NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Just starting my ls1/t56 build!

NewZed replied to CableSrv's topic in Gen III & IV Chevy V8Z Tech Board

Forgot about this guy. He seems to be coming in on the low end of price and people seem happy with the products. Don't know who he is, just see him filling up his product portfolio. One example. He has a whole bunch of other products. http://forums.hybridz.org/topic/123612-new-part-chromoly-axle-companion-flange-to-930cv/ https://zcardepot.com/driveline/rear-axle/axle-stub-companion-flange-chromoly-930-cv-racing.html?search=axle -

Just starting my ls1/t56 build!

NewZed replied to CableSrv's topic in Gen III & IV Chevy V8Z Tech Board

Torque, traction, and shock loads damage the drivetrain. Not just the available numbers. You can't even buy a set of adapters for half of $850. But Chequered Flag Joe took over MM's business and makes adapters and shafts if you do it anyway. You'll have to call him his web site is out of date. Copied some links to other options. http://www.chequeredflagracing.net/Datsun.html http://forums.hybridz.org/topic/119708-modern-motorsports-240sx-rear-caliper-brackets/ http://www.driveshaftshop.com/import-axles/datsun-510-240z-c-v-conversion-kit-with-108mm-flanges http://forums.hybridz.org/topic/123305-need-some-opinions-on-rear-half-shaft-route-with-r200-vlsd/ Why don't you just buy another ECM and send that one in for tuning? Then swap it in when it gets back. They're wrecking yard products, right? $40? -

Need some opinions on rear half shaft route with R200 VLSD

NewZed replied to seattlejester's topic in Drivetrain

Some, maybe all, of the aftermarket new CV axles use standardized joints and center axles, with different ends to match the applications. So they won't combine with a Nissan axle to make a hybrid axle. Beware. Remanufactured axles should work, but even those might be reman aftermarket. Better examine closely before buying. Check the axle manufacturer web sites and some will describe the details. -

New to me '74 260z has a very bumpy ride...

NewZed replied to ZMONSTR's topic in Brakes, Wheels, Suspension and Chassis

cgsheen sells a kit. He must be modest. Google the "garage" in his sig. -

New to me '74 260z has a very bumpy ride...

NewZed replied to ZMONSTR's topic in Brakes, Wheels, Suspension and Chassis

Make a list of the things you read about in your shit load and post it up. People can give the pros and cons of each. There are basically two ways to go - lowering springs, or "coil-over" kits. Coil-overs offer adjustable ride height, with lowering springs you get what ever they give you (like what you have now). Coil-overs are best for fine-tuning ride height. -

Back to the original question. You mentioned a MAF(Sensor) and O2 sensor. Those two things do not serve the same function, one is quantity and one is air-fuel ratio. One is before the combustion process, one is after. One is on the intake system, one is on the exhaust. You're in an interesting spot, knowledge-wise. You write like you know, but hopefully, (for you) you don't spend the same way. You should spend more time learning before you spend more money.

-

New to me '74 260z has a very bumpy ride...

NewZed replied to ZMONSTR's topic in Brakes, Wheels, Suspension and Chassis

The springs aren't stock size, whatever they are. They're not preloaded like the stock length factory springs would be, thye're hanging free with the car lifted. They've been painted orange so hard to tell what they are. Stock is black, Tokicos are red, MSA's are blue...etc. Scratch the orange and see what's underneath. Look at the end of the spring coil to see if it's a clean cut, pinched off like a factory cut, or a hack job. You could probably get set of stock springs, or lowering springs, and a set of new KYB shocks and be better off. You also have anti-sway bars front and back, which will firm up the ride. I don't know a lot about how to mess with those. -

Found a picture from the Arizona Z Car site. Lot of images though, don't click unless you have time. Grabbed a picture. http://www.arizonazcar.com/cars.html

-

I don't really know how that site works. It did tell me that the Whitehead link was saved one time on January 28, 2013. Probably by me in a Hybridz thread. Arizonazcar was saved 107 times and none of the old snapshots show the diff mount. It was referenced in the other thread so the picture was there at that time. Not sure the Wayback snapshot shows the old data or the new.

-

New to me '74 260z has a very bumpy ride...

NewZed replied to ZMONSTR's topic in Brakes, Wheels, Suspension and Chassis

It is a nice-looking car though. Too bad the photographer couldn't fit the whole thing in the frame. -

New to me '74 260z has a very bumpy ride...

NewZed replied to ZMONSTR's topic in Brakes, Wheels, Suspension and Chassis

Determine what parts you're running. Stock springs, cut stock springs, lowering springs (brand), "coilovers", shocks (dampers, struts), etc. All your picture shows is a car and some tires. -

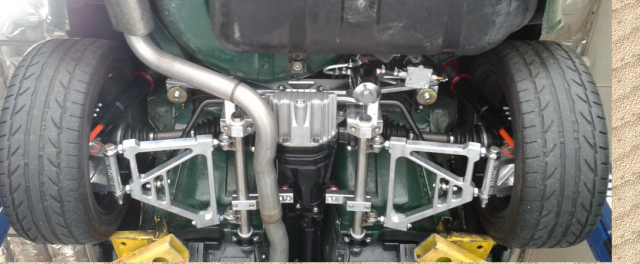

Just noticed that your picture in #5 has the center brace up to the body. That changes everything. I think that other stuff is in the way though, so not as simple as it seems.

