-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

I think color has a lot to do with looks of this car. My daughter's Z in black with the gold interior is really classy IMHO. Wider tires and rims would give the car a more muscle look-hope to do that if I keep the car. The front end needs something too. I think painting the bumpers sleeks out the car and gives it a more modern look. I really like the car, but it is a toad compared to my s-30. The rear brakes on these cars-81 version-suck, can't get them to perform well. But driving a s-30 with wildwoods will spoil you! Leaks, leaks , leaks are a problem with these cars and you can't buy a new hatch seal:( Most of the metal repair i have done is because of water leaks. Auto climate control is a joke, but every manufacture has had its f$ck-ups. I hope to keep this car and fix it up to better then new, but that is a more costly and more involved then a s-30. I will say that everything but the climate control still works and works well. Another big issue for me is the auto trans, It needs an overdrive. This car would be a highway gobbler with an overdrive with an electronic control, but that will be a 2500$ venture in a 3500$ car. Though my daughter loves this car, I imagine it will be a distant memory when she sees the 2007 subaru impreza wrx wgon I got her. Let's face it, a 81zxt is cool, but not a good daily driver when the weather changes. She loves the fact that her Z causes many conversations and compliments, but for everyday convienence the Subby will spoil her!

-

LOOKS GREAT!!!!!!!

-

Bo, I like that set-up. I was going to get an analog guage with a black face, so I thought it would blend in well enough. I'm not worried about it looking completely stock, but it would be nice to have the guage mounted in the cluster. So Bo, is the color on the background just white, or did you figure a way to use the green light? Anyone mount a fuel pressure guage inside their car? I noticed some guages are not for use "in" the car. I would like to monitor fuel pressure "real time" running down the road. Their seems to be a big difference in price and quality in fuel guages.

-

Wanting to install a wideband on my 71 and put the guage where the clock is. Most of the guages I have seen have been 2 1/16" , but I guess we need a 2 5/8" guage for it to fit correctly? Like to get some ideas here so I can order a guage set-up.

-

Well they want you to use the marine clean first, then metal ready, then por-15. If you haven't tried the marine clean-it is awesome stuff for getting things very clean-no grease. I think they want you to use the metal ready on everythng you paint, it helps prep clean metal and treat the rusty stuff too. Looks like you have the ideal canidate for this stuff!

-

derek, what is the difference between that pulley and the one on an early(9/71) that would cause your wheel not to fit. I am unfamiliar with the differences, but it looks like the front pulley is smaller in diameter compared to the rear. I only ask because my damper has been rebuilt and balanced and would like to keep it and use your set-up. thanks

-

I think that last line was for me

-

Same experience I had months ago. What a way to run a company. Maybe that's why their panels are sh%t too. Their QC department is asleep at the wheel also.

-

Not a Mikuni expert -BY FAR, but you didn't mention if this fuel pressure problem is affecting the engine performance? Could you just have a guage problem?

-

Okay, but what about gasket matching! Only kidding:)

-

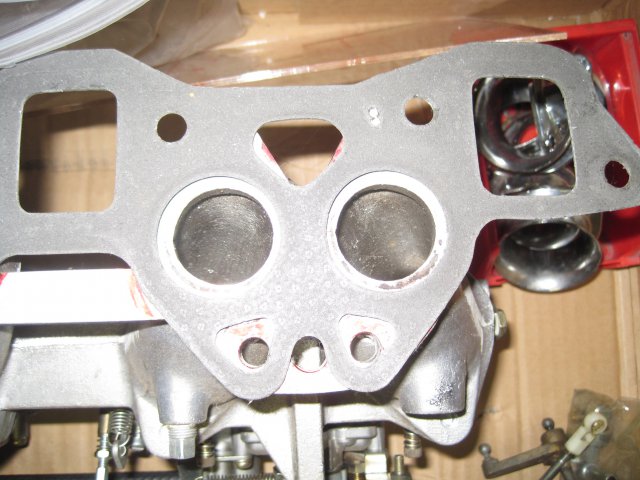

Okay, I understand the logic behind the reversion better now, but again I was suprised of the size difference. And when refer to overlap, are you refering to a cam that has an overlap grind? Does my stage 2 270/270 with 480 lift qualify that statement? Also, does the fact that this is a Mikuni short manifold change the effective velocity as compared to a long manifold? In other words do changes as far as the possible negative effect of gasket matching to velocity lessen, because of the less distance for the charge to travel? Lastly( I hear a sigh of relief from the crowd), when using this manifold later on for ITBs, would this be a mute point as far as fuel injection? Would gasket matching be a better course at that point? I hope someone else is getting something out of all these questions!!!!!!

