All Activity

- Today

-

I think the only downside, other than size, is the 180 pounds these weigh, from my research. DCGs are very heavy and have a deep oil pan that limits ground clearance. For a high HP car where the weight isn't a problem, I think that they could be a good solution. The MaxxECU is a nice bit of kit. I got to see one being put on a friend's car and it had tons of IO for the cost.

- Yesterday

-

I'd suggest a flat metal bracket that bolts (rivnuts) to the inner fender and goes over the top of the battery and has a small jog bend to capture the side and then bolts to the upper angle of the drysump tank bracket. And maybe some aluminum angle riveted to the bottom to keep the battery from shifting.

-

On a friend's race car he has two things that help to speed up the removal of the transmission. A dry break on the clutch line and the second is the over the top of the bellhousing exhaust. Having the exhaust out of the way when the car is still warm helps a lot if you need to remove the transmission for gear changes.

-

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

I am posting this to celebrate my triumph! After full assembly of engine and tranny I could not get the clutch to release. Quartermaster 7.25 v-drive attached to L6 flywheel from TTV Racing. Quatermaster 710 series TO bearing. Chevy clutch disks to mate with 4sp Jericho. QM Button clutches require precise gap from fingers to TO bearing of .120-.150 so I removed tranny multiple times and reset the gap with shims. Everytime I measured gap I got a different measurement. The clutch slipped a little with pedal in but required a breaker bar to rotate driveshaft. Remove tranny, reset gap, reinstall, bleed clutch, check release. After maybe 8 times I stopped and thought about it. Then read directions for the 10th time. Suddenly it stuck out, make sure clutch disk does not interfere with flywheel bolts. I've seen this before. Years ago I ran a similar set up with the head ground down on OEM flywheel bolts. This time I am using ARP flywheel bolts for a RB26. They are 12pt bolt heads already kind of thin, so I didnt consider they could interfere. Well I was wrong. So I ground maybe 0.020" off the head and reinstalled. In the pic you can see marks where the clutch rivet went across the bolts and 3 bolts I have already ground down. On the positive side, I am very efficient R&R the tranny now. Maybe 90min total. And it pops into the pilot bearing like a glove. -

Anyone running a Schneider 270-60F-14? Questions about idle

NewZed replied to juggernautjoee's topic in MegaSquirt

https://www.schneidercams.com/270-60F-14_LET6.aspx Did Schneider give you an idea of what vacuum reading you should be able to get? Opening up the lash effectively "detunes" the cam. Less lift. Seems like an odd suggestion. Does your engine have any EGR remnants? The EGR passages have been known to rot inside the manifold and leak internally. -

Well my stock speedo only went to 85mph and i know it was revving a lil high at that point for long distance driving. But hey, if you have 75mph posted signs and your car don't mind 85-90, then u have a good car! I can't imagine an original 84 Maxima wants to do that speed anymore than my zx did when it was stock. Sorry i cant be of any help other than replying to your post, to keep it fresh

-

Building Another Stroker Engine for the Track

clarkspeed replied to inline6's topic in Nissan L6 Forum

Nice work! -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

It was a neat circle track solution to a packaging problem. In hindsight I think it added too much weight. May try to redesign way in future. -

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

Thanks. the stock cam and the Diesel crank gave me that torque figure! - Last week

-

My Z car log....small jobs done and fun things

FastFloridian replied to A to Z's topic in S30 Series - 240z, 260z, 280z

Nice results, torque is amazing, Dyno day is always a fun day -

I've got an l28et, P90A head swapped to solid lifters. 5 angle valve job. Dished pistons, so low compression. Cooling head mod. 440cc injectors. Stock 280zx throttle body and intake. Aeromotive FPR. Home-made detcans. MS3x COP AEM Wideband 2.5in downpipe into a 3in exhaust Cam is a Schneider 270-60F-14 degreed to what the cam card said (I think it said 108?). At cold start I get ~10in of vacuum. Once warmed up, the best I can get with ~850RPM idle is ~14in of vacuum. I talked to Schneider about this and they told me to open up the lash to .010 and .012 respectively. That improved my idle by 1-2in of vacuum. I know the cam might be causing the wideband to not give a true reading, but at warm idle it likes ~12.2-12.5:1 AFR to achieve a smooth albeit weak vacuum idle. I have checked for vacuum leaks everywhere. Totally removed the intake/exhaust manifold, purchased new gaskets and applied a very thin coat of rtv. I made sure the intake was flat with a very large bastard file. All ports have been plugged including pcv for testing. I put it all back together and got the exact same amount of vacuum. No change. I have verified with a timing gun, set to 2 stroke mode, cranking and idle ignition are lined up perfectly with what tunerstudio says. No drift. I've got my idle set to 20 degrees advanced. Does anyone else run a cam like this with a similar setup? I'm guessing I need more advance at idle, maybe 25-28. But I want to compare to someone who has a similar build, or has more experience than me. Specs of cam: Part Number: 17043 Grind Number: 270-60F-14 Intake Duration (gross): 270 Exhaust Duration (gross): 260 Intake Duration (.050”): 230 Exhaust Duration (.050”): 220 Intake Valve Lift*: .460" Exhaust Valve Lift*: .460" Lobe Separation: 114 Intake Valve Lash: .008" Exhaust Valve Lash: .010" RPM Range: 2200-6400

