-

Posts

970 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ezzzzzzz

-

Talk to me about the spare bits you have, Ken. I had Isky grind a custom cam based on my engine specs and power goals (275-300hp). He took into consideration that it was for a roots style blower, not a turbo. I was specific that this was to be a street car with good manners and longivity in mind. It isn't a monster profile but should provide spirited performance and excellent drivability. Lots of usable torque right off idle. The cam card is somewhere amongst piles of paperwork and receipts. I can't recall lift or duration right now. It's the asymetrical ramp profile and centerline that makes the difference. In the early eighties I owned a 73 Z-28 RS rock crusher 4 -speed with a full tilt motor LT1. Idled at 1200 rpms pulling 8 inches of vacuum. It was a ***** to drive in heavy traffic but gawd was that car fast! I used to go hunting for the new Corvettes and Mustangs with a gleem in my eye. One of my biggest regrets ever was selling it.

-

It was well under 5k. I think I did okay at the end of the day.

-

You must be referring to Ken's setup. Yeah, that engine is awesome. Sucks to have to fit a hood and hide it.

-

My photos don't show it well but the damper is a two row v-belt off a later 280Z. It was chocked in a lathe and cleaned up on the inside to accept an aluminum insert and allow clearance for the bolt/washer. It's just shy of an interference fit. The plug is held in place with 6 countersunk 8mm socket heads. A GM power steering pulley was modified to fit the pulley lip and sit flush against the outer v-belt flange. The heavy ring clamps the pulley snug. It's modest in ratio providing about 6 psi to get started with. I looked at the BHJ damper but decided to save the cash (at least for the moment). I'll be turning the M62, a/c compressor and alternator. The possibility of power steering also exist as I have a STI PS rack I modified months ago and place back on the shelf. I've followed every thread regarding supercharging and always admired your setup as well as other's designs. My SC sits forward since the snout is only 8" long. The tensioner will take a little creativity. The biggest hurdle now is clearance for the serpentine belt to clear the fan/shrould. I'm thinking I'll be dropping the engine mounts about .375" (to accomodate the .75" taller LD block) and move it back .5" to provide added space up front. The WC T5 shifter (Pro 5.0) can be modified to recenter it in the console. The transmission mount and the diff will likely need shifting to get u-joint angles satisfactory. One step at a time....

-

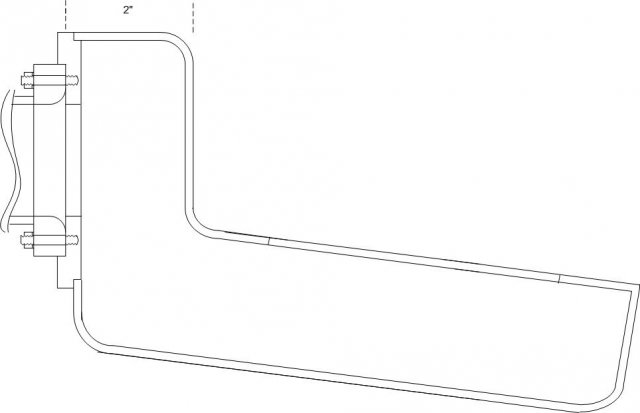

I haven't fitted it under the hood as my 240Z is fully functional right now. You can't tell from the pictures but the plenum actually tilts downward about seven degrees to account for the engine lean. That lets the SC sit flat and looks better too. I'll slap it on the long block tomorrow or Saturday and take a couple more pictures. There were numerous measurements taken to ensure clearance at the strut tower and under the PDK strut bars. It sits below the valve cover height and strut bar so hood clearance is a non issue. I decided to build the intake in two pieces so the runner and header hardware would be easily accessed. It weighs quite a bit despite being aluminum. An adjustable brace will come up from the a/c compressor bracket to support the outer edge weight and provide additional stability. I'll have to work out cold air ducting.

-

The thought that the PO might indeed see it here crossed my mind and want it back. Hell, I'd want it back too. It was a legal transaction and the car is now titled in my name. I hate to say what I paid. Embarrassed that I got caught up in the auction madness. Most bidders (about 20 there just for this ride) dropped out around $2500. The price exceeded that by a bit still. It was more than I even intended to spend that day but still way less than the cost to build it plus the body is in very good shape overall. I was really suffering buyer's remorse until I got it running and realized how nice the whole package really was. I needed an 8th vehicle anyway...yeah right.

