NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Which causes more damage to metal-on-metal contacts...

NewZed replied to parsethis's topic in Miscellaneous Tech

No effect. Once contact is made, the two sides are essentially one piece of metal, as far as electricity is concerned.. -

L26 blowing back through the carburator

NewZed replied to amplogic's topic in Trouble Shooting / General Engine

He said it has a Holley 390. Is that your distributor or a picture from the internet? Looks like a ZX distributor. If you can't check the timing at least make sure the triggering points are aligned in the distributor. Or about 10 degrees retarded with everything at TDC. That will give you clue about timing. I've seen Chevy small blocks pop back through the carb when a cam lobe was flat. I'd imagine a burnt/warped intake valve might pop back also. Valve lash will decrease as valves sink in to their seats from wear. The old unleaded gas problem. Focus on what the valves are doing. The sprocket problem is odd. Maybe it's on backward. Some of the aftermarket sprockets don't have the mark. -

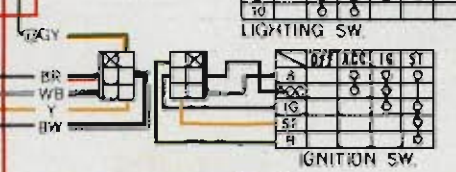

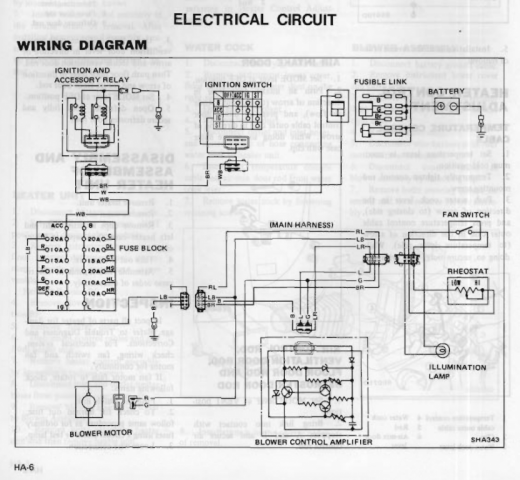

No apologies necessary. I was just pointing out how obscure your question is. In the picture I posted in #4 it shows GY (green with a yellow stripe) as a Start Circuit. I can't see why you would connect that to the blower unless you connected it to an NC (normally closed) relay that opened to cut off blower power. The GY wire is supposed to have power at Start only so you'd have to measure with a meter to know if it was working.

-

I see it as splitting up to two locations, one a green/blue wire. No connection to the blower motor. But the diagram is hard to follow without losing track. Regardless, you're digging in to a problem almost nobody has ever had in an area nobody really wants to browse around in - wiring diagrams. Looks to me like it should only have power at Start though, maybe it switches off instrument panel power or lights something up. Not sure what R means, if that is an R. But, a look at the Starting section of the FSM might find something.

-

He said it happens with the engine not running, so no spinning of distributor parts. Weird problem. For the coil to discharge the primary coil circuit has to be broken, after being energized. It could happen either on the supply side or the ground side (ignition module side). I think that even the early ignition modules had a safety circuit designed in that would cut the power after a certain amount of time to save the coil from overheating. Not sure if happens slowly to avoid a spark or quickly, giving one spark. Maybe it's failing and not cutting off completely. Anyway, (Edit - Maybe ) it's your ignition module. You could determine if it's power supply or ignition module grounding by disconnecting the power to the coil positive and running a jumper directly to the battery positive. Turn the key on so the module is powered and see if it still sparks. If it doesn't spark anymore, (maybe) there's something cutting power on the supply side, maybe the ignition relay. If it does still spark, (maybe) there's something happening on the grounding side. Could also probably be the coil heating up and opening circuit. Try disconnecting both post wires on the coil and wiring directly to battery and ground. Don't leave it that way too long, it will get hot. If it still sparks, it's the coil. This might actually be the most likely cause.

-

v8 frame twisting with fiberglass body panels

NewZed replied to hooahh3's topic in Gen III & IV Chevy V8Z Tech Board

931 -

v8 frame twisting with fiberglass body panels

NewZed replied to hooahh3's topic in Gen III & IV Chevy V8Z Tech Board

930. http://forums.hybridz.org/topic/119982-2jz-overkill-z-for-sale-35k-obo/ -

The first could just be wide tires. I don't know what "tramline" means, but if you mean it tends to grab and follow road ruts, that's a sign of loose bearings, and maybe other steering components. Wearing out tires is also a sign of loose parts. Excessive toe will do the same. That orange boot is not stock so somebody's been in there. Either they tried to fix what you're dealing with or they caused it. I had loose bearings and a wandering, rut-grabbing car for about a year. I adjusted toe to compensate, dinked around with the rack a bit, and wore out my tires pretty quickly. Replaced the bearings and set the toe to zero and I've had the new set of tires for about 4 years (just a street car). It can be hard to tell if the bearings are worn. Mine didn't seem worn but they were. Often the bearing seats in the hubs are worn so new bearings won't properly torque down. But if you get everything right, the car will track straight over typical worn, high-volume highway grooves, and feel tight at the steering wheel. Like a normal car.