-

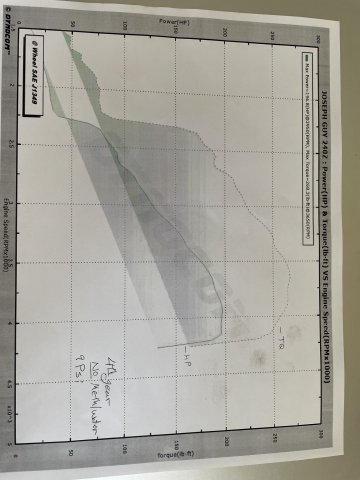

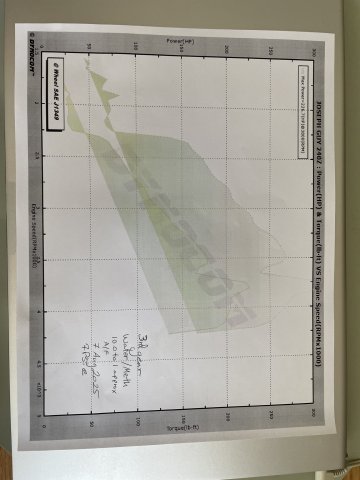

08-07-2025. DYNO morning. Found out a couple of things. 7 psi in 3rd gear WOT at 5500 RPM, 9 psi in 4th gear WOT 5500 RPM. She is RICH....rich to the point of fuel popping, 10.0 to 1, A/F rich, and didn't want to go past 5500 RPM (strange since on the road she will but nevermind). So, there is probably 40 horsepower left in her in the DYNO guys mind. We made 4 runs, and in 4th gear without using any Water/Methanol injection, it pulled 196.8 hp at the rear wheel, at 5500 RPM and at 18% drive train loss that is 232 hp at the crank@5500 RPM. Torque was 268.3 at the rear wheel, 316.59 at the crank@ 5500 RPM. Boost was 9 psi at 5500 when he had to let out because it was so rich. We did a run in 3rd gear WITH water/Methanol and it pulled 226.7 hp at 5500 RPM at the rear wheel, so 267 HP at the crank@5500 RPM and 260 torque, which is 306.8 TQ@5500 RPM, boost was 7 psi. So, as I thought when building it, the stroker and the stock cam made it into a torque monster. well over 300 ft lbs. torque, 232-267 horsepower.....but it is PIG RICH. So, power is limited by being rich. I have dyno charts, but the RPM range at the bottom is all wrong. we weren't able to get to 6000 RPM because of the rich condition. He said it was basically 10 to 1 A/F on the runs, which is WOT, so the main jet is just too big. I can step it down one. As expected, the carb is the limiting factor. At any rate, this is where this engine setup is at now. As predicted, it is a torque monster.

-

08-07-2025. DYNO morning. Found out a couple of things. 7 psi in 3rd gear WOT at 5500 RPM, 9 psi in 4th gear WOT 5500 RPM. She is RICH....rich to the point of fuel popping, 10.0 to 1, A/F rich, and didn't want to go past 5500 RPM (strange since on the road she will but nevermind). So, there is probably 40 horsepower left in her in the DYNO guys mind. We made 4 runs, and in 4th gear without using any Water/Methanol injection, it pulled 196.8 hp at the rear wheel, at 5500 RPM and at 18% drive train loss that is 232 hp at the crank@5500 RPM. Torque was 268.3 at the rear wheel, 316.59 at the crank@ 5500 RPM. Boost was 9 psi at 5500 when he had to let out because it was so rich. We did a run in 3rd gear WITH water/Methanol and it pulled 226.7 hp at 5500 RPM at the rear wheel, so 267 HP at the crank@5500 RPM and 260 torque, which is 306.8 TQ@5500 RPM, boost was 7 psi. So, as I thought when building it, the stroker and the stock cam made it into a torque monster. well over 300 ft lbs. torque, 232-267 horsepower.....but it is PIG RICH. So, power is limited by being rich. I have dyno charts, but the RPM range at the bottom is all wrong. we weren't able to get to 6000 RPM because of the rich condition. He said it was basically 10 to 1 A/F on the runs, which is WOT, so the main jet is just too big. I can step it down one. As expected, the carb is the limiting factor. At any rate, this is where this engine setup is at now.

