AydinZ71

Members-

Posts

1073 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by AydinZ71

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@clarkspeed thanks man. Yep! That’s the idea… the car had been stored for 20yrs with this finish (and raced before that) so I assume if it’s stable now it will remain so. I removed the finish anywhere I saw cracking. speaking of body work, got started on some of the few body panel areas that need replacing. First stop is the gas door. PO just used the door and welded into the recess. This created a 1/8-3/16” gap that was filled. Naturally, it expanded/contracted over time and cracked through. I removed it entirely and put in a replacement sheet. Hammered off-dolly with a torch to bend and straighten it out when complete. Not much warping and it’s pretty straight! Now onto to the rest of the rear quarter panel. hey, do you apply DTM primer before you use filler, or do you apply filler straight on bare metal? IMG_8443.MOV IMG_8436.MOV -

'82 280zx Turbo max boost without an intercooler

AydinZ71 replied to cpan's topic in S130 Series - 280ZX

Sorry friend, I’m an S30 guy so not familiar with bolt-on anything for an S130. I could help you with a custom solution that is specific for an L28et, but not specific to an S130 chassis. it is a slippery slope, like you said. The long block can reliably handle 300-400hp, but any solution will require you to do some minor fab work. Even an aftermarket Plug-and-play EFI will require you to mount the electronics somewhere and do some wiring. If you don’t have the confidence to relocate or remove the carbon canister, I suggest keeping it at or below 8psi or paying a tuner. There are lots of little problems here and there that need solving once you start down this path, and it may be quite stressful if you don’t have the mechanical experience or not willing to garage the car for several months while you work out the kinks and learn. In general, getting an IC and upping the boost until you (safely) max the OEM EFI/injectors is your best bet. Beyond that, you really need to do a lot more work. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Removed all the body leading. Not clear if this was factory or from a previous repair. Will do some welding to bind the seams, the apply short-stranded fiberglass filler to fill the gap. Took a DA sander to existing finish. Lots of body work ahead. IMG_8413.MOV -

'82 280zx Turbo max boost without an intercooler

AydinZ71 replied to cpan's topic in S130 Series - 280ZX

You will make more power for the same boost with an IC. I wouldn’t go past 10psi without an IC. You shouldn’t detonate with such a low static CR (7.4:1), but your cylinder temperatures will be high and your rings will not last as long. -

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Looks wonderful Clark! I see you also have gussets inside the car where the nose of the diff mounts. Cool! I did the same Your cage also looks great! You going with a Tilton pedal assembly? What steering shaft/housing are you going with? OEM rack too? -

Oh you follow me on IG? Cool! So you already know I’m silly AF 😂 He charges one head-Pat and 4oz of kibbles. Except, he just takes your offering and promptly goes to sleep. yeah you are probably OK using it, not using it. I mean, it’s $50. But yeah, if you do want to improve upon it, you could use a sandwich plate on either side of the OEM wheel well to make the attachment point more rigid.

-

I have a seibon unit for the street Z but it is uninstalled still. The outside finish is great but the engine-side face needs quite a bit of filler work.

-

When you say offset, do you mean the drivers side bars are not a mirror image on the passenger side? I’m my case this is true. It’s because the most efficient bar placement on my passenger side could not be reproduced on the drivers side due to the Tilton pedal assembly interference. It could have been made a mirror image, but I would have had to design it on paper first vs. install the pedal reinforcement first then iterate on further reinforcement. It only looks goofy. In terms of performance, there will be negligible different. In My case, I have one bar that straddles the inner fender wheel-well. The 20-gauge steel shrouding it acts as a shear-wall resisting bending in that direction. The other bar terminates to the firewall and continues to the roll cage. The last bar is actually a semi-circle of 16-gauge tube that ties the thick steel at the top of the strut tower to the 14-gauge 2.5” 316SS frame rail. This one is acting mostly in tension.

