-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

Might add to the Oreck method that make sure you start with a clean bag in your vacuum. My reading the second time around were not stable. I thought I should check the bag and sure enough it was plugged full. New empty clean bag cleared that up. Feeling pretty good about the carbs I moved on to changing up the vacuum log. I shortened things up so I could keep the vacuum hoses from running all over the engine bay(it seemed). this will look some cleaner when all together!!

-

CR should be 10.65 based on 39cc chambers. Got another mn47 that wasn't warped, just rusted and a bent valve :0 At the machine shop getting a valve job and surfaced. Sticking with stock valve size for now and will dyno . I might unshroud the exhaust side a little, it's really tight. Plan on swapping all parts from warped head to rusty head= 1 good head job!

-

I have a head at the machine shop that was a victim of bad rockers. The two surfaces of the rocker were not parallel and the rocker sat crooked on the valve. It wasn't caught because the rocker was only swiped tested at the cam, which looked good. So my question is - do you just Dykem the wear area on top and bottom of the lash pad when checking? Since the rocker just moves up and down on the valve side, does the wear Dykem test work as well there too? Trying to make sure I get this right

-

Like Jon said, use the fire ring as a guide and give the valves some more room to breath. Looks like someone has taken a few thou off of there, might get it CC. Clean up the spark plug threads that are showing, make it all smooth with no sharp edges.

-

Must have been appearance alone at the time because he hadn't installed them. I will update if he ever gets my head done.

-

I meant to say rocker arms unlimited were the better choice

-

Sorry, I did get them back and my machinist did like the ones from Rockers USA better than the Delta ones.

-

What's a consistent load? Jetting by the numbers doesn't look that far off. What's the spark plugs show?

-

I agree to all that Tony, the Oreck method(for me) almost seems dumb proof for getting everything set to the same opening in the beginning. Then once on the car, it's a measured turn on the screw for each carb. I only opened them enough to get a reading and set a standard for all of them.

-

Door panels look fantastic. Still hoping for a console that blanks out the shifter holes so I can move mine forward. I'm quite sure I'm not the only one either. Sure glad I started this thread- lol

-

As far as Oreck procedure. My buddy stared at those throttle plates and poked and prodded them and I was sure that some of them were off by a little. With the Oreck they showed all the same. I couldn't come up with another idea to get a good measure on the opening. Feeler gauges don't work because of the size and shape of the area. Visual perceptions are just that.

-

1" drum sander in a cordless. 80 grit drum sander will do everything fast. Used it to notch my cylinder bores too. Very manageable and hardly a chance of misfires, if you know what I mean.

-

NA 3.1L=>head & camshaft questions. No shortcuts, max

madkaw replied to zredbaron's topic in Nissan L6 Forum

I'd say those carbs are too small--- period. Put some bigger ones on with the same jets and let the numbers do the talking -

Putting this combo together and will document the fun. I bought a 1983 zx motor about a year ago with plans to put my E88 on the short block. I sold off the P79 head since I didn't have plans to use it. I only paid 200$ for the motor and got 150$ for the head, so not too bad a start! The engine had 110K miles on it and the internals looked good. Maybe someone can verify for me that the stock p79 pistons do indeed have P79 stamped on them like these. The main bearing caps also had dots numbered in them-factory? The bores were so smooth it could have been touched before but all measure within stock limits. a cleaning and ball hone was it needed to be useable! The crank end could look better, but at worst a speedy sleeve could cover the groove and rust. Pistons measure above deck as archived at 19 thou. The pistons themselves look new after cleaning. I plan doing a minimal, frugal- rebuild, bearings and piston rings. We know all the Nissan stuff is good. The head will be a Maxima 47. I have always be intrigued by readings in the archives by 1fastZ and others about this head. It might be the best band for buck for our motors, if it can be done right. Yes the CR will be high, but thats the fun right? I'm hoping the versitility of my MS3 will help me manage and control the high CR motor. Not sure if i will be going straight to FI with this build or using the Mikuni's first. I have an early FI intake on the way now since I sold off my 83 intake for 75$. I found a n47 on the innerweb and had it bought and shipped for 150$ Took it to the machine shop to find it was .030 out of flat-not good. It did come complete with cam and rockers which i think are very useable. They did refund my money and I kept the head. have another on the way

-

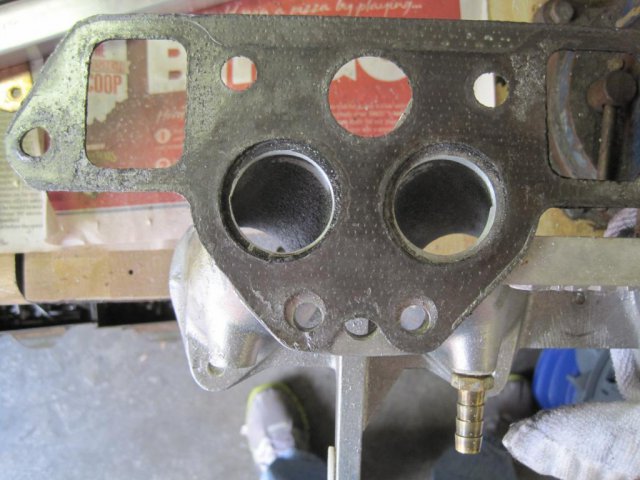

Looking for way to preset my Mikuni's before installing I came up with this. My wife got excited when she saw me dragging out the Oreck, but I let her down as I carried thru the house and into the garage. I thought the ole Oreck would supply a very stable SUCK on the carb that I could set all the carbs too. At the same time I could eliminate any possibilities of a bent throttle plate if each carb barrel pulled the same amount of air. I used my Unisync to measure and set all the carbs at the same level according to the unisync. I never liked using the feeler gauge on the idle scews because it was hard to see and feel. I also didn't like the way my Mikuni intake lined up with the head ports. Looking at the gaskets you can see that the ports aren't centered . Without eliminating the step for anti-reversion control, I opened the holes enough to make them centered with the head ports. Be careful to check your gasket centers on the head . I have 2 felpro's and they line up differently.

-

So he's running 155 mains with almost the same engine. It seems you have another issue or you have chased your tale to 190 mains. Not critizing, but your jetting has seemed way off for your build.

-

Got one guys-thanks

-

How much?

-

Jamal, Just took a closer look. Not really wanting a webbed type intake. I appreciate the thought

-

Jamal, Pm you later.

-

Let me see what you got. PayPal ready.

-

Thanks for correcting. This carb tuning is tough enough to figure out--LOL. It's pretty cool Dave could take the time to personally get your car running right. It's also good to know you can turn down the venturies since the larger ones seem hard to come by. So did you do the cam timing change all at the same time or did that after changing the venturie.

-

To keep things correct - you ended up with 65 pilots, not 65 pump Jets. Interesting to know you can turn down the venturies like that- good info.