NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

You mean Tool Shed? He must not want much help. A stud is a stud, it can't be that special. It might be a bolt though, a unique one. Unclear.

-

Words and their proper usage are key to really understanding how things work. What I said can't be qualified with "technically, I'm right". You wrote something that is geberally wrong. There's no "technical" involved. It's just wrong. Thank for the link though. Here's a direct quote, just for fun. Although, there's no guarantee that the DSMTuner guy is completely right either. "There is a common misconception that engines need backpressure in order to run properly, generate low end torque, etc. That is simply untrue. Backpressure is a bad thing. Always."

-

The part for the Z31 BW T5 (FS5R90A) has Z31 in the part number. Might mean something. The 280ZX T5 is also the FS5R90A. Probably just a different bell housing. Number of teeth is shown in the part description.

-

You did not actually figure out the problem. Those two things are unrelated. Good luck with the new/old cars though. Good to have a hoard of spare parts.

-

That's a lot. If you can't find the info on BW gear colors you could just bite the bullet and get one with more teeth and swap it in. See what happens. You'll find the closest match eventually.

-

There is some good general engine knowledge on their web page, that translates to liquid-cooled engines. Informative reading. http://www.geneberg.com/techtips.php

-

I copied and pasted it directly from their web site. Thought it was humorous, an obvious typo. The Driveshaft Shop must have a Hybridz mole, they fixed it. Good for them. http://www.driveshaftshop.com/import-driveshafts/subaru/r180-stub-with-porsche-930-108mm-cv-mount

-

Thanks. I was thinking of sectioning actually, not dropping the BC tube over a stub. My mistake. Nice work.

-

This is the part people have problems with. And you have no details. Nobody really cares about the other stuff. No offense.

-

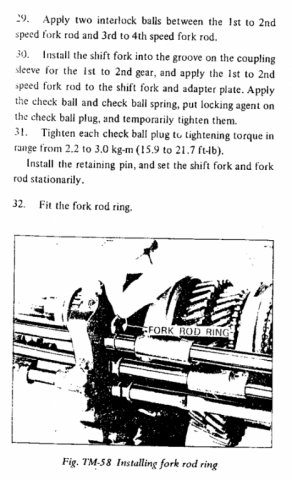

The pin is #15 in your second diagram. Retaining pin. But, checking the center position seems like a good way to check the fork location. Sounds like they're okay. I'm not sure what stops the fork from moving forward though. Maybe that's the problem. 2nd gear might use the same stop as 4th, so that's a sign. Figure out what stops the shift fork travel. Might be the detent balls on the shifting rods. The notch or the ball might be damaged allowing too much travel. They're in the adapter plate (center section) under those bolts. Found a drawing in the FSM that's interesting. Maybe you're missing a "fork rod ring". Don't know what they do but they look like stops for the rod. I've been in to a few transmissions but they're not my forte.

- 4 replies

-

- Transmision

- 4 speed

-

(and 2 more)

Tagged with:

-

Would have been informative to see where the inserts are in 3rd gear. Maybe your shift fork is moving the coupling sleeve farther than it should. I've messed with a torn down transmission (didn't put it back together though, it was beyond fixing) and did have to hold those inserts in place to get the sleeve around them so they would pop out if you move the sleeve too far. Check the shift fork's position on the shaft. You might have a broken or missing roll pin. Kind of looks like your shift fork has moved on the rod. If that's not it, there's a Hybridz member, duragg, who has delved deeper in to these transmissions than most. Not the early ones like yours, but I believe the internals are about the same. Might be worth shooting him a PM with a link to your thread to get his attention. He's around, but not recently. Here are a couple of his threads. http://forums.hybridz.org/topic/110792-high-rpm-shifting-dynamics/ http://forums.hybridz.org/topic/109855-green-machine-online-logbook/

- 4 replies

-

- Transmision

- 4 speed

-

(and 2 more)

Tagged with:

-

Those signs are typical of a bad tach. Not sure why they do that and I've not seen anyone post a way to fix them. How to remove and replace those items is described in the Body Electrical chapter. If you have a dash cap you'll have to try some tricks or maybe even remove it to get the instruments out. http://www.nicoclub.com/FSM/280z/

-

This guy has one, apparently - http://whiteheadperformance.com/product-category/240z-260z-280z-70-78/240z-280z-diff-differential-axles-lsd/ Where they actually come from is often discussed but rarely confirmed.