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@Dat73z appreciate it! That helps a bunch. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Ahh I see! Here let me show you what I’m working with. Gouges are too broad of a describing by me. These are areas where rust had come through, or the finish had cracked. Took them down to bare metal. Ideally I’d like to keep the existing filler in place and patch up to it, feather it. It’s a lot of work to take the exterior down to bare metal and build the filler back up. It is clear the body had some accident damage in the past so it’s there for a reason. thanks for the tip on applying the sealer o to the bare metal before filler. 10-4! i have zero body work experience. Here is a pic of what I am used to painting. That is the silly experience I got from understanding how paints differ. I chose a generic silver because it covers so easily, and with such little paint. You make a much better point about matching. Please do let me know how you would tackle these missing patches if it would differ from my new plan. Epoxy, filler, base, clear -

For power and common distribution, consider these general guidelines: 1) + leads for controls (items that use very little amperage but require stable voltage, like electronics, ECU, etc) should be separated from major power consumers. Therefore you should have one common bus for your relay power, starter, incandescent lights etc. separate wire all the way to your battery for ECU and electronics. 2) consider a dedicated negative lead from your battery to your starter. Another dedicated (much smaller) negative lead from your bat to your electronics/ECU stuff. The rest (lights, relays) can ground yo the body. Race car guys and others considering from-scratch wiring often used these. I have a set. They come with fuses and relays all ready to go, and the switch panel illuminates to indicate if on or off. You can also switch them from momentary to latching. Not cheap, but boy does it save space and time. https://www.summitracing.com/parts/arc-8000d?seid=srese1&gclid=Cj0KCQjw37iTBhCWARIsACBt1IyHLm6hJXg3sUYdh_g2OtgiA80EvvkU2HOsn90Aa6CviHExhKuqe5EaAtKYEALw_wcB

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@Dat73z ahh interesting! So when did you choose stranded filler over standard light-weight filler? I already have a ton of 2K white epoxy so my plan was to put the filler directly on the exposed metal, scruff the surrounding finish with a DA sander, feather the filler into the surrounding finish, seal it with the white epoxy, base coat, then clear coat. What are your thoughts? I already bought 2K urethane clear so that’s what I have on-hand. My base coat is silver, which usually works as a single coat on a white base. I learned why the epoxy can’t be bare… it’s too porous. Soaks stains right up. Instead of wet sanding the urethane, I was just gonna buff it with compound and leave the dust and peaks as they are. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Hi all! Asking for advice from you race car folks out there. 1) Did you perform your own bodywork? If so, can you describe your process briefly? I have several spots on body where I gouged out with a. Wire wheel because rust had penetrated through the finish or the finish had cracked. Did you remove any of the factory leading? I have tried, but it’s not easy and quite messy (not to mention toxic). Knowing Gracie cars get banged-up, I don’t want to over-do-it as if it were a Street car. 2) if you are running an L-series, what size exhaust are you running? I got a great deal on a bunch of 2.75” 16-gauge 316L tubing which I planned to use, but I know many folks run 3”. Ideally I’d like the same exhaust to work for my 2.4L EP motor and the upcoming 3L. The header certainly has the capacity with 1-5/8” runners and two 2-1/4” collectors. 3) I’d really like to get this guy as quiet as possible so I can tune it at home without the neighbors calling our friendly blue uniforms. I plan to terminate with a burns stainless unit, but would it help to run a resonator as well? 4) I planned on using standard undercoating (asphalt) over the DTM 2K epoxy primer in my wheel wells. Assumed this would be more durable than paint plus clear, and only marginally heavier. My floor pans are done this way now. 5) have you ever had (or almost had) something break-off, pull-off, or otherwise deform at speed? I have my eye on the hood, but curious if anything else has caused you trouble. 100-120mph is not unheard or at willow springs. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Cool 😎il share as soon as my machine shop and CP have settled on them. I went with Mountune here in socal for the block. I liked that they were local and do both modern Race engines for Honda, and thier bread-and-butter are cosworth racing engines. The head is with Mike Yoes up near Antioch. Il have Mountune do the final fitup and mark my adjustable cam sprocket so I can disassemble the motor at home without having to “dial in” each time. im curious how much of bottom cylinder wall they will need to eyebrow, but that happens to be the thickest spot when we checked wall thickness, especially on the thrust sides. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

PS: updates on the 3L… I went with the Jenvey ITB’s. Configured on their website direct from UK. I called Datsun spirit to ask them a few questions about the ITB they listen on their website but I could not justify the value-add purchasing through them. It seemed they were adding their margin while I could source their supplied parts on my own. spoke to my shop working on the block today. They will be attempting a longer rod geometry and departing from the OEM pin height. I will share the final specs if y’all are interested. -

Looks super clean. I still think your welds look great despite your lack of recent practice. All I have been doing is sheet metal welding with a MIG. In comparison, it feels like slinging shit at a wall and using a squeegee to grind off the excess. I don’t have enough chassis welding left to justify prioritizing TIG, but maybe on the next build.

