All Activity

- Today

-

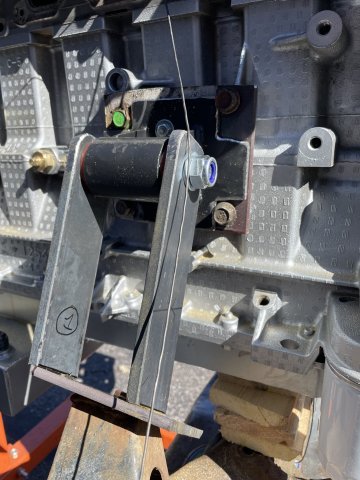

Today I got the motor mounts all done. I used my idea of holding a spare crossmember with spacers under the engine to make the mounts. 3 inches clears the steering rack with a hair of space. I used LS mounts I found on ebay for 32 bucks, and had to chop them up a bit to make them so they would weld over 1.4" steel plate that was cut and drilled to fit the 4200 block. The metal spans that it came with were too short, so I used a length of 3/16 steel bar and cut and drilled them. Then using the bolt, one at a time I pushed them up to the plate and used a sharpie to draw the angle then removed them and cut them down. You have to remember to mark everything so when apart, you don't get pieces mixed up, as the sides are not identical. After that, I boxed up my core transmission and then cleaned up a bit and headed to the other garage for 260 work. I ground off remaining brackets and other pieces that still needed to be removed in the engine compartment, then used a DA sander to get it all sanded down. The old paint etc....well 80 grit wouldn't even phase it, so I had to use 60 grit. I was able to get everything sanded down except for the corners and tight spaces. I have an elliptical sander I bought that I will use next to get all the corners sanded out with 150 grit, then go over what I finished today to let that 150 grit smooth out any sanding marks. After that, I will then slick all the panels with Dolphin glaze, and sand the entire deal in 220 grit. Then 3-4 coats of sandable filler primer to fill in any imperfections, then color, then 2-3 coats of clear. A lot of work, very dirty, but progress was made. Pics:

-

Motor mounts finished today. Fought me all the way. Now they go to be welded, then cleanup and repaint. Pics:

- Yesterday

-

There is still a few around (I’m not one of them). I’ve gotten some good advice. At least this site is still up, the 370Z site just went down a few weeks ago, ugh.

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Got the u-joints sorted. I could not get it off, ended up cutting it off and buying a new U-joint. Quadruple checked they were in phase before attaching this time 😅. Also got pedals finished, should put them in tomorrow. -

Oh I know, I just meant that most people only speak when they've got a good answer, and there are fewer people around now, so you're going to get fewer answers. It does suck how little activity there is these days. A lot of the experts aren't around anymore.

-

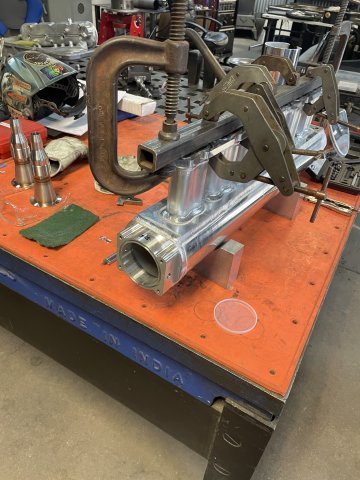

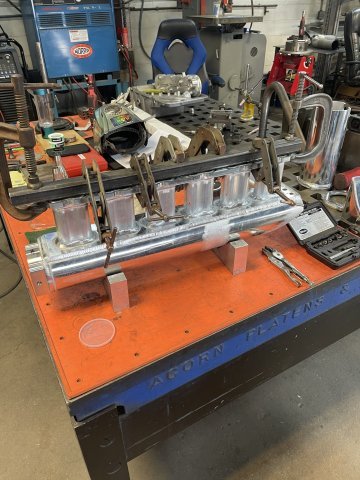

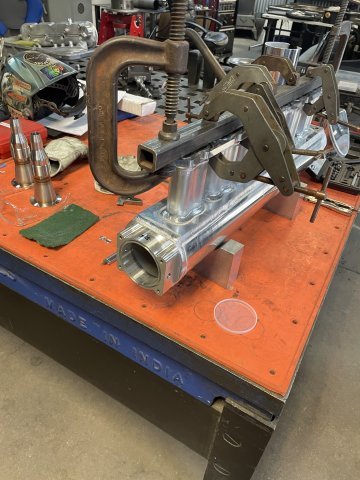

Started work on the motor mounts for the Atlas Z car swap. I bought the motor mounts online for a tad over 30 bucks, apparently made for an LS, then I had to chop on them ( doesn't look good )and then made 1/4" thick steel plates for them to bolt to and then plates for the K member. It is all being bolted togther, and will then be welded when done. Next is taking the spare K member and strapping it to the engine in place, and cutting the remaining pieces and marking everything so I can take it to a shop and have it all welded. After that, sI will be doing a lot of cleanup on them to make them look pretty and then the Atlas will be ready to drop in! Once it's in, then everything will be bolted on to it. My remanufactured AR5 5 speed also arrived today, looks brand new.....no bellhousing, so I have to swap the old bellhousing on, and box up the old tranny to send back for the core charge....they are paying the shipping! Pics:

