-

Posts

661 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by blue72

-

I have pictures of a Hayashi Racing manifold which looks exactly like the one you posted except for the fact that "Hayashi Racing L28" is cast into it.

-

I actually just used a small, cheap paintbrush (Crayola) and a steady hand. Any excess I wiped off with the tip of a finger. I know what you mean with the "while I'm at it" syndrome. This was just supposed to be "Hmm, wonder how far I can get with a $900 car and a $1500 budget" then a little interior refreshing led to a little mild rust repair which in turn became an engine rebuild then an R200 swap and eventually morphed into "What!?!?!? I've spent how much time and money on this thing?"

-

Thanks guys. I'm pretty pleased with the results for this being my first full job on a car. The bumpiness has sorta grown on me too. I'm almost tempted to do my 510 now before it has a drivetrain. I've even gone as far as researching paint brands and reading up on urethane paints but got stuck when it came to isocyanates. Until yesterday I didn't even know that the hardener for the paint I used was 65% hexamethylene diisocyanate by weight. It might be a while before I paint another car now, probably until I can afford a supplied air system with full hood to avoid any future contact with the stuff. I haven't ever felt any ill side effects (I had a full paint suit, head sock and half mask organic cartridge respirator but nothing protected my eyes or hands), and my booth was well sealed against dust, yet also properly ventilated, but based on everything I've read about that stuff I'm going to avoid any exposure to it in the future. Right now I've got most of the interior in on the back half and most of the weatherstripping glued down, working my way forward. There has been a lot of glue application, waiting to tack, sticking together, pinning in place and waiting to dry. I'm now fully stocked up on clothespins for the rest of my life. The other day: The paint looks darker under direct sunlight. That spare hood I was using as a test panel is now outside on my Suburban again. I had it listed for sale the entire time I'd been experimenting on it. A guy called me up on Monday looking for one and I wound up selling him the primer gray one that had been on my Suburban. He helped me put the half blue one back on, and it is a bit starling for me to see color on a vehicle that has been primer gray for the past ten years. As an example of all the small stuff that eats up your time, here is one of the emblems I repainted. Before After I've also had to spray vinyl dye on all the interior plastic pieces to get them the right color. As far as I can tell this car was originally dark blue metallic on the outside with a white interior. All my interior pieces were black or had been re-dyed a dark blue. I bought a whole new vinyl kit from MSA and took a piece with me to the local paint supply place. I got lucky and found a color that is very close. It is SEM's Color Coat #15103 Super White. The weather this week has been quite warm for December and the interior panel painting has gone smoothly. This is about where I knocked off this evening: Maybe next week I'll tackle the windshield and rear hatch.

-

Need help with how to paint stripped shell

blue72 replied to Charles Patterson's topic in Body Kits & Paint

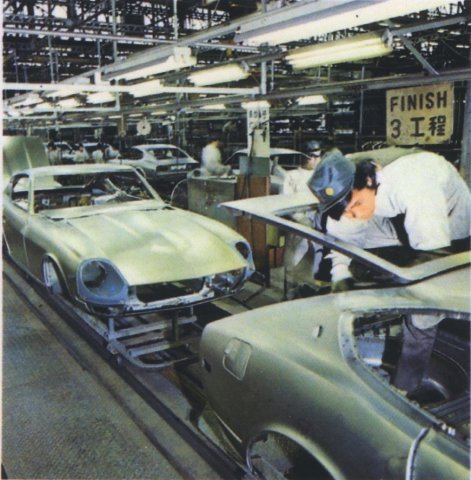

This picture might give you a clue as to how far assembled the cars were before paint. Note: not my picture, just sharing one that I found somewhere. -

Is that some variation of a Crown setup in the last two pictures you posted? I've only ever seen one of those in person.

