-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

Twin cam head for the L6 from Derek at Datsunworks

madkaw replied to Derek's topic in Nissan L6 Forum

It’s been a while since I’ve read on this thread. I wish I was # 23 ! Wish the thread did see more action as well as the site . I’m so tired of the FB shit -

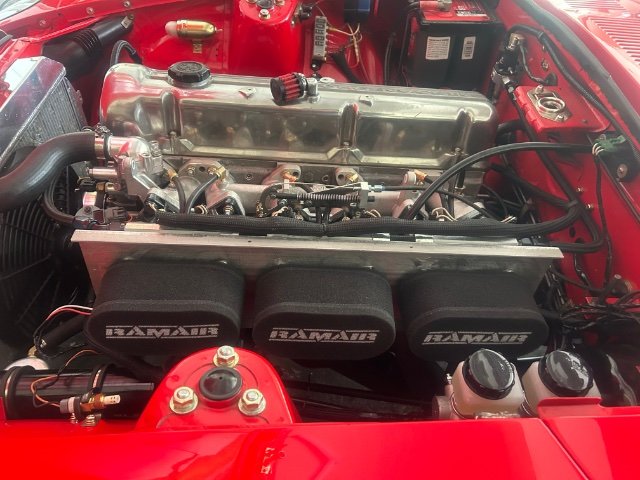

Ordered some cheaply sponge filters while I wait for my CAI box to get finished . Made a smaller vacuum log -3/4” PVC pipe . Despite having one of my widebands flaking on me I was able to drive around well enough that I wasn’t scared of dying on the road anywhere . Not much help out there for guys running MS and ITBS. Seems most Haltech or others . I’ve also got different perspectives on how to load certain tables . I have Yanni saying that all the tables can be run off of TPS and Richard that says running timing off of MAP is best . Presently I am going to try and run it all TPS . I can only hope the FAJS version of a TPS is accurate and reliable . I might eventually go with a contactless style from EFI hardware . For now I haven’t gotten past 38% TPS on my tuning so I’m not stressing my TPS to hard that’s for sure . Honestly - I didn’t think it would run even this good this early in the tune . I am trying to be patient with throttle input since I do hit big lean spots . I am also learning how to use Megalog Viewer at the same time that has a VE analyzer which is pretty damn cool .

-

Drove around yesterday with heat shield on . The tune is pretty rough and and sometimes the car wanted to die from starvation -scary . I used timing to lower idle after reading about a trick to deal with hit idle . Might have to call on Richard to help me remotely . Lots of rain right now so driving time is scarce .

-

Reducing vacuum line size seems to have helped the MAP reading. Looks like I might even get 60kpa at idle too! First drive was interesting for sure. Almost stalled pulling out in traffic and rich and lean mixtures all over the table-lol. The autotune was trying to correct but some of my settings were off. I didnt stay out long because it was Little 5 in Bloomington and too many crazy kids out . Monday when everyone is at work Ill do some more tuning, Idle seemed to increase as the engine got hotter. No heat shield yet so that is an issue

-

Latest version of mock up for test flight . It started up easy and just idled nicely - I was in shock - lol. MAP readings was around 65kpa at idle which isn’t much different than the plenum idled at . Reading was jumpy so I talked with Richard and dropped the vacuum like size from .250 to .125 - which should help smooth out the reading . Big cam and all it just idled and blipped ! Wont have the my CAI done for a minute so I’m going to run open stacks until my foamies come in . I won’t run it long like that but to get a base tune down . Murdered out my vacuum log so it would be so obtrusive .

-

Good news is my exhaust collector is ready for pick up ! Bolt this thing up and ready to fire . Reached out to Chickenman- Richard Boyk - who said he’s done tuning with ITBS before has set me up a base tune . Can say enough how helpful this is since Alpha N is all new to me .