-

Started work on the motor mounts for the Atlas Z car swap. I bought the motor mounts online for a tad over 30 bucks, apparently made for an LS, then I had to chop on them ( doesn't look good )and then made 1/4" thick steel plates for them to bolt to and then plates for the K member. It is all being bolted togther, and will then be welded when done. Next is taking the spare K member and strapping it to the engine in place, and cutting the remaining pieces and marking everything so I can take it to a shop and have it all welded. After that, sI will be doing a lot of cleanup on them to make them look pretty and then the Atlas will be ready to drop in! Once it's in, then everything will be bolted on to it. My remanufactured AR5 5 speed also arrived today, looks brand new.....no bellhousing, so I have to swap the old bellhousing on, and box up the old tranny to send back for the core charge....they are paying the shipping! Pics:

-

The frame rails are nothing special except folded metal. You could make a pattern from heavy card stock and have them created locally and save a lot of money. Those would fit your car exactly. That will save you the tarrifs and the shipping. 1,5 mm thick rails should be more than enough. The other option is to split structural square tube and if you can't find a sheet metal shop. That will probably be more expensive, but is an option. The fender brace is a very simple item you could save money having made locally too. I helped a friend with a street car project and rather than weld items to the unibody and increase the potential for rust we opted to use some of the structural adhesives that new cars get built with. It's been on the car for 15 years and seems to be holding up well. Hope this helps, Cary

- Last week

-

Sven started following Has anyone tried to install 180 degree headers?

-

I am planning to do it the right way but finding a body shop that can straighten the car is a bit difficult. I was always planning to fully strip, repair, straighten and repaint the car at some point but if it’s possible I would like to at least be able to drive the car on the road. Seeing as I don’t have a car trailer and “officially” my daily driver isn’t allowed to tow more then 1400kg it would be a lot easier to transport the car to body shops under its own power. And for that I need an valid inspection…. Instead of diving head first into an full restauration, which will take years and tens of thousands of euro’s in one go, I’m just trying to spread out the costs and take it on piece by piece. I would like to at least enjoy the car for a bit and attend some meetings in my 280z instead of my Opel Astra diesel estate. Seeing as most parts come from the US it’s a big hurdle to buy. Shipping is very expensive, there is a 4,5% import cost and then a 21% tax on the total amount. In all I pay 50% more than someone from the US for parts. This also gives me time to calm down the misses a bit as she only sees the dollar signs flying away. I have seen this spiral before and I don’t want to end up with a stranded project. I want to keep my Z for life and I will take care of her.

-

-

-

-

jhm started following Opinion on Apex Engineered rear control arms and frame rails?

-

tonight I pulled the tape, it had cured enough, it will continue to harden even more. This is not "just filler" or bondo.....it is 80% aluminum filings and 20% resin. It will not shrink, it will not crack, it is hard as a rock. They poured resin over the Pharaoh Tutankhamun's body, and 3500 years later, to get him out of his coffin they had to chip him out......so it is permanent. ALL METAL Filler. wear gloves! It reacts on skin and burns like there is acid in it.

-

I started at dark this morning, and got the seats, center console and dash out of the 260Z. prepped the holes in dash and they are now plugged and curing. then I took some time and just gutted the whole area, to include the dash. Finished at 1:40 this afternoon.

-

I'm not complaining to anybody specific. Ive been around this site for close to 20 years and back in the day it was so helpful. Now its dead. Is what it is.

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Stock diameter I think is alright with wider wheels. 245/50/16 looks good honestly, but 225/60/15 has only a few options, and they're all basic all seasons As much as I want Watanabes in maybe a 16x8 0 offset I may just end up with the Panasports that Z Car Garage offers in a 16x7 with a slight positive offset. I'm not completely sold on the +11(?) offset of those. They're on a ton of Z's, and I think they would look a bit better as a 16x8, but short of something custom and over double the price I just don't think I'm going to get exactly what I want -