-

Q over 240z factory engine rods

blue72 replied to chrismiller5157's topic in S30 Series - 240z, 260z, 280z

Ah, the sight must be impressive. Those shiny datsun conrods foraging in the wild before being rounded up and stuffed into a dark engine block. Wait, what were we talking about? Oh yeah, forged rods in L series engines. Yep, they were all forged so no worries there. The '73 engine would have even had the 9mm rod bolt style. -

That's what I would have said too if I hadn't done the measurments myself. I don't rely on the Z Engine Calulators out there on the internet, and that compression ratio is using the piston pop up measurement from my engine, the compressed gasket thickness that is consistently agreed upon, 1mm overbore and all other factors combined gave me that number. If the top of the block hadn't been cleaned up and was still stock height then I'd be at around 9.3:1

-

I have a ported and polished P79 on my N/A car and its working fine for me. Just as long as you make sure the liners aren't loose you should be good to go. As an added side effect they might just burn off extra hydrocarbons and clean up your exhaust a bit. I had the head done by Bryan Blake (1fastz on here) and he even took time to blend the edges on the exhaust side and open it all up a little bit. He also set up the asymmetrical cam and all the valvetrain too. Going from a stock P79 to this thing completely transformed the experience of driving the car. Before it would run out of breath at about 5500 rpm and now I can take it past 8K if I really wanted to. Everything was much improved afterward. We didn't modify the combustion chambers or shave down the head and I run flattop pistons, but according to my calculations I'm at right about 9.7:1 compression ratio with a mild / medium cam and can run 87 octane in it no problem at my elevation (5600+ feet). That combustion chamber shape combined with the quench effect apparently helps reduce detonation too.

-

I'd love to help but I'm in Southern Utah, and as far as I know there aren't any shops around here that specialize in old Z cars. As far as the basic machine work goes, I had mine done at Chuck's Speed & Marine in Phoenix. Those guys were all excited when I brought in my L28 stuff for a bore / align hone / clean / press fit new pistons / polish and balance crank. They were hoping I was going to bore it out big and make a 3.1l stroker. They were okay with just cleaning up the bores though and they did a great job on all my stuff. Very reasonable turn around time too. After that I slapped the thing together on a big piece of cardboard in the garage.

-

Thanks for the compliments. As far as color sanding, I'd love to do it and really smooth out the car but since this is a metallic and it doesn't have a clear coat, everything I've read says not to do it. Apparently it can really wreak havok with the appearance of the metallic flakes. I do have my test panel (the old hood from my Suburban) that I will probably try it out on anyway, just to see for myself. On Thursday (12-02) I finished up the last of the painting. I had used my whole gallon of Acrylyd on the parts that would be most visible but I had to wait until the paint hardened some then do what was left. Luckily I had a pint of BASF Limco acrylic enamel in this same color code. I only had the paint and some general purpose reducer, but not the Limco specific hardener so I decided to experiment. I mixed in the proper quantity of my Acrylyd hardener and did some test spraying on the old hood. Everything looked good and it didn't crack, fisheye or craze after flashing, so I went with it. I also bumped up the pressure at the gun a bit and got it to spray nice and smooth. The Limco's metallic flakes didn't look all goofy if I sprayed a bit much in any one spot, unlike the Acrylyd had. All in all I had to spray the: underside of the hood underside of the hatch and the underside of the passenger door The Limco was just a smidge darker than the Acrylyd, but no one would ever notice unless I pointed it out to them, plus, it is on the underside of the panels. On Friday everything was hardened enough to let me remove all the masking tape on the rest of the car and not ruin the parts I painted the day before. I immediately started putting stuff back on and aside from driving to California and back this weekend, that's what I've been doing since. That was on Friday. I've now got the fenders all bolted down, all the lights back on, the tailpipe, headlight buckets, inspection lids, front valence pieces, hood, cowl, wheels, quarter windows, drip rail trim, side mirror, side emblems and headliner in place. It had been up on jackstands for so long that I'd completely forgoten how low the car is until today.

-

You didn't tell us what kind of paint you're planning on spraying. Enamel, laquer, urethane? Single stage or two stage w/ clear? Jumping from one to the other can cause quite a bit of price discrepancy. If you were planning a two stage urethane then that $400 is probably a pretty decent paint. If you were planning on shooting a single stage Acrylic Enamel then that $400 price does seem a little steep.