-

Nope, petrol. I had to work out the details of mating a P90A head to the diesel block and come up with viable headbolts. It has taken a long and costly path to get this far but it should be a blast to drive.

-

I finally got the intake system worked out...almost. I still have to machine the spacer between the aftercooler and supercharger and sort out the belt drive system. The engine is a LD28 block and V07 crank mated to a P90A head and uses JE pistons and L20B rods for a displacement just over 2.8 liters. After all the time and money spent on an old chunk of L6 iron I keep hearing the "I shoulda had a V8" juice commercial in my head.

-

Somewhere is a very upset PO of this car. I really feel sorry for the fella but life has it's bad moments. It was auctioned off by the Morale/Rec/Welfare office of the local Naval Base. Rumoured it was parked at the auto hobby shop. Maybe the owner had to ship out or was stationed elsewhere and couldn't retrieve the car. It will be taken good care of by it's new owner if that is any consolation. I got into a bidding war with a knucklehead and paid more than I had intended. I still got a good deal. It was setup as a track car. Built-in rollcage (less the front bars to firewall), Panasport wheels (like new), coilovers, camber plates up front, Wilwood disc's, heavy sway bars, ATL fuel cell, MSA 6-1 header, Magnaflow exhaust, 240SX throttle body, CAI, fiberglass bumpers, etc. Little rot in the rails under the seats but no other serious rust issues and I've got a set of new rails in the garage. Battery area is great. No rust in the floors, sills, doglegs, fenders, hood, hatch or anywhere. Couple of dings, scratches and fading paint. Got it home and it wouldn't start. Left the battery changer on it for a while. Had to use a remote start button to turn it over (bad switch, wiring or interlock unit?) Just turned over slowly for a while then suddenly it roared to life. It spit and sputtered for several minutes then smoothed out to a nice tickover and thumping exhaust (must have a hotter cam installed). Nice clean exhaust. No smoke at all. I rolled it off the trailer, checked the brakes and clutch. A quick spin around the block was fun. This car hauls azz. There's a knocking in the rear when slowing down and when reversing. I suspect a halfshaft u-joint has failed which might be the reason it was parked at the auto shop. When the snow melts I'll climb underneath to get a better assessment. Also need to setup for a parking brake (Wilwood combo calipers I'm guessing) to pass state inspection. Now I'm the owner of two running Datsuns, my pristine 71 240Z and this soon-to-be daily driver.

-

I'm in the process of building a Ford WC T5 for my L28 project. You need a NWC T5 from a 280ZX to make this easy. What I have determined so far is the NWC T5 bearing retainer will fit the WC T5 casing. Both bearing retainers use the same bearing cup. The WC T5 10 spline input shaft is about .006 larger in diameter than the ID of the Nissan bearing retainer. You'll have to open that up with a die grinder and a coarse sandpaper porting cylinder or similar so the input shaft will pass through. The stock Nissan NWC T5 bellhousing will bolt right up. The top cover and linkage of the NWC T5 will be swapped over to the WC T5 case. The NWC T5 tailhousing has to be moved over too. There is a small plastic funnel stuck in the back of the countershaft on both transmissions. These funnels need to be be swapped. Another issue is the speedo drive gear location. The WC T5 has this gear located closer to the case. You'll need to relocate that gear further outboard to align with the speedo gear output of the Nissan tailhousing. That area of the mainshaft is not raised up and machined for the gear. You can epoxy a piece of .0026" shim stock in the proper location holding it tightly with hose clamps. A hole is drilled for the retaining clip of the gear. I plan to clean the area well and apply some 'Lab Metal' around the circumference. I'll get that cut down on a lathe to the required OD (since my lathe is broken) and drill the hole for the clip. I'm using a 240mm flywheel and the 280Z 2+2 pressure plate. The clutch rag will be a 10 spline 9.5" Ford piece. It is actually very close to 240mm (ideal). This will allow me to use the stock clutch fork and tall throw out bearing. My WC T5 has the Mustang 3.37 1st gear. I'm am considering swapping it over to the close ratio 2.95 gear set since I'm using a 3.90:1 R&P and a stroker SC'd L28. Only that cost is putting me off.

