DuffyMahoney

Donating Members-

Posts

488 -

Joined

-

Last visited

-

Days Won

13

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by DuffyMahoney

-

Someday! I don't get out much though.

-

The 240sx trans fits perfectly in an early 240z. No cutting required. It's almost identical for the shifter hole. You need to buy the new mount. Godzilla race works has a package for it. I have this in my 240z.

-

I have the AHP and I love it, I have professional welding buddies that help me when I want a part to look nice. They are always impressed.

-

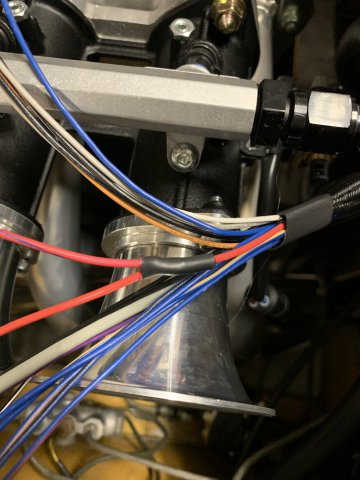

Injectors are wired. I can’t tell if that was fun or not. But I’m proud of how it turned out. Matches my coils pretty darn well. Now the easy stuff is left. Hopefully I will get that all done tomorrow.

-

This is my plan for the injector positive. Basically a Y splice and crimp. The pulley wire isn’t cut. Just the sheath is removed. Then crimped another wire onto it. Then a dab of soldier. Then heat shrink. Should work perfectly. It’s just going to take a long time!

-

It’s shorter. Which I didn’t want. I actually called Jenvy and asked for raw in the standard size. They said no

-

That was also an option, but your tape lines would have to be perfect. Honestly I wish the throttle bodies were raw aluminum.

-

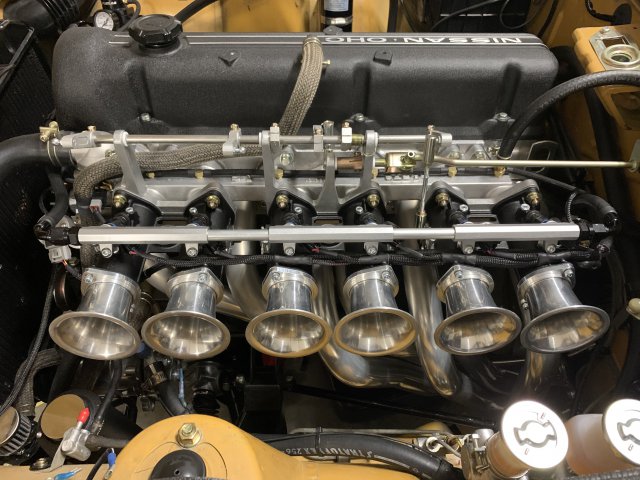

The Mangoletsi intake is very well thought out and made. It was on the top of my list. SK Mangoletsi Jenvy

-

Those look to be very similar intakes. I would guess most intakes were copies of designs. So similar runner length and spacing. Maybe I am wrong. Who knows, point being I dislike the look of fuel rails:) I was going to cover my tubes between ITB in some sort of cloth to mimic fuel hose, but decided against it when i didn't have any on hand. I have owned a Harada, FET, SK and TWM. I love my SK, to me it'just old school cool with the linkage. Plus the casting is light years nicer then the harada. Which I couldn't live with.

-

I have owned 4 triple intakes. All are slightly different lengths, spacing etc... the dcoe pattern spacing is the same. But spacing from carb to carb would be different.

-

I actually don’t like the look of one piece fuel rails. All triple intakes are different. So they could make one for their own intake. But not all without a lot of effort. My SK has the idle bump/ stop.

-

These injectors can be pointed any direction. I will leave enough pig tail for each to plug and unplug easily. Shouldn't be an issue. I am copying the datsun spirit wiring and injector wiring setup. I bought the kit from them. Swap wires? No room to change any of the wiring without a ton of effort. It's all shielded and should be perfectly fine though. I am using a hall effect home sensor on the cam. Not enough wiring length for the crank sensor wiring to be on the injector side.

-

I think this is how I will run my injector wires. Then y off at every runner. It would take some time. But look reallynice.

-

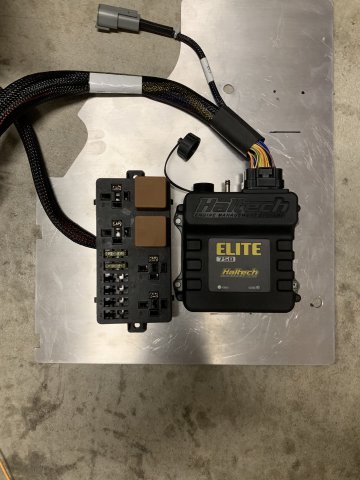

I got way further on my ITB install. My kick panel mount worked perfectly and I have about 2 spare inches on the wiring harness. I successfully installed it all with zero cutting of my stock harness and zero new holes which I’m pretty happy with. Now the hard part. Making all the shrink wrap and loom look clean.

-

Well I found a 2nd hole I didn’t know I had. I tested it and I should be able to fit all wiring with zero new holes in the car. So that’s a full efi install with zero holes or Permanent mods! Stoked. 02 sensors go through the shifter hole. Tps, air temp, coolant temp, home signal and injectors through the choke hole. R35 coils, crank trigger, oil pressure, fuel pressure, dual positives and ground will go through the hole below the stereo.

-

Thats cool.

-

No need. I’m not worried at all.

-

Tioga. That looks great. the balancer on the outer ring isn’t perfect. But it will work fine. Lots of high end motors/ builds use his kit. It’s super well designed.

-

dampener doctors rebuild my stock Dual v crank pulley (keeping AC) . Then this is a 60-2 trigger from Hoke. I had to lathe off the back slightly. The trigger ring was not made for my pulley. Works awesome. It’s a great kit. I will have it professionally epoxy painted black. They must of rattle canned it.

-

I'm not using a surge. No reason for it unless you are racing. I adapted the small hose to 3/16 and then the larger hose to 5/16. I got AN adapters that are are 5/16 or -4 3/16 for the return. But it should be easy to route. This is a neat product. https://www.ebay.com/itm/Billet-Aluminum-Bosch-044-1L-High-Flow-External-Fuel-Pump-Surge-Tank-E85-For-IE/323080627152?_trkparms=aid%3D555018%26algo%3DPL.SIM%26ao%3D1%26asc%3D60037%26meid%3D20fcd3a75b66442190761e0dfac6fcba%26pid%3D100005%26rk%3D7%26rkt%3D12%26sd%3D323419174147%26itm%3D323080627152%26pmt%3D1%26noa%3D0%26pg%3D2047675&_trksid=p2047675.c100005.m1851

-

I fit all of that stuff under the car. Wasn't too hard and looks nice. Just FYI.

-

Built a passenger kick plate out of aluminum. I will powder coat it to match my stock one (sort of darker matchbox )This ecu location is about the best location I can find.

-

Mine seem fine, but driving will tell, I have a few adjustments on each section of the intake linkage.