-

Posts

201 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by theczechone

-

Thoughts on my dyno result, 280z, triple webers

theczechone replied to Ssaga's topic in Nissan L6 Forum

Do you have any way of knowing what your actual spark advance is at 3000-3500rpm? i forget what the timing curve looks like for the zx dizzy. the 6AL doesn't modify the curve right? -

Thoughts on my dyno result, 280z, triple webers

theczechone replied to Ssaga's topic in Nissan L6 Forum

I think that's very respectable for the peak numbers. It would be interesting to see the scale for the lambda curve as well. The dip in power and torque at 3400rpm is quite interesting. There is also a drop in lambda over this section. Too rich? -

I'm using corbeau clubman seats which seem like the us version of those seats. Mine have been recovered. See my build link in my signature. Post #2 for pictures. I think cobra had some really nice classic looking seats, being in UK they will be much readily available to you.

-

Has anyone used this? wondering what peoples opinions were. It seems they have two different types https://zcardepot.com/exterior/sheet-metal/battery-tray-bracket-stainless-steel-240z-260z-280z.html?search=battery+tray https://zcardepot.com/exterior/sheet-metal/battery-tray-holder-sheet-metal-240z-260z-280z.html?search=battery+tray I'm leaning towards the cheaper one... well cuz it's cheaper and thicker gauge.

-

Carbon Signal JG Spec Moonbeam kit ( 8/100)

theczechone replied to texis30O's topic in Body Kits & Paint

that turned out really nice. love the wheels -

Sweet thanks! I will plot it first and check fitment first. Let me know if anyone wants one made. I can get a couple made. The more I do the cheaper it will be.

-

Hi, I have a header that i got as a gift from a good friend of mine. it's nothing special but i have it and would like use it on my car. Unfortunately the flange is fairly thin and seems warped, someone has also tried to modify. Anyway i have some friends at a laser cutting place and was going to get a flange cut out and welded to my header. I was wondering if anyone had a cad or even a drawing of the exhaust flange. Square port. thanks

-

I have noticed that the comments are slower to come than it used to be before facebook groups like DPAN started up. Still if i need any info this is the first place i go to.

-

Anyone have any tips???

-

I've got two questions: 1.) There are a number of different places that sell the complete interior vinyl (diamond pattern) kit, is one better than the others? The prices are about the same. 2.) I stripped my interior to do the floor boards and i have also pulled up the sound deadening. I've purchased Themotec - Cool It mat (tar mat) but i heard that some people used something else on the back side of the vinyl. If you could share what you used and how well it worked for you it would be greatly appreciated. Pics would be great too! Thanks

-

Twin cam head for the L6 from Derek at Datsunworks

theczechone replied to Derek's topic in Nissan L6 Forum

The highest temperature of the head would occur after you parked it, as basically there is no more cooling going once the water pump stops spinning. My guess is that's when the valve seat dropped just like stated before. Would be interesting to find out the residual press fit on the seats that have not failed. In the past i have done a study on different materials used for the small end bushings. I varied the interference level and the material. The small end bushings i was evaluating were made of bronze which has a relatively low yield strength. The rods were heated 400F and the bushings were cooled in liquid nitrogen to reduce the possibility of material removal during the installation. THen the assembly was heat cycled a few times. The bushings were then removed with more liquid nitrogen and measured. It turned out that the bushings with highest initial press had the smallest residual interference. My best explanation was that the bushings yielded under the stress. This should not be the case with the seats, however the yield strength of the aluminum is also not the highest. If you could freeze out the "still functional" seats you could establish an "installed back pressure" and see if it's too high and could cause the casting to yield. -

Twin cam head for the L6 from Derek at Datsunworks

theczechone replied to Derek's topic in Nissan L6 Forum

Ouch, do you think the fit was out of spec? -

In all fairness if you have a spark out of your spark plug then you should be good on the spark side. Timing could be off but it would have to be off for all the cylinders. As Ryan points out swapping carbs is not that much work and you could see what effect it has.