Another source of frame rails and chassis reconstruction pieces is Charlie Osbourne of "Zedd Findings" in Ontario, Canada. He used to have a website; but I think his only online presence is on FB, and he retails his products through MSA Auto. I've used his frame rails and can vouch for their quality and fitment...he's an extremely reputable vendor. https://www.thezstore.com/product/5249/premium-front-frame-rail-kit-70-78-240z-260z-280z I've used Apex Eng for their steering knuckles and some other pieces; and have always been impressed with their quality of construction and customer service. I really like the design of their low-profile outer tie rod ends, which should be a great choice for your 15" wheels. Keep in mind that wheel design and construction, and wheel offset, can still affect interference between the rim and the outer tie rod ends. If you know your specific wheel model and width/offset, I can probably give you more definitive answer based on my own experience. Not to take anything away from AE; but have you looked at the other vendors for those pieces (e.g. T3, Futofab, etc?) They all have their pros and cons; so make sure you've done a full industry survey before spending all that cash. And nearly all of them also offer Black Friday specials; so you're smart to wait a few weeks before making your purchases. Good luck with it -- it looks like you're really digging into this project aggressively; looking forward to seeing your progress!!

-

As I’ve documented on this forum before I got kind of stift by the auction company and the previous owner of my 77 280z. The frame rails are rusted and need replacement to pass inspection and something is wrong with the rear suspension. I’m trying to not spend too much money at the moment but still want good parts that will stay on the car trough out the build as doing thing twice costs more in the long run. I will have to take the car to a body shop to get the frame rails welded so I’ll be looking to get pre made frame rails to save on labor cost. That gives me two choices, 1,5mm thick reproduction rails from KF vintage or the 3mm thick rails from Apex. The KF rails are send trough a warehouse in Spain so that saves a lot on import cost for me but the Apex rails are twice as thick which may give the almost 50 year old car some much needed strength and rigidity. Does anybody have the Apex rails on there car and how are they holding up? As for the rear suspension the question is if it is the chassis itself that’s crooked or something in the suspension. As I can’t find many stories of bend chassis online I’ll take the bet that it’s the rear suspension. That means I’ll have to look for adjustable rear control arms. That way even if the chassis itself is a little bit crooked I can tune it out for now till the car will be fully restored. Again that search let me back to Apex, there was also Silver Project from Europe which was a lot cheaper but I don’t hear much good from them. Has anybody installed the rear (or front) control arms from Apex with mostly stock suspension? I currently have a list of products form Apex which interests me and I’ll probably wait till Black Friday to see if they got any good deals. I don’t know if I’ll order everything but the frame rails and rear control arms I’ll probably order. This is what I’m interested in at the moment: - Frame rails - Rear control arms - Fender brace (If the car gets welded anyway, why not) - Rear strut brace - Front control arms - Low profile outer tie rods (I run 15” atm) - Inner tie rods (because of the threat difference) - Steering knuckles All combined should give the chassis and suspension a nice upgrade and the adjustability I need to get the car on the road. I do plan on keeping the four lug setup and the coilovers that are currently on the car. I do like there coilovers but That may be too much money for now. Yesterday I contacted Apex Engineered with some questions and they claim that the suspension components I’m looking at do work with the stock components. Are there people on here running Apex components (except the track attack kits) and what is your opinion on them.

-

A COMPLETE EARLY MODEL 240Z BODY may be available soon

calZ replied to toolman's topic in Body Kits & Paint

There's a shop near me that has been advertising pre-buys for these bodies(and others). I get the impression that they're working with the manufacturer.- 1 reply

-

- 1

-

-

I answer questions whenever I've got a good answer, but I haven't tried enough different sealers to be comfortable risking your engine on my recommendation.

-

He does mention having to trim his stock valence a bit with the 245s, but 225s and you having an air dam is more clearance in two ways. Small chance of rubbing though.

-

Here's a link to pictures of @ktm's car that has 245/50R16 tires, so you can see the diameter.

-

You could step up to 225/60R15. They're a inch larger in diameter than your current tires, but I think stock diameter tires are a little small for the wheel wells anyway. Some guys run 245/50R16 tires, and a 225/60R15 is the exact same diameter, so I don't see why they wouldn't work.

-

I took a break from the project but recently started getting back into things. I also went to go visit the shell at the bodyshop earlier this month and they're doing a great job. Buttoning a couple of things up, I finished setting up the fuel surge tank. The original FPG setup had some looped fuel lines and other things I wasn't keen on. I ended up doing 10mm nylon hose to a Y block and a -10 SS hardline return into the side of the surge tank away from the wiring. Generally the whole contraption is a pretty tight fit and just about everything needed to be exact/deliberately placed. I've also been working on modifying and welding a bunch of suspension parts. Mostly plating and reinforcement, some aesthetic before sending things off for powdercoat and zinc plating. In the next few weeks I need to figure out some wiring and misc. bracketry before the engine bay gets finished out.

-

Who's Online 1 Member, 0 Anonymous, 1514 Guests (See full list)