-

TonyD, thanks for the response, but confused about this line I'd not screw with it, port matching will gain you nothing if the manifold is smaller than the intake port I think you meant that I don't want the intake manifold port larger then my head port-which I understand that. My E-88 head is modified with the larger valves, mild porting, unshrouding of the chamber area and a stage 2 cam. I was just taken back by the size difference in comparison to the gasket-as in the photo. If there was some opening up to do I wanted to do this before I mounted these up. This is all a learning curve for me and I just ASSumed that gasket matching was prudent, but worth while effort towards performance. I have no proof, but I believe my SU's are choking my engine performance in their stock form. With my humble head improvements and dual 50mm exhausts it seems my engine needs to 'breathe more', but I might be just talking out my a$$. I will probably just bolt on as they come for now, and see how the improvement goes. These 40's came off of a car running a L24. I believe the brochure for the Mikunis stated that this was a 23% hp increase!

-

Steering rack mounting rubbers - poor fit?

madkaw replied to Boy from Oz's topic in Brakes, Wheels, Suspension and Chassis

Are the new ones rubber or urethane? If they are urethane then drop them in some boiling water for a couple minutes before installing and they should form into place easier. -

I saw some of your posts and pictures when doing the research. This blow thru set-up is very cool, but I think I will be over my head. I think I will stick to my original plan to go from SU's, to Mikuni's, then EFI TBI's and then maybe turbo charge that!!!! I think with the advantages of wide band O2 set-ups and edis you could maybe help the blow-thru set-up work better without a lot of guessing on your afr's. This doesn't change the fact that the Cartech box is too small or the set-up is not as driver friendly as what I want for a semi-daily driver. Tony would say-go efi is the better way to go-and I agree. The money spent on this set-up would be much more cost effective to buying a wideband/O2 and EDIS and getting the optimum tune on my SU L24 now and slowly work towards a MS controlled EFI.

-

This is the problem when considering this set-up, there is not much info out there for the non-expert mechanic. I read that this Cartech set-up puts boost out like an on/off switch which cause lean issues. This might be a waayyy cooolll set-up in it's time, but it might be more expensive and time consuming then just going from carbs to EFI. Yes there are threads about the Cartech, but no specific instructions.

-

Thanks Tim, I'm not really interested in doing any "porting " as much as doing gasket matching. Looks like you went beyond gasket matching, but your intake ports might be enlarged. I only enlarged my e-88 ports to match the stock gasket and SU manifold.

-

Thanks Sam ,and as Shane said, he sent me that info. I wish it was for the Mikuni set-up. Sam , you said the Mikunis are for the cartech set-up specifically-do you know if the jetting is set-up for the blow thru and does they have different floats?

-

I know this is a long shot, but does anyone have any info on the Cartech mikuni blow thru set-up. I would love to find a copy of the installation of this set-up. I have contacted cartech and they said all that stuff was destroyed when they moved offices.

-

Okay, I was told this kit(came in a mikuni box) was for the 240z specifically. So they intentionally make the runners small to apply to all the L6 motors? I noticed quite a lip behind the mounting flange area- in the runner, so gasket matching shouldn't take it beyond the actual runner diameter?

-

I broke out my Mikunis to look them over for the future install on my Z. I wanted to check out jet sizes and such to get my base line for future tweeks. I went thru great trouble to gasket match my SU's to my e88 before install and thought I would do the same for the Mikuni set-up. But WOW, i couldn't believe what I saw when I layed an extra intake gasket against the manifold. Am I missing something here or is this right? That is a huge difference-not sure what to do here guys, I just seem baffled over this. These are 40phhs by the way. Comments please.....

-

Yeh, I realize that, that is why I am anxious to get a wideband on this car and stop guessing as to what I'm doing. I didn't just bolt on parts---well I did-but I do realize it's about tuning them all together. The car seemed lethargic revving out in 3rd gear. It was like I was watching the tach in slow-mo. Somethings a miss there, so I need to know what's going on----back to the O2 sensor.

-

I am kind of where your at right now-lot's of work and not happy with the end results. I agree with the above statements that a more precise tune will get better results. I need to get a wideband also, so I am not just guessing about what's going on. I believe I have an engine that wants to breathe, but my SU's are not providing enough air to the engine, but can't prove that without the O2 sensor. Your engine sounds good-don't give up on the L6 yet, it has the way-cool factor going for it!!!

-

Well a totally disappointing trip to the dragstrip. Though the car held together great, my times sucked, The best i could muster was a 15.6, I have a lot of time and money in this car for 15.6. I'm hoping the triple Mikunis will wake up this motor. I will be getting a wideband shortly to verify what I think is a lean top-end.