-

Looks like the mount you're using is the TTT mount. Surprising that they sell that. https://technotoytuning.com/nissan/260z/complete-r200-r230-rear-end-conversion-z-car Arizona Z Car has (had?) another mount style. It had some minor issues, Word was that they were working on another design. Might be worth a call. Or you could fab up something similar. It puts the diff nose load perpendicular to pieces that can handle it. He used to have pictures on his site but they're gone now. Maybe working on a patent or something. Or maybe they have problems. Who knows. Here's where the pictures used to be - http://www.arizonazcar.com/lowarms.html Used to be here also - http://whiteheadperformance.com/1971-datsun-240z-restomod-rear-suspension-build-wilwood-arizona-z-car/#prettyPhoto Somebody's cleaning up their IP path.

-

This actually sounds more like an ignition problem. Put the points back on and see what happens. No need to buy a complete distributor.

-

Doesn't sound like an ignition problem. You'll be wasting money if you don't do some better diagnostic work. You'll get much better advice too if you add more information. "Mostly" stock 71 240Z with Crane XR3000 ran great now dies in neutral. Distributor has play. Not much to work with. Certainly not enough to go buy a new distributor.

-

That's for the short nose R200 or R230. Not a great design. The nose of the diff is lifting on a short lever arm, with the mounting bolts in to the frame as fulcrums (fulcra). It's been critiqued (criticized?) before. Make a better title, with the diff style in it, and a description and you might get some recommendations.

-

No pictures of the destruction? Guaranteed to get more responses. Assuming that you have an RTZ style mount and the bolts are tearing the holes? Or is it something else?

-

S30,Z31,Z32 hub/big brake conversion.

NewZed replied to FTE_WesmaN's topic in Brakes, Wheels, Suspension and Chassis

You missed my point. It depends on which type of 260 you have. And what you mean by "major": Can't tell what those last few words above mean. And the turbo engines come in 280ZX's. Another completely different body design. So if you're buying a 280ZX donor, the engine and drivetrain is about all you'll get out of it. Your project. You can research before you spend or after. Cheaper and more effective to do it before. And if you knew it was a common question, why ask it? Doesn't make sense. Just saying... -

Here's an interesting thread. http://forums.hybridz.org/topic/55119-making-my-own-efi-intake-system/ Seems like you're interested in just piecing a bunch of parts together to see what happens (re your Mix and match thread). Like a rat-rod, but instead a "rat-engine". There's a lot more thought and design work that goes in to making something that works well. Probably get some good WTF!'s when you're done though. Here are some good coments about just one 240SX TB - http://forums.hybridz.org/topic/54029-240sx-throttle-body-on-a-280z-l28/ 6x60= 360

-

S30,Z31,Z32 hub/big brake conversion.

NewZed replied to FTE_WesmaN's topic in Brakes, Wheels, Suspension and Chassis

Brake and axle questions are frequent. Lots of good stuff in the Frequently Asked Questions (FAQ) sub-forum. http://forums.hybridz.org/forum/38-faqs/ There are two 260Z's - 240Z=like body and 280Z-like body. Suspension and drivetrain parts vary depending on which you have. And the other parts are a blend between the two models. -

No expert, but if you break the system down in to its parts you might figure something out. Yours has a CAS which produces a signal, an ECU which then uses that signal, to produce a spark. I would confirm that you have a CAS signal first. It looks from your other forum thread that you're not really sure how your CAS is wired, or what it's supposed to do. It might show in your log files, but I didn't look through them. Probably wouldn't know what I was looking at anyway. I put three things in order here: "DIY autotune 12-1 Trigger disk (83 distributor using CRANK output to trigger, no pullup resistor in line, I belive Matt wired it through TACout)" ECU BIP373s wired for Wasted Spark using Ford COP (Continuity checks out)

-

Should run off battery power for a short while, with a good charged battery. For a test drive.

-

Why is distributor rotor facing wrong direction?

NewZed replied to mainboyd's topic in S130 Series - 280ZX

-

Try working through the Fuel Injection Guide. You can't fudge your way throguh the EFI system. You need to get everything set back to factory levels. Might be too late for the AFM. http://www.xenonzcar.com/s130/other.php And work through the FSM chapters. You haven't even confirmed that basic things like cam timing are correct. Engine Mechanical chapter. Who rebulit the engine?

-

280zx turbo GM HEI won't Rev past 2000 rpm

NewZed replied to rickyellow zee's topic in Ignition and Electrical

You might also add a condenser/capacitor to the W wire. The HEI module is supposed to work from zero crossing, positive to negative. But in the the ignitor swap it's actually working from positive TO zero, the ECU signal. So it's not quite right for the application and might be more susceptible to noise. Just a guess. I've fixed tachometer problems with an extra condenser. You might also move the ground point for W farther away, and/or just make sure it's a good ground. Maybe move the whole assembly away from the coil to reduce potential noise.