-

Posts

1201 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by duragg

-

Waiting on the seals for the shifter body and striker rod. By reference to this ancient writings:http://forums.hybridz.org/topic/31661-280zx-short-throw-shifter/?hl=msa%20short%20throw%20shifter and this: http://forums.hybridz.org/topic/101175-raised-shift-lever-and-linkage/?hl=short+throw+shifter&do=findComment&comment=949101 I think I will machine a 2nd hole 20mm higher in the ears for a shorter shifter should I want it down the road. I have a spare lever I will modify too.

-

Aluminum Radiator with electric fan shroud

duragg replied to Mace.un's topic in Trouble Shooting / General Engine

Do those fans have their own themostats?- 19 replies

-

Trans gear-set is back together and sure looks to be in better shape for fast shifting. Regarding 3&4 grinding, all the parts looked perfect except for a few anomolies. The 3&4 Synchro hub was a little narrow. Of the two I had one was .030" wider so I used that one. I analyzed and measured my 9 spare keys and picked the best and sharpest. Installed about .060" shim under the key springs and installed the widest and cleanest slider i had. I used two #2 stainless washers which are each about .030" under the spring keys. Anymore and you just can't get the keys in there before exhaustion sets in. I also noted some unusual wear and metal transfer on the 3&4 shift fork, and so I switched to my spare fork. And also one of the sliders was wider than the others so I ran that one. After doing this when I begin to engage 3rd gear, simulating the gears in action, the dog keys all line up just right. So I am hoping for a "good kill" this time. When I pulled the tranny Saturday there was some leakage from the shifter area so I ordered new o-ring and lip seal for the shifter mechanism which has to come Overnight from LA. Lastly... A few times while beating on the car and reaching for 3rd gear I got 5th instead. To preclude this I put a shim under the 5/R thing to increase the force required to get into 5th. This should give me a better gate to 3rd. Should be back on the road late this week and finally done with tranny mods with no leaks and a whole lot more knowledge on what to look for when rebuilding a tranny.

-

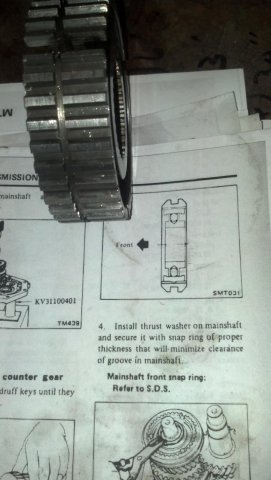

Today: Pulled the C/G Main drive gear which allows removal of the input stub, 4th gear and access to the synchro ring, springs and keys. Indeed I could do surgery on just these parts without having to strip the entire main shaft. If you have read the article referenced above by Jacks's Transmission then the pictures below will be self-explanatory. 2nd gear looks perfect 3rd gear looks like it is too far. Jack calls this "Teeth preloaded too early". Same with 4th, to a lesser degree: I believe the gears and hub are all assembled properly. There is a note in the FSM about making sure this 3/4 hub is installed correctly, but it could be vague on the exact direction of installation. Assuming "Front" means Front of car? Or does it mean something else in metric? I can assemble my spare shaft (as if) and test easily enough. I believe if I could case 3/4 to look like 1/2 I would be home free. Still mentally determining if springs tension would even alter this, or if it involves machining.

-

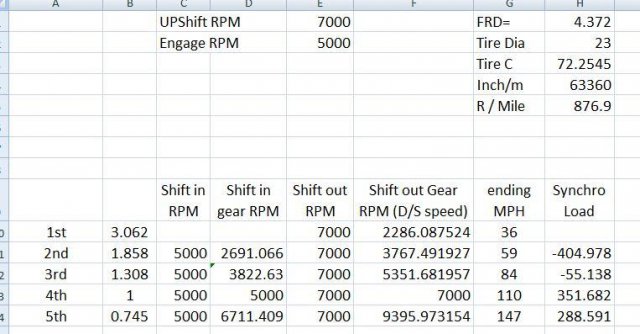

Going academic. DANGER- Math ahead which is 80% likely frought with errors. I made a spreadsheet to think about what each gear is doing at the point of Shift (7000RPM, clutch in, pull lever). What does the Synchro see now? Some things to think about as I test this spreadsheet. - Suppose a draggin clutch: Shift-in RPM would = Engine RPM and skew that number higher? - THick fluid would cause the inter-gear drag to be higher and the input RPM would more cosely match the output shaft RPM? - Ultra thin fluid might cause the input RPM to decay very rapidly compared to output RPM? Does my spreadsheet work to describe the Delta in RPM seen by the Synchro? Crap... cant upload XL spreadsheets.

