All Activity

- Past hour

-

FYI -- I've confirmed with SuperDan that the site certificates have indeed been updated. Some users may need to refresh their browsers to update the cache or empty the browser cache. Cheers.

- Today

-

This matches my experience too - a lot of aero “common knowledge” starts to fall apart once you actually try to measure things. The front-vs-rear balance point really stood out to me; I always assumed any lift was bad, full stop. Makes me rethink how careful you have to be adding splitters or diffusers without addressing the whole car.

-

AxtoFenway joined the community

-

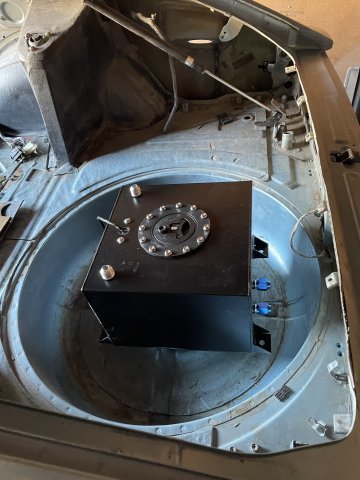

01-21-2026 UPDATE: I started the day vacuuming out the entire interior......A ton of bondo dust, and junk.....finally got it out. Later I will just have to mop it out and a light vac and it will be okay. I then installed my quarter windows, the drip rails, and the rear hatch. Installed the inspection doors and then installed the new parking lamps I got off of eBay, the sail panel emblems, and front fender emblems. A tad bit of clear caulk to help keep them tight against the metal like I want. I was also able to clean out the garage, throw away a lot of stuff no longer needed, empty boxes, etc. I set the 5 gallon fuel cell in the spare tire well for a quick look, it will be on a rack holding it up a couple inches and offset towards the driver's side to offset the weight of the battery which will be to the right of the spare tire well. PICS:

- Yesterday

-

curlyhairedcarlito joined the community

-

maxaril47 joined the community

-

01-20-2026. Engine wiring harness. So, today I took my custom Lime-swap wiring harness for the ATLAS, and stripped off the looms and tape, so I tailor can fit everything and cut the wires down for a good, hidden fit. it's quite a bit of work removing the plastic bracket that originally held it on to the valve cover, straightening it all out, getting it all ready to be installed and then separated and cut and spliced back together correctly. I have these special splices they advertise that melt with a heat gun and solder the center.....I thought I'd try them. Some exposed wiring parts will have the chrome looms I bought over the wires, as you can see in the Injector wiring in the separate pic.

- Last week

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

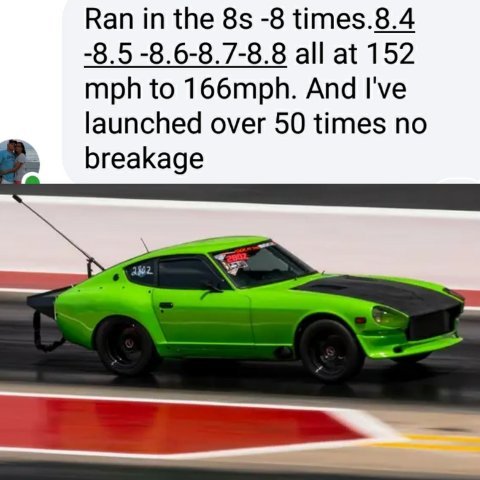

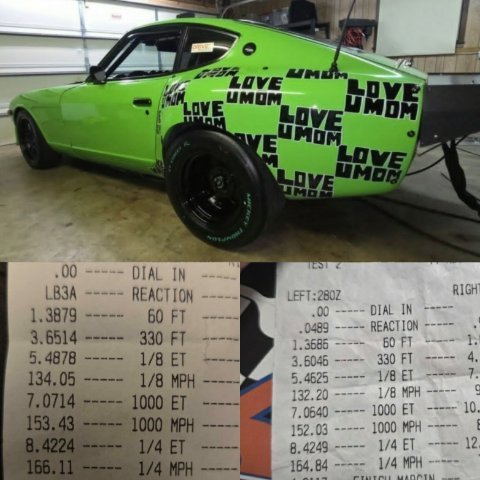

Unless somebody has a faster timeslip, fastest IRS s30 (barely) so far is Terry Garmon with 8.42 @ 166 mph in the 1/4 mile. Also included is a picture of Rick dunns 700hp car with the newest version of the rear swap, and a picture of all the components laid out, including the axles. The setup has evolved over the years, but even the earliest versions are out there putting down thousands of miles with all kinds of high and medium hp levels.- 281 replies

-

- 1

-

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

rjsicard joined the community

-

GetRishBish joined the community

-

Infest1382 joined the community

-

Novice Petrol Head started following 280z 1jz track build from a pile of parts

-

Another pic of the toggle cluster I am putting in my Atlas Z. fused and the start toggle is a momentary switch. when you flip the ignition toggle it will kill all power to the stand alone engine harness that the fuel pump runs through. I love the old school look. The quality of these toggles when you operate them you don't see often these days anymore....I got it at Summit and yep, the price is high, but the quality is A+.