-

There is an easy way for checking spark. Pull the plug and and attach it to the wire. Start the engine and ground the plug against the valve cover or chassis. If you see a spark between the center electrode and strap than you have spark. Be careful no to get too close to the spark, getting shocked won't be a lot of fun. if you are not getting spark check your gap. Also what plugs are you running? Good luck! I have been following this thread for a while. Love the build! https://youtu.be/mUOmsGiirTU

-

Pillar, so you bonded the tar material to the foil insulation rather than the metal as factory? i figured the bond between the metal and the tar was necessary in order to dampen out noise

-

Tires 225/45/15 or 225/50/15

theczechone replied to theczechone's topic in Brakes, Wheels, Suspension and Chassis

Why did you go back to 15" -

And the passenger side is in! Just wondering if to get the prospect D seat mounts or the Bad Dog seat mounts. I think im leaning towards the prospect d mounts

-

Extra BC Racing strut tubes or a trade.

theczechone replied to winstonusmc's topic in Brakes, Wheels, Suspension and Chassis

I believe they will, all other components are available separately springs, struts, camber plates. just give them a call. -

A little update, progress has been slow but finally getting somewhere. Due to rust i ended up replacing half of the firewall and the battery tray. new metal is now welded in. Also the new frame rail from John at Bad Dog Parts has been installed along with his rear subframe connectors. The final fitting of the pan on the passenger side should happen tonight and welded in hopefully this weekend. Etching primer and seam sealer after that and it's off to the driver's side!

-

If you are getting the stub axle and companion flange do you still care that they have 27 splines? I know i have some 240z ones, 23 splines i think. I could ship them to you a 150 for the set shipped, if 280z-75 doesn't work out.

-

Just a little update, I started working on the floors, which as usual includes replacement of the battery tray and half the firewall... why did I think this time would be any different. grrr If you are reading this and think about repairing your floors with fiberglass....DON'T!! New metal is the only way. See Exhibit A: Anyway this is what the passenger floor looked like after the fiberglass removal. Note the dark spot in the upper left. Lots of moisture here. Which i don't understand because the car hasn't seen rain in over 7 years!!!! if you notice there is also a big hole next to the wire harness hole and i was able to push through the battery tray with my finger. so all that needs to be replaced as well. I got to cutting, here is the passenger floor out, still have more trimming to do and have to replace the section of the firewall before the floor can go in. I got some floor pans for Classic2Current Fabrication. They are local to me so i was able to go to their shop to pick up the pans. I'm happy with the quality, just missing the dimple on the outboard sides like you get with zedd findings.

-

grannyknot, you make a good point, however, i'd hope we had advanced a bit since the 70s. I deally i would like to put just one product down. Maybe the best way to approach this would be to: 1) do so driving with no insulation at all (record the noise) 2) add the tar such as noico or raamat (record the noise) 3) if needed add foam or other style insulation (record the noise) yay for experiments, now someone come help me finish my floors so i can do this lol

-

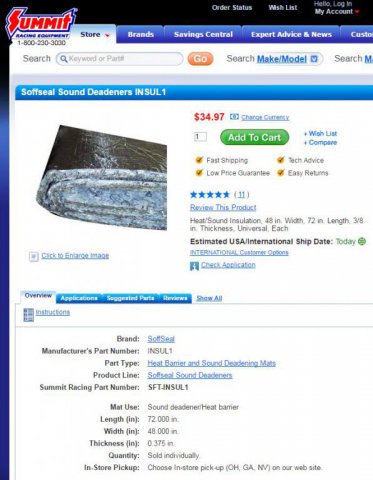

i like the noico! one thing i was worried about with the soffseal is how thick it was 3/8" also how well would the vinyl stick to it. noico seems like a better option

-

-

Anyone used this stuff before? https://www.summitracing.com/parts/sft-insul1/overview/ I ended up removing the tar and the original "horse hair" insulation out need something to replace it. Seems that the reviews are good and price is low.