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

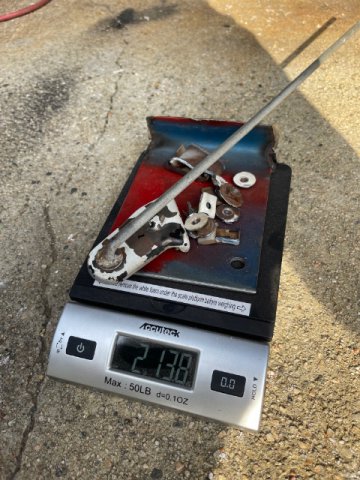

Updates: - replaced PO’s cage welds. Confirmed with SCCA that grinding the welds is acceptable as long as a filet remains. - added cage attachment points to the door jam and unibody near the roof. -continuing to remove finish and prepare for primer -will be completing the body (filler, sanding) prior to painting the interior so I don’t need to mask it off. - quarter panel window (polycarb) mounts replaced and OEM lap joints stitch-welded and ground. -another nearly 3lbs removed from the chassis -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

i realized I never thanked you for your input! I removed the old bolting plate and palm to mount straight to the roll bar. Thanks!! -

when you disassemble your pedal assembly, you will see it is not only bracing against your cowl chimney, but also your firewall as well. On the engine-side, this section of the firewall re-unforced pretty well too. You could stitch weld the OEM lap joints here if you want, but go super slow as the firewall is prone to warping. If you plan to leave it OEM (single dual-acting MC) w/ brake booster, it is probably stiff enough. If you are putting in a cage, you can have a tube run from your cage through this general area of your firewall through to your strut tower. You will need to mock everything up though, just so you are sure there is no interference. A friend of mine did this recently much better than I did. He is on IG “gregs_gears”, lives down yhe street from me. Us silly race cars (often) run dual master cylinders so we can adjust the front/rear proportioning on-the-fly (with a knob). The hydraulic ones work but they can fall out of adjustment as the fluid changes temp etc. my pedal assembly is a Tilton unit, but will wood makes them too. I removed my (rusty) OEM pedal assembly altogether, and replaced the firewall section with a sheet of 16-gauge (where OEM felt like 18-gauge) and reinforced it on all sides with tube sections. Pics attached. Finally, I have a 1.5” tube running from my roll bar to the firewall, then from the firewall to the strut housing. When I slam it, the tube sections on the firewall makes the whole thing move as a ridged section, and the tube to the roll bar keeps the whole firewall from flexing. blah blah all this to say if you want to keep OEM, you can stiffen the chassis to the strut towers (important) and pedal/firewall interface all at the same time. That way you don’t have to add extra metal just for the firewall/pedal assembly.

-

Dude did you TIG weld that yourself? It is beautiful!

-

It looks a little gimmicky to me. I suppose it is a solution if you don't want to weld to your car or remove the brake booster/cylinder assembly. I just doubt it would make much of a difference in the end, since it does not take much force to deflect 20-gauge sheet metal (what the bracket is bolted to). Do you experience a lot of deflection in your pedal?

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Beautiful! Same price range as the Jenvey and OER 😕 New Zeeland. I wonder if anyone is state side. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Ok, so I am sold on EFI ITB’s. Now, who’s to buy. It looks like OER sells a set for $2100, and of course Jenvey. Y’all have any experience with either, and any opinions you can share? Any other alternatives? -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

ahh, gotcha. Yeah my head builder thinks the 50mm OER’s are too big for my needs but the Venturi orifice is definitely smaller than 50mm. I’m going to talk to him about the jenvey manifold now. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

I chatted with my head builder about this. He and a few other experienced folks feel the 50mm DCOE’s are too big for a 3L L-series. Il ask them what the down-side is. It may be throttle response? You are correct that most of the time is spent at WOT (vs. partial throttle), but there is also a lot of off-throttle between shifts, braking, etc. the 50mm is also a big leap in price from the 47mm. Good point on the EFI cost vs. carbs. Definitely a reason I’m leaning EFI. @clarkspeed that makes a lot of sense. The motor would be swapped in-out of the EP car so it will be competitive, just not THAT competitive 😂. Widening the track a few more inches and running wider wheels would be some quick-fix improvements from EP. This all assumes I can drive worth a damn, which is yet to be seen. The local VARA president was super nice and we chatted quite a bit yesterday. Busting my ass to finish this damn thing.