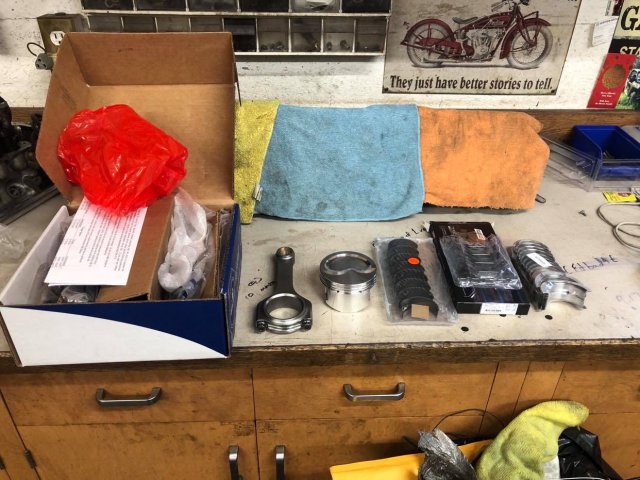

3.2L engine parts arrived from Rebello today! JE Pistons, Eagle rods and king race bearings. Rod bearing clearances are spot on. Marine Crank did a fanstatic machining job on my extra long stroke LD crank.

-

Probably my favorite engine swap in a Z

-

Engine builder is removing the casting flash and de-burring the block today. Getting ready for Glyptol coating. Pretty neat.

-

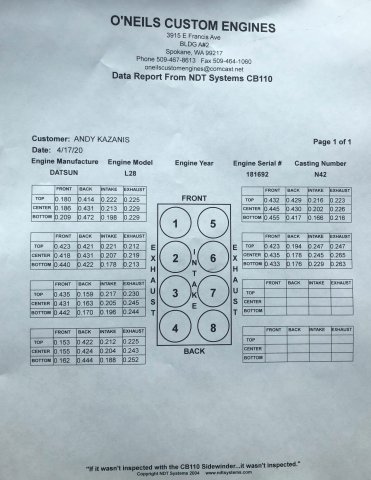

Well we finally got a block that passed sonic testing. It took 4 to get one that can handle the 88.5 pistons. N42 for the win! Thanks Andrew Kazanis! It’s going to be a sweet motor.

-

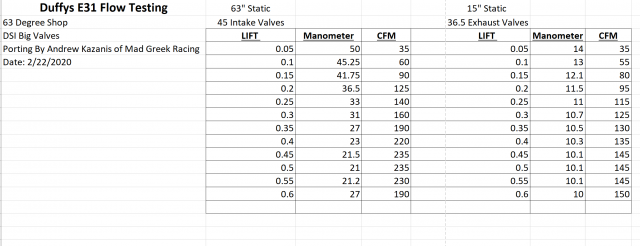

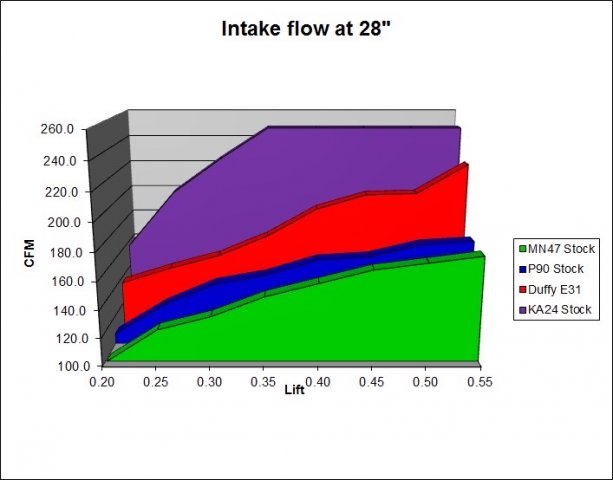

Not keeping the intake ports rough. They are done already. Flow data is attached. Valve guides were left in during porting then replaced after by a machine shop. I don’t believe the chambers were touched. But I will ask Andrew (engine builder) I went through 4 E-31 heads before i found one that was cast nicely and no flaws.

-

I did the dsi valves. Nothing was done to the chamber. But I installed dsi valves. Lots of port work though. Flows awesome.

-

Well it runs, but terrible. I have a massive vac leak, either from my balance bar not sealing or maybe a throttle body wasn't bolted down correctly, I had issues with one not seating well. Even with throttle plates in the fully closed position it runs happily at 900 rpms. So it's getting a ton of air from somewhere.

-

Haltech elite 750. I will set the butterflies first. Then I can still use the iac for a rock solid idle. But it’s normally perfect.

-

Warm I want the valve almost 0% open

-

Pretty neat feature. I will try to set warmed idle at butterfly’s and at the ITB air bypass screws. Hopefully i can leave the IAC adjustable bleed closed

-

PCV question. This isn’t a debate about the need for a PCV vs a catch can. I want true postive vent. I decided I want to use my exhaust to pull the fumes out, to keep the dirty fumes out of my intake. But since I have Fujitsubo. I have true dual exhaust. Is plumbing to one good enough? Should I still use the stock check valve? I would guess it holds back a tiny bit of pressure before popping open? My plan was to weld this bung at a 45 just past my o2 bungs on my exhaust. With the stock check valve in line.

-

My comment wasn't directed at you.

-

Well I wanted it flawless. So it takes a while. my system uses the exact pumps and nozzles as the top system on the market.

-

Well the 80s bmw iac is awesome, smaller and nice looking. Let’s no air or minimal amount by when physically closed. Now to find out what pin is positive.

-

It probably took 5 hours to vapor blast all of it. Lots of surface area.