Noddle

Members-

Posts

572 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Noddle

-

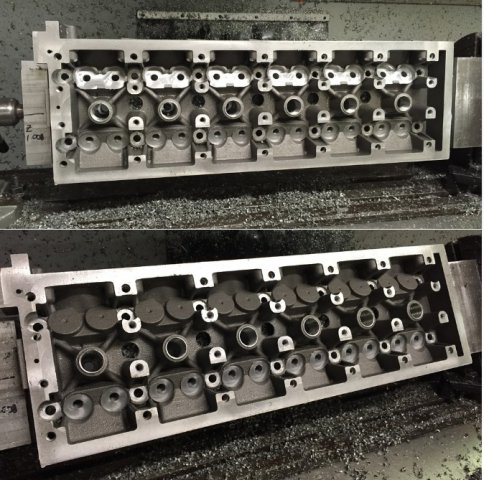

Twin cam head for the L6 from Derek at Datsunworks

Noddle replied to Derek's topic in Nissan L6 Forum

Do you have a laser / water cutter, or do you c&c all these type of parts ? -

Twin cam head for the L6 from Derek at Datsunworks

Noddle replied to Derek's topic in Nissan L6 Forum

Hi Derek, as I said before, Great work.. Can you do a picture or two from the top, side showing how far the sprockets sit way from the head, and the alignment, also, can you show some picture how the mid 2 sprockets attach to each other ( to lock them together ), and how the sprockets connect to the head thanks you in advance Nigel -

Twin cam head for the L6 from Derek at Datsunworks

Noddle replied to Derek's topic in Nissan L6 Forum

Hi Derek, Great work I must say, On your next batch of head, was you going to add some more martial to this area ? Nigel -

Twin cam head for the L6 from Derek at Datsunworks

Noddle replied to Derek's topic in Nissan L6 Forum

MPI / DI, multi point injection / direct injection ? -

my 240K has a reverse switch, that is the same height (or close enough ) as the fill bung... I have used that before. that's on a 5 speed box..

-

Twin cam head for the L6 from Derek at Datsunworks

Noddle replied to Derek's topic in Nissan L6 Forum

anymore progress, pictures ? -

Twin cam head for the L6 from Derek at Datsunworks

Noddle replied to Derek's topic in Nissan L6 Forum

I hope you will do a blog about the build.. or at least on here (hybridz.org) Nigel -

Twin cam head for the L6 from Derek at Datsunworks

Noddle replied to Derek's topic in Nissan L6 Forum

Hi, Is there a reason you have no oil return path in the front of the head ? I understand that on acceleration, the oil will want to pool towards the back of the head, but a constant cruise, I would think the oil could return at the front of the head.. maybe some 1/2 inch holes or so ? Nigel -

Twin cam head for the L6 from Derek at Datsunworks

Noddle replied to Derek's topic in Nissan L6 Forum

Hi, Derek, was you going to make changes to your patterns, so you have less machine work in the future ?, like the amount of martial you have to remove from the valve spring area ? btw, very impressive.. Nigel -

Maybe it's just a standard L24, my datsun 240K ( not Z ) was like this. standard.

-

CTC, is that your silver 240K ?

-

Hi, Have a look in here http://forums.hybridz.org/forum/93-megasquirt/ look at "MegaSquirt Map Information Sharing (all code versions)" it may give you some ideas, Nigel

-

http://forums.hybridz.org/index.php/topic/85051-external-wastegate-adaptor/#entry806157 Nigel

-

How high is your idle ? what is your crank speed set to ?, on my car, crank speed is set to 300 RPM ( i think ) idle is 750, if i try to take off, and the RPM goes to 300 or lower, it thinks its in crank mode, and leans out and wont rev, the only fix, is to "clear it", by turning the engine off, and restart it, my car has no fast idle, i have this issue mostly when the engine is cold... it took me weeks to understand what was going on.. but now, it's a easy fix.. I hope this helps. Nigel

-

I had icing issue on my Ford 250 X-Flow engine running an after market intake manifold (aluminium) and a Holley carbie, start the car, drive 3-5 minutes, and it would run like a pig, stop , leave it a couple of minutes and it was fine, If you put your hand on the underside of the manifold, where the carbie sat, it had ice, leaving a few minute let the heat from the head transfer into the manifold , and warmed it up. note though, this manifold had no water passages in it. Nigel

-

Hi, A few years ago I looked at doing this, but for me it was to much work, and for my setup, it may have not been worth the cost, ( L24 ) I did ask Jeff this, and his reply, which may be useful to others, I hope he does not mind me sharing.. Hi, I was checking out your pictures here http://www.angelfire...zxt/page11.html and i was wondering if you had any from the other side, showing where you had welded up the outside of the runners. thank you for your time Hi There, I was looking for pictures of the welding completed on the manifold. Unfortunately, I did not snap any shots of the before and completed part. I did have to grind the radius in each side of the manifold to fit the fat washers again correctly, but the dremel with the cutoff wheel was the perfect diameter to make the new radius for the securing washers. The manifold is fully opened up at each runner. The turbo inlet took significant work to open up. The front main tube through the header to the turbo inlet was opened up significantly. So the header now lets the engine breath well. there was a little more but not relevant to this topic. Nigel

-

I had an issue with my Megasquirt, EDIS setup, it worked fine, but under boost, and hard acceleration, it would just "cut out" like turning it off, what it turned out to be was the shielded cable I used for the EDIS pickup, had been slightly melted, and the internal wires would flex under hard acceleration, and short , thus cutting the sensor output. it was an easy fix once I found the issue, but it took me a long time to find it. Nigel

-

I had a Ford 250 X-Flow that did the same thing, give it high rpm and the blots came lose, It did this 3 times in all, the fix was to replace the flywheel and bolts.. NIgel

-

They were standard for other, non US markets, the MR30 Skyline has them, I have 2.. (mn47 heads)

-

I think Tony D's answer here, would change your mind with doing this,

-

Since I don't own one of these cars, what is this pipe ? because it looks like it has a hole in it. Are you having a dig at my profession ?, who fixes you PLC equipment when it breaks ? all in good fun.. Nigel

-

When I got my EDIS setup from the US, for me, it was easier to press the wheel on, I had limited access to a lathe, so this is the way I went, but you should look at putting the pickup on the 'inside', I have not replace the fan belt yet, and the way I did mine will add an extra 20-30 minutes to the process, since I would have to remove the pickup to do it. Nigel

-

-

Tony prefers to spend his quality time with sheep

-

The arm does not move. it's made of 4mm steel ( from memory ), and shaped so it will not flex, 3 sides, the base is 6mm I have had no issues what soever ( besides a melted shorting wire ) Nigel