-

A full length metal\composite shield will be installed to deflect radiant heat. I personally do not like header wrap. My header is an old school Janspeed S\S 6-2-1 so a coating is out of the question too. The header in the photo is just a spare piece lying around for mock-up. Some sort of air duct will likely be incorporated to feed cool air into the intake\exhaust area. The inspection covers are louvered. The hood has a Nissan competition hood scoop and the hood has two rows of louvers to vent out heat.

-

Actually, I just had these produced in the last month. One was needed one for my SC'd L28 stroker project. I figured I'd have four made to help others and offset the cost a little.

-

Hi,

seen that post of fuel rails a few years late. are you still manufacturing them? thanks.

-

I'm looking at replacing the stock front LCA's on my 240Z to get some camber/caster adjustment. The T3 pieces look good to me. The problem I'm envisioning is stress placed on the TC rods when correcting caster. The ZCC TC rod has a pivot at front to allow for angular changes. By default it also adds one more failure point. I was thinking that the T3 LCA could be slotted at outer TC rod mounting hole. This would allow the TC rod to pivot on the inner bolt into a natural position when setting caster. Once done, the TC rod bolts would be snugged up locking it into place on the LCA. Am I seeing this correctly or missing something very obvious. I also like how ZCC uses a tierod instead of a heim joint at the chassis end. That could possibly be addressed on the T3 TC rod too. Lastly, it occurred to me that a poly/rubber end at the chassis would be more compliant on the street than a fixed heim joint or tierod end. Is there any reason to fear the heim/tierod on a street-driven vehicle other than the harsher ride?

-

Hi ezzzzzzz I am new to this Forum, still finding my way, I'm writing this in the middle of the night because I'm in New Zealand. I have read a post you wrote about conrods, stating 8mm ones are more available, can you help me locate an 8mm conrod for a 240z, i.e. early L24 conrod using 8mm rod bolts not the later 9mm ones, I'm looking for a number 4. if possible, or a supply of ne...

-

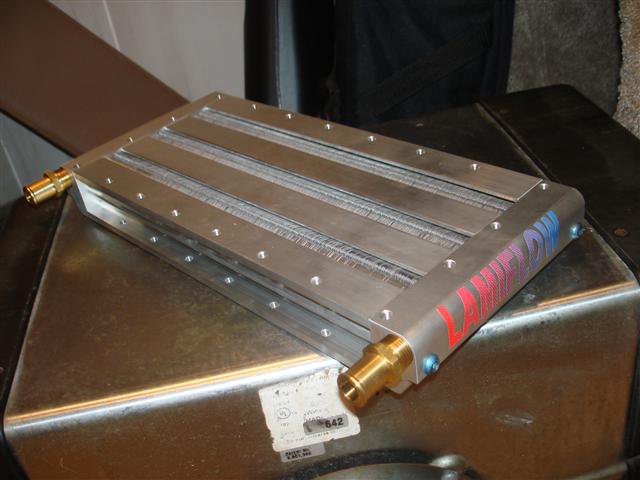

I'm using a Laminova three core aftercooler built by Rick Zimmer at www.boostecus.com for my SC'd L28 240Z. This is a mere 14" x 6" x 1.6" and rated to approximately 350hp. It is sandwiched between the SC and the plenum. A 12 volt pump, reservoir, hoses and a small radiator (around 20" x 6" x 1") will complete the system. No problems with long complex piping or giant intercoolers. Cost will come in around $1200.

-

Thanks. I found my way to your supercharger boost calculation post. I came up with approximately 5.9 psi of boost with my pulleys. I'll start with this lower boost and see how the engine performs. Compared to the 2.4 N/A with a 272 Crane cam this 2.8 should be a lot more interesting. Upgrading to a larger crank pulley would not be a difficult task if it is warranted. A reliable spirited vehicle is all I want to achieve. Trying to beat every vehicle at every stoplight ended years ago. L28 SC.bmp

