-

Posts

1568 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zmanco

-

Ok, I'm finally taking the plunge over to the dark side on my 73. I found a deal on an engine and transmission from a wrecked 82 turbo. Interesting story: the car was stolen from the dealer lot and totaled. The dealer removed the engine/tranny/driveshaft and sold it to the brother of the guy I bought it from. It sat in his garage for 20+ years and then when he sold his Z it went out into the field behind his father's home. I picked it up this week with less than 100 miles on it. I've been spending a lot of time searching but there are a few issues I'm just not able to clear up. I thought I'd try asking those questions all in this thread so the next person might have an easier time finding the last bit of information. Question 1: Does anyone have any pictures showing how they mounted the rear transmission mount? I've found a few threads discussing this, but the descriptions just aren't clear to me. The issue appears to be that the center line of the T5 mount is 15 or 30 mm off the stock one, depending on how the T5 mount is oriented. Bryan Little's site talk about using 2 pieces of angle iron, but I think that is only for the early 240s, not for my 73. Question 2: For the BW T5 transmission, what is the proper fluid and how much? I found a book called "How to build and modify your manual transmission" that says the early T5 can use GL4 70w and that later WC T5 use ATF. But I'd feel better if I heard this from multiple sources. Also, I've read the amount is 2.7 - 2.8 liters. Does that sound right? I had planned on going with Redline MTL until I read the passage in the book. Question 3: I know I need to shorten the drive shaft. I currently have a 4.11 R180 diff with CLSD that I would like to keep. I understand I need to find the special diff flange from the turbo R200, but need to confirm if it will fit the R180? Question 4: I've read the diff sticky over and over, but don't see anywhere that specifically says if the R180 is the same length as the R200? Or maybe I should really ask if the R180 and R200 both can use the same length drive shaft? I ask because if they're not, then if I am going to swap to an R200, I should do it BEFORE I shorten the drive shaft. I'd rather not change its length twice. Question 5: What is this sensor near the oil filter? Perhaps a switch to sense low oil pressure? That's all so far, I'll have more as the build progresses. TIA.

-

http://denver.craigslist.org/pts/1109651831.html This has been listed for several months now. I don't know them or if they would ship. Good luck!

-

Looking for a good Street/Autocross/Road Race tire

Zmanco replied to PETEW's topic in Miscellaneous Tech

Just a little more feedback on the direzza z1 star spec, for a street tire they maintain grip when hot on the track better than most, but the tradeoff is they are slippery any time it's cool, even on 50 degree days. I would not recommend them for a daily driver except in the summer. -

Woldson, that's what I'm wondering: I know I can't replace compression rings without honing, but what about oil rings? The rebuild only has a little over 20k miles and except for the oil consumption, the compression is fine and it runs great. The rings came with the ITM pistons and are chrome/molly on the compression ring, and I believe cast iron for the rest. If I could just pull each piston, replace the broken oil ring (assuming of course that's the real problem), and reassemble, then it's just one long day and a set of rings. Of course, you must know me because what I'd REALLY LIKE TO DO is go turbo and use this as the excuse But now really isn't the time

-

Derek, just a suggestion on tuning MS, turn off AE, Over-run fuel cut, MAT correction, etc when you do your datalogging. Even though Megalogviewer ignores records where those are active, you'll see artifacts show up on the edges of those settings, especially since MLV only works with a single fixed delay for the O2 sensor. In other words, it isn't always ingnoring the records that it needs to ignore. If you turn those off and do a variety of driving (get data all over the map), you'll be pleasantly surprised with how well MLV will tune it. Once you're happy, then turn all the other gizmos back on. You'll find that you need very little AE too. BTW, if you want to really fine tune, try using MLV in 2 passes. Here's a thread where we're discussing that with the developer: http://www.msefi.com/viewtopic.php?f=25&t=26021&sid=552c2dcfce598cd233369af0d77bfd92&p=212159#p212159 My suggestion is at the bottom of the first page. Sorry for the thread hijack, but hope this was helpful.

-

I'm afraid I can't help you with how to get things back, but once you do, I would suggest using Mozbackup http://mozbackup.jasnapaka.com/ to backup your profile at least once a month. Besides restoring if something breaks, it also makes it easy to move your entire Firefox configuration (even cookies and history if you want) to another computer. Good luck!

-

The turbo pan has a connection on the driver side for the turbo oil return, but some have made their own fitting and used a NA pan. Not having done this myself, does anyone know if there is any other difference?