-

01-19-2026 First survey of my customized stand along wiring harness for the GM Vortec 4200 / ATLAS 4.2 engine swap. Keep in mind If I had kept the auto trans there would be more....I also deleted 90% of engine functions as well....only kept the cool stuff like gauge feeds, etc. At least I have a wireless throttle! enjoy the video. 01-19-2026 harness video.MOV

-

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

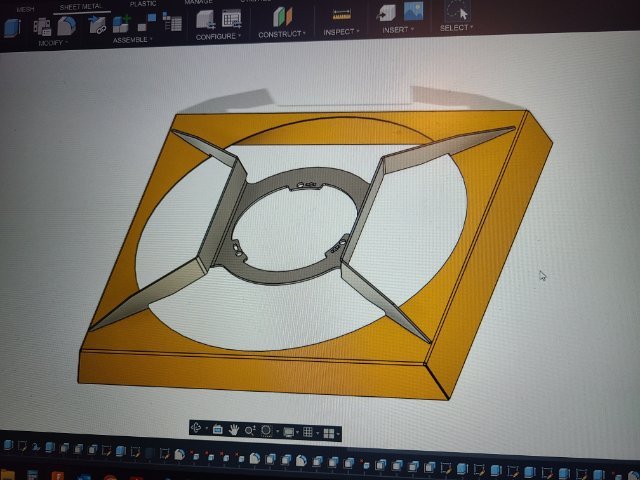

Next order of business was electric fan and shroud, and radiator hoses. I chose the 2016-2019 Camaro single SPAL 18" fan. it will be PWM controlled and is a very popular choice according to the internet as it can flow 5000CFM. Although I cut up the factory shroud to "work" I felt like I needed something fancier. modeled up a base to start working from and had my friends at laserbros in NC laser cut and bend it up. Should have gone one or two AWG thicker so added some bracing as well as some mounts and very happy with the final product. Cut down the radiator and inlets and outlets on the engine and welded on some -16an bungs, made up a couple hoses. in the last photo of the "hose installed" you can see the end of the pipe for the intake I welded into the chassis I mentioned in the previous post. Also decided to move the alternator to the other side of the engine to get it away from the heat. When i pull the engine to paint the bay i'll design and make a bracket to permanently mount it over there. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

