-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

I understand that there would be a difference in bore size, but what else would be different on the L6 blocks. I have also learned by ordering a gasket that some have all the coolant passages open and some don't. In my case with a p-30 block where I have notched the bores for bigger valves, I wonder if a l28 head gasket might not be better since the notching is very close to the fire ring-less chance of getting under the gasket. I have searched on all the Z sites and have found very little specific info on this.

-

I never had any cooling issues what so ever with my engine, but I'm not hardly pushing 200hp at most. Would an 83 gasket work on a p-30 block? Is is a Nissan gasket? Nevermind, I just reread your post.(nissan) Courtesy had cheaper Nissan gaskets for later years, but I wasn't sure I could use those. I searched for a while and couldn't find a definitive answer

-

Just ordered my 150$ gasket-OUCH!

-

Hey Tony, in the market for a Nissan gasket and plugged the above part#11044-R1005 in at courtesy nissan and they are about 50$, so you better order some. Now I searched the Nissan # 11044-E4620 for my 240 and it's 150$. Not sure why their is a big difference unless the 240 gasket is made up of a different material.

-

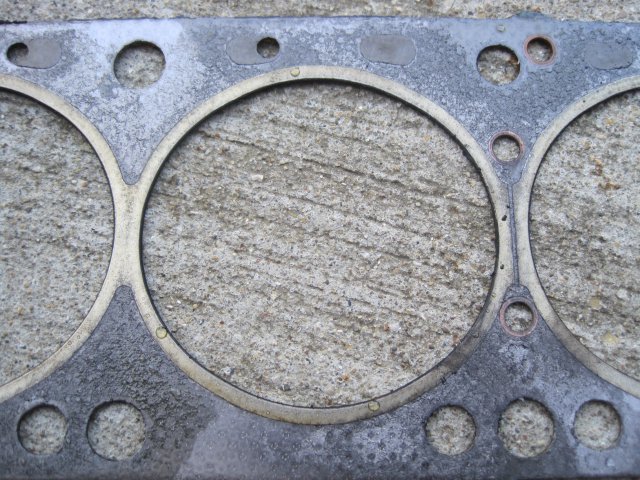

Well unfortunetly, I think I got the same garbage . What really concerns me is the difference in the coolant passages. If you look at the first pic of the gasket that I had on there, half of the coolant passages were blocked by the gasket. On the Victor reinz gasket they are all open? Also asked the Rock Auto sales rep to pull a gasket and tell me the make up of the gasket. I told him that i was not interested in a fiber board type of gasket, and of course thats what I got:( I guess that's what I get for trying to go cheap.

-

Tony My experiment was on a fresh rebuild with the block oil passage enlarged. The only fault in my experiment was the fact I used a drill to turn the pump and that might not have been enough rpm to apply enough pressure-2800. I did verify pressure with a guage and visually verified the spray bar oil not reaching the folowers. This was a high pressure pump. I had a thread on classiczcar documenting this

-

Just read through this thread trying to get insight on my clunk issue. I am also running RT mount and all my suspension bushings have been replaced. I also have had a high speed driveline vibration. I concluded that all these items were related to a compromised tranny mount(welded on and probably ruined rubber). I recently moored my tranny down with a cable set up and the tranny is now very secure against the rubber mount-and the clunk is still there. I think I got rid of my high speed vibration-still need more testing-but my clunk during gear changes(mostly at lower rpms) is still there. Please keep this thread updated. I will be changing out my R200 for a STI r180 and we will see if the diff has anything to do with my clunk

-

Well one benefit from this job was finding an exhaust leak that I knew I had but couldn't see. Damn MSA header had a dimple on the flange right below #4 - it was pissing out right there- time for JB weld .

-

5000 + miles on my schneider cam and it looks perfect. I have read of cams that the holes were not drilled through properly. And I have tested running both hollow camAND spray bar and it didn't work as well as you think. The hollow bar takes to much pressure or volume away from the spray bar and the oil never sprays far enough to do any good. I also run additive with very oil change

-

Took the head to the machine shop so they could chek flatness with a good straight edge. Since the head is still assembled he could go right down the middle, but on either side longitudinally he couldn't get a feeler guage under anywhere. He attempted to measure diagonally and he was able to get a .015 guage under the straight edge towards the middle of the head. Not sure if that equates to anything, but he felt that on that long of a head, it was probably OK. Ordered some Victor Reinz gaskets from Rock-Auto. They are having a close out on them right now and they are only 9.96$ They are some kind of metal gasket with a composite covering-similiar to what I pulled off. I guess if they don't hold I will try a Nissan gasket at 150$$

-

I'm seeing something around the five o'clock-is that an oil gallery right next to it? The reason I ask this is because I have been having a oil leak on thr rear main and I have changed everything. Is it possible this compression leak could in anyway pressurize the oil system enough to cause blow by on the rear main?