-

What kind of tools do you need? It all depends on what you’ll be doing the most. The tools used most often by a heavy equipment or diesel tech will invariably differ from those used by a HVAC specialist or a paint and body man. Here’s a list of tools that I personally use most often as a general DIYer with a collection of classic cars. There are a few things I consider essential that the basic tool kits don't include. 1. The very basics: 3/8†Ratchets = short and long handles. Sockets = deep and shallow, metric and standard. You want a decent range of sizes, for example from roughly 8mm up to around 21mm work pretty well in 3/8â€. Twelve point sockets are okay for general use. Six point sockets can really decrease the chance of rounding the heads off of bolts, but can sometimes be trickier to fit in tight spots or on dirty / mangled fasteners. Wrenches = combo wrenches with both an open and closed end are great to start out. You’ll probably get along just fine with the 12 point style here too. How big or small you need these things depends on the car and type of work you’ll be doing. Luckily, the manufacturers sell them in kits with common sizes grouped together. Also, make sure to buy wrenches that are comfortable. I’ve used wrenches that had thin handles which would cut into your hand during use and it wasn’t pleasant. Screwdrivers = spend enough time with screw heads and you know they aren’t all the same size. Especially with Phillips head fasteners, having the wrong size can mean stripping the head completely. As an added bonus, if used gingerly the better quality screwdrivers can handle limited double duty as prybars and chisels. I know that’s not what they’re designed to do, but if its all you have / can afford then you learn to make do. Also, be sure your kit comes with stubby screwdrivers because sometimes they are the only tool that will work in a given space. Hammer: You’ll probably start out with one medium sized example. Wood handles are replaceable, but composite handles can sustain much more damage before failure. The Science Channel told me so. 2. Above and beyond those basics: Medium – Large Crescent Wrench: If you’re just starting out, it’s better than nothing. Sure, if used improperly it’ll round off a bolt head no sweat. Can sometimes be used to loosen a large, awkward fitting or bolt in a size that you don’t yet own. If applied carefully and tightly then it might just get that bolt out or hold a large brass fitting firmly. Extensions: Necessary. Buy a three or four pack to start out. One or two nice long ones don’t hurt sometimes too. Swivel / U-Joint: To help reach around tight spots. Breaker Bar: You’ll probably want a one of these to help release frozen bolts / nuts. I’ve broken a 3/8†ratchet while using it to free a really stuck head bolt. They make breaker bars for a reason. Cheater Bars: I’ve got a length of pipe left over from doing some chain link recently. It comes in handy on the end of a breaker bar for really, really stubborn stuff like rusty lug nuts. Pliers: A good variety doesn’t hurt here. Needle nose, standard, Vice-Grips and Channellocks. They’ve all got their uses, you will need them. Flare Nut Wrenches: Absolutely necessary when doing any work on brake lines, cooler lines and any fitting you absolutely don’t want to mangle during removal. Metric and standard sizes. One Quality Flat File: Can help smooth burrs, remove material and any of a number of other uses. Razor Blades: When used carefully they can be very helpful at removing old gaskets, cutting new ones, stripping paint, cleaning glass, opening packages, trimming plastics and any of 1000 other uses. Spark plug sockets: They manufacture these for a reason and they’ll make your life easier. 3. Another step above: 1/4†& 1/2†ratchets, sockets and extensions: Easily justified for use with big and small bolts / nuts. Socket Adapters: ¼†up to 3/8â€, 1/2†down to 3/8â€, etc... For example, you can really put some torque on a smaller fastener without having to buy a 1/2†version of a socket you already own. Allen Wrenches / Hex Keys: Not much of a concern on older cars, but even the beginner will find instances in which a decent set is advantageous. These come in metric and standard too, so don’t think you can just jam one inside the other, it doesn’t work that way. Torx Bits: nonexistant on older cars, sometimes plentiful on newer ones. Especially abundant on electronics. You can probably get away with a small general set and only buy any big ones you might occasionally need. I’ve got a T-50 socket that I’ve only used once, but it was the only way to remove and replace something on my Jeep. Pry Bars: They make some nice ones with metal caps on the end so that you can beat on them. This item is pretty self explanatory though. Just get a combo pack with a few lengths. Telescoping Magnet: Everyone drops stuff or has come across a fastener in a tough to reach spot. Side Cutters: Cut electrical wire, bailing wire, fencing, small fasteners, clip the ends of zip-ties, etc... Chisels, Punches and Drifts: The size you need depends on the job at hand. Buy a decent quality variety