-

It has been over two years in the making but I'm moving closer to a finished LD28/P90A supercharged L6. The plenum is in the works at a local metalsmith. It will bolt up to Justin Olson's intake flange. The Laminova water/air aftercooler is finished and will sandwich between the plenum and M62 SC. That brings me to the crankshaft pulley. I labored for a cost effective means to procure a pulley without machining one. What I came up with should fit the bill. The stock two pulley damper will be machined out slightly to provide a uniform smooth inner bore and drilled in a six bolt pattern to fit a cylinder shaped plug (it then goes to damper doctor for an overhaul). That plug will sit flush with the surface of the outer pulley and have a protruding step to provide a hub for centering the 6-rib pulley. I'm using a reworked GM 24500426 power steering pump steel pulley. The center shaft sleeve was pressed out and then I pressed the whole center section flat in my press. It needs to be chocked in the lathe and turned to open the center uniformly and drilled to bolt to the damper. Another thin spacer will sandwich the pulley to provide reinforcement. It measures 17.125 around the ribs. The SC is 8.75 giving a 1.957:1 ratio. I think that should provide about 8psi boost. This has been a long expensive exercise in frustration. I'm thinking I'll have to push the engine back 1" and down about .5" to provide clearnce for the SC belt/pulley to fan and account for the .75" additional height of the LD28 block (note the V07 casting number in the engine photo).

-

Anyone travelling Tuesday morning out of SE Va? I was hoping to caravan out of Portsmouth Va into Tenn.

-

As I vaguely recall, after much research a few years back, there is no stock piston to accomplish what you want. Even with a custom piston the pin is up in the oil ring area and the lands would be so close together that longivity would be a serious issue. That is why I used the LD28 block with the L20B rod. Tony will likely have a better answer though.

-

Me - "There is no possible way to get out to 89mm (or even 87mm comfortably)." Tony - "Then you shouldn't say it can't be done." I kinda expected someone to make that response. I did clarify that sleeving was an alternative but, as you also pointed out, it means a lot of $$$$$. After many dollars and hours invested it is still an archaic engine by any measure. It would be cheaper to drop in an LSx but you lose the wonderful sound of a L6 winding up. The destroked 2.5 would be a great engine with the better r/s ratio. Giving up .3 liters to gain an engine that would spin at 9000 would suit some. I opted for the r/s ratio while keeping the displacement and creating a square engine. For the street, torque is king. That's my opinion and I'm sticking to it.

-

sway bar bushing bolt holes fell out?

ezzzzzzz replied to chicago240z's topic in S30 Series - 240z, 260z, 280z

The only reasonable repair is to drill all the way through the frame rail. Don't drill through the wiring harness on the passengerside frame rail! Once done, you'll want to drill the bottom hole just a little bigger to fit a crush tube inside. The tube should be long enough to contact the frame rail at the inside top and be flush with the bottom of the frame rail. That tube will prevent the frame rail from being crushed together as you tighten the bolts/nuts holding the bushing bracket in place. There are other options which require finesse with a cutting tool and a welder. Most would be better off staying away from that though. -

I've built a petrol 2.8 using the LD block and crank, L20B rods, JE pistons and a P90A (mechanical) head. It is nearly square, has a great rod/stroke ratio of about 1.73 and compression at 8.3:1. It was no easy task to figure everything out. There are coolant holes to tap and fill, head bolts to resolve (of which I have worked it out for those that might follow this path), etc. Prior to the machine work I did some measuring of bore separation at the head gasket surface and the gap between the cylinders (through a freeze plug hole). Somewhere in here is a post of that info in some detail. The bottom line is there is enough material to punch out a cylinder about .040. After that it starts getting thin. I only went .020 over so I could do another rebuild if it ever came to past. The stock bore of the LD is 84.5mm. I went to 85mm. There is no possible way to get out to 89mm (or even 87mm comfortably). There just isn't enough wall to work with. I suppose you could sleeve it but the cost would be crazy for the results gained. My 'stroker' 2.8 is going to be SC'd when I get back to finishing the intake, bracketry and pulley system.

-

Help. removing the rear LCA from hub

ezzzzzzz replied to Dannyh4's topic in Brakes, Wheels, Suspension and Chassis

Pray for devine intervention. Outside of that happening, you'll likely be due a medal of honor after the battle. We should have a cloth badge made for the 'Spindle Pin Club'.