-

Posts

13742 -

Joined

-

Last visited

-

Days Won

68

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JMortensen

-

ANOTHER Datsun Z/LS3/T56 Swap Thread

JMortensen replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

On the flip side of the pedal ratio vs master diameter/effort thing, if you don't have a booster then the pedal won't travel as far. If I let you drive my car you'd never come back with a comment about the brakes, either travel or effort. Just feels normal. As to your first drive comments, when I drove mine for the first time it was just around the block and I found that I could just step on the gas and roast the tires for basically as long as I held the pedal down. It was intimidating, and immediately brought up that Mark Donohue quote. Anyway once I got it out on the track I realized that it is in fact drivable, and doesn't do anything stupid. Pretty easy to drive for what it is. Hope yours turns out the same, I expect that will be the case. Congrats! -

Using 5/8 bolt in place of spindle pin

JMortensen replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

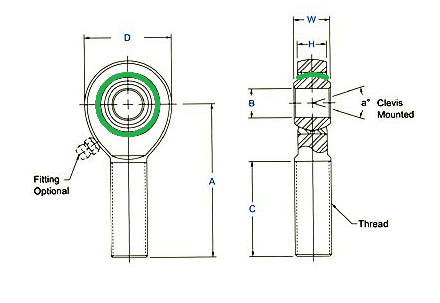

Again, nothing rotates around the spindle pin, so this isn't necessary. In the case of the bushings, the polyurethane or rubber is doing this. In the case of a rod end setup, they do have teflon impregnated steel races and chrome balls. Here's a shot of an aurora rod end, I've put green where the teflon lining is. -

Using 5/8 bolt in place of spindle pin

JMortensen replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

Not only is it not necessary, it's harmful. The suspension should move with as little resistance as possible, and the resistance that you do have is provided intentionally by the shock and spring. That's why I posted that video on how properly designed PU bushings are made. You can copy some of their tricks with energy suspension stuff and improve them quite a bit. Cary convinced me to do a lot of things on my car in the search for the least amount of friction possible. That's why I have the weird sway bar mounted on heims joints that I do among other things. -

Using 5/8 bolt in place of spindle pin

JMortensen replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

Cary beat me to it. -

Using 5/8 bolt in place of spindle pin

JMortensen replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

That is incorrect. The bushing has an inner sleeve which slides over the spindle pin. When you tighten down the nut on the end of the pin, it locks the sleeve in place, and the rubber distorts to allow for the motion of the arm. This is why you should tighten all of your bolts and nuts with the weight of the car on the ground when using rubber. You want the bushing not to be deflected at ride height, so that it can move equally easily and equally far in either direction. If you were to tighten the nuts on the spindle pins with the car in the air, then the rubber would deflect quite a bit just to get to ride height, since the bushing and the sleeve does NOT rotate on the spindle pin. The arm is separated from the spindle by the bushing, that is its purpose. As it happens I recently did battle (and lost) with probably my 10th set of spindle pins. This one broke my BIL's puller, it was a real bummer. Anyway, I still have the ends of the control arms that I hacked off with the rubber bushings in situ. You can see that the sleeve in the middle of the bushing protrudes out from the arm. When you tighten the spindle pin nuts, this locks the sleeve in the middle of the bushing in place against the strut housing. -

Using 5/8 bolt in place of spindle pin

JMortensen replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

The bolt SHOULD NOT be pivoting. It should be stationary, with the bushings or bearings moving independently of the bolt. If the bolt is spinning in the housing, it's going to wear the bolt. If you're using poly bushings, refer to the video I posted earlier, which shows the sleeves being captured and the poly rotating around the sleeve. If you're using rod ends, the monoball is captured and the rod ends do the pivoting. -

Using 5/8 bolt in place of spindle pin

JMortensen replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

https://www.boltdepot.com/fastener-information/Bolts/US-Recommended-Torque.aspx 5/8-18 is 180 ft/lbs -

Wide body Options for a 240z?

JMortensen replied to HunterCustom's topic in S30 Series - 240z, 260z, 280z

ztrix.com IMSA fenders are wider than the YZ stuff if that sounds appealing to you. I have read that back in the day they ran 16x14 or 16x15s. I have rear flares that were taken off of the molds for Frisselle's car, and they fit my 15x14s like a glove. Always thought the BSRs looked a bit wider, might be where the 16x15s come in... -

My custom rear suspension redesign

JMortensen replied to clarkspeed's topic in Brakes, Wheels, Suspension and Chassis

So you're not using the big ass bolts on the ends of the arms? I recall Jeromio and maybe one or two others had the experience of the bolts coming out and the arm slid back far enough to fall out of the bushing and disconnect itself from the car. I see you've made a cradle to capture both bushings. Lots of force there, just hope it's strong enough. -