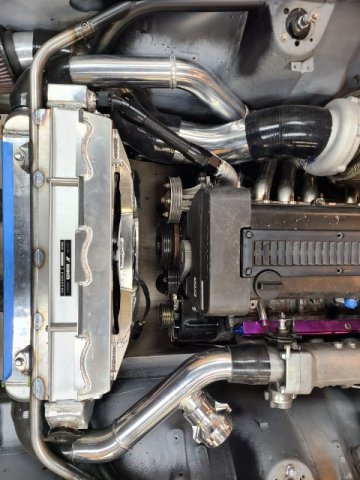

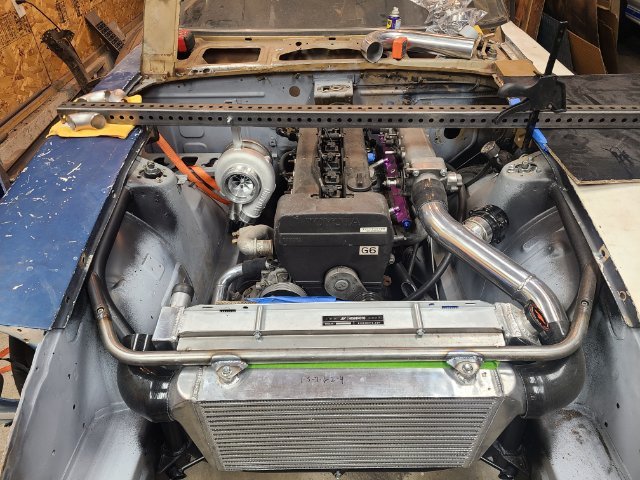

over the christmas break I got the rest of the turbo hot side plumbed. the manifold is like 3/4 welded up. My purge bottle was getting real low so instead of risking it i held off and started working on the rest. Notched a hole in the "wheel well" to go around the new added strut support bar I did that allowed me to run the 4" intake tube thru the front end and put the filter out in fresh air. Just made a piece out of 4" stainless exhaust, notched and welded it into the chassis. welded an elbow to the turbo. simple intercooler pipe made up. tial BOV on the throttle body side. have the downpipe fitted and tacked together back to about the bellhousing. Forgot to note. ditched the 350z trans for a tremec TKX. The size, weight, and gearing of the 350z transmission were all turnoffs to me. having run the tremecs in other cars i knew it was a good choice for this build. Much smaller. better gearing and options for a saftey blow shield made it my first choice. The car already had the factory trans mount cut out (poorly) so i cleaned it up and added a new mount system off the full frame rail pieces. that were also "added" They are so poorly welded that i used "added". I'll finish welding them in. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

Thanks, Im trying my best to build something fun, reliable and something I'm proud of. -

The Actual Chinese Reproduction of Toyota A86 Body was purchased and examined by several individuals who expressed their opinions about the body. The owner will attempt to assemble the vehicle with available Aftermarket Parts( tail lights, interior parts,etc. This body was the same one at the SEMA Show so time will tell its quality and parts fitment is up to the OEM Standards. This body came from the same factory as the 240Z body at the Sema Show. I checked this at the Sema Show and after watching this video, my opinion on this car is there is a definite lack of quality control in the welding of this car. There seems to be a lack of spot welds on some of the panels. On Utilized Body Cars, spot welds determines the strength of structure. Normally, the original manufacturer would use Robot Spot Welders on the Assembly Line. On this car, the welds are not close together thus not providing a strong panel. Another major flaw are the Front Strut Mounting Holes are oval not round as they should be. This shows a definite quality Control Issue. It seems that assembly of this car was rushed and put together just for the show. The Collision Industry has a established Standard -ICAR which provides proper methods of assembly of Body Parts. A ICAR Body Specialist should inspect this car before it is put on the road or used as a race car.

-

280z 1jz track build from a pile of parts

Novice Petrol Head replied to flatout's topic in S30 Series - 240z, 260z, 280z

Fantastic build so far! My favorite thing about this forum is learning new ideas for my build from more experienced builders. I always learn something from the different ways the rad and front supports are built to improve on the factory design, but I also love adding the small stuff to my list, like the gussets on the pedals. Great idea, that I would never have thought of. -

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Part of the move is definitely to keep the rolling diameter closer to oem. Separate from that it's really just about tire selection. I have lots of adjustability with all my parts, so other things are less of an issue. -

A 2026 SEMA SHOW 260Z Build all the way from Great Britain

toolman replied to toolman's topic in Body Kits & Paint

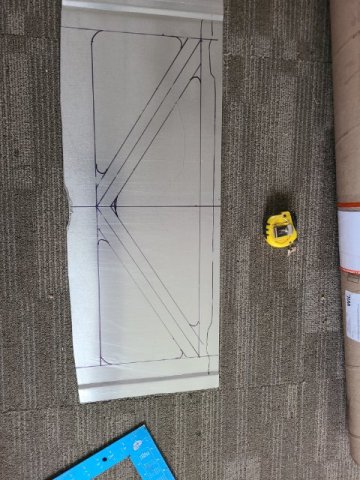

Part 4-Making the Right Side Gull Wing Door and Detail Work Duplicating the Gull Wing Door to the Right Side Door. Also, some detail work with the CAD Laser Cutting Machine for some Artistic Designs. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

Its so much fun being in the pits and having the Porsche guys come over and be so surprised how fast an old car can be. "I expected to blow right past you and I did everything i could to even keep up". We get it all the time in my uncles GT40. Hopefully this year we can have both cars out there doing the same. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

got some more photos uploaded. Switching to manual brakes per the recommendation of wilwood. moved the pivot point for the pedals to give me a 6:1 ratio. Also added one for 5.5:1 and 5:1 incase i feel the need to. welded up a gusset to the "bend" on the pedal as well as machined bronze bushings for the clutch. Designed and 3d printed an adapter plate for the firewall to accept the wilwood balance bar adapter raised to match the 6:1 pedal ratio better. Made a few design changes and machined it out of anodized aluminum. Real happy with how it came out. Ignore the mismatched hardware. thatll get changed later at final assembly. Didn't take any photos but took the factory pedal box assembly out and added some stitch welds around all the spot welded areas to reassure myself that it would hold up to the added abuse of racing. I went to PRI and talked to wilwood and tilton and couldn't come up with a real good reason to spend the extra money on a aftermarket pedal box. so well see how this holds up. I can always change it later. -

Kansas240Z joined the community

-

280z 1jz track build from a pile of parts

FastFloridian replied to flatout's topic in S30 Series - 240z, 260z, 280z

Love the build so far, looking forward to watching the progress. Same reason I decided to go with the s30 chassis for my build, wanted to (my skill permitting) beat some modern cars with a 50+yr old car. -

On a random visit back to Hybrid-Z. I kept the rolling diameter and back spacing, etc. as close to OEM. Today there are SOOO many more options for suspension setups. I bought my 240z back in 2005 before they were popular. Ebay listing was under 1,000 and they were all true Datsun parts. Glad to see this community is still alive.