pack. You will need these for core plugs, roll pins, chiseling away at spot welds, etc... Torque Wrenches: Upon reassembly, many engine, transmission and differential fasteners have a torque measurement that they must be tightened to. I personally like the ‘click’ style rather than the beam style. A decent 3/8†will do for many fasteners, but larger bolts need more lb-ft of torque and that’s where the 1/2†torque wrench fits in. Even small fasteners are sometimes very specifically torqued, so you may eventually end up owning a 3/8†or 1/4†torque wrench that measures in in-lbs too. Feeler gauges: Just skip the cheap spark plug gappers altogether. These are much more precise and you will find a need to use them from time to time. Drill and Drill Bits: Self explanatory 4. Beyond those basics, there are some simple items which will make your life easier: Oil Filter Wrench: A little less messy than stabbing the old filter with a screwdriver and turning. Ratcheting Wrenches: Mostly a convenience that speeds up tightening / loosening duties. Ratcheting Screwdriver w/ Interchangeable Bits: Same as above. Doubler Pointed Pick / Scriber: Just plain all around handy. Tap and Die Sets: For tapping new holes and repairing old threads. Box End Wrenches: With long handles. For when you really need to put some leverage on a fastener and don’t want to worry about galling up the bolt head. Some have a greater angle and / or offset on the heads than other wrenches which can also prove advantageous on occasion. Swivel Sockets: A socket with its own built in swivel / u-joint. Great aid in tight spots that might have an obstruction that no straight socket would ever fit around. These come in both deep and shallow too. Hammers: Eventually you’ll step up to dead blow, brass and rubber mallets for special non-marring purposes. Impact Gun(s): These will increase the speed with which you can tear down and rebuild. That becomes quite important when you’re working on a deadline or wrenching for money. Buy something good quality with adjustable torque settings. 3/8†work great for general use. 1/2†are physically bigger and torquier, great for stubborn bolts and large fasteners. They come in both air powered and electric varieties. Of course, if you get the air powered variety then you need an air compressor and that opens up a whole new money pit. Impact Sockets: You don’t want to chew up and start splitting your chrome sockets with regular air tool use, so invest in a dedicated set of impact sockets. You’ll need them all all over again, deep, shallow and swivel sockets in 3/8†and 1/2â€. Angle Grinder: Cut, grind, sand, bevel, chamfer, level. These things are very versatile and handy. Bench Mounted Vice: Holding stuff steady is pretty darn important sometimes. 5. Other Stuff: Measuring Tools: Tape measure Micrometer: Will be needed to verify tolerances and accurately measure all sorts of stuff. Digital readouts are convenient, the simpler ones with a dial measure just as accurately for less money. Basic Diagnostic Tools: Compression tester Vacuum gauge Timing light Remote starter button Electrical: Wire Strippers: for all sizes. These are pretty cheap and do a quicker, cleaner job than a razor blade. Test Light: simple tool to test for the presence of voltage, very handy during initial diagnostics. Soldering gun and solder: for making nice, strong electrical connections and repairs Multimeter: a must have for general electrical diagnosis, from continuity to resistance and beyond. Equipment: Floor Jack Jackstands Creeper Safety: Safety glasses: Essential and inexpensive. I have a piece of shrapnel now permanently a part of my arm because I was using a transmission input shaft as a drift and it splintered while I was hammering on it. I’d be blind in one eye if the trajectory had been 1’ higher. Closed toe shoes Much beyond that and you start getting into specialized tools. Things like snap ring pliers, seal pullers, an Oxy/Acetylene torch, tubing benders and flare sets, harmonic balancer pullers, valve spring compressors, leak down testers, pickle forks, coil spring compressors, body hammers and dollys, dial indicators, paint guns, welders and such will have to be purchased as needed. With only a few tools and some ingenuity, plenty can be accomplished. When my dad started working at a dealership he left his tool box at home and threw his spare tools on a mobile cart. Most of the other technicians laughed at him on the first day, saying that he wouldn’t last. No one was laughing at the end of the week when he was faster than half of them with ¼ the tools. Using only items from groups 1 and 2 I have done some stuff that amazed other people. For instance, adding only a torque wrench, piston ring compressor, feeler gauges and a 10mm Allen socket I rebuilt the engine in my Z. Who needs a clutch alignment tool when I’ve got assorted sockets and a screwdriver? I can keep most of the tools listed above in a small, portable toolbox and go anywhere with it. I’ve also seen what Grumpy talked about, guys that are deep in debt to the tool truck and don’t remember why they ever bought half the stuff in their box.