ANOTHER Datsun Z/LS3/T56 Swap Thread

JMortensen replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

Looks pretty sweet! Are those Jongbloed wheels? Nice job on the exhaust too. Really tight up against the bottom. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

3KGT strut arrived. Here's what I learned. 1. It's short. Really short. The housing and strut totals about 18" before the studs at either end. The internal portion that would fit into the strut tube is about 3.5" shorter than the Mustang strut tube, which is 13.5" deep. So I'd have to weld the plate that the strut bolts to in the Mustang tube 3.5" from the bottom of the tube. My friend said he could have them shipped to me with the end plates loose, but I think it would be a serious PITA to weld the plates in that far up the tiny tube. Don't think I could even do it with my mig. 2. It has less travel. I'm measuring 4.75 to the bumpstop. I'm told the bumpstop is 2" and that looks about right, as that would put the 40mm part of the inverted strut flush with the case. Travel is about the same as the P30 from the VW, but quite a bit shorter than the Mustang. 3. The OD of the Mitsu strut is about 1.807". The ID of the 240 strut is 1.690" according to an old post by John Coffey. Was hoping I might be able to hone out the strut housing. Ain't happening. So now the question is do I get the Mustang struts instead and have the top stud cut down, or do I work with the 3KGT strut? Thinking Mustang strut might be easier, but I have had pretty bad luck with machinists generally speaking. It's nearly always late and more expensive than I was quoted, and I generally hate dealing with them. The one pro here is that I could have the top stud turned down to 5/8 and not have to use bushings like I do with the P30. Suggestions appreciated, although I'm guessing the answer is going to be buying the Mustang parts and machining the studs. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

3KGT strut ordered. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Yes, there are similar pistons, shims, etc for the 36mm stuff and he's telling me if I rebuild the Ohlins pistons are better, so apparently from more than one manufacturer. I don't think 36mm is as popular with racers as the 46 which is used on pretty much all circle track stuff, but it's still a lot more available than the 30 stuff, it seems. I did come across one pretty big issue, the Mustang strut has about 4 or 5" of shaft sticking out the top where it goes through the camber plate. Definitely wouldn't clear the hood. Thinking I'm going to buy a tube for the Mustang and buy a strut for the Mitsu and see if I can put them together. If that works, then I might just go for it, buy 4 mitsu struts and revalve, then mod the housings. Also I misunderstood and the tube can't be cut down, but as it works out it's almost exactly the right length. Looks like if I pull the stock tube out of a 240 strut and install his, the tube height from the base of the spindle to the top of the tube will be 14.5" or so. My sectioned P30 was cut to 14.75" so just about dead on. His tubes have 2 bushings inside, one at the top and another one right in line with the piston (which doesn't move up and down relative to the housing), plus a dust seal top and bottom. The one issue is that the rear strut tubes need to be longer so would need to cut the original strut tube and weld together with the new one maybe 2 or 2.5" up, not unlike sectioning the tube. Coffey suggested doing that at the bottom of the tube, but I always did it at the top and thought it was kinda weird to do at the bottom, seems like that's where all the bending load is. Not the biggest problem. If I felt like it wasn't strong enough would be super easy to get a 3 or 4" long section of 2" ID tube and slide it over the top and weld. I'm just about ready to pull out my wallet and make some of this happen. Likely won't be with adjustable struts though. Just revalved. A big problem is the adjusters are on the bottom of the inverted struts, so you'd have to pull the steer knuckles off just to see them, let alone adjusting correctly. Maybe could cut a window in the strut tube, dunno. Sounds sketchy... -

I hope you do better than that...

-

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

That's essentially what my Mustang engineer friend has done. They made a 2" OD tube that fits a 36mm Bilstein and has bushings in the tube and a seal on top. So gets around all the issues with the 240 strut tube. I need to look at the shock tech post again and verify, but I think they had a gland nut that fit the 280Z, but I don't think it fit the 36mm strut, just the 30mm. If they had a 36mm gland nut could probably use the 3KGT insert and save some money vs the Mustang parts. The problems I see are that the Mustang strut has 7" travel where the Z has 6. He is telling me I can cut down the tubing a ways before I hit anything inside, but I need to make sure I can cut enough so that I get the right amount of bump travel. Also says you can limit droop from inside the tube. I need to have more droop than necessary because I use 2.5" tall spacers to lift the front so that I can get the car on my trailer. Bunch of little things to make sure of, but I think this is sounding like a really good solution. -

NA stroker. I can't give any specifics, but Mark Belrose sold his race car with 3.1 stroker to a guy in Oz. Rebello motor with 50mm Mikunis, I think it was making 370 bhp or 390, can't remember. Anyway the new owner wanted more and built it again and was saying 400+ but wasn't an L24. Here's a vid of the car blowing a halfshaft at Bathurst:

-

LOL. Thanks for posting Bob. That one pops into my head every now and again: "WTF cam did that guy have in that thing anyway?!!?" Apparently it wasn't magic. We have had some people get their 240s down to 1800ish pounds, and engine builders in Australia are pushing 400hp NA, but haven't seen anyone put the two together yet.