-

Unknown creator: Thinking out loud: If I were to tap out that counter-gear just a bit, and pull back the input shaft, I ALMOST think I could pull the 3/4 slider off enough to expose and tweak the keys and springs without disturbing the Main Shaft which is all setup real nice. From Studying Jacks Website it seems I may need to look real close at how and where the slider and brass ring are making contact. Based on what he describes, my teeth may be meeting too deep allowing the ring to pass before the job is done.

-

Stuart took a video of the crimes in action: I was trying to shift slowly and not out run the synchros. Oil leak causing some smoke on over run and the friggan thing was WAY hot.

-

Today saw a lot of 6500 to 7500 action trying to stay ahead of a fast group. Tranny torn down (2 hours total). Gears and synchros all look perfect, no wear or damage from todays pounding. We're gonna make a big increase to the key springs and see what that does. There is remarkably little overall wear in the tranny. It is all well within factory specs. Failure not being an option... we'll make this work.

-

Tranny back on the bench- 1 hour to remove, a record for me. 3rd gear would grind unless I was super gentle and patient with the synchros. Going to check the clearances tonight and then go drink... Plan is to do the super-spring mod.

-

Racing a different track today. 2nd gear decent. 3rd gear sucks. Pulling tranny to do the super-spring trick next week. Or maybe build up the spare.

-

Webers using walbro 225 and aromotive regulator?

duragg replied to Med Center Z's topic in Nissan L6 Forum

I have a dead-head setup and it works ok. I think a return is superior since you can pump cooler fuel through, which is of marginal value since the headers are nestled comfortably between the float bowls. The needles shut off the fuel when the bowls are full. Personally I think fuel delivery / pressure gets over analyzed. Supply adequate quantity fuel under moderately low pressure and it seems to be just fine. -

Nice work dude! I know the feeling. Getting the triples running is the first step in a long relationship. TJ

-

Aren't they? Assuming he shipped them to me, but haven't seen yet...? I'm stealing that design.

-

Weber jets??All who live for their triples please read this

duragg replied to datfreak's topic in Nissan L6 Forum

The idle "speed screw" sets the position of the butterfly and it really should be direclty under the progression port closest to the engine- RPM be damned, it will be what it needs to be. This position allows best throttle tip-in response as the butter fly JUST moves, it begins to pull fuel from that prog port. On some carbs this will make an unacceptably high or low rpm (>1200 / <700) in which case prog port modification can be done which I had to do. Later carbs have a balancing screw so you can match one barrel of each carb, then match the other barrel with the balance screw by opening it a little. So ideally one balance is always closed, other may be open just a touch. And yes, as you tighten it down it all moves out of balance, so you start over (fresh cold beer about now) and you may have to "lead" the error to get it all locked down just right. This may help: -

We're done. Back on the road. Leak tested and road test good. The shifts? About like all of these FS5 trannies with new synchros. A big delta in speed requires a momentary delay prior to the lever just "Falling" into gear. I haven't forced any of the gears yes as I only drove about 5 miles just to see how it felt. I am running a fairly thin gravy. The exact makeup will remain a secret (prevents the inevitble "I TOLD you...") Will put a bunch of miles with easy shifts before hammering it, 5 more miles should do it. Really about the only thing I could do different is heavier synchro key springs. The only thing this would prevent is the engagement ring being forced past the brass ring before it is ready. EXAMPLE: Pull hard, speed not equal yet, but the brass ring is bypassed early resulting in a grind. If this isn't happening, then the system is doing its job and the syncros just need more time to equalize speed. THanks for all the help along this journey, I can only hope that future Z fans will find something useful in this thread.

-

Adapted 280ZX parking brake cable to my 1973 240. Fair amount of drilling, tweaking, shaving and the geometry isn't perfect but it should hold, while probably not lockup.

-

Can't tell from the pix. You'd have to ship it to me so I can look closer. Badass!

-

Tranny is back in and bolted up, but I forgot to order a new tranny mount and so that will be in tomorow afternoon. . No Clutch Drag: Reached in through the tunnel and turn the driveshaft with the car in gear and the Clutch pedal IN -> No drag. I had to come out about 2-3 inches before the first hint of drag. So the clutch drag issue is confirmed not a player. Hopefully I can finish this friggan saga prior to honey-dos.