-

http://forums.hybridz.org/forum/90-l-series/

-

A dial-back timing light might help you see the advanced number. I'm just trying to figure out your words. If you can't see the marks, then how do you know it's jumping? That's where I get lost. Another clue, overall, might be - why are you looking at it? Does the engine not run right? That might offer some guidance. And the thing about spinning the cam gear still makes no sense. You might bend some valves, but the CAS is in the distributor, driven by crankshaft rotation, through a gear that spins the oil pump shaft and the distributor shaft. It's not driven by the cam shaft. You can have perfect ignition timing control as the cam gear spins randomly. Sorry, but that's the way the stock system works. Maybe your crankshaft drive gear is loose. Maybe the distributor/oil pump drive shaft has play in it.

-

Than you have a blockage or a bad gauge. Yes, high fuel pressure will cause the problems you described. Proper fuel pressure is the foundation for the ECU's injector control algorithm..

-

Seems unlikely. You didn't confirm that you saw page EFEC-67. Why would you look through the suspension chapters? Seems more like you're just not sure what you're looking at. You said you can't see anything but then implied that you can see 0 and 20. And "spinning the cam gear" doesn't have anything to do with anything really. Certainly not erratic ignition timing. Sorry, just trying to find your level. You're obviously new to engines so you're going to have to put some work in. Give some background on you, and how long you've had the car. If this is a new problem, if the engine has ever run right, did you do somehtng and this problem cropped up, stuff like that. You're just a guy who has a problem he can't describe well at this point. Good luck.

-

1983 is new. That's a start. 3 ECU swaps is new. That helps. How about some timing numbers? 10 to 20, 15 to 16, 5 to 25. Those would be significant. Have you looked through the manual? EFEC-67 describes what the ECU uses to adjust timing. Just trying to help. There are many reasons timing can move around. Maybe somebody will feel energetic and make a list.

-

There are no facts in your post except 280ZXT, crank angle sensor, and timing mark jumps around. Could be as simple as your inductive timing light pickup is too close to another plug wire. But without some details, nobody can offer anything useful.

-

How is your FPR connected to the rail? If you connect the FPR backward it just blocks the return line and you'll get full pump pressure in the rail.

-

cold start issue, more amps from charger needed

NewZed replied to 280znewbie's topic in S130 Series - 280ZX

The system taking more amps implies that you have a short somewhere or a bad component, like a starter. Something must be taking that energy and getting hot, better be careful. What's the voltage do if you don't connect the charger? -

Here's another - http://row52.com/Vehicle/Index/JN1CZ06S0DX703075

-

This 83 in Arlington might have one. http://www.picknpull.com/check_inventory.aspx?Address=97225&Lat=45.506451&Lng=-122.775622&Make=Datsun&Model=280&Distance=200

-

77 280z no power + backfires under heavy load

NewZed replied to 280zHeat's topic in Trouble Shooting / General Engine

Either your new regulator is bad, or one the wires at the T plug on the alternator is not connected to the battery. "checked fuel pressure" doesn't mean anything without numbers. Open the Engine Electrical chapter and get a multimeter. You mechanic friend should have one. Check the bottom (edited - said top before) of the T plug at the alternator for battery power. Measure fuel pressure, according to the procedure in the Engine Fuel chapter. Edit - actually, with the key on, both top and bottom contacts of the T plug should shows battery voltage. -

This is classic dirty-or-stuck-dimmer-switch-contacts behavior. High beam contacts work, low beam don't. Spray some contact cleaner in to the white plastic switch at the base of the turn signal stalk and work it back and forth many times. There's crud and corrosion in there.

-

Find out where the click comes from. Put a meter on the starter terminals and see if the starter is getting voltage. You'll need to think about the difference between the solenoid and the starter motor itself to figure out if the solenoid and starter are getting proper voltage, but not working, or if they're just not getting battery power.

-

Advise on suspension needed

NewZed replied to docjim's topic in Brakes, Wheels, Suspension and Chassis

That helps. I was really looking for tire dimensions, not brand, but the pictures show a "normal" tire, probably 70 series. Ride height does not look that low. One thing you might clarify is if you mean factory-spec. ride height or what you have now, when you say you're happy with the stock ride height. Because if the springs are sagging, you're not at the spec. ride height, you're lower. Do you plan to keep those tires? If you don't you might get the new tires before going too far. They might change things. Also, you said camber in the first post, but caster in the last one. The only thing that's adjustable though is toe so doesn't really matter anyway. Unless you have adjustable camber plates. If you do have adjustable camber plates, even though you don't have adjustable spring perches, there might be other changes to the strut mounts. I might be complicating things but it's not clear what you're dealing with. Your car's been modified and there are a variety of changes that could have deviated from stock late 260Z. People do strange things once they start cutting and welding. Anyway, the shop's comments about alignment can't really be acted on easily. They're just observations. So you're left with a car that looks right (if I read your comments correctly) but has a harsh ride. So, tires and shocks, and spring preload are the three main things to consider. The KYB's are generally considered to be a mild, OE-type shock. They don't get much softer. -

Chevy 350 Swap... What Manual Transmission?

NewZed replied to Simeo's topic in Gen I & II Chevy V8 Tech Board

"World class" just means "world-wide market". "Class" just means a market classification, not like "high class". Kind of off-topic but it is one of those things that shows if you want to sell a lot of something, give it a name that sounds good.