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

08-07-2025. DYNO morning. Found out a couple of things. 7 psi in 3rd gear WOT at 5500 RPM, 9 psi in 4th gear WOT 5500 RPM. She is RICH....rich to the point of fuel popping, 10.0 to 1, A/F rich, and didn't want to go past 5500 RPM (strange since on the road she will but nevermind). So, there is probably 40 horsepower left in her in the DYNO guys mind. We made 4 runs, and in 4th gear without using any Water/Methanol injection, it pulled 196.8 hp at the rear wheel, at 5500 RPM and at 18% drive train loss that is 232 hp at the crank@5500 RPM. Torque was 268.3 at the rear wheel, 316.59 at the crank@ 5500 RPM. Boost was 9 psi at 5500 when he had to let out because it was so rich. We did a run in 3rd gear WITH water/Methanol and it pulled 226.7 hp at 5500 RPM at the rear wheel, so 267 HP at the crank@5500 RPM and 260 torque, which is 306.8 TQ@5500 RPM, boost was 7 psi. So, as I thought when building it, the stroker and the stock cam made it into a torque monster. well over 300 ft lbs. torque, 232-267 horsepower.....but it is PIG RICH. So, power is limited by being rich. I have dyno charts, but the RPM range at the bottom is all wrong. we weren't able to get to 6000 RPM because of the rich condition. He said it was basically 10 to 1 A/F on the runs, which is WOT, so the main jet is just too big. I can step it down one. As expected, the carb is the limiting factor. I will post the dyno sheets, but as I said the RPM range at the bottom is wrong. he let off at 5500, I wanted 6000 RPM but he said it just wouldn't do it., when he let off the throttle the unburned fuel was popping and banging. Pics follow (video at the end). V1.MOV -

Found this on Grassroots Motorsport web page. Seems Legit Garage is adapting some interesting modern trannys to other platforms. Think $2k for a fully sequential used 8sp box, any HP needs you have. The ZF-8HP from BMWs, Dodge and others can be fully reprogrammed for sequential operation and even add a dbw pedal to simulate a clutch launch. Might be a good project for someone that could adapt this to an L6 easily....Derek? Transmission Solutions | "Seems Legit" Garage https://share.google/HyOxohcae82yQu0Th

-

In doing a V8 swap, are you able to hook up the factory speedo cable to a GM trans? I guess there is a box you can install to get the factory tach to work. Can't think of the name right now. Thanks.

-

jeffer949 started following 280ZX Cruise Control Limit.

-

Wy wouldn't you want cruise to set faster than 75? Interstates are 75mph and traffic goes 80. Turnpike speeds are 85.

-

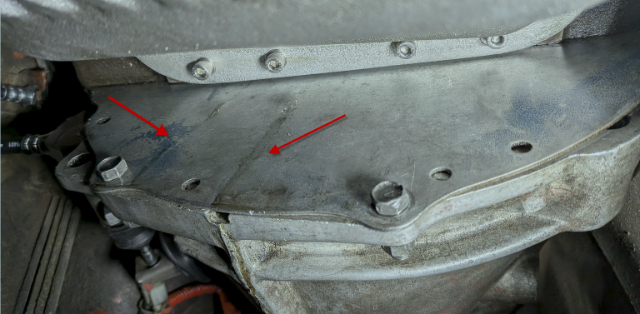

After priming the engine oil and starting/warming up the car, there is a small leak around the rear main seal. It is either my side seals or the rear main. Considering how easy it is to bump the seal while installing the rear cap, I wouldn't be surprised. I guess it is time for a tranny drop operation. I will check with my endoscope.

-

Hi CalZ, It is https://www.amayama.com/en

-

Cool stuff Clark! I dig the ARB. Cary

-

If i still had cruise on mine, i'd be happy to find out for you. But i don't have it no more. Props to you for thinking you need a cruise control unit that goes higher than 75. Good luck. Hope someone can help.

-

I'd take them off and have a close look. If the bleeder screws have holes through and the screws seal, then they MUST have an effect. If you can't measure a difference with the synchrometer, then there must already be an overwhelming amount of air going past the butterfly. Either they're already open, or they're poorly centered.

-

What is the name of the company selling brand new timing covers?

-

Back to synchronizing itbs . #4 reads less than #3 port . Bleeder screws do nothing on any ITB - are they just there for looks ? No blockage I can see anywhere . I can pull the needle completely out and it does nothing to change air flow . I thought previously it was #3 was hanging on the linkage but that turned out to not be the issue . If I got any adjustment out of the bleeder screws I think I could get it dead nuts . I’m at a loss . Been searching on line but with no luck . Maybe cheap Chinese stuff .

-

Aussie Speed has a dual SU intake for draw through turbo setups. This intake would also allow for dual Mikuni HSR bike carbs as well!

-

Who's Online 0 Members, 0 Anonymous, 462 Guests (See full list)

- There are no registered users currently online

.jpg.b34f27553f5960421801c8ab2cbf5db3.thumb.jpg.7889e8073010b6a0d8d6aae0626e768b.jpg)