-

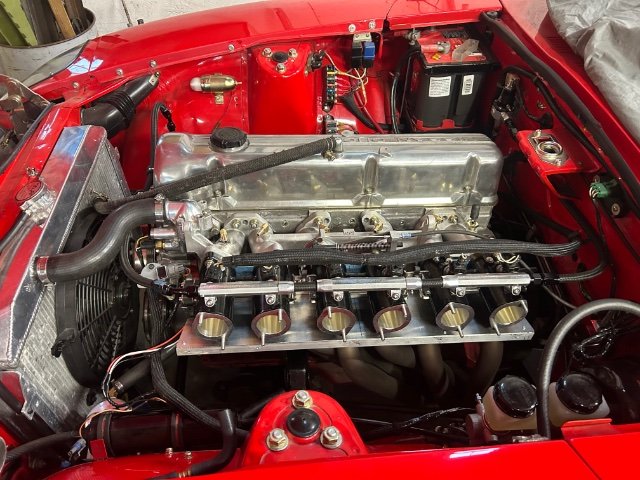

ITBS are bolted down after doing some fitting of the Maxima Diesel intake . Still waiting on the welder to finish up my collector pipe so I can’t start it yet . Also need to finalize location of vacuum log that will be inside my CAI - whenever it gets done at the welder . I wish I could TIG worth a shit and my life would be easier - lol. Still most of the back breaking work of bolting this down and plumbing should be good to go .

-

New exhaust for the 3.2 ! Serious drone issues from failing resonators made me go to a single thru the resonator . This resonator has a J pipe to help with the HZ 110 I had at 2200 rpm . With my tall OD this was an issue. I went with Borlas out back as big as I can fit so in the end I’m hoping for a quieter exhaust and less drone .

-

Did more work in the ITBS . I’m mocking stuff for test runs to see what might work and what might not . Goal is a decent MAP signal up to 30% throttle and be able to run brake booster and PCV . I thought the PVC would work for the PCV - lol. Just all temporary fun. The base plate will be trimmed down to about 6” . Running 1/4” vacuum lines to this 1” log . It might be a bit big but I want it to do a lot Final iteration might be 2 vacuum logs . Maybe ready to fire in a week or so

-

Well as I change my induction I am also changing the exhaust . I am trying to quiet down the exhaust and also reducing drone I have around 2k . I had cheap resonators on there before and they were making more drone than preventing it I believe . I decided on a single resonator with a J tube targeting the frequency of the drone . It’s a 123 resonator I found on eBay . SS everything including packing . So now my exhaust is 6-2-1-2 ! I also got new mufflers for the rear . Added larger Borlas to replace my Magnaflows . Keeping my fingers crossed that I my choices produces the right results . I will still run two widebands - one for each bank . I was able to tuck this exhaust tighter with the single resonator . I also did all SS this time which is a first . MIG welded most of it and had the collector TIG welded to assure of no leaks . V banded for quick removal

-

local dealer here told me that they were no longer available

-

Looks like those might be it but no sizes are listed . I have not heard of this vendor before.

-

Okay - you would think they are the same . Were you able to specify sizes ?

-

I am trying to find a source for shims that fit under the rear bearing . I want to change the depth of the pinion but can’t seem to find shims .

-

The info is in the guys computer but I’ve never seen the results of my porting

-

You’ll probably have to remove any “ear” casting at the bottom of the case to help fit between LCA and diff . I don’t have to cross behind so I can’t help you there

-

Well things changed a little . Bought some FAJS 45’s to put on the 3.2. I’ve tuned triple Mikunis using Megasquirt to control the ignition . I figured I get ignition sorted first and then go EFI . While the diesel Intake is going thru its R&D I wanted to make sure I had something to drive and I sold the Protunerz . Always looking for helpful tips for tuning - even basic linkage reminders - it’s been a minute . I opted for the cable linkage though my Harada intake cam with rod linkage . I plan on trying to make cable work because it was brilliant on the single TB .

-

Just a thought but you will find small cracks sometimes on the nose between the valves which might be more cosmetic than anything else and can be welded . I’d see what the machine shop says

-

What year head ? Where are the cracks ?

-

Adapters for Subbie diffs are still plenty available . That’s not the cheapest but easiest option - plug and play . 3.54 is the most common but there are 3.9 clutch types around .

-

Time to modify over the winter . On the list is to quiet down the exhaust and try and get rid of all my drone issues . Also on the list is make another intake manifold based off of the diesel intake . Currently at the welder for the first step in the process . I am flipping around the plenum part of the intake to ‘uncurl’ the intake away from the engine . This gives much more room for the fuel rail and injectors . Also provides straighter shot to my CAI . I also plan on increasing plenum size for more volume . I noticed with the Protunerz and its 38mm runners that I lost a lot of torque down low . The diesel intake runners are an ideal size to match my ports in the head . Longer runners should also help . It will be interesting to see how the engine performs with this intake

-

What year Z ? what trans crossmember ? Is the crossmember the early or late ? If the crossmember ( late ) is put in upside down that would lower the rear of the trans and raise the front of the engine .

-

Not mounted in stock location though- right?

-

So with his kit you have to run a 5mm spacer which I don’t have room for . I don’t remember reading about that with the kit offered here .