-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

You’ll have to pull that rear main and get all that RTV off of there . Nissan makes all in one seals that don’t require the metal strips . Read carefully how to put the metal strips in if that’s what you are using . I’d ditch that water pump . Get one with a cast impeller .

-

I even sent a pic to Dave and he said to not worry about it

-

Can you catch the scratches with a fingernail? I just pulled the head on my Rebello build and have the same markings . Wish I took a pic - but it’s all taped closed now . Dave allows a lot of room for the pistons to grow - like .006 difference . I have thousands of miles on this engine and have had the head of twice . Very early in the engines life it looked the same as now . I always let the engine warm up but I run it hard - A LOT

-

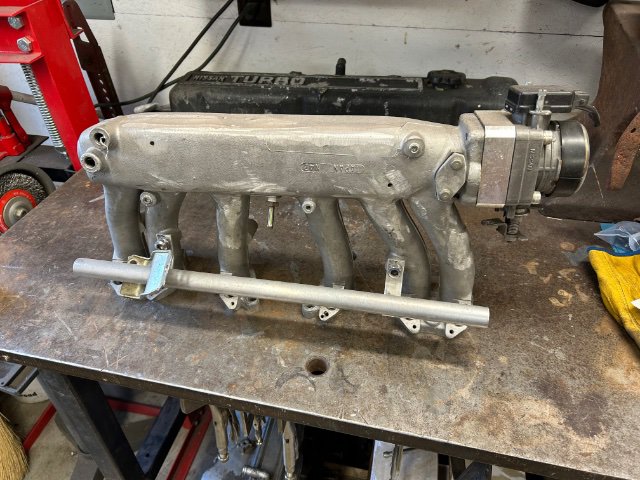

Well I am taking this opportunity to fix my intake flange position for the TB . I had the angle wrong and it made running the piping difficult . Also going to weld build the runner flanges to get rid of the step washers required with the Cannon intake . Doing all this why going with a bigger cam . While the head is out I am going to open up the ports at the neck . Currently intake runners are tapered to 37mm at the head . The head ports taper down to barely 32mm . This is one of the first MN heads I ported . You can’t hog these like some of the other L heads . I have learned after slicing up a head that I can get closer to 35mm at the smallest ID at the neck . I guess I am pleased I did 230 hp with the port pinched this much . I’ve been able to get 34.5mm just before the bowl in some of the other heads I’ve done . One person I sold a head to got 220 hp with a 2.9 running the head I built for him . This is at the tires ! Im also going to smooth out the ports a bit . I opened up the ports at the head opening to 37 - while the head was on the engine . Needless to say not optimum - but I was careful not to get shit in the motor . With it on the bench I can do a better job . Also going to CC the head and possibly do some work in the chamber . I’d like to bump up the CR to 11:1 for the next - more aggressive cam . It will be 565 lift and I believe 290 duration. I never had any detonation issues with the current set up . Once I crack the engine open I will see how the pistons look . I think with the closed chambers and 93 octane I can get away wit more CR . I can always drop some timing if needed or retard the cam timing a bit if it’s too much . Lots to do before driving season !

-

I might have an extra set from a roof part out. I’ll see if I can get them off

-

Kameari Adjustable cam gear. Adjustment lines....

madkaw replied to A to Z's topic in Nissan L6 Forum

I thought mine came with instructions that stated the increments . I thought it was 2 degrees which kind of makes sense because the total amount of change available is the same as the stock sprocket -

Requesting some L-24 rebuild advice and opinion

madkaw replied to Daniel Fox's topic in Nissan L6 Forum

Valve seats replaced ? I’d recommend to at least going to 35mm exhaust valves - it’s kind of necessary for a performance . If the seats need to be replaced might as well go the bigger size . OEM exhaust valves are good and can be had cheap -

Ignition wiring for a carbureted Rebello in a 77 280Z

madkaw replied to MM569457's topic in Ignition and Electrical

I would wire it whatever way the tach will still work . I would highly recommend a 123 ignition set up for that engine . Though I know it’s $$ and the Rebello already hits the purse hard -

SOLD Ready to go . Had this set up on my stroker and managed 226 rwhp ! Notice- 14mm fuel rail - but the injectors do seal on the stock intake . Bracket in pic is used as a stand-off for cable linkage . I used a 3ft Lockar Minor port work to match TB and blend openings at runners 500$ obo

-

No relay for the fuel pump?