-

Ah, so the rim style that was available as an option on BLACK PEARL edition 1978 280Zs, just like JSM posted.

-

Iron Cross style? I've got a pair I'm not using. I'm all the way over in Utah though.

-

Thanks! I probably could have played with my gun settings a bit more. If I sprayed a thicker, more even coat then the metallics would start to group up and look funky, but it laid out smoother. I wound up spraying a light mist coat over the whole thing to help even out the metallics, but it left the finish a bit more orange-peely than I would have liked. Still, it's shiny and one color. Those were some of my main goals, so I'm happy. North of St. George a ways. About 2.5 hours from Vegas. I actually am not totally done yet. I've still got to paint the underside of the hood and the back side of the rear hatch. I've got some of this same color in a different brand and it should be enough. I really want to start putting it all back together now that the paint I've already sprayed has hardened and gassed out on the surface. I should be completely done with the painting this weekend.

-

$20 'aint bad for that little 42 piece toolkit to throw under the seat of my Z. It'd be better than nothing if broken down on the side of the road. I might just buy one of those.

-

You mean the same idea these people had years ago? http://forums.hybridz.org/index.php/topic/58484-hybridz-needs-a-wiki/page__p__534666__hl__wiki__fromsearch__1#entry534666 http://forums.hybridz.org/index.php/topic/67299-z-car-parts-index/page__p__632123__hl__wiki__fromsearch__1#entry632123 There was one that got off of the ground. I remember perusing it, but it wasn't updated very often. Had a nice list of differentials with spline counts and such though. -edit- It was probably this one from rudypoochris (post #2), link is dead now though: http://forums.hybridz.org/index.php/topic/70534-r-200-spline-counts-and-mystery-hlsd/page__p__667551__hl__wiki__fromsearch__1#entry667551

-

Finished, done, finito. I'm out of paint and all panels have complete coverage. 1 gallon of paint was just barely enough for the whole car. The outside air temperature today got up to 57Ëš and inside my now fully enclosed carport (aside from the vent for the fan) the temperature reached 65Ëš from about noon to 2:00. I put up three more tarps to cover the remaining openings and wetted down the floor before each coat so dust and other contaminants were much less of a concern. I can't wait to peel off all of the masking tape, put the wheels back on and roll it out in the sun. I've only seen it under artificial light so far.

-

WTB: S30 Map Light, Headlight Bucket, Interior Finisher

blue72 replied to blue72's topic in Parts Wanted

It tells me that I can't send you a message, so perhaps your PM box is full. You can let me know here, or PM me when you figure out how much you want for it I guess. -

WTB: S30 Map Light, Headlight Bucket, Interior Finisher

blue72 replied to blue72's topic in Parts Wanted

Hmmmm, vedy interesting. I'll have to PM 'ya. -

Seen one in a Chevy S10 on Craigslist once.

-

That's what I'd do, use Eraser, CCleaner, etc... to remove any and all personal info you can think of and then do a reformat and load windows fresh for the next person in line.

-

Thought I'd chime in now that I found the paper I wrote this down on. I performed the exact same measurements as BRAPP on a P72 EFI manifold about a year ago or so. The average runner diameter (taken at .25", 2.5" and 4.5" from the flange) came out to be 1.247 inches (31.694mm). Just ever so slightly smaller than the other N/A EFI manifolds already measured.

-

This one was up to 17 pages: http://forums.hybridz.org/index.php/topic/53391-whats-everyones-occupation-here-at-hybridz/page__hl__animation__st__280

-

I got it figured out yesterday. Apparently the closest distributor who supplies Sherwin Williams Automotive paint is in Northern Utah, a good four hour drive from me. My local Sherwin Williams rep did help confirm something I'd already read about, that Martin Senour is a division of Sherwin Williams and that it is carried by most any NAPA store. I went online and downloaded the .pdf instruction sheets for the Sherwin Williams Acrylyd paint and also the Martin Senour Acrylic Enamel paint. They are both exactly the same. Line for line, word for word. The only thing different between the two documents are part numbers because they're sold under different names. Here in a few minutes I'm driving to my local NAPA store to pick up the pint of Martin Senour 8850 hardener they ordered for me yesterday. I only had a half pint to begin with and the whole pint was apparently the smallest size NAPA could get me, so I'll now have more than I could ever need. I still have enough paint to spray the entire car at least once over. Today I'll start on removing bugs and dust with a quick pass of 600 grit (as recommended to me to promote adhesion of the next coat of acrylic enamel instead of finer paper which might not give enough bite). Then I've got to wait for a day with decent weather. Last Thursday the high was 72 degrees and now this morning there is a half inch of snow on the ground. Next Tuesday might get above 50!