-

Actually, I suspect my mileage would go down a little as a lower CR means a less-efficient engine all else being equal, doesn't it? Yeah, I suppose that's possible, but given how cheap a crank is, I was thinking it made more sense just to replace it. But your post has me thinking: assuming it is a broken oil ring, is it possible to just replace the bad ring and reassemble the engine with everything else left as it is? I mean, no honing the cylinder walls, replacing the rest of the rings, etc? If that's possible, then the lowest cost solution would appear to be to leave everything else as it is and just replace the bad ring. That would be A LOT cheaper, although just as much work as rebuilding.

-

I have the same issue with the stock MC and slave cylinder (both replaced and system flushed). Why would the rubber hose have this effect on the clutch but not on the brake system? I haven't seen this discussed, but always assumed that the type of rubber used for the MC cups and hoses was the same for both brakes and clutches. This part doesn't make sense to me - what's different about the clutch system vs. the brakes?

-

I have to make a choice about rebuilding my engine and need advice. Background: It's a 73 with L28 that I rebuilt about 20k miles ago with flat top pistons (.030" over), shaved P90 head, stock intake, headers, Megasquirt, reground cam, oil cooler, etc. The engine runs great and is a ton of fun, but in the last few thousand miles has begun to burn a lot of oil. It consumes a quart roughly every 200 miles driven reasonably, and even more at the track. Compression checks out just fine, yet I can see the blue in the exhaust even at idle. I've also had to retard timing significantly in the 4k - 5k range which I believe is due to oil getting into the combustion chamber and detonating. My suspicion is that an oil ring is broken. To make things more interesting, 2 summers ago the damper came lose and damaged the crank keyway and I fixed it using some Locktite products and it has held up well. But if I ever tear the engine down again, I'm going to replace the crank. The issue is that it's time to fix the bottom end and here are the options I'm considering: Option 1: find an old L28 short block and rebuild it using my current oversize flat top pistons. Total cost: estimate $500 - $600. Note: I'm not considering rebuilding the current block as I used a local machine shop that in hindsight probably didn't do a good job on the boring. When I had the head off recently I could see some cross hatching, but it was very uneven around the cylinders and between the cylinders as well. Option 2: I've located an L28 short block that was rebuilt with dished pistons years ago by a guy who specialized in Datsuns. It has never been run and the top of the block is still taped/sealed. The price is very reasonable, and given all the other mods I've already done to the car, the thought is to swap this short block in and then go with a mild turbo build, not to exceed ~225-250 whp. Total cost: estimate $1500 - $2000. I live at altitude in Colorado so the increase in HP would be even more significant since a NA engine loses aproximately 20% and the turbo can get that back and more. The dilema is that this summer is really not the time for me to spend this extra money, but I have to do something with the bottom end and feel now is the time to make the switch to a lower compression engine if I ever want to go turbo. I did have another thought which was to go with the dished piston short block for this summer and just run it NA. My CR would go from 10.0:1 down to 8.5:1. I imagine I'll lose some power, but wonder how much? I'll stop here and wait for some feedback and thoughts.

-

I'm still curious what the difference is between the standard and turbo pumps? Besides the increased pressure, does it flow more at a given rpm? Given the turbo engine has the extra oil flow to lubricate the turbo, that would make sense. But is that really the case? Another way to ask this is if it's necessary to swap to a turbo oil pump when converting a NA to turbo?

-

Well that's not all that exciting, but it's probably the sensible thing to do. Last summer I drove from Colorado to the Bay Area (~1300 miles each way). I drove it non-stop in around 20 hours. It was actually a lot of fun and the car ran great averaging 27 mpg for the entire trip. Given I have a 4.11 diff and moderate cam, I was pretty impressed. Got to love megasquirt fuel injection! The hardest part was maintaining a reasonable speed without cruise control. Steady 80 mph is rather boring, but since I knew I was likely to be fatigued, I didn't want to take chances. I did take a lot of little breaks to get out and stretch. I was a bit tired the next day though and think it would be a lot harder to go all the way across the country. I was glad to not get back in the car for a day or two.

-

I'm pretty sure this is a MegaTune issue, and since it seems to be table dependent, probably something due to one of the config files. I brought this up on the MS/Extra forum, but the developers are putting all their efforts into getting the MS/E features to work. Since there's a simple workaround, I suspect it's not going to get attention any time soon.

-

I'm assuming you're using MegaTune. I've found that on some tables, Alt-B will burn it, but on others that doesn't work. I've found that "Burn to table" option off of the File menu works consistently for me. Also, tab or click on a different cell after you make a change before you burn it. Otherwise "burn to table" may not capture the last change.