-

Duffy, Do you know if the stalks can be modified on those coils ? I’d like to use them on my truck but I would need to have a 45 degree angle off the spark plug . Id need to go around the fuel rail .

-

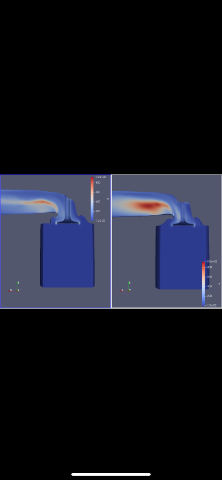

Well about ready to tear things apart again . I need to cut off the mounting flange for the TB so I can get it better angled to the core support . The angle now puts too much bind on the piping leading to the core support . While it’s off I will also weld build the intake manifold flange mounting ears so I don’t have to run step washers . Very difficult to tell if I am installing the step washers correctly and it’s a vacuum leak ready to happen . Also need to church up some of my welding of the plenum . My welds sucked and left pitting that needs addressed . Im going to make all this happen in conjunction with a bigger cam . Want to get a little more duration in order to match cam to intake . I will probably bump compression closer to 11:1 also . I will also address anything that needs to be done to the ports based on finding with the CFD model . I think I can open up the ports a little more , but won’t do that unless the model suggests that. I’m about at the limit now with port size

-

Like to find the limits of the linered exhaust port as far as flow and see what we can do with the liners pulled . My friend Andy is working on some old Volvo heads now that have a worse short side radius on the exhaust valve than what the MN has with liner pulled . He has some interesting ideas to improve the flow to get the flow around the sharp edge of the seat . Id say either subject has not been dealt with any amount of effort . Most just went on to a different head

-

Not sure there is a way to weld the short side radius which is arguably the most important . I had it welded under the seat on the long side - that was tough enough

-

One of the things I’m hoping to verify . I will be doing a head that has liners removed

-

One of the Maxima heads I have - might be the one on my stroker- was previously on a turbo motor . The later heads seem to be better castings and I think for low boost motors it would be fine .

-

The process has started . First the silicon model and then 3D scanning and then computer porting . Love science

-

Ran this stock 71 radiator in my stroker no issues . It’s been cleaned by radiator shop that was impressed how well these 3 rows flow . No leaks but lower outlet is dented . Probably be straightened fairly easy . 75$ plus shipping in the USA obo

-

-

Probably going to give a LOT more info before anyone can give you an intelligent answer. History on the car? Any maintenance done lately? In gear of out of gear? etc….

-

I would just get a standard dizzy shaft and sell the turbo one

-

Currently contemplating my next move . I think a cam with more duration would work well with this intake . Need to take about .020 off the head surface to raise compression . Maybe cut it open and install some velocity stacks on top of those runners and make them a bit longer . Also have another head I’ve been messing with . Liners removed on this MN . Also have a friend that can 3D scan my combustion chambers and ports and give me some recommendations on how to manage these exhaust ports . Short side radius suffers without the liners . Maybe his computer program can find me some CFM

-

That AFR gauge is a curse sometimes . I think I’m your build that I would want one . Even with my NA build I obsess over that damn gauge . I have dual exhausts and a O2 sensor in each bank and they can be off from each other as much a 2.5 pts . I guess it’s the way the air moves around in the plenum . I think you will have to just go to the rich side and be happy with that ?

-

I appreciate your attention to detail. You are taking on a tough task of pressurizing those carbs . Can’t wait to see the end result . I thought about it with my Mikunis . I even had my MS3 running ignition with the carbs . In the end I chickened out - lol

-

What idle rpm do you shoot for ? I let mine idle pretty high - 1000rpm. I figure it keeps oil on the lobe and easier to find a happy spot for the engine to idle . I use stepper IAC myself , and it’s been a challenge . Getting the idle to come back to the same spot every time with a big cam was also part of the challenge . I also think my 3/8 I’d hose is too small for this engine . I need to put a 1/2” since that what a lot of OEMS use .