-

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

started tackling the turbo system. designed and machined a stainless exhaust flange because I couldn't find one I liked. 304ss that seamlessly transitions the oval port to round so i can use sch 10 stainless. Went with a billet turbo flange from elmer racing. I make these kind of things but no way I could have made one for what they charge. beautiful piece. I ordered 321 sch10 stainless weld els to make the rest. after a little "writers block" i finally got a decent layout for a turbo manifold. The car came with a precision turbo but unknowing the condition and the size wasn't ideal i ended up going with a garrett gtx3076r with a v band inlet. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

The car came with s13 front knuckles. Apparently this was a thing a long time ago but the geometry is terrible. So I 3d scanned a knuckle and started designing a knuckle that will work. in the mean time I am modifying these with the corrected geometry I came up with for real word testing before I made a set from billet. My new design will use the 370 wheel bearing so I modified these to accept that as well to go 5 lug since I'll need that bearing eventually. They need more changes but I figured i needed to get moving on other projects like brakes, turbo stuff and body work so these will have to wait a bit before any more modifications. Went with a custom set of wilwoods. after talking with the reps a few times settles on a set of superlites front and rear. The piston volume front and rear meets the common spec of twice the front piston volume compared to the rear. designed and 3d printed calipers brackets that will get CNC machined when i have some spare time. Plan was to do 7075 for the front brackets but may get made from titanium because I have some in the right size, but rear will be an alloy steel because of the design I want the strength. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

the 1j factory throttle body is big is dumb looking so i decided to trim it down and remove all the unnecessary pieces. made up a little billet spacer to remove the cruise control pulley. I may go dbw eventually but this will do for now. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

spend some time planning out the front, bending up some tubes and getting the tubular front made up. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

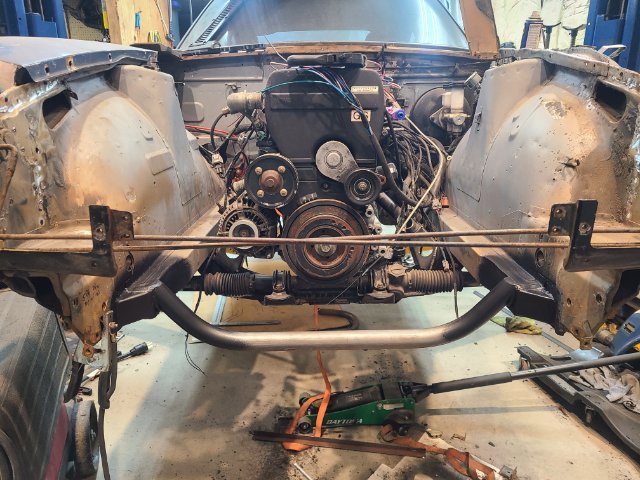

Next order of business was to get the 1j sitting in there. It came with some cx racing motor mount kit but I really didn't like them so decided to make my own to put the engine where i wanted it. Apparently i only took 1 photo. but just imagine a second one of these mounts. once the engine was sitting where i wanted it i decided to cut the factory radiator support out and make something removable to make service easier. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

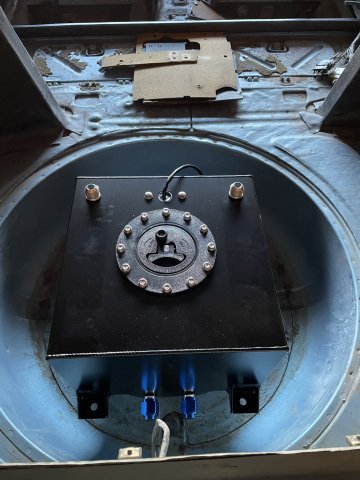

first order of business was to add a fuel cell since i didn't have a fuel tank. Went with a radium 14 gallon unit. Cut the trunk out between the factory frame rails and built a basket. Cleaned it up with some bead rolled panels. plan to add a fill behind the license plate like an old muscle car.

-

Who's Online 4 Members, 0 Anonymous, 532 Guests (See full list)