-

That throaty sound reminds me of triple webers (not a surprise of course). But now you have the benefit of fuel injection. Sweet! BTW, if it helps, attached is my VE table for 280cc injectors. Req fuel is 3.7 with 2 squirts with a stock 280zx fuel pressure regulator. In case you haven't already figured this out with Megatune, you can save (export) VE tables as well as import them to avoid rekeying. Just open the VE table and go to the file menu. You'll see Table Import and Table Export. Before I start messing around with the VE table, I'll take a snapshot. That way if I make a mess of it, I can just reload the original table. veTable1_200902140643.zip

-

The fan is mainly to move air over the radiator when stopped or at low speeds (creeping in traffic, parking lots, etc). At any reasonable track speed the movement of the car through the air is the main source of airflow over the radiator and the size of the fan at that point has little impact on cooling.

-

I think there's a misconception about the tensioner. While there is a spring inside to keep it pushing out, the spring is relatively weak and won't provide much tension on the timing chain by itself. With the engine running oil pressure is applied to the tensioner and that's what provides the tension on the chain. With the engine off, I don't think pressing on the slack side of the chain is a good indication if the tensioner is properly installed and/or working properly.

-

It's my understanding (don't remember where I read this) that the pinion housing isn't supposed to be rotated to adjust backlash. Rather there are 2 positions: the regular position, and another where the pinion is rotated 180 degrees. The latter is for the larger gears used with the higher (numerically) ratio diffs, such as 3.9 and up. If you just align the pinion housing in one of those 2 positions, does that solve the binding issue?

-

It might just fit. You should definitely try as the Taurus fan moves a lot more air than the 2 12" thin fans I have. They're only about $20 at the local picknpull so worth the experiment.

-

Actually, it was the back of the fan's motor that interfered with the compressor belt's adjusting pulley IIRC.

-

I asked earlier but perhaps you didn't see it: did you check the wipe pattern?

-

Derek, I've been lurking on this thread and like others, think the work you've done is really fantastic. For a NA motor the stock intake manifold is a limiting factor for power and so I'm thrilled to see you breaking new ground here. On the electric fan issue, I see from one of your pictures that you still have AC. Assuming you're going to keep the compressor, I think you'll find that the Taurus fan's motor interferes with the compressor pulley, at least it did with my setup which includes the MSA 4 core radiator. There just isn't enough clearance between the engine and radiator. In the end I took a different approach using 2 12" slimline ebay fans. After having the radiator begin to leak from the cable tie mounting approach through the fins, I switched over to this approach. I don't want to hijack this thread but I'll throw it out there as an idea to you hoping (expecting) that you'll come up with a more cleaver, or at least better looking, approach.

-

misfiring 280 with 3.1 stroker

Zmanco replied to Z-drive's topic in Trouble Shooting / General Engine

From what you write, it sounds like the misfiring is intermittent? I doubt out of sync carbs would give you an intermittent misfire. Also, from your comments, it sounds like this problem came on suddenly? I'd put my focus on the ignition system and make sure it's not the culprit before I went after the carbs themselves. BTW, if you are sure the ignition is ok, how about the electric fuel pump, filter back by the tank, and condition of the tank itself? Could any of those things be causing problems with fuel getting to the carbs? My own experience with triples was with webers, but once set, they were pretty reliable. I imagine mikunis are about the same. Unless you see something obviously wrong with them, as I said above, I wouldn't start tearing into the carbs until I had eliminated the easier stuff. -

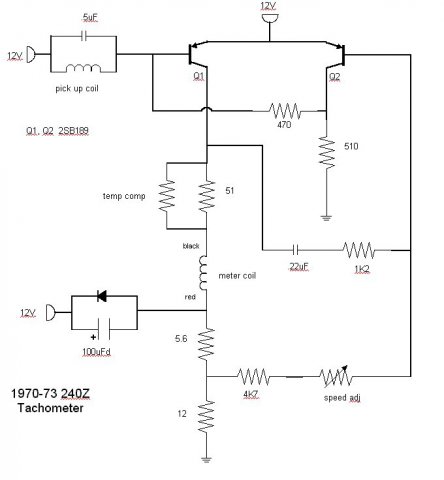

It's most likely the tach. I was adjusting mine and was too lazy to turn the engine off and killed it the same way. Luckily I had a spare. I may try to rebuild the bad tach and if I succeed, I'll post how I did it. Note: I thought I remembered a writeup somewhere (not on hybridz) on how to rebuild it, but can't find it now. I'm attaching the schematic. I think the issue will be finding replacement transistors.

-

Did you check the wipe pattern when you installed cam? I'm not sure why you would only hear the noise at a certain rpm range, but it's something you should check, especially since if it's too far off, it will likely damage your cam. Other than that, I follow your thinking about the chain, specifically the tensioner, given it's only across a relatively narrow rpm band. But I'll have to defer to others to comment if that's likely.