-

Pete, I know it's hard to tell with these pics, but where are you seeing the blow by--o'clock position? I guess I will take the head to a machinist that probably has a better straight edge and have them look at it. thanks

-

Well if no one has ideas I guess I will just slap another gasket on there and hope for the best

-

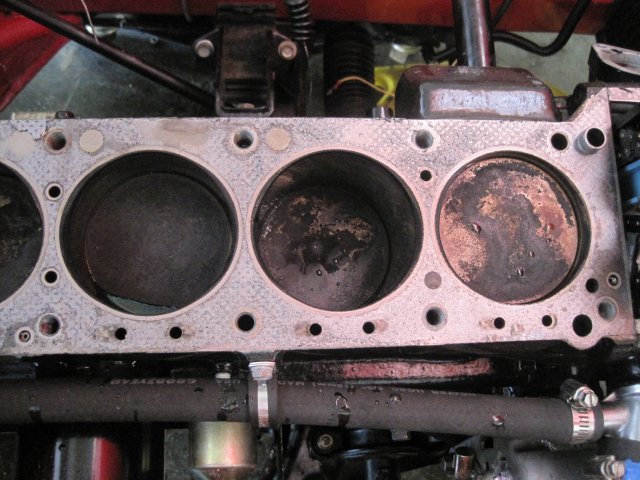

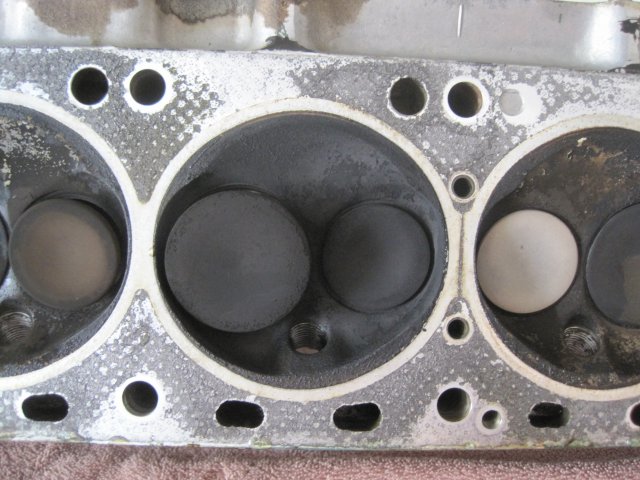

Pulled the head and here some pics. I don't see anything that jumps out at me, but not sure what to look for. #3 cylinder firering has some"discoloration" around where the water comes thru the head. Looks like #3 is the worse and #6 looked like it was getting there This pics are BIG-sorry, but you might see more detail this way Any ideas

-

That's what pissed me off. About 97% of these engines have cameras, but this engine didn't.

-

Yes I was the engineer and that was my first collision. The yellow mass is a catapillar dump truck frame that was loaded on to the low boy. It got stuck in the wrong place at the wrong time. I do feel lucky that we only experienced that much damage. I was on the floor waiting on the impact and possible derail. It was a very loud bang to say the least. I would venture that he wasn't completely centered over the crossing or it would have been worse. What's funny is where my train stopped. There was an empty train car stopped right by the truck at the crossing that we actually use to haul this type of equipment. He should have just loaded it up and we could have shipped it for him. The driver was on his last trip before retiring-WOW.

-

http://effinghamdailynews.com/local/x1953746100/Train-semitrailer-collision-closes-crossings

-

P-30 block with original 1971 e-88-probably 10 to 1 compression. I think my head CC'd at 39.5, but I also notched the bores for bigger valves. Stock head gasket that came with rebuild kit-probably not the highest quality gasket. Justed rented a coolant pressure system guage from Autozone. Never did this type test before, but followed instructions and set pressure to 13lbs on the tester and started car. Pressure very slowly creeped until the engine started to gain temp and then it started rising quickly. Instructions stated to pull plug wires one by one while running to see if diffuses pressure. I went directly for #3 plug(suspect area) and the pressure immediately stopped rising. #3 was carbon fouled, but showed 180 on a compression test? Any thoughts????

-

Car was running excellent the other day then she started to run like she had a slight miss and down a bit on power. I pull the plugs and #3 looks carbon fouled. I had just pulled the plugs a couple hundred miles ago and they looked perfect. So I'm thinking bad wire or plug. I put on some Bosch wires that were almost new and cleaned of the plugs. I also changed my wideband O2 sensor around to the other pipe(duals) to see if the banks are running consistent-which they were close). I go for a long ride and pull the plugs again and the front 3 have a greenish tint to them. I have never had any overheating problems with this engine, the 3 core runs cool-always. The engine always started easily-never labored the starter. Timing is set at 20 initial with the vacuum advance disconnected. I am running 36 degrees all in. My exhaust is loud, but never heard anything I could call detonation. Compression test showed 175 to 180 all the way across. The kicker is that she's spitting fluid out the pipes now. I guess the question will be-WHY! Maybe I was too optimistic with my timing. I have about 5k miles since complete rebuild. Any feedback would be appreciated. What should I be looking for when I pull the head off to help me determine the cause? Lastly, can I tie this in with a persistant oil leak from the rear main? Would a small breach in the head gasket near a oil passage pressurize the oil?

-

I have a real nice clean set-pm me

-

There's a datsun 510 site that lists all applicable Subaru LSDs that will bolt in with no mods. Try searching 510 sites. The early LSds from subby will bolt in, but it is only just a few years that work. It's a rare find if you have the right year! good luck

-

Anyone want to verify my math???

-

I have 5 9mm rods. Somehow in all my moving I have lost one I guess. They still have the pistons on them- 100$ shipped OBO

-

Okay, let me see if i am adding this up right. My air box dimensions are 3X5X22 which figures to be 330 cubic inches. So I am covered for my 150 cubic inch p-30---right?

-

Interested in this thread! I have also studied a bit about plenum size and I believe I have read the same numbers you have found. I like your design with the center inlet, just makes it tougher to fit in our cars. I am currently making an airbox for my 2.4, I get confused on the math to figure volume size of the airbox compared to engine size.