-

I always wanted to take a header like that and run dual tubes all the way back, never merge the two. Probably a crappy flow solution, but might sound neat. Super-twiceys like.

-

What are you going to do for tires on those rollers? Its hard enough for me finding suitable tires for my 15x10s. I think there is a size the Countache (sp) guys use, but not cheap. Maybe pure race tires are easier to find.

-

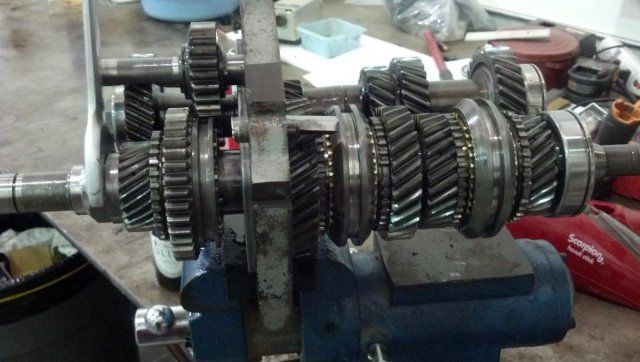

Thought maybe I was in trouble again... Ok she's back together and now we are circling back to the start of this thread. Desire for an FS5w71B that shifts real good. I ordered all the new parts I could and canabalized a spare tranny to get the best of the best. For now I left it all stock but with new synchros, good gears, new check balls and springs and just better assembly attention. Due to cost and availability I will probably do 50/50 MT90 and ATF, but I need to read way back into the thread to see what those with more seat time said. I also installed the 12lb flywheel. So this is all coming down to the following machinations: 1) It works great and I love it, but always wonder if modifications would make it even better (Greedy B'tard) 2) It doesn't work and I lie about it to save face, or just not come here anymore... but I usuallly end up with a few beers crying in my keyboard so that probably won't happen. 3) Do it all over again,.. which is likely as I will probably have a Z of some sort forever and I enjoy the process. Blah blah blah... Pictures or it didn't happen, ya I know: Behold!

-

I have that special float gauge and wasn't all that impressed with it. Very tricky to locate the exact spot to set the base and can impact measurements. Surface tension can cause the liquid to creep up the well and spoof readings. I had better luck with a micrometer and a bright light. Slide the micrometer depth checker into the well and watch for the gas to just tickle indicating contact. This was by far the most repeatable measure for me. I even posted some pictures over on the Yahoo "Sidedraft Central" forum Tj

-

I certainly didn't (can't) do such a thing. I see your last input around #40, #42, #45, #46 Shenanigans? Call it if you see it.

-

Its all fun when the parts are in... Museum of Baulk Rings (aka: Brass synchro rings:). Reassembled per the FSM and picked the best of the parts along the way. I didn't do anything tricky with the synchro key springs. Maybe I should have. I Collected all 18 and picked the biggest and the best. Then measured and picked the best of the keys and put it back together. All gear end plays are perfect in spec. All the baulk rings have great clearance, its kinda funky to measure. Tomorrow I will torque the big Mainshaft reverse thread nut. and then start focusing on the forks and selectors. I am planning to double pin the forks and just run the best of what else I have. Circling back to the very start of this thread. I think a thinner juice along the lines of 50/50 MT90/ATF.

-

Being this a documentary about improving shift quality I am bypassing all the other Overhaul type stuff going on. I have 2 trannies now. One I pulled from a 1983 ZX and this new one is supposedly from a 1979 ZX but it is clearly a much later tranny as it has identical ratios to the 1983 model, but has the shorter ears, one leg and Passenger side fill port. The 1/2 shift rod and fork on the 1983 models is totally different. 1983 model has the fork actuator receiver thing cast into the rod. on the earlier models it is a seperate piece that is pinned on. Pics below. Also the 1983 1/2 shift fork is a much larger, heaver piece and has 2 holes like the 5/R fork. Is also has the pin in a different place. So... 1983 type 1/2 shift rod and forks are totally incompatible with earlier models. My 1983 1/2 fork was wasted and the part is No Longer Available. They sent me a new one for the earlier tranny so I will be swapping some of those parts out to make one box work. Next I have collected all my sliders and need to pick the best 2. 1A 1B ************* 2A 2B ************* 3A 3B ************* 4A 4B