-

I made my rail but it's essentially like the ones made by Pallnet, link below. Either type, barbed or O-ring, seems to work (there was a discussion that supported this, on another forum). My insulators are experimental and made from kitchen sponges, installed after the system was put together (didn't want to take it apart again). But they made a difference. I'd use the newer plastic mounts instead of the older aluminum and Bakelite two-piece units if I was starting from scratch. Your engine may already have them, they're common. I have a set I'll be installing next time I take my system apart. http://forums.hybridz.org/topic/99098-pallnet-fuel-rails/ Your tach problem is interesting because the tach will show signs of a bad ignition module. They go bad independently too though, so may not be a factor in how the engine runs. Post some pictures of the engine so people can pick at it.

-

The factory sets their distributors up to have full advance by 2500 - 2800 RPM. Curves are shown in the FSM's, Engine Electrical, if you want to browse them and see. BRAAP had some recommendations and discussion in the post linked below, Post #30. Engine size would not be a big factor. Maybe bore-stroke ratio but still nothing to suggest continued advance up to 4000 RPM. Your curve seems unusual. http://forums.hybridz.org/topic/95316-braaps-l6-efi-induction-advice-and-tips/page-2

-

It would be interesting to hear the builder's rationale. Confused maybe? Or maybe he knows something. Who is it? Are we calling them "frost" plugs now? How about "pretty darn cold" plugs? Or "time for a jacket" plugs. "Hope my block didn't crack" plugs. No offense, just amused.

-

Stock fuel pressure regulator with new walbro 255 pump?

NewZed replied to supernova_6969's topic in Fuel Delivery

The only way it could "kill" the FPR is if the flow rate was so high the pressure built up and blew the diaphragm. I've never seen anyone report this. If you have a pressure gauge you'll know immediately if the FPR is in danger. Your friend pulled an Ace Ventura on you.- 5 replies

-

- fuel regulator

- furl pump

-

(and 1 more)

Tagged with:

-

I had a fan for a while. But an aluminum -6 size fuel rail and insulating the injectors got rid of the problem. The fan is gone. That's if it's the typical "heat soak" problem on a good-condition fuel system, intact, with heat shields. The problem is from engine heat buildup, transferring to the injectors and rail when the car sits, not necessarily related to outside temperature. Since you've only had the car two days you might wait and see what else you'll be working on. But there is a ton out there on the internet about "heat soak", "hot start" or "vapor lock".

-

Get one of these from a 280ZX. Or just put a 280Z throttle body back on. Most people say if you haven't done any cylinder head work the 240SX TB is too big anyway.

-

Send a message to borini63 or dangerdan88. They sell a lot of parts.

-

Good luck. Probably need another rebuild kit.

-

There are springs but they're not "on the piston". Probably fastest to just go to your local auto parts store. http://www.oreillyauto.com/site/c/search/Drum+Brake+Hardware+Kit/01271/C0064.oap?model=260Z&vi=5142642&year=1974&make=Nissan

-

Coil bind implies that there might be enough spring there (length) it's just getting compressed completely by the weight. Seems like he has two weak springs, and two okay springs. So "coil over" wouldn't fix this specific problem.

-

To anyone who's followed the new Stagg/Vogtland spring/shock option, the Brandcarparts site is in much better shape than it was, with parts and packages listed by car. Pretty easy and looks promising. I'm mainly here because I'll probably buy the suspension package someday and like to keep up.

-

Actually, what johnc is saying, combined with the other thread, I believe, is that they're all the same company/person. Something weird going on, beyond LS engine. To summarize what you're saying - one spring (the VA) is way too low both front or back, the other spring (HA) is way too high both front or back. So both springs don't work. One question that might clear some things up is - where did you start? With a stock 240Z spring and strut combo and LS engine? Where did it sit? Or are you piecing the whole thing together? Could be that you just have a mishmash of parts that don't work together.