-

Suspension Setup Gurus....help...

JMortensen replied to Ironhead's topic in Brakes, Wheels, Suspension and Chassis

I had a lot of runout when I first bolted them up, I shimmed it straight with .002" washers between the hat and rotor. Now there is more runout. One side is straight the other is about .020" out, thinking about cutting the rotor. We talked about that here 10 years ago or so and determined shimming was the right way to do it, but cutting sure seems easier. Shimming was a PITA. And yeah, my friend is able to make a Fox body Mustang legitimately fast, so he's doing something right. Between him and Cary (tube80z) you can get a ton of good info. -

Suspension Setup Gurus....help...

JMortensen replied to Ironhead's topic in Brakes, Wheels, Suspension and Chassis

Akshully, since you brought it up... Same engineer suggested I ditch my aluminum hubs because he said the hub and bearing expand at different rates and it's pretty common to spin a bearing in the hub at high temps. Most people who buy this all this blingy stuff just drive on the street, but for those of us who really push it it's a different story. I have a completely separate front brake setup with steel hubs and I'm going to get it all prepped and take it with me when I finally do a track day, and I'll be prepared to swap hubs if I have problems at the track. -

Suspension Setup Gurus....help...

JMortensen replied to Ironhead's topic in Brakes, Wheels, Suspension and Chassis

I think I already said it in this thread, but an old racing buddy and engineer made a point of saying that the straight hole with a thick spacer preferable to a tapered hole stud that uses spacers. It makes sense. The diameter at the large end of the tapered hole is quite a bit smaller than 5/8" so it's only going to get weaker from there. As to the aluminum vs steel, never underestimate the selling points of BILLET aluminum: 1) OMG it's BILLET!!1!!1!! and 2) its legitimately lighter weight. -

ANOTHER Datsun Z/LS3/T56 Swap Thread

JMortensen replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

Can't you put a one way check valve in the line between the scavenge pump and the tank? -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I'm going to wait to hear from MCA. Looks like they do an upright monotube. Not my favorite. If that's the case, I'm thinking really hard about these 2" strut tubes for the Mustang. That really seems like it solves a lot of my problems. Should be easy to weld to the 240Z strut housing, fits the 36mm Bilstein, then I can get some revalved and it's been suggested to use Ohlins pistons in the Bilstein strut, as the piston machining is better and the struts are supposed be more consistent. Then it's really down to how much the DA strut tubes and the rest of the parts add. Looks like they're $3K, which I might stretch for, or I might just go with a revalve and then try to resist the temptation to change spring rates, but man, I'd really love to have adjustables and know what the adjustments do, and put the valving I want now in the lower 3rd of the adjustment range. Then I could go a little softer or a lot stiffer. Decisions decisions... -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Looks like they also don't invert their struts... hmm. -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Koni's road course tuning instructions: https://www.koni-na.com/en-US/NorthAmerica/Racing/Road-Course-Tuning-Guide/ Autox tuning: https://www.koni-na.com/en-US/NorthAmerica/Racing/Autocross-Tuning-Guide/ -

Circle Track Sway Bar

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Koni has some rough guidelines on how to tune shocks but if you're doing it by feel that's subjective and what you like might not be what is best. I prefer to do it by the numbers, and what I'd really like to have is some dyno plots, so that if I changed the spring rate (which I've already done a couple times) I could move to the next closest adjustment. I have a feeling I'll end up with more Bilsteins and they won't be adjustable... Side note - I did talk to a friend of mine who does Mustang stuff and he can get me inverted 36mm struts with a 2" OD tube. It's what they use on old Fox body Mustangs. The stock 240 tube is 2" OD or 51mm which is very close, so might be able to grind off the weld at the base of the knuckle, remove the original tubes, and weld these in their place. They'd probably need to be trimmed to the right length, but it sounds very doable. Problem is struts through them are more expensive and likely not valved right. I have an email in with MCA. I think that's my preferred solution right now. If that doesn't work out I'll probably look at the 3kgt stuff since it's the cheapest. If I can figure out how to install them I'll go that route, and if that doesn't work